Patents

Literature

116results about How to "Eliminate detection errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

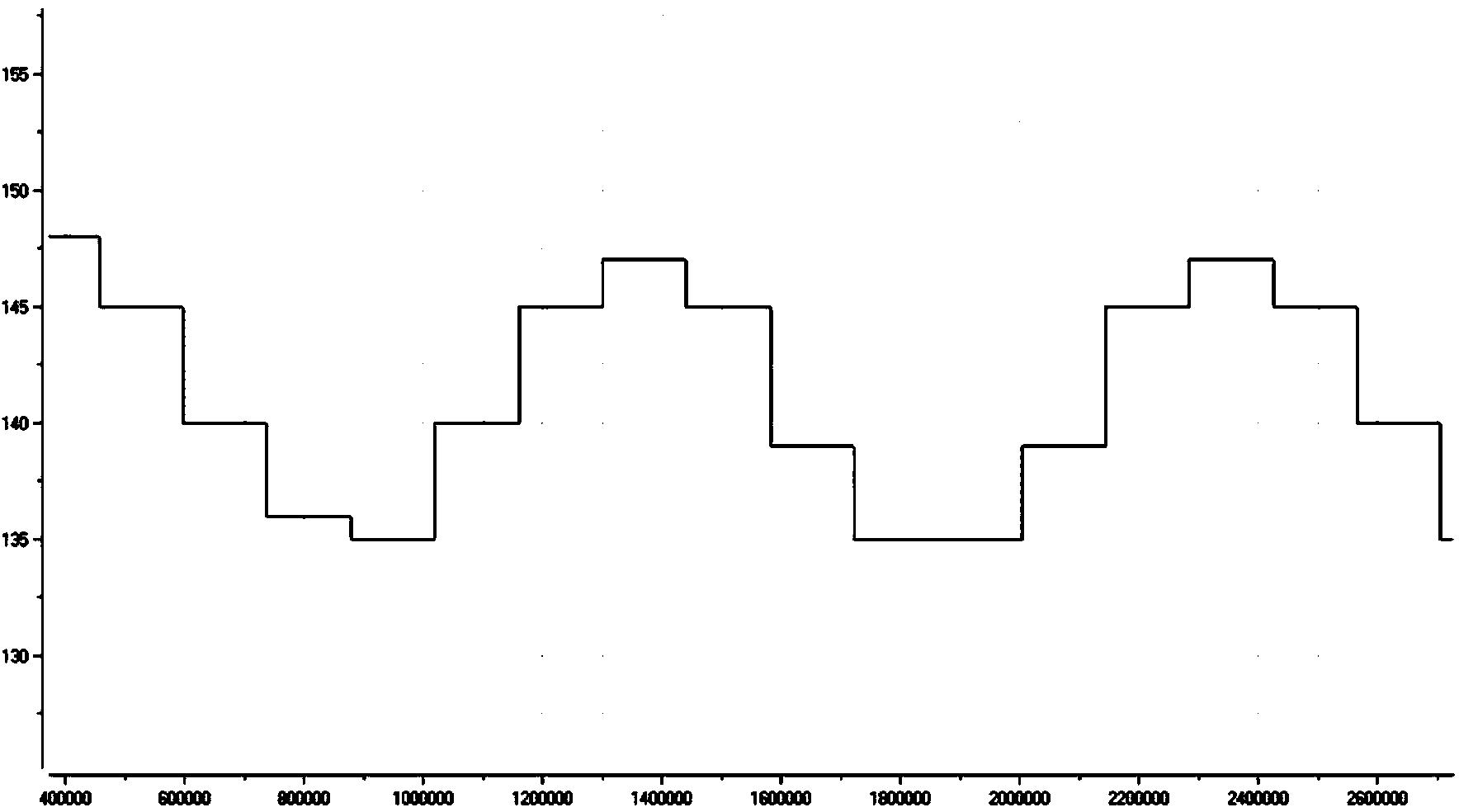

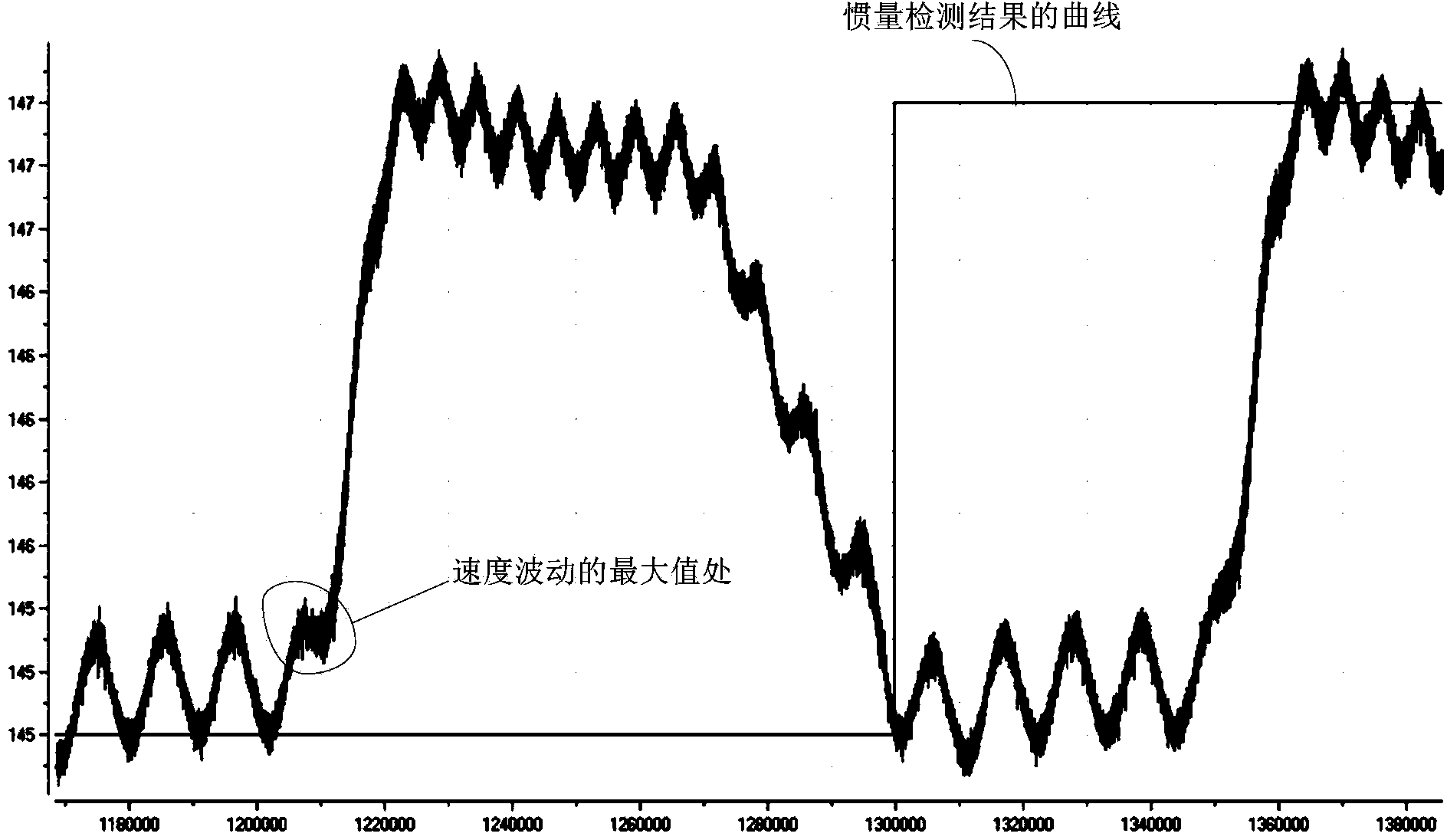

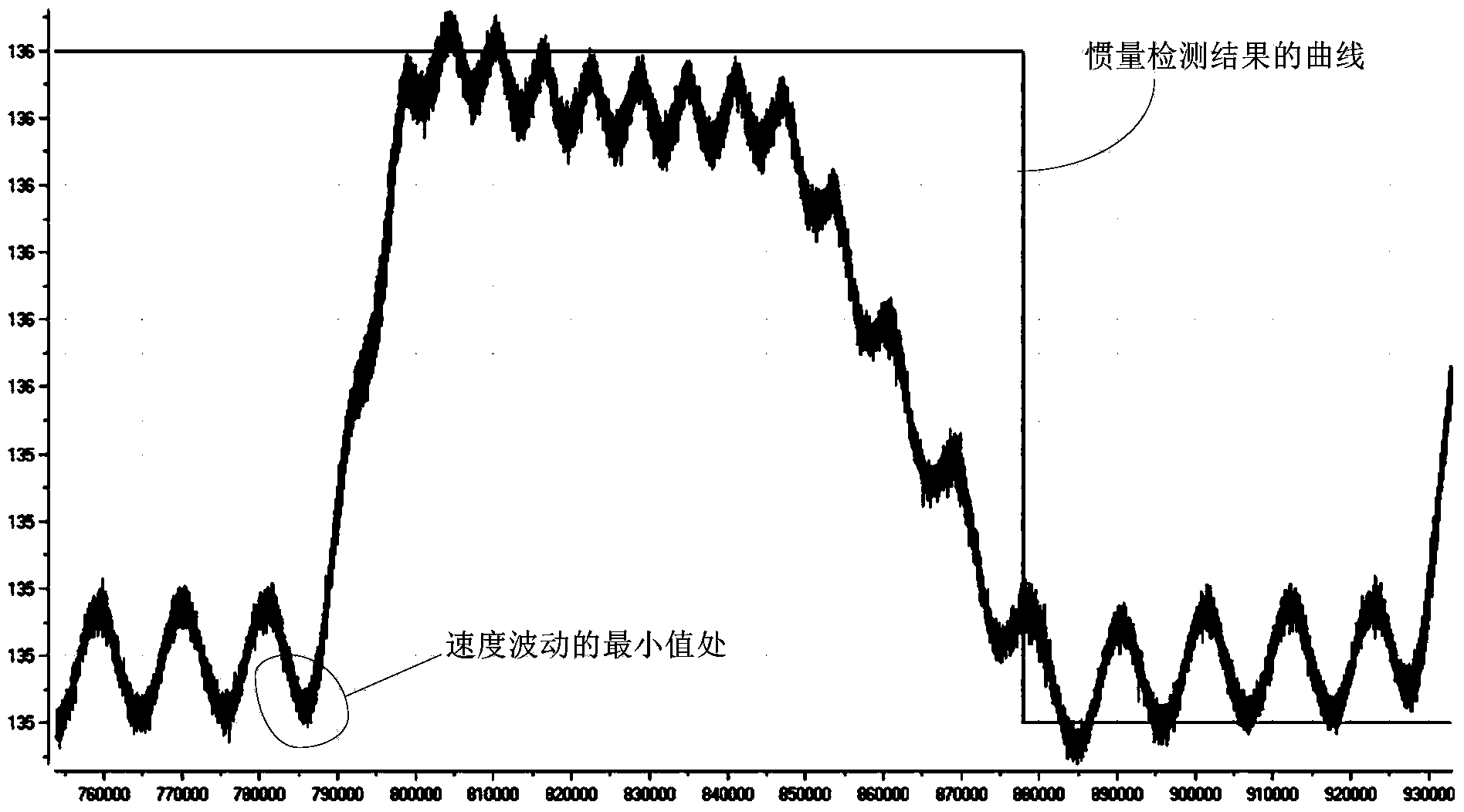

Roller washing machine and inertia detection method and device thereof

ActiveCN103966799AReduce detection errorEliminate detection errorsOther washing machinesControl devices for washing apparatusControl theoryElectromagnetic torque

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

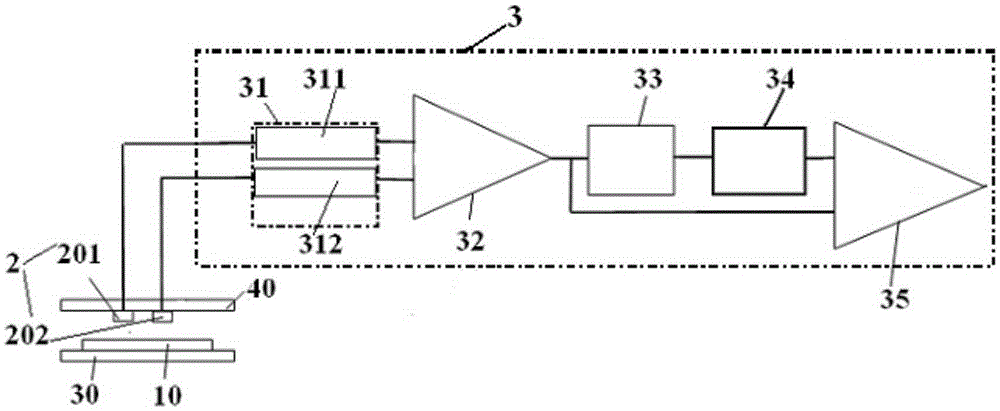

Membrane thickness detection device

ActiveCN105318819AThe test result is accurateNoise signal removalElectrical/magnetic thickness measurementsElectricitySignal on

The application provides a membrane thickness detection device, comprising a common electrode, at least one detection electrode and a detection circuit, wherein each detection electrode and the common electrode are arranged oppositely and at intervals in a first direction; the first common surface of the common electrode and the first detection surface of each detection electrode are opposite, and form a detection channel therebetween for a membrane to be measured; the detection circuit is in electric connection with each detection electrode, and comprises an error elimination unit used for eliminating noise signals, wherein the noise signals are electric signals on the detection electrode when a voltage is not applied to the common electrode. The membrane thickness detection device utilizes the error elimination unit to eliminate noise signals on the detection electrode, furthermore eliminates detection errors caused by the noise signals, and makes detection results more accurate.

Owner:WEIHAI HUALING OPTO ELECTRONICS CO LTD

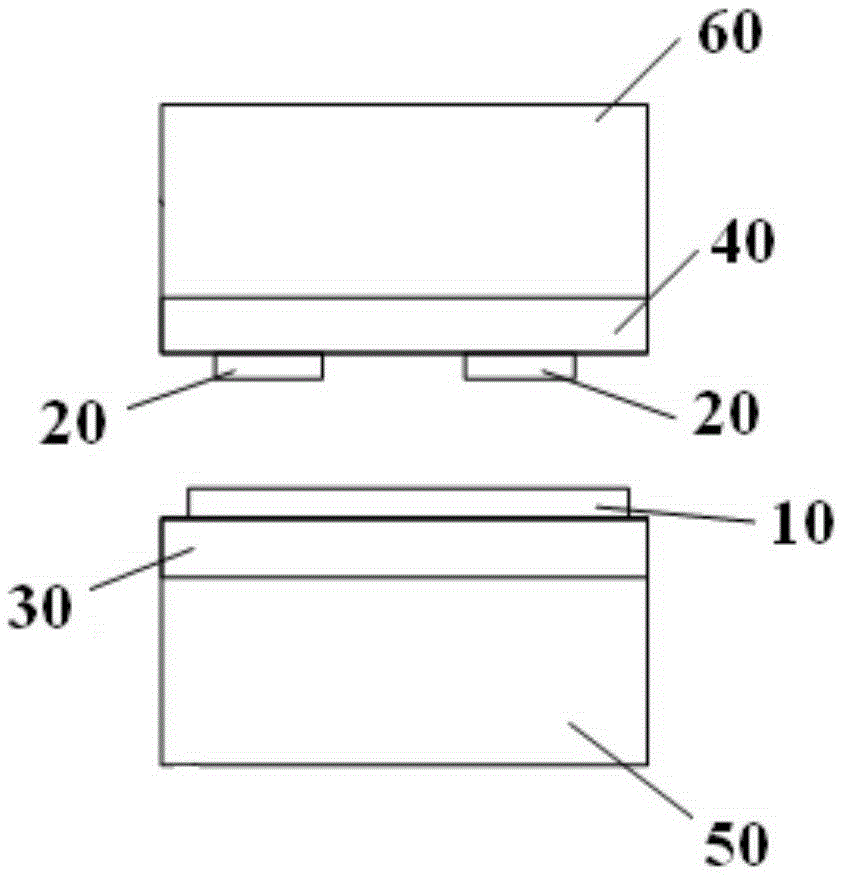

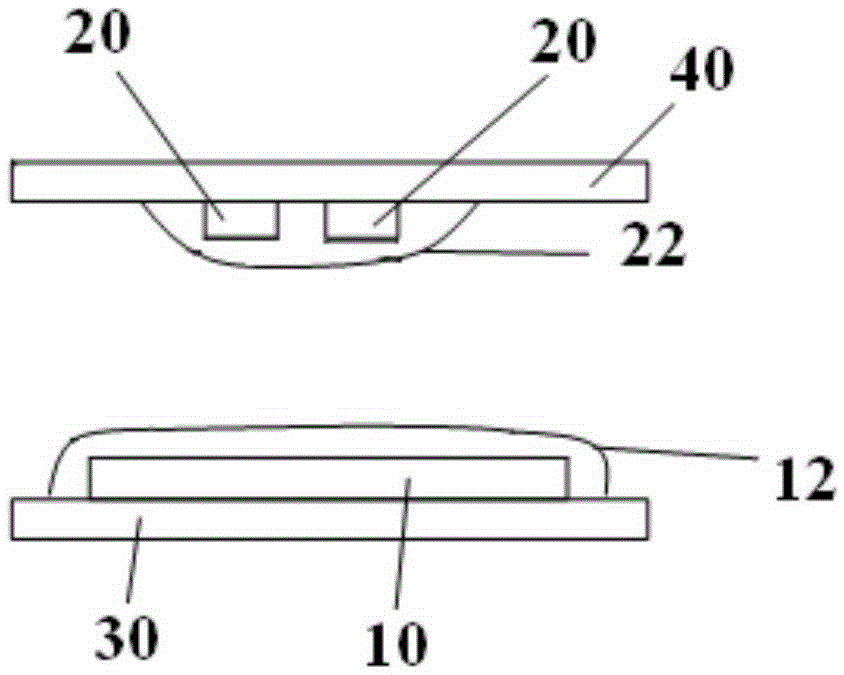

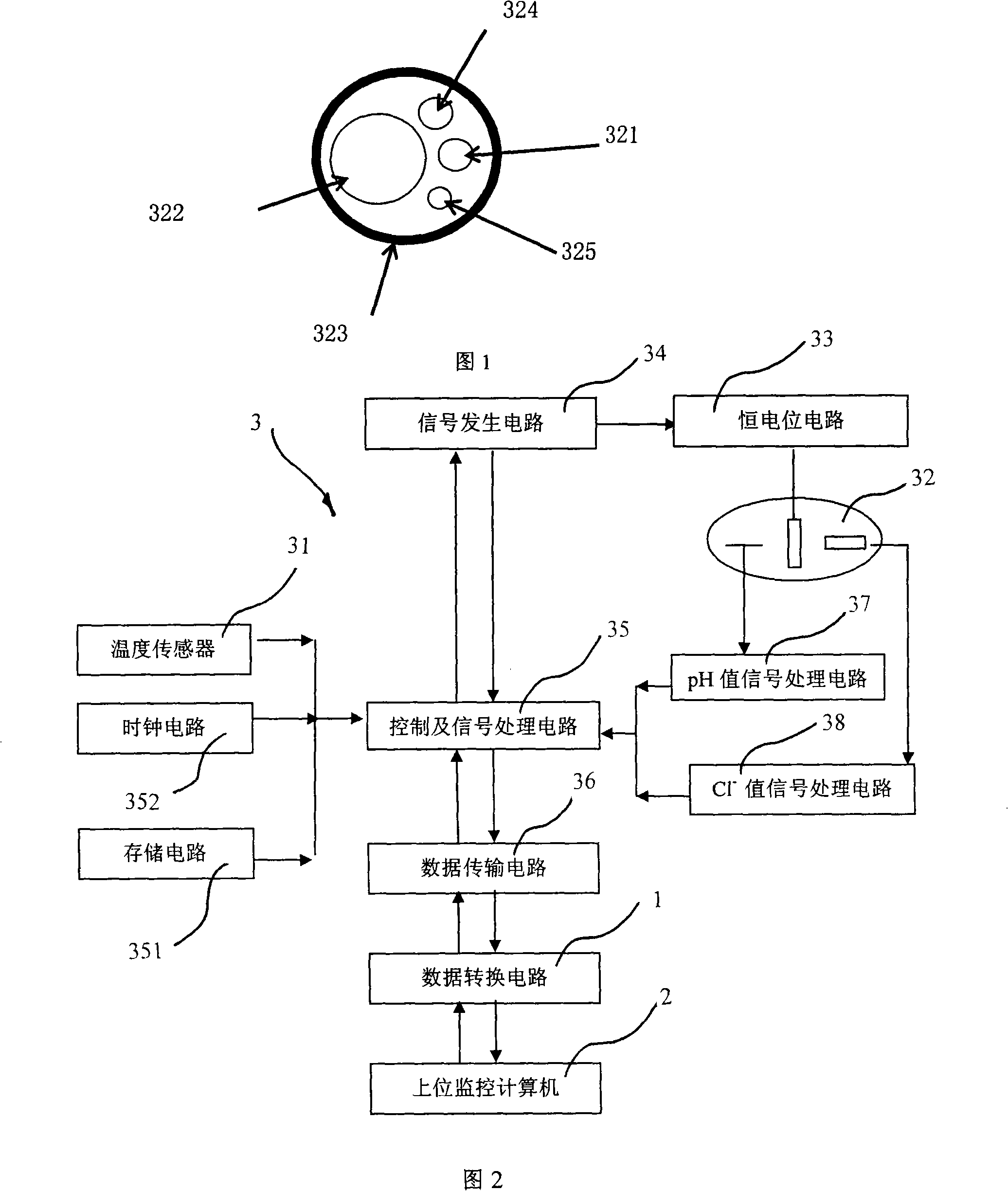

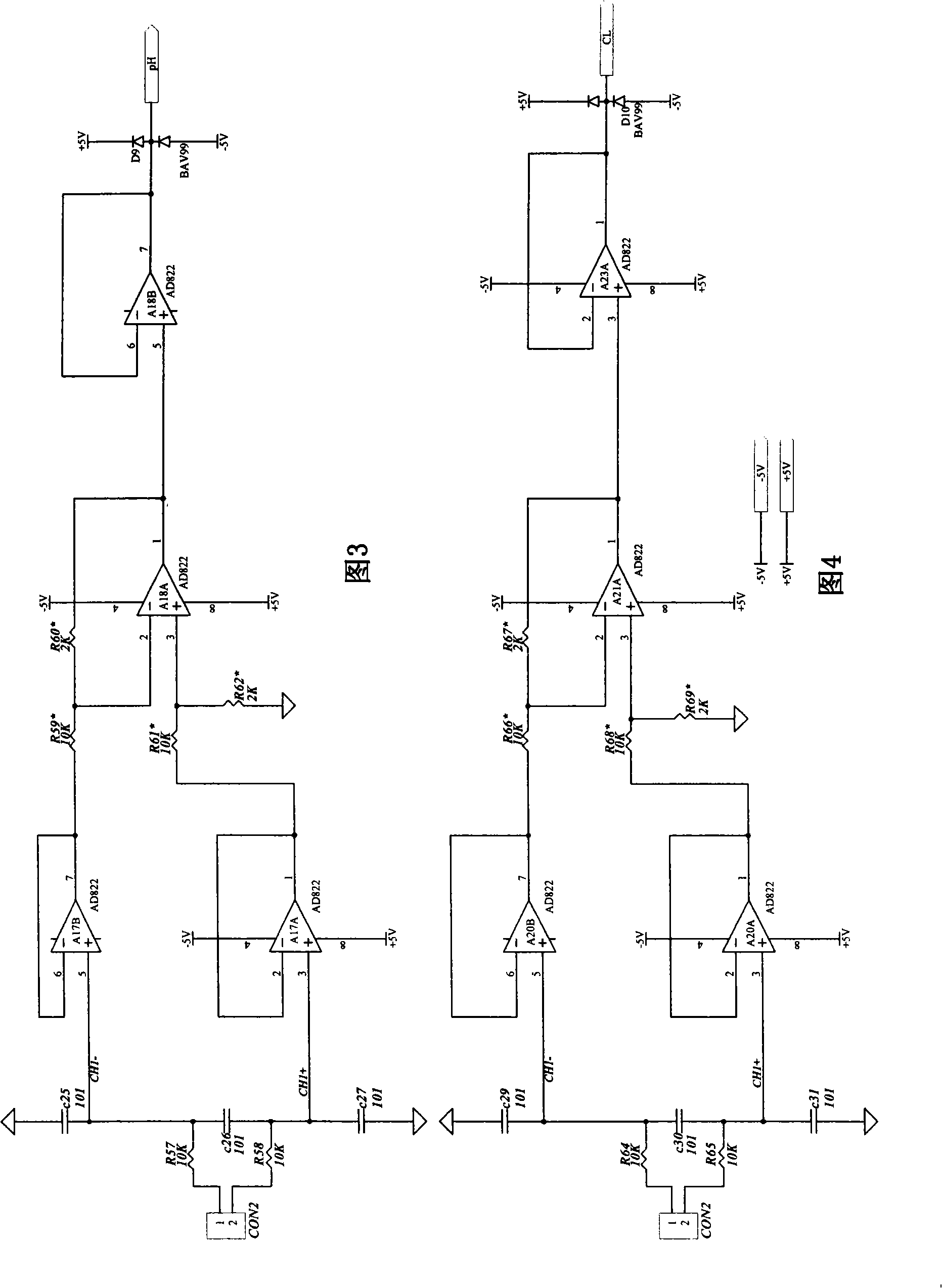

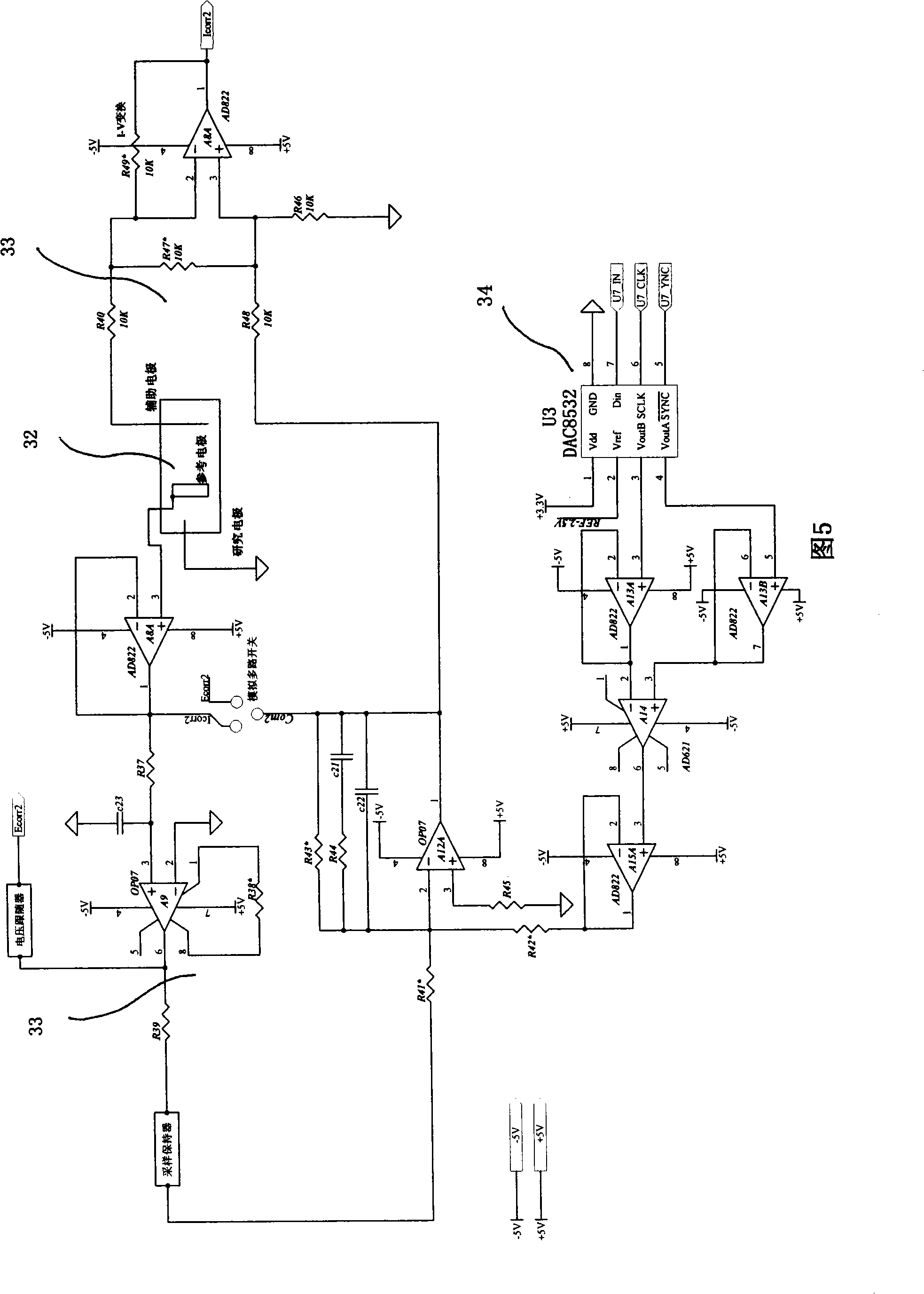

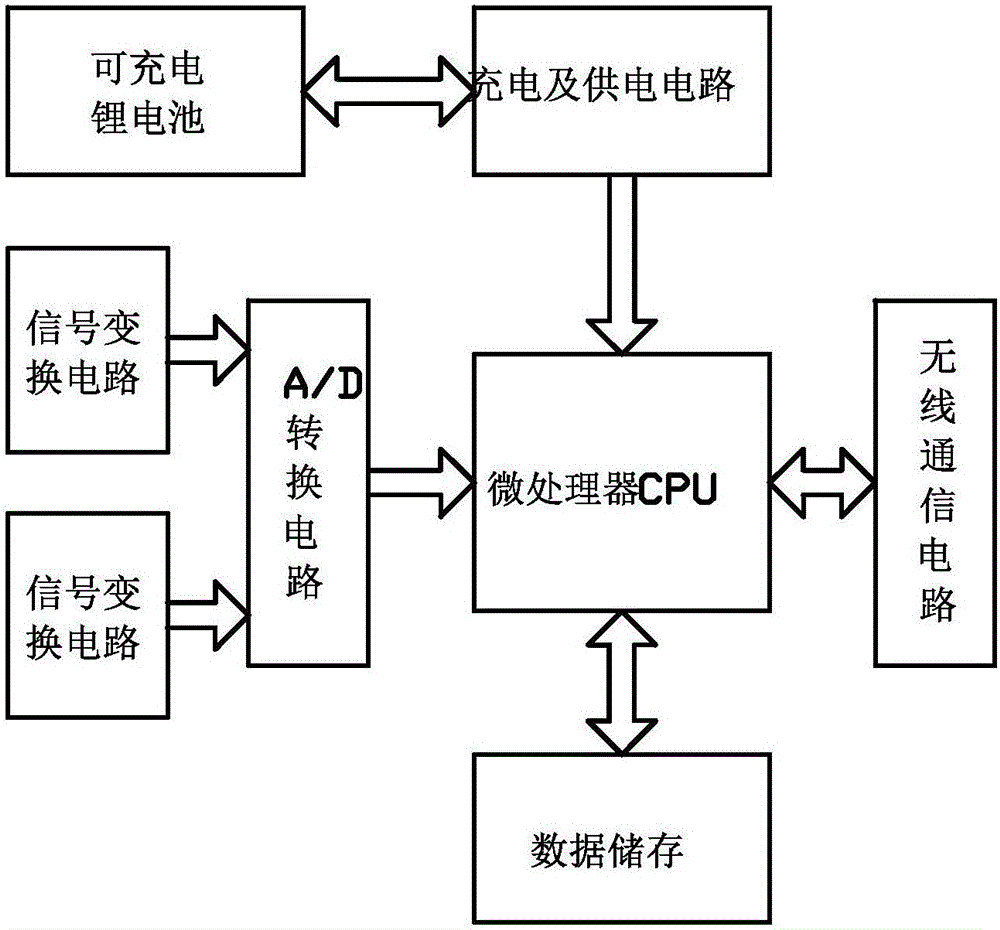

Corrosion on-line monitoring system for reinforced bar in concrete

ActiveCN101315324AHigh precisionHigh sensitivityWeather/light/corrosion resistanceMaterial testing goodsSignal processing circuitsMonitoring system

The invention discloses a system for conducting online monitoring of reinforcement corrosion in concrete. The system comprises a plurality of sensing devices and upper monitoring computers which are arranged at each detecting point in the concrete. The input end of the upper monitoring computer is connected with a data conversion circuit. The system is characterized in that the system further comprises sampled signal processing circuits correspondingly connected with the sensing devices at each detecting point. The sensing device comprises a temperature sensor and a combined sensor which can simultaneously detect pH value, CI<-> ion concentration value, open circuit potential, polarization resistance and corrosion rate function. The signal output end of the sampled signal processing circuit is connected with the signal input end of the data conversion circuit. The system can compensate temperature, eliminate detection error, and improve the precision and sensitivity of a detecting device in the detecting process. Furthermore, at the same time of improving the detection precision, the system greatly simplifies the structure of the circuit. In addition, when a failure in one detecting points occurs, the whole monitoring system can still operate normally.

Owner:宁波科金工业腐蚀监测技术有限公司

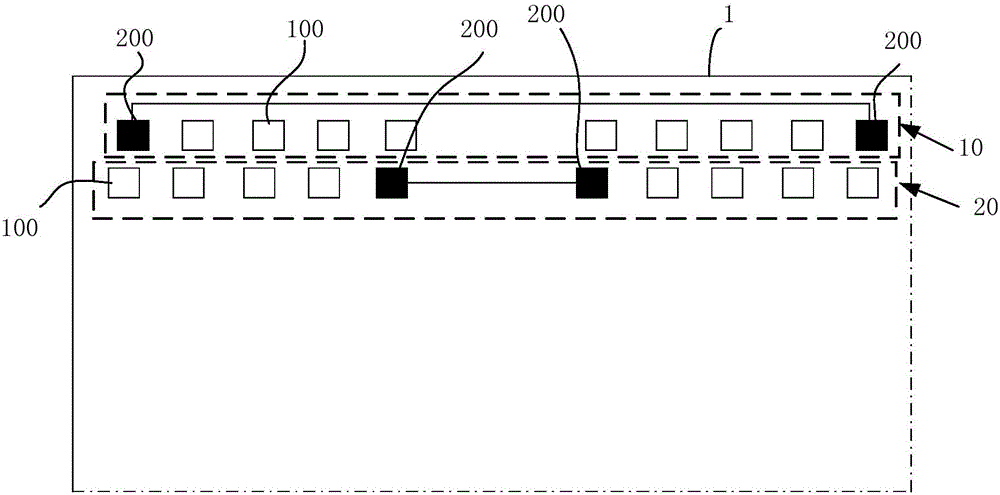

Display substrate, light-on equipment and detection method of light-on test pin alignment

InactiveCN105785607AEliminate detection errorsImprove inspection accuracyElectrical measurement instrument detailsLamps testingElectricitySignal lines

The invention provides a display substrate, light-on equipment and a detection method of light-on test pin alignment.The display substrate comprises a display drive signal line and at least a group of testing bonding pads, and the plurality of testing bonding pads in the same group are sequentially arranged.Each group of testing bonding pads comprises the plurality of light-on testing bonding pads connected with the display drive signal line and two pin miss testing bonding pads which are not connected with the display drive signal line, and the two pin miss testing bonding pads are electrically connected.The arrangement of each group of pins in the light-on equipment is identical with the arrangement of the group of testing bonding pads corresponding to the group of pins.The detection method uses the light-on equipment to perform light-on test pin alignment detection on the display substrate.By the display substrate, the light-on equipment and the detection method, extra detection time is not needed, high reliability is achieved, staff needs not to contact the display substrate during operation, static is reduced, and product damage risks are lowered.

Owner:BOE TECH GRP CO LTD +1

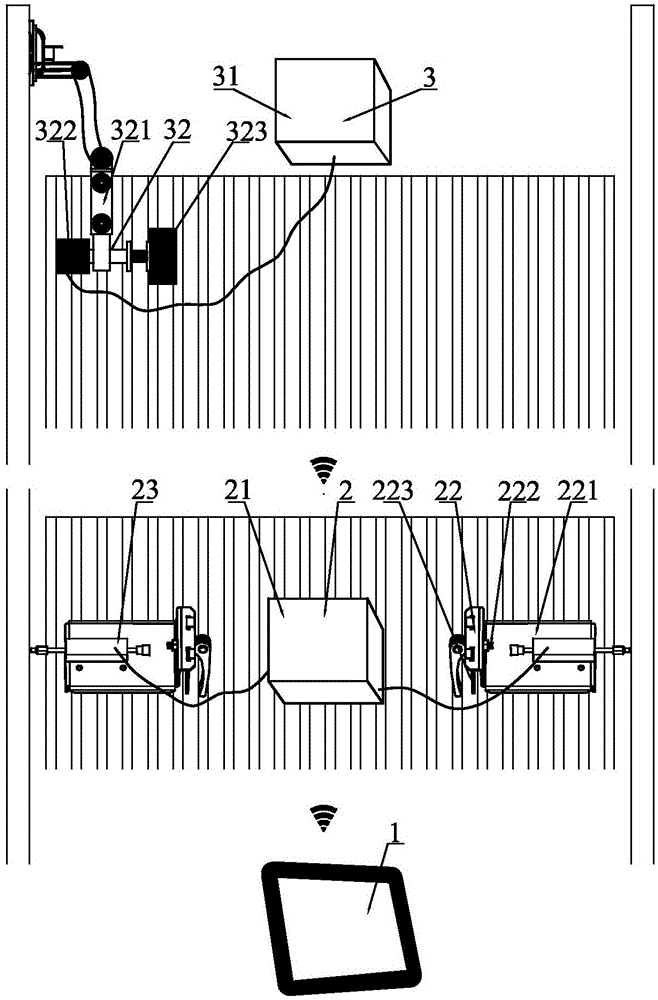

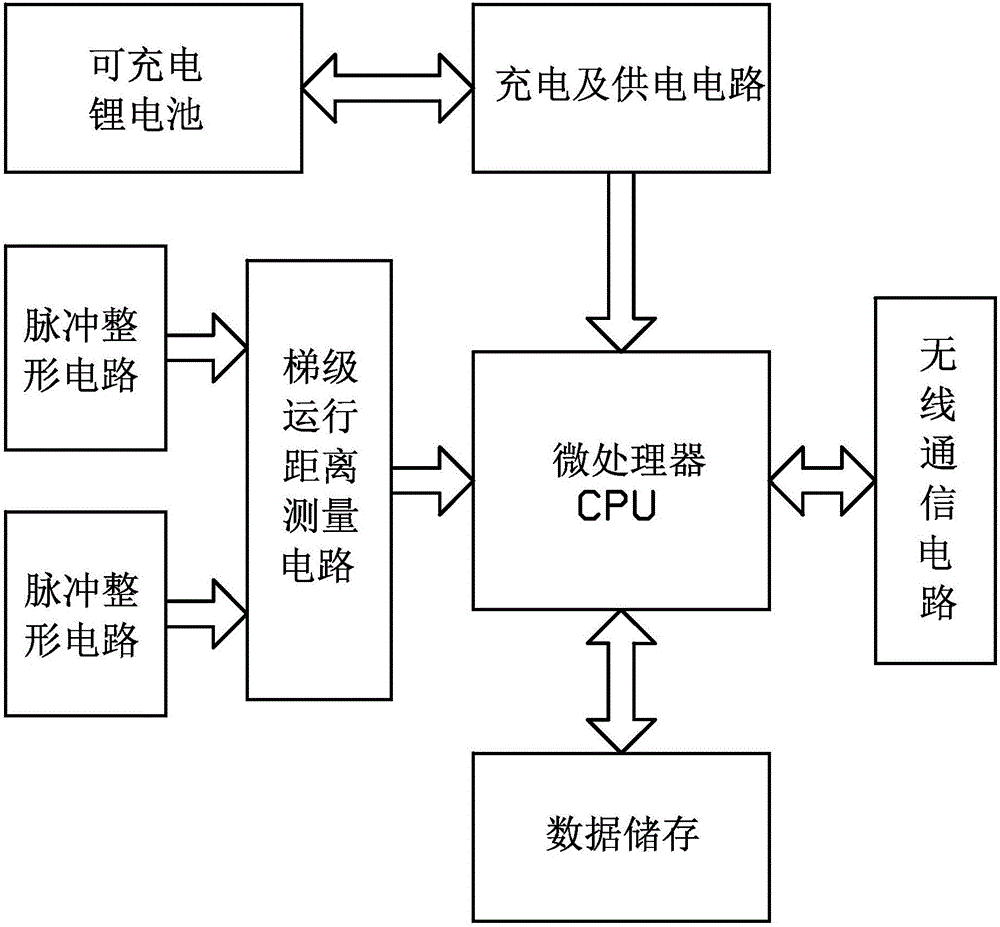

Step and skirt panel safety gap measurement and hidden danger positioning system and method for escalator

ActiveCN106629366AReduce safety incidentsImprove work efficiencyError detection/correctionUsing electrical meansEngineeringPositioning system

The invention discloses a step and skirt panel safety gap measurement and hidden danger positioning system and method for an escalator. The working efficiency of detection personnel is improved, and the labor intensity is reduced; the precision is high, detection errors caused by manual observation and poor personnel responsibility are eliminated, the detection personnel can be assisted in discovering hidden dangers more comprehensively, and escalator safety accidents caused by the hidden dangers are reduced to the utmost extent; and the precise hidden danger positioning function can help maintenance personnel to quickly conduct maintenance and adjustment. The step and skirt panel safety gap measurement and hidden danger positioning system and method for the escalator have significance on safety running of the escalator and personnel safety of passengers, and have a positive promoting effect on development of the whole quality supervision cause.

Owner:GUANGDONG INSPECTION & RES INST OF SPECIAL EQUIP ZHUHAI INSPECTION INST

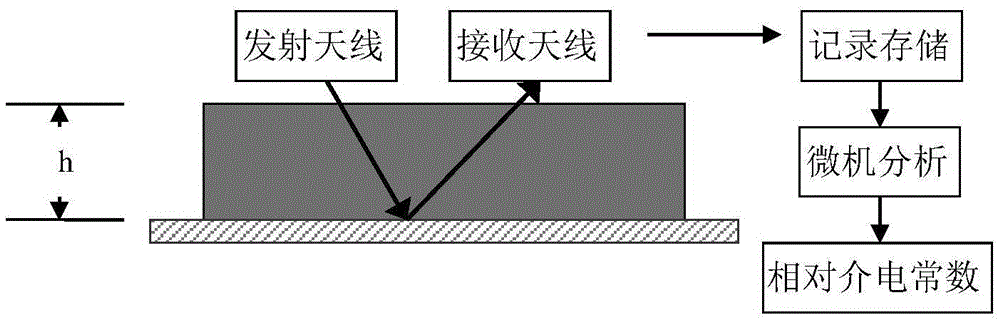

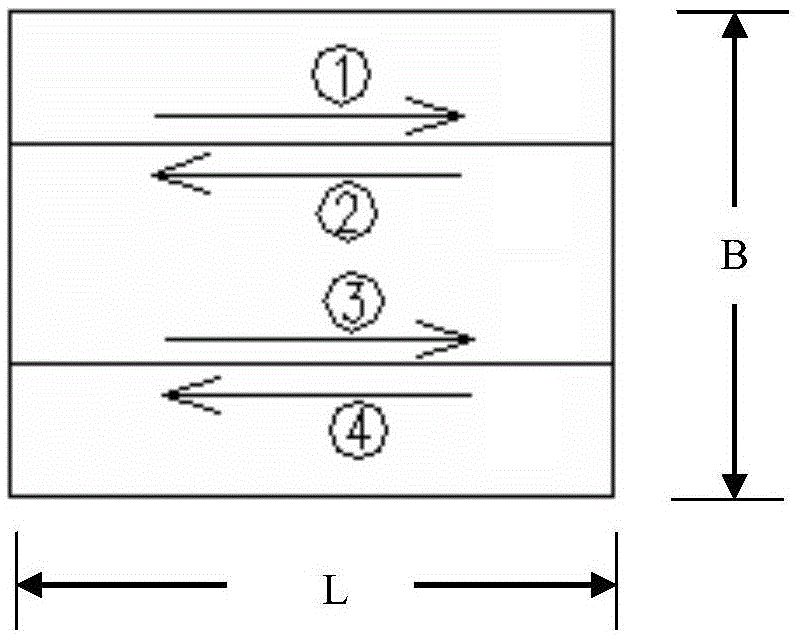

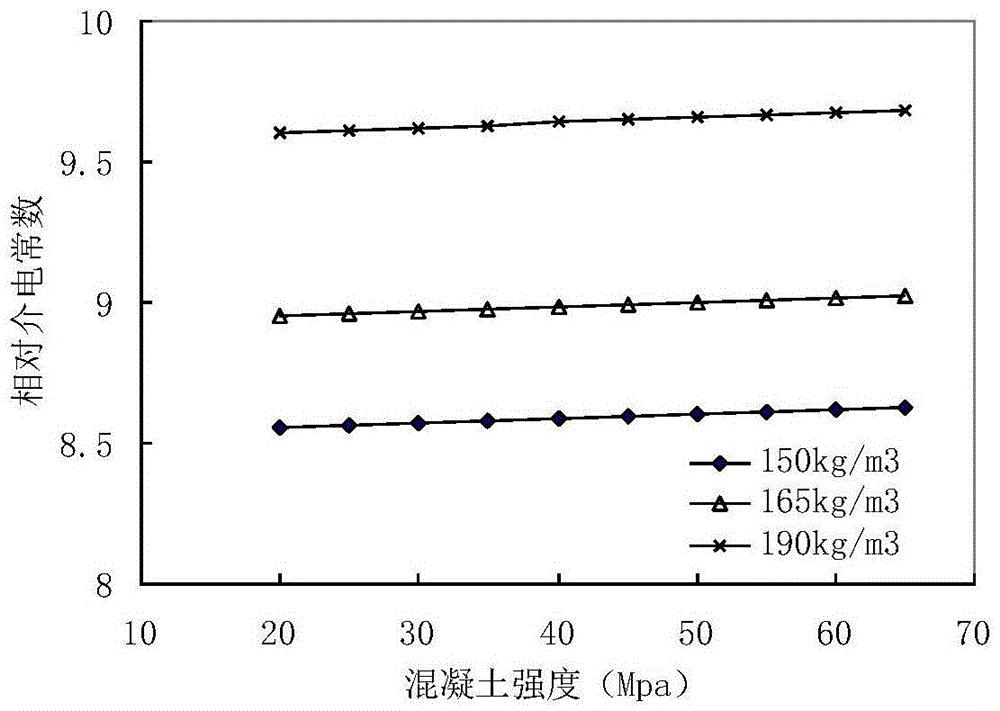

Concrete strength detection method based on electromagnetic properties of material

InactiveCN105527305ANo damageQuickly Determine IntensityMaterial analysis using wave/particle radiationElectricityDielectric

The invention discloses a concrete strength detection method based on the electromagnetic properties of a material. The concrete strength detection method comprises the following steps: preparing a concrete test piece with a mix ratio identical to the mix ratio of actual structural concrete and carrying out maintenance for 28 d under conditions identical to maintenance conditions of the actual structural concrete; carrying out nondestructive test on the concrete test piece by using a ground penetrating radar according to a reflection method or transmission method; calculating the relative dielectric constants of the concrete test piece according to the propagation time of electromagnetic waves in the concrete test piece, carrying out detection a plurality of times and taking an average value of the calculation results; and acquiring concrete strength according to a curve model of the correlation between the relative dielectric constant and strength of concrete established on the basis of experiments. The invention has the following characteristics: radar nondestructive testing technology is employed; original structure is not damaged; testing precision is high; the speed of testing is fast; the test piece is simple to prepare; since the mix ratio and maintenance conditions of the test piece and the actual structural concrete are identical, detection results are genuine and believable; and the method has wide applicability.

Owner:JIANGSU UNIV OF SCI & TECH

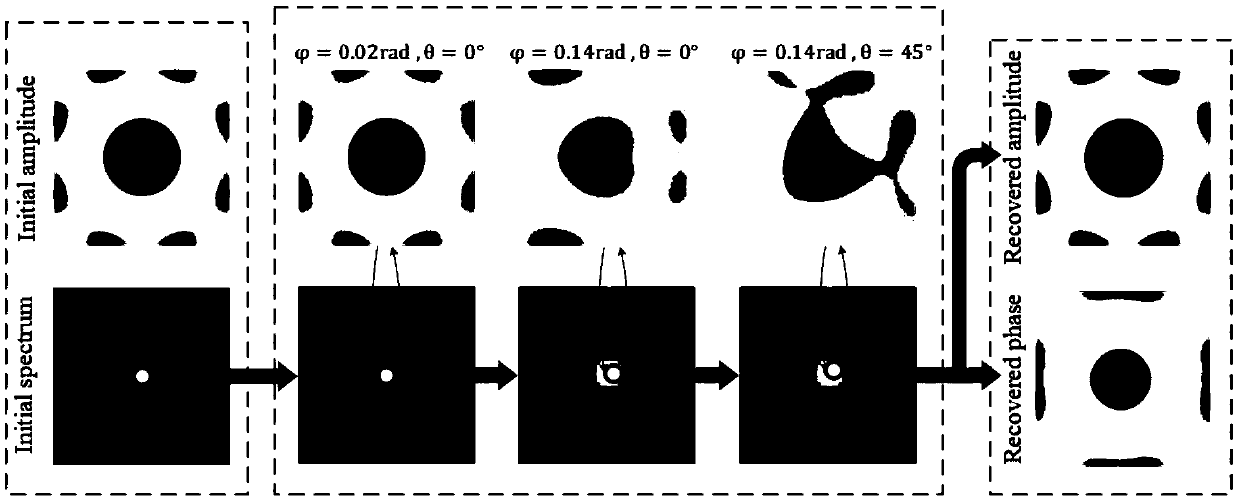

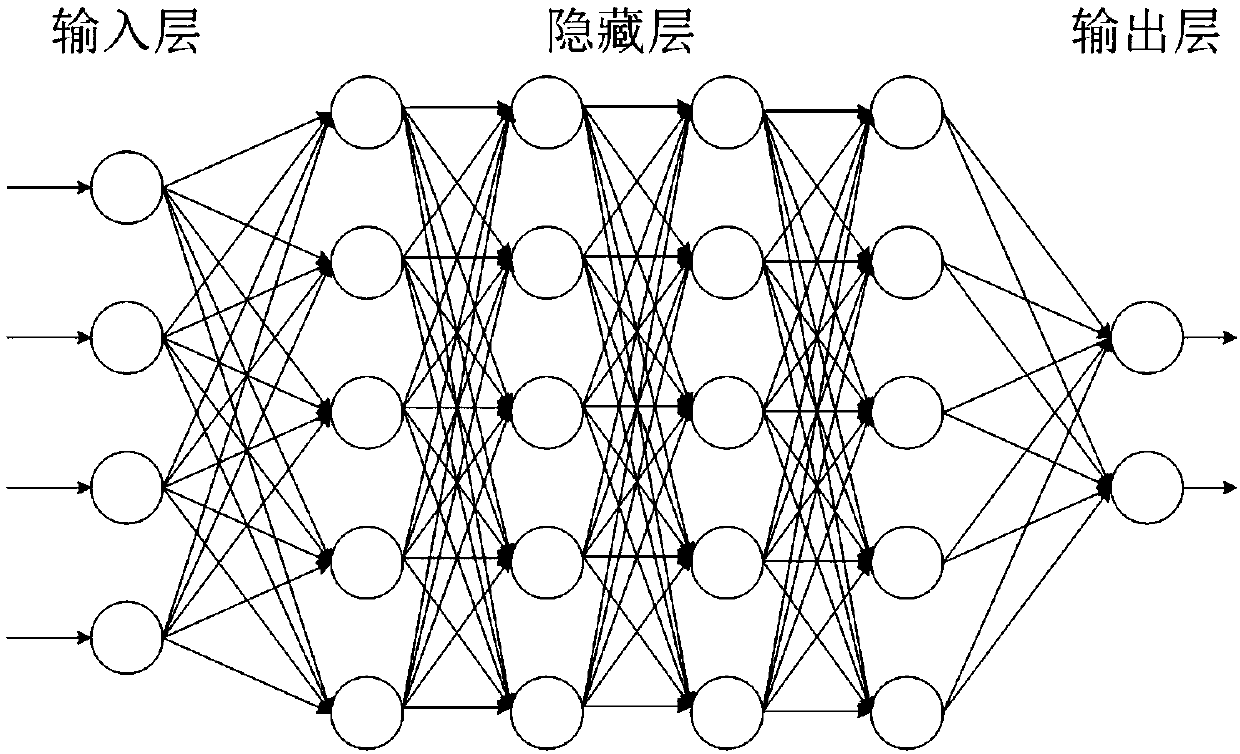

A method for detect that bottom topography of phase defects in an EUV photolithography mask multilayer film

ActiveCN109031894APrevent movementEliminate detection errorsPhotomechanical exposure apparatusMicrolithography exposure apparatusExtreme ultravioletCoherent diffraction imaging

A method for detect that bottom topography of a phase-type defect of an EUV photolithography mask multilayer film is disclosed. The method includes modeling and detection. In the modeling phase, firstly, the spatial images of blank mask with multilayer phase defects under different illumination conditions are simulated by photolithography simulation software. Fourier transform coherent diffractionimage (FPI) is used to recover that phase of the spatial image, Finally, an artificial neural network is used to establish the detection model, which takes the spatial image information as input andthe mask multilayer phase defect bottom topography parameters as output. In the detection phase, the actual mask space image is collected, and the bottom topography parameters of the actual mask defects are calculated by using the detection model, and the bottom topography of the mask multilayer phase defects is detected. The invention can quickly and accurately detect the topography of the bottomof the phase type defect of the extreme ultraviolet photolithography mask multilayer film.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

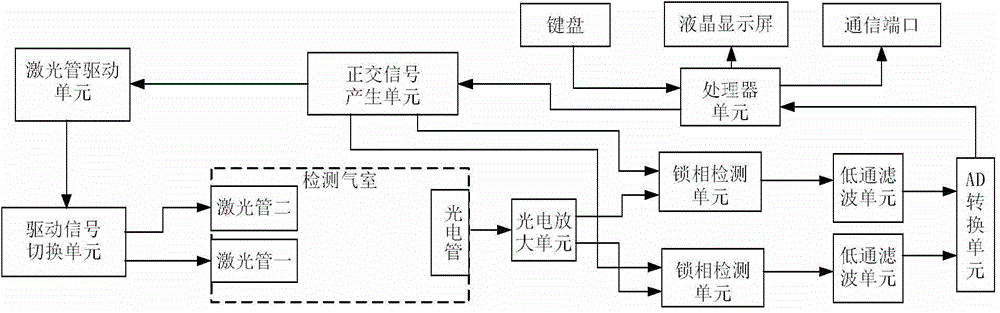

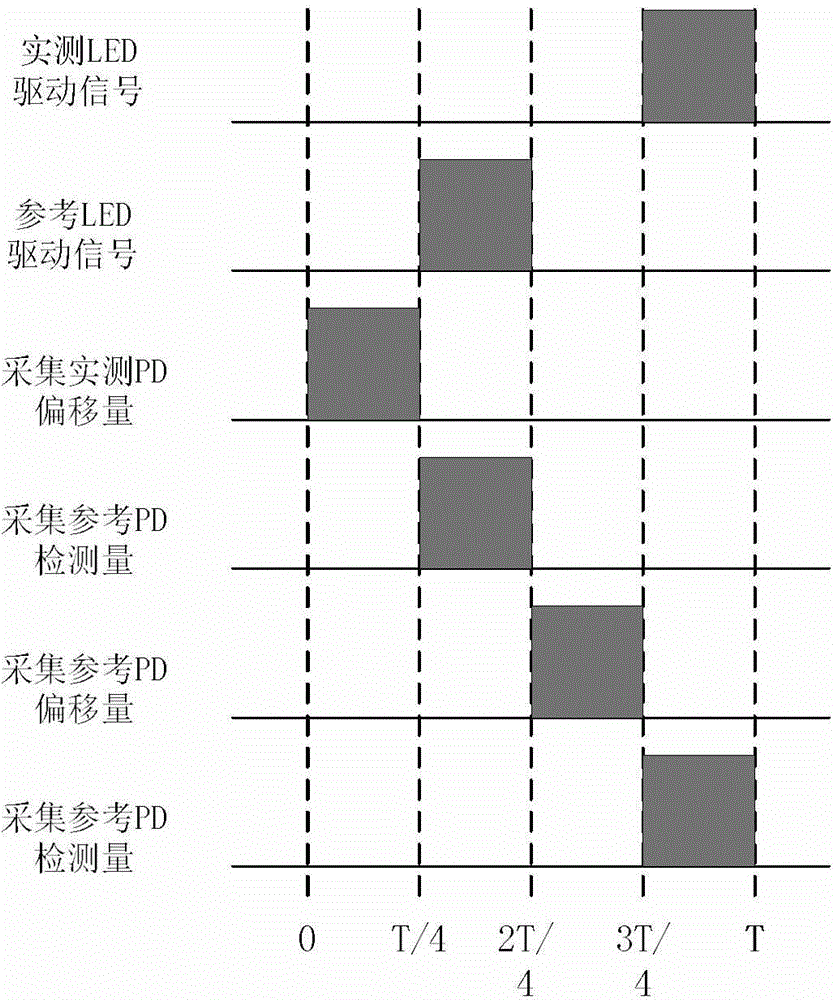

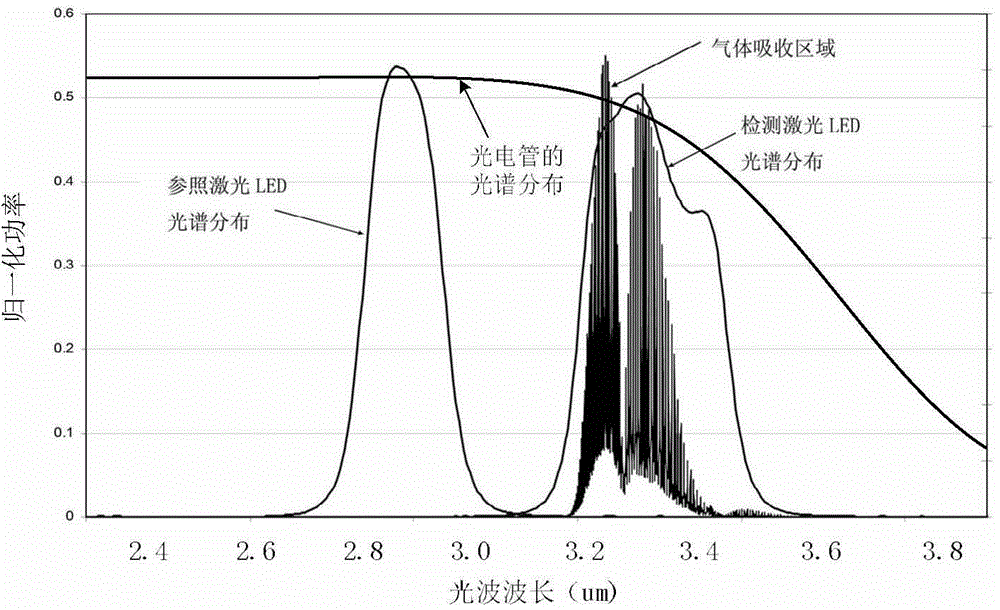

Intermediate infrared laser gas sensing detecting device and intermediate infrared laser gas sensing detecting method

ActiveCN104596970AEliminate the effects ofEffective Minor ChangeMaterial analysis by optical meansOptoelectronicsMid infrared laser

The invention discloses an intermediate infrared laser gas sensing detecting device. An intermediate infrared laser LED and an orthogonal phase-locking detection technique are adopted for effectively detecting the trace gas. The light source of the device is composed of two pieces of far infrared laser LEDs and respectively covers a gas absorption spectrum of the gas and a non-gas absorption spectrum. The detecting signal is amplified by a driving and switching unit and two laser tubes can be controlled by the driving and switching unit so as to emit the light according to the time sequence, meanwhile, the gas is detected, the impact caused by the environment and the circuit drift is effectively eliminated, the precision is high, the cost is low and the noise is low.

Owner:NANJING UNIV +1

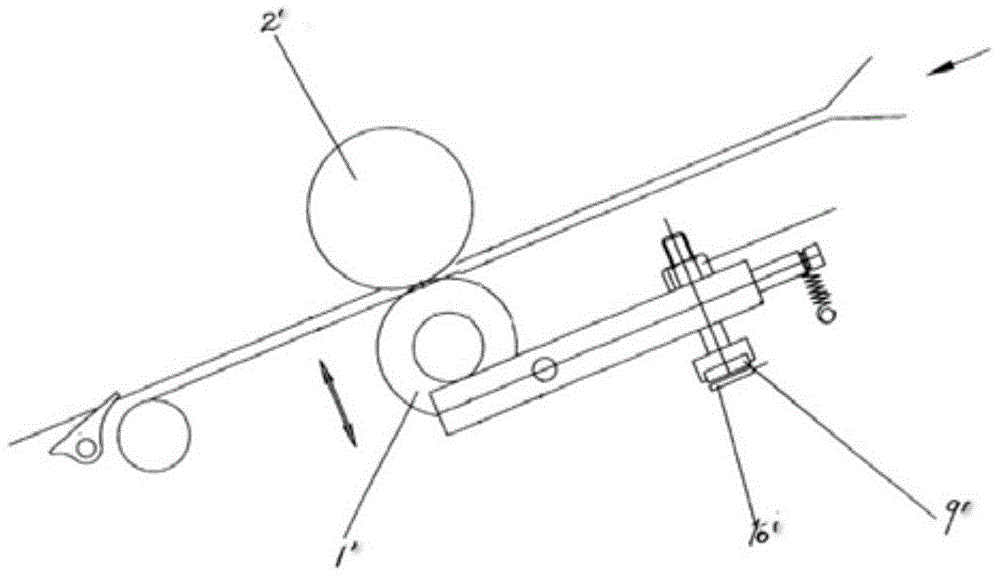

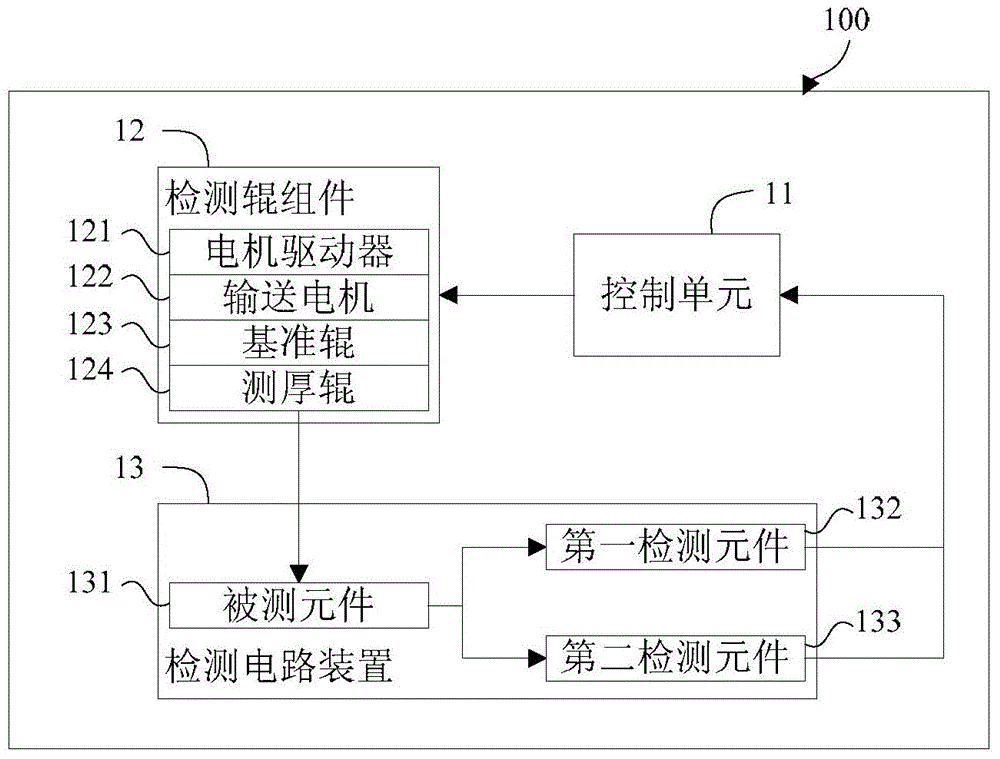

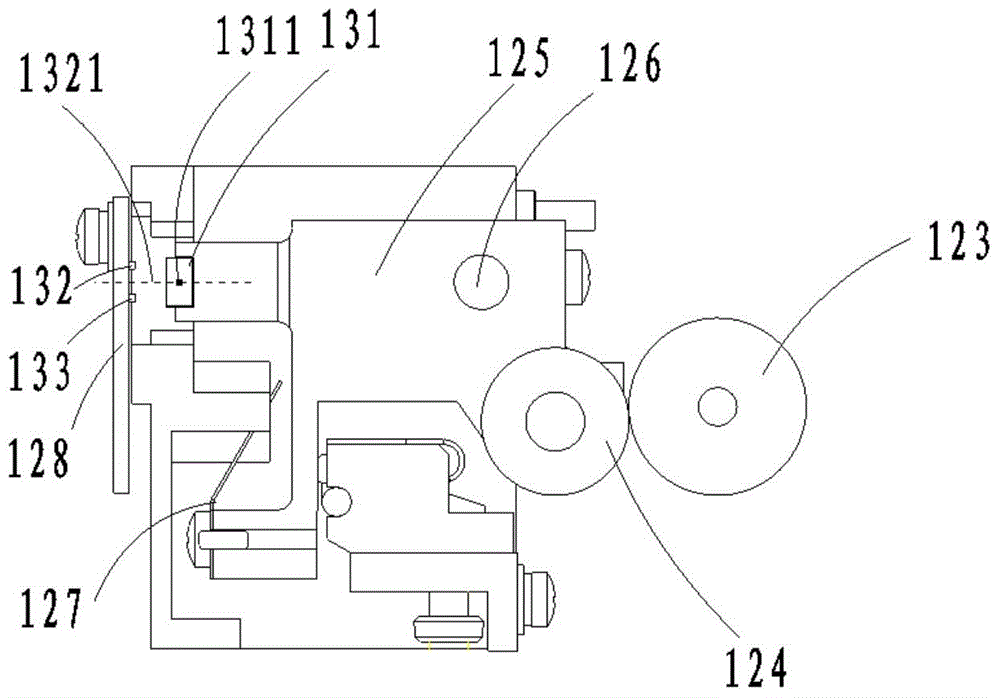

Medium thickness detecting device

ActiveCN105469497AEliminate detection errorsSolve the inaccurate thickness detectionCoin/paper handlersElectricityEngineering

The present invention discloses a medium thickness detecting device which comprises a reference roller (123), a thickness measuring roller (124) opposite to the reference roller (123), a detected element (131) which moves with the thickness measuring roller (124) synchronously, a first detection element (132) for detecting the detected element (131) and outputting a first electric signal, a second detection element (133) which is arranged at the second movement direction of the detected element (131) and outputs a second electric signal, and a control unit which detects the thickness of the medium between the reference roller (123) and the thickness measuring roller (124) through the first electric signal and the second electric signal. A medium transmission channel is formed between the reference roller (123) and the thickness measuring roller (124). Through the medium thickness detecting device, the accuracy of the medium thickness detection is improved.

Owner:SHANDONG NEW BEIYANG INFORMATION TECH CO LTD +1

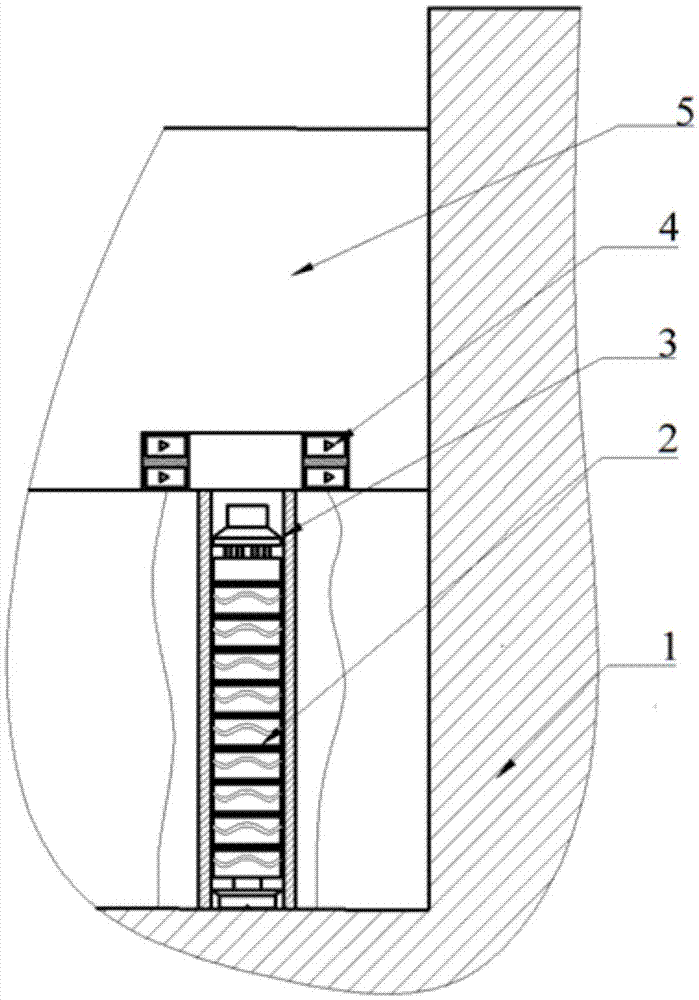

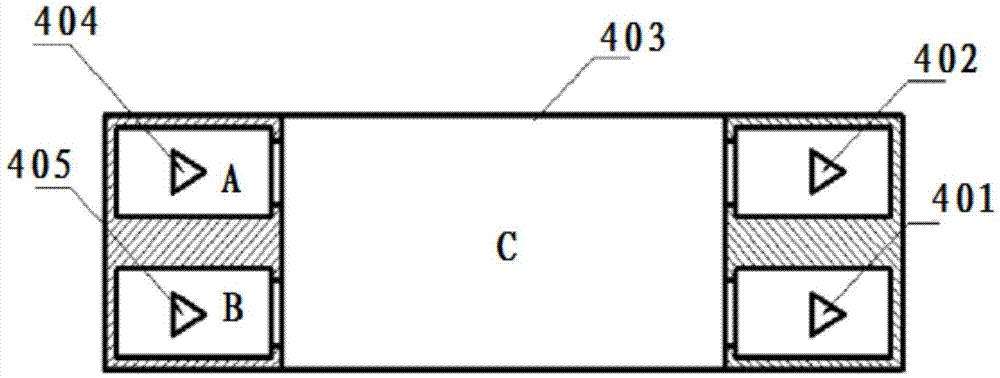

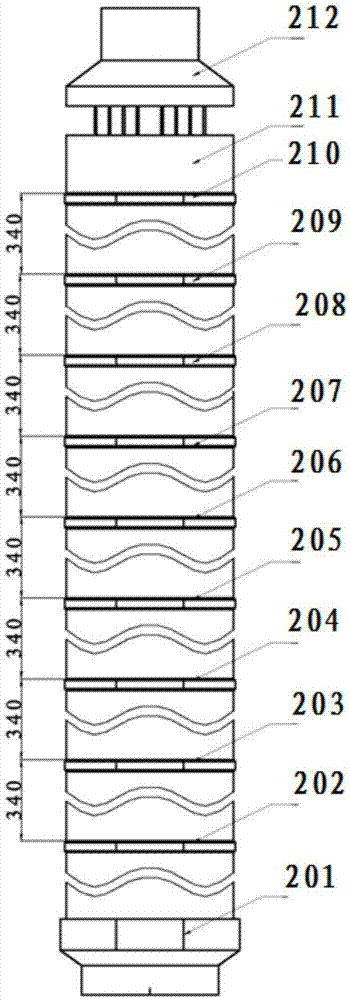

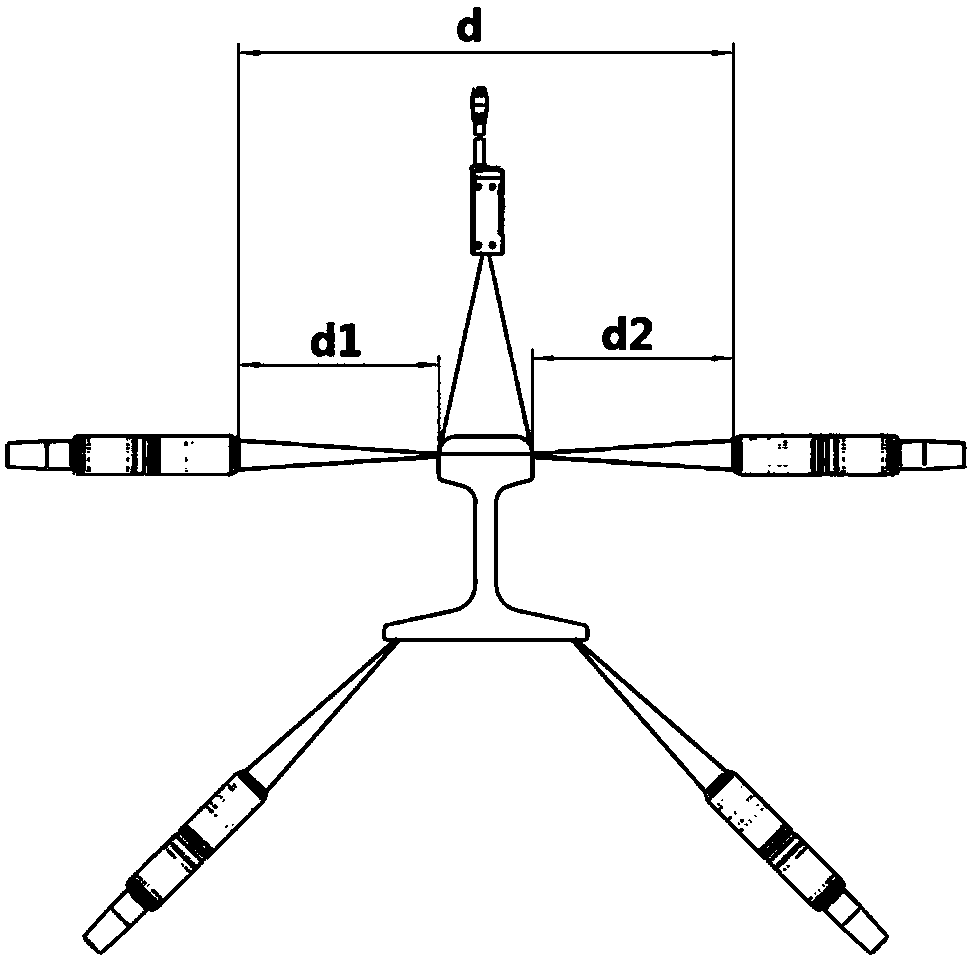

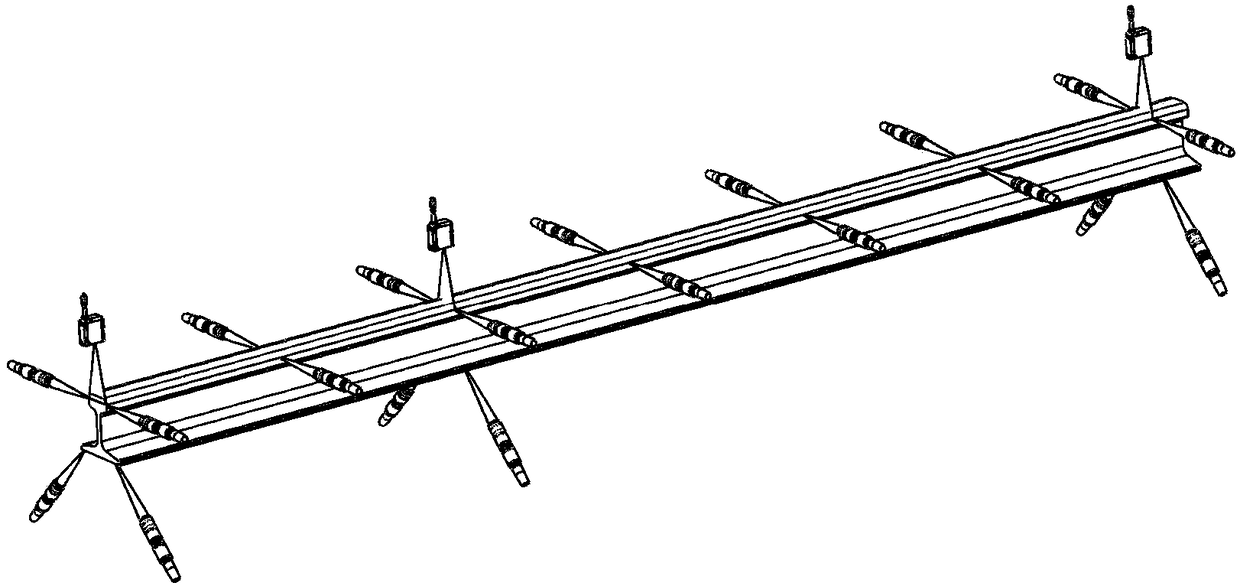

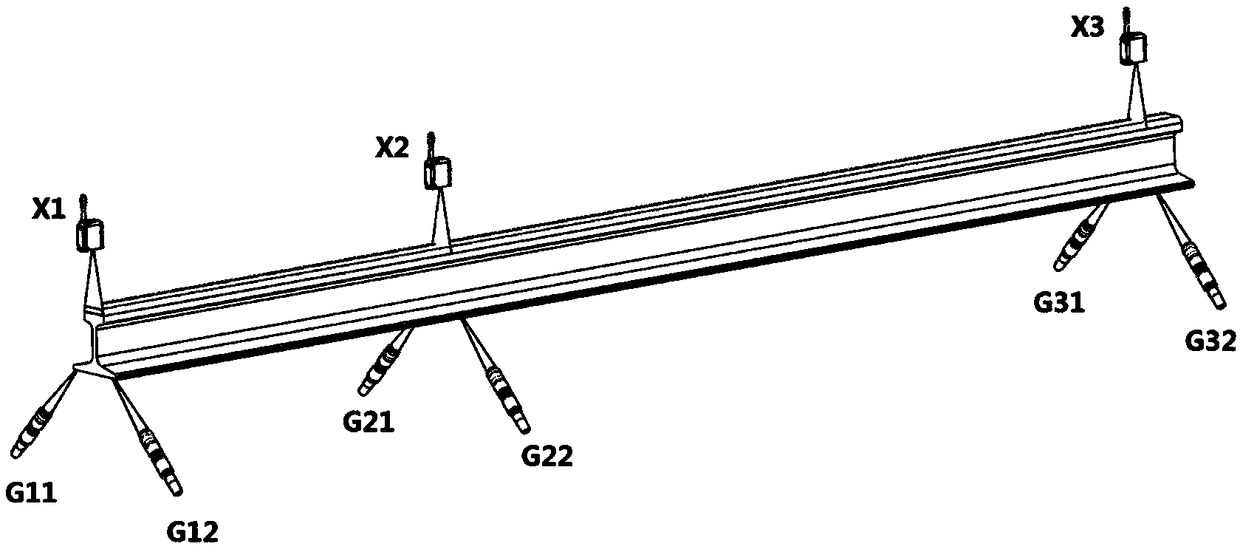

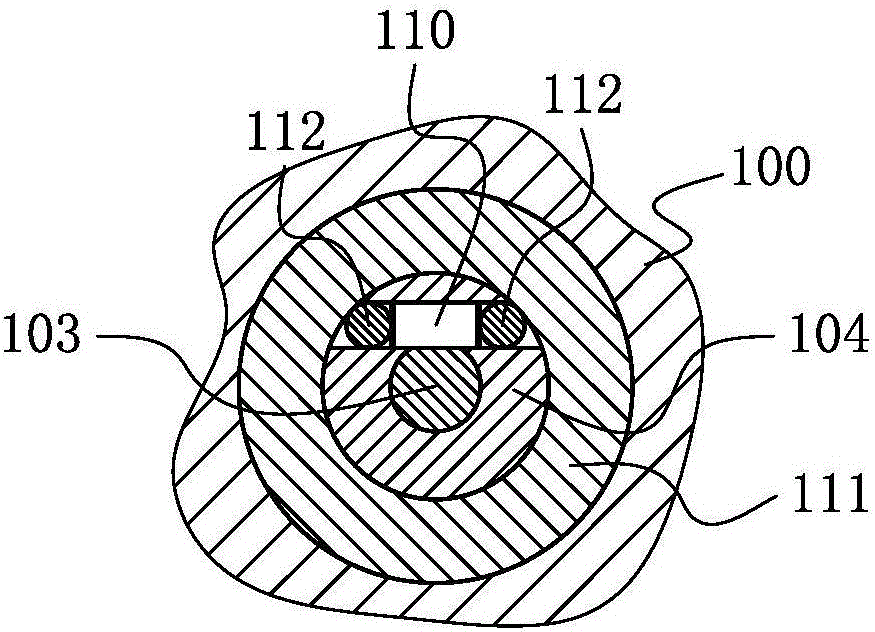

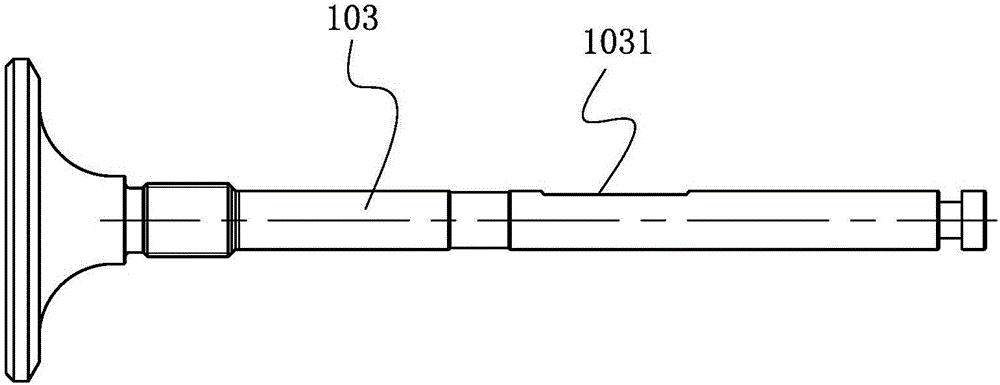

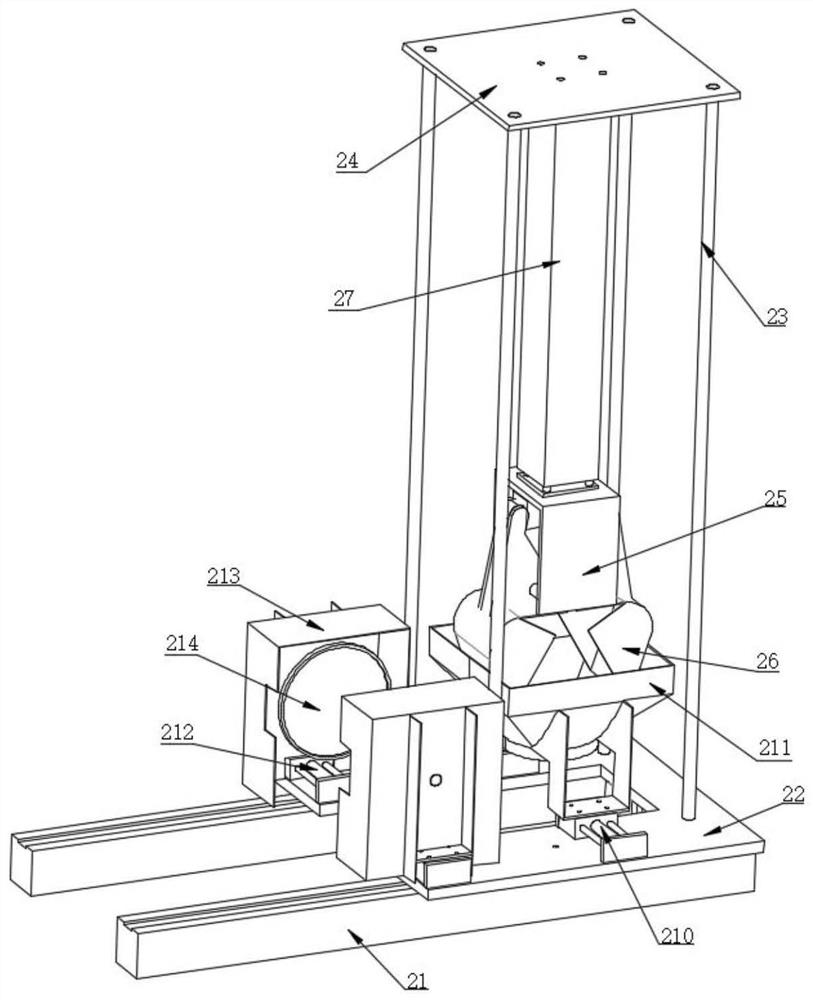

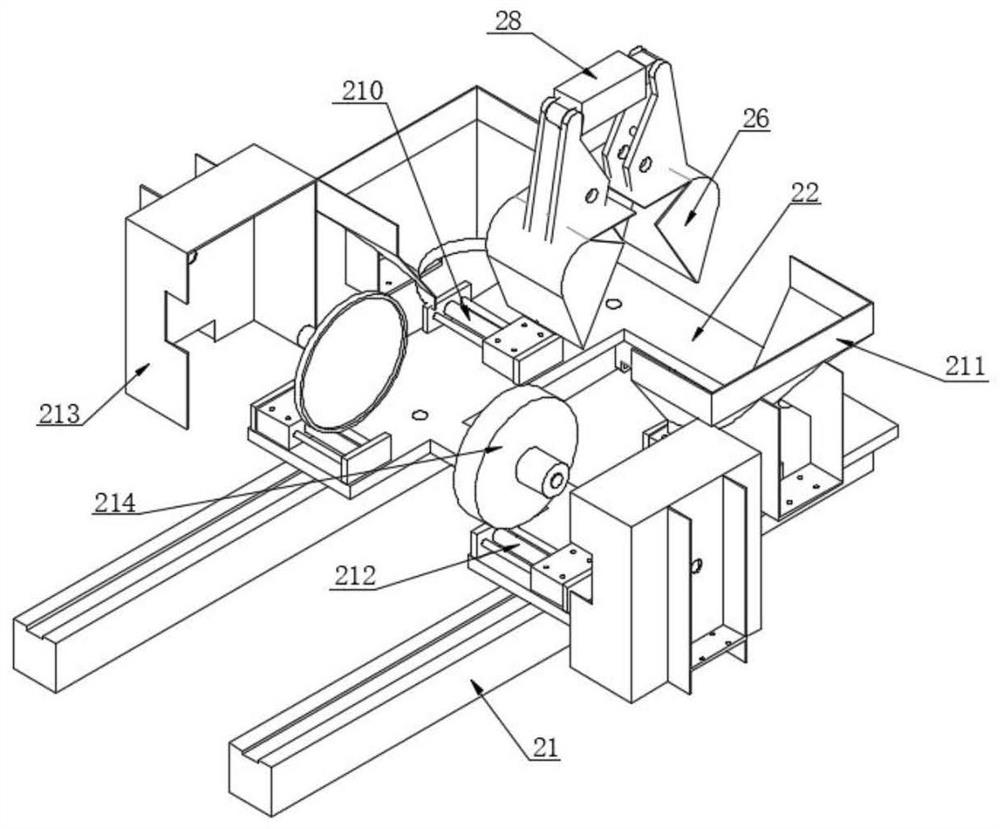

Fuel-assembly deformation-quantity double-layer measuring system and method

ActiveCN106935291AImprove deformation detection accuracySolve the problem of poor deformation detection accuracyNuclear energy generationNuclear monitoringAccuracy and precisionEnvironmental geology

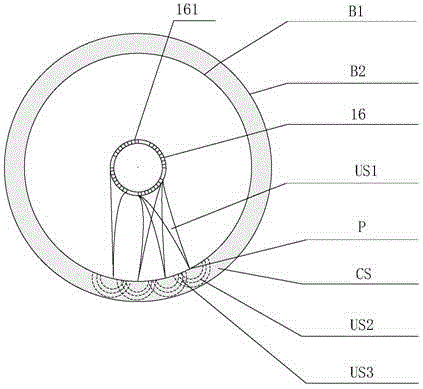

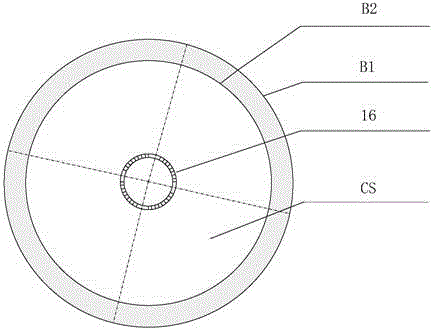

The invention belongs to the technical field of fuel assembly measuring, and particularly discloses a fuel-assembly deformation-quantity double-layer measuring system and method. The system includes a measuring system substrate, a first-layer detection system and a second-layer detection system, an upper annular cavity and a lower annular cavity are formed in the measuring system substrate, the second-layer detection system is arranged in the upper annular cavity, and the first-layer detection system is arranged in the lower annular cavity. The method includes the steps that a refueling machine grabs a fuel assembly, and the fuel assembly is moved to be above a spent fuel pool frame; the refueling machine inserts the fuel assembly into the spent fuel pool frame; the second-layer detection system and the first-layer detection system sequentially detect two adjacent fuel-assembly frames, and the fuel-assembly deformation quantity of each fuel-assembly frame relative to the first-layer fuel-assembly frame is obtained; from the fuel-assembly deformation quantities, the maximum value is selected as the deformation quantity of the fuel assembly. The double-layer measuring system and method can eliminate errors which are introduced due to the transverse sloshing of the fuel assembly, and the measuring accuracy of the deformation quantity of the fuel assembly is improved.

Owner:JIANGSU NUCLEAR POWER CORP

Gas storage well shaft detection system based on ultrasonic phased array technology and detection method thereof

InactiveCN105486752AEliminate detection errorsSmall footprintAnalysing solids using sonic/ultrasonic/infrasonic wavesTransceiverUltrasound

The invention discloses a gas storage well shaft detection system based on an ultrasonic phased array technology and a detection method thereof. The system comprises surface equipment such as a system host, optical fiber communication equipment and an encoder as well as underground equipment such as a centering device, an ultrasonic phased array detector and an annular phased array probe. The detection method includes the steps that the system host is started, and the centering device is adjusted to keep the underground equipment in coaxial parallel with a shaft; electric signals, for detecting control information, of the system are converted into optical signals through an optical transceiver and are transmitted to the ultrasonic phased array detector through optical fiber; the annular phased array probe is stimulated by the ultrasonic phased array detector according to the focusing law to transmit ultrasonic waves to scan the shaft wall; after being converted into optical signals, collected echo electric signals are transmitted to the system host through optical fiber to be stored and processed into images. Real-time S display and C display can be achieved by the detection system, the scanning coverage rate can be flexibly adjusted by changing the stepping magnitude of an ultrasonic deflecting angle, a corroded part is located and scanned carefully, and detection speed and detection precision are high.

Owner:SPECIAL EQUIP SAFETY SUPERVISION INSPECTION INST OF JIANGSU PROVINCE

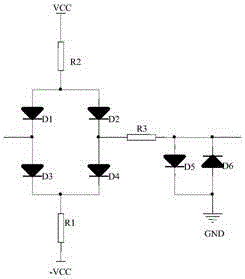

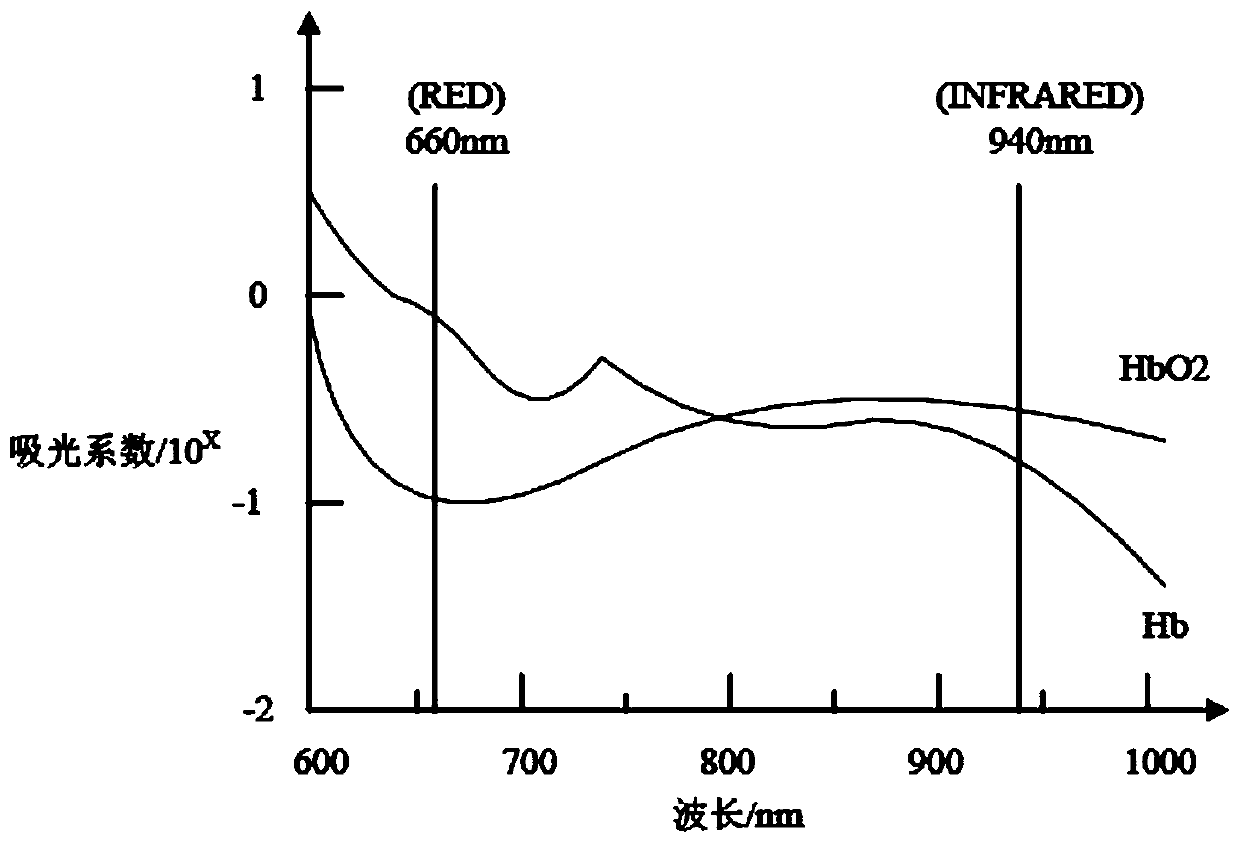

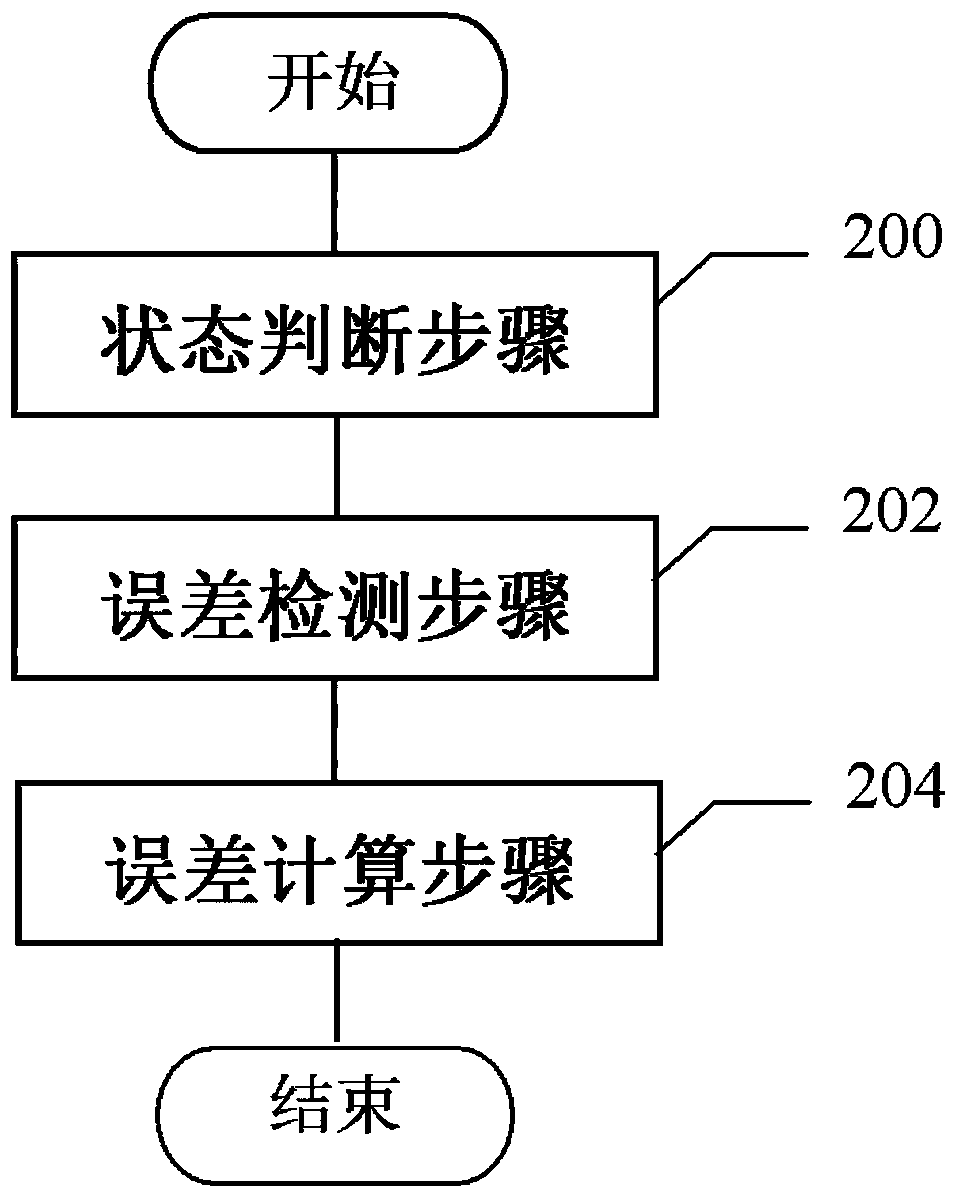

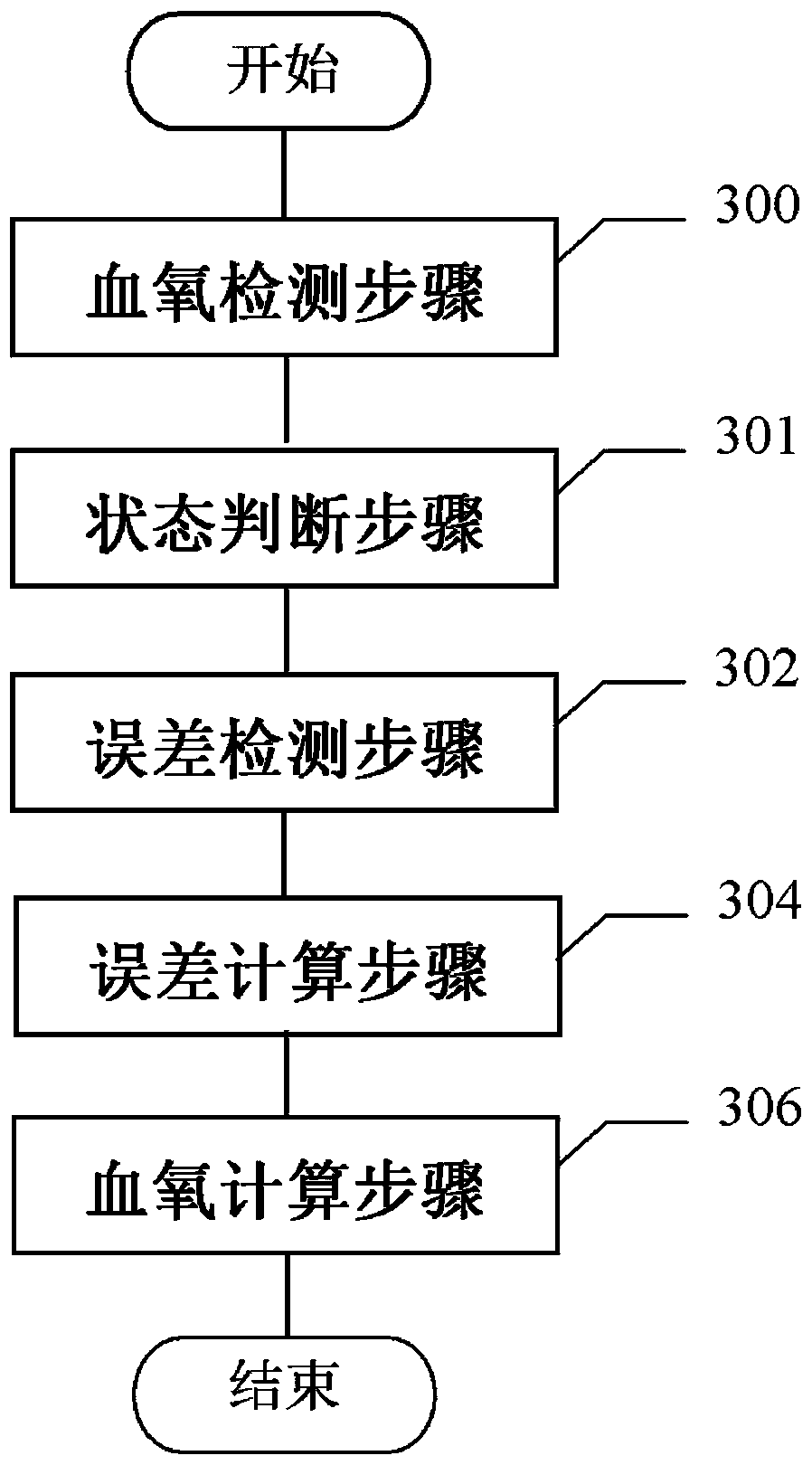

Three-wavelength oxyhemoglobin saturation detection method and device and wearable equipment

ActiveCN107714050AEliminate detection errorsAccurate blood oxygen saturationInertial sensorsDiagnostic recording/measuringLength waveOxygen saturation

The invention discloses a three-wavelength oxyhemoglobin saturation detection method and device and wearable equipment. The method comprises the steps of oxyhemoglobin detection, error detection, error calculation and oxyhemoglobin calculation. By means of the three-wavelength oxyhemoglobin saturation detection method and device and the wearable equipment comprising the device, the detection errorcaused by noise due to movement can be removed, and a more accurate oxyhemoglobin saturation detection result can be obtained.

Owner:GUANGDONG TRANSTEK MEDICAL ELECTRONICS CO LTD

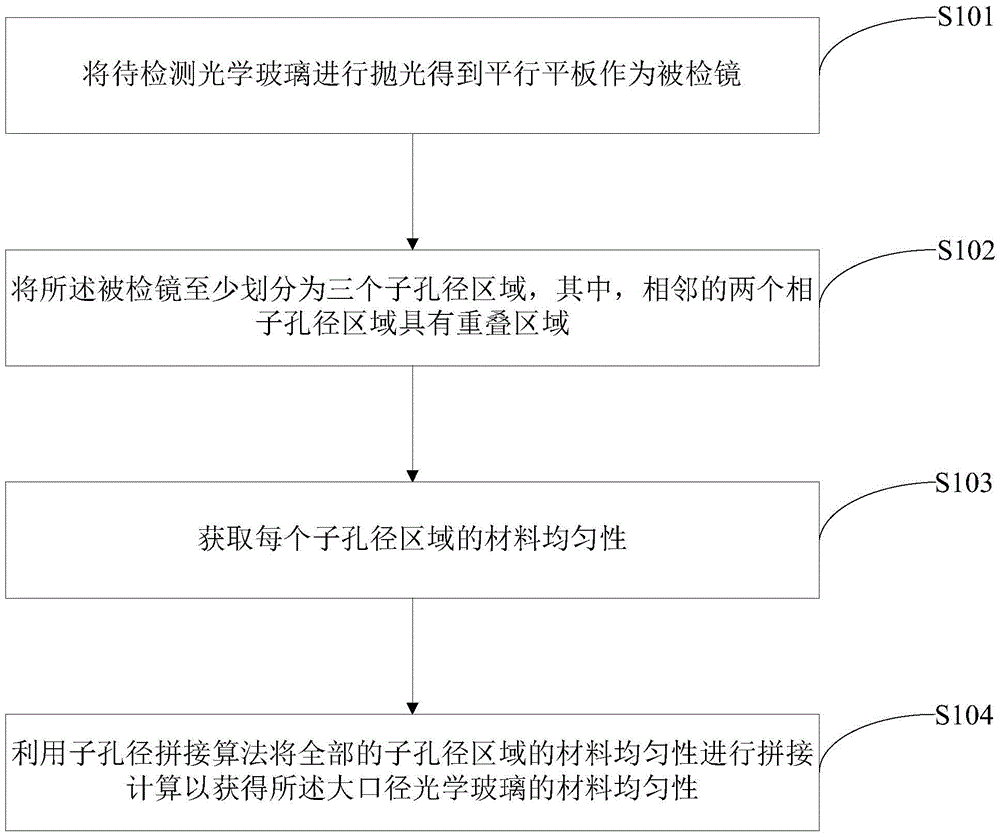

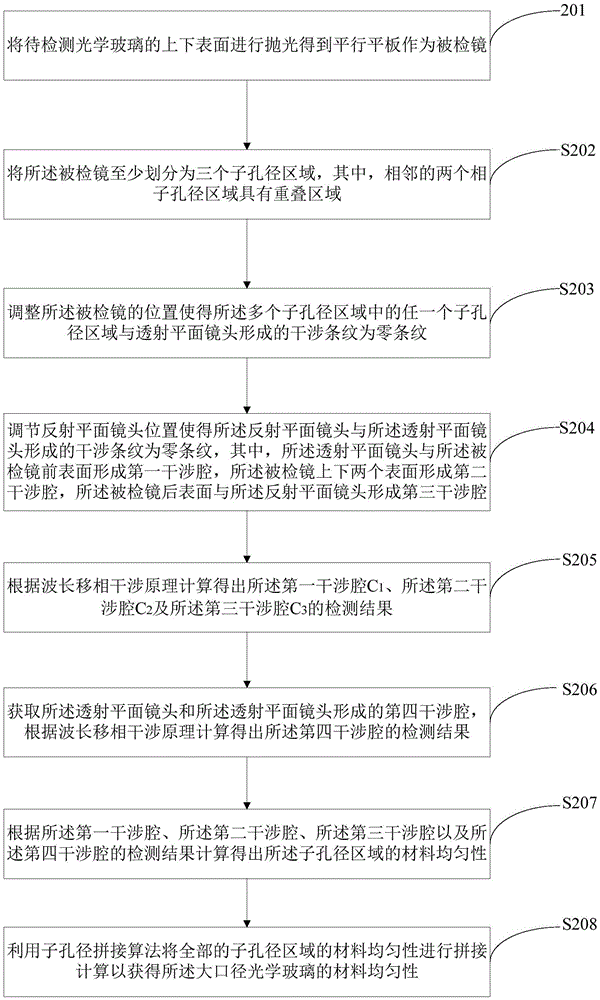

Optical glass material homogeneity detection method and device

ActiveCN106248350AAchieving Absolute DetectionEliminate detection errorsTesting optical propertiesPlane mirrorWave aberration

The invention puts forward an optical glass material homogeneity detection method. A detected lens is divided into at least three sub-aperture areas, the material homogeneity of each sub-aperture area is calculated, and then, the material homogeneity of the detected lens is calculated using a sub-aperture stitching algorithm. In addition, the tilt posture of the detected lens is monitored and collected by a monitoring interferometer and a lateral plane mirror, and therefore, the homogeneity test results of different sub-apertures are completely consistent in tilt state. The amount of 'tilt' introduced to the sub-aperture interference detection result by de-focusing and astigmatism in homogeneity can be truly retained, so that splicing trace discontinuity in full-aperture homogeneity of the detected lens is avoided. According to the method put forward by the invention, in the process of large-aperture optical glass material homogeneity detection using a small-aperture phase-shifting interferometer, absolute detection of all wave aberrations of material homogeneity can be realized, and detection error caused by splicing trace discontinuity can be eliminated.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Detection device for depth of workpiece sealing groove

ActiveCN104406561AGuaranteed stabilityWith precisionMeasurement devicesElectricityMechanical engineering

The invention discloses a detection device for the depth of a workpiece sealing groove. Workpieces are mounted on one side of a tooling support seat; a gap is formed in the tooling support seat; the gap corresponds to the sealing groove on each workpiece to be detected in position; a detection mounting plate is fixedly connected to the other end of the tooling support seat; a sliding table air cylinder is mounted on the detection mounting plate and is controlled and driven by a PLC (Program Logic Controller); a datum plate is positioned at the gap and is connected with the moving end of the sliding table air cylinder; the end face of the datum plate is attached to the datum plane of each workpiece; each displacement sensor is connected onto the datum plate and is electrically connected with the PLC; the position of a measuring head of one displacement sensor corresponds to that of one sealing groove on the corresponding workpiece. Due to the adoption of the structure, the stability of the datum plane is guaranteed, the detected data is enabled to have accuracy, and the errors are reduced.

Owner:NINGBO SHENGLONG AUTOMOTIVE POWERTRAIN SYSTEM CO LTD

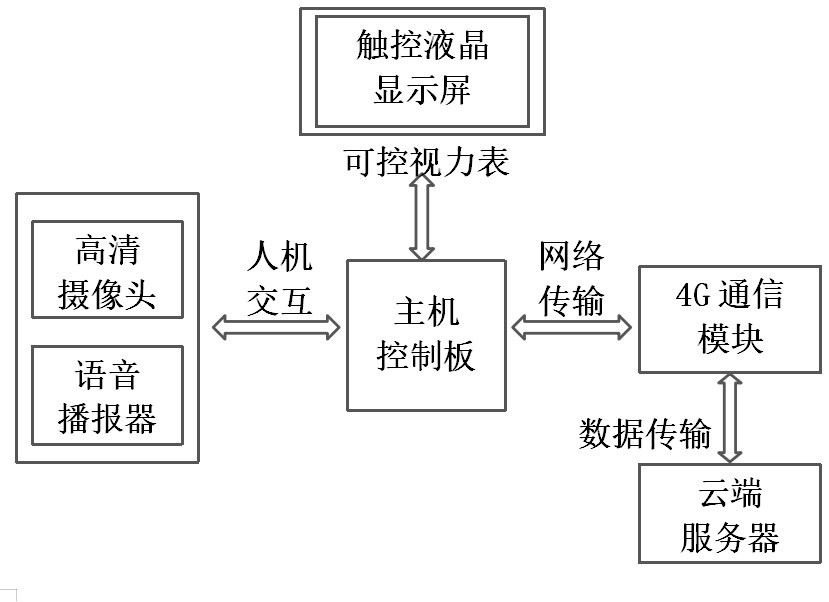

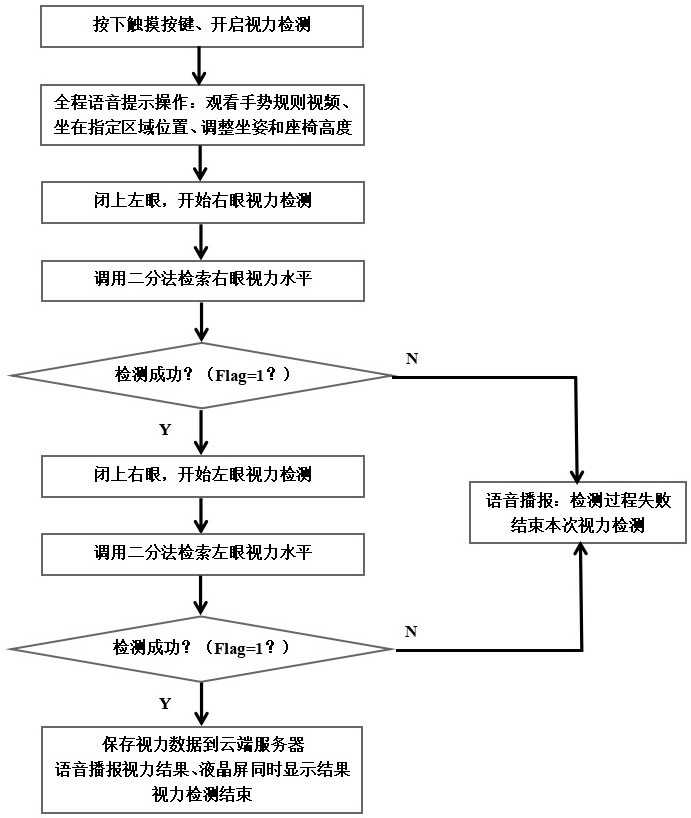

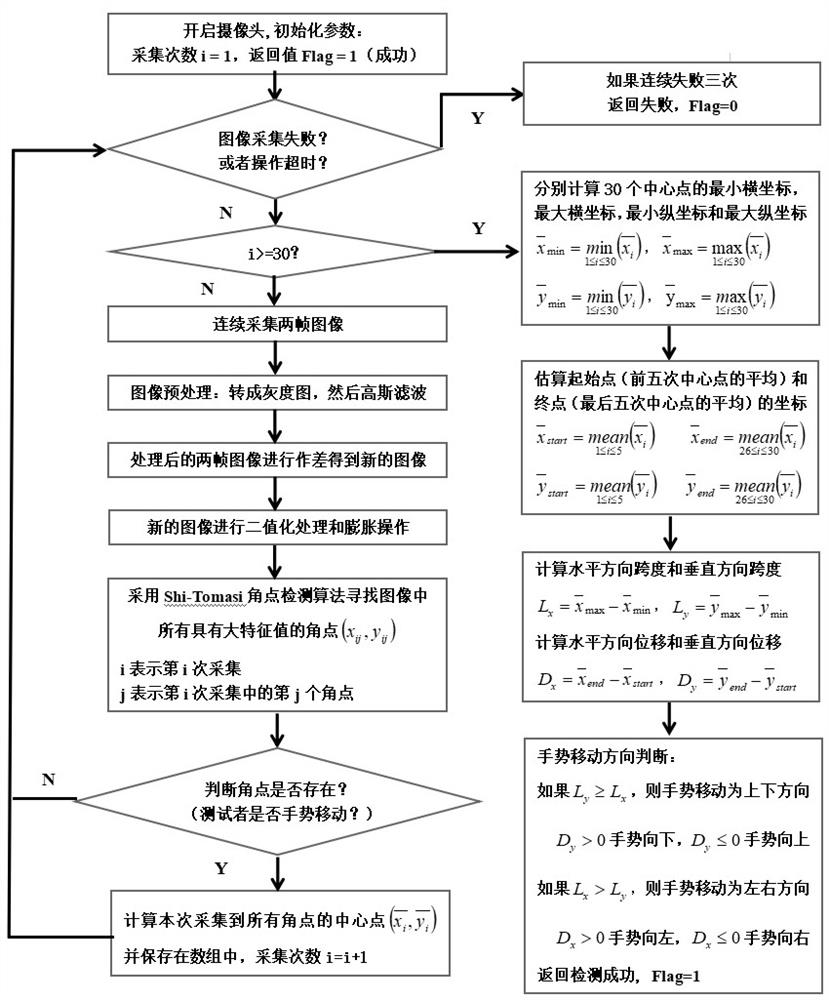

Indoor sharing self-service vision detection system and detection method thereof

ActiveCN111700583AImprove accuracySmall amount of calculationCo-operative working arrangementsCharacter and pattern recognitionComputer graphics (images)Engineering

The invention relates to an indoor sharing self-service vision detection system and a detection method thereof. Vision detection is started, and a tester operates according to voice prompts of a voicebroadcaster. The vision of the right eye is detected firstly, the vision level of the right eye is retrieved by adopting a bisection method, and the specific process is as follows: when the tester sees a sighting mark of a display screen, gesture movement information is generated, a host calls a gesture movement detection algorithm based on a frame difference method to carry out single gesture information acquisition and direction discrimination, then whether the tester can see the sighting mark of the level clearly or not is judged according to a single-level sighting mark recognition and judgment rule, and the bisection method is circularly called to generate the sighting mark of the next level until it is detected that a tested person can see the sighting mark of the minimum level clearly. The process is repeated to complete a left eye vision test. A vision detection result can be stored in a cloud server terminal for the tester to call and check at any time. The vision detection process is convenient and fast, the detection efficiency is high, and self-service vision detection and regional sharing detection can be achieved.

Owner:福建生物工程职业技术学院

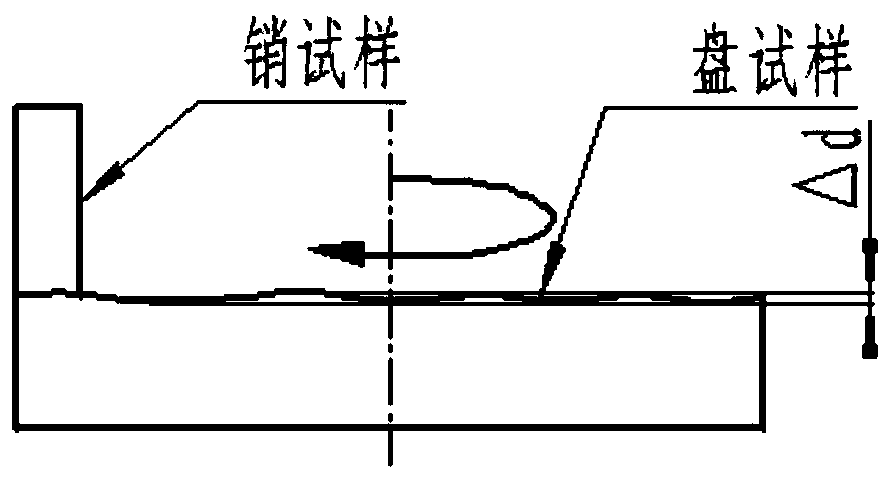

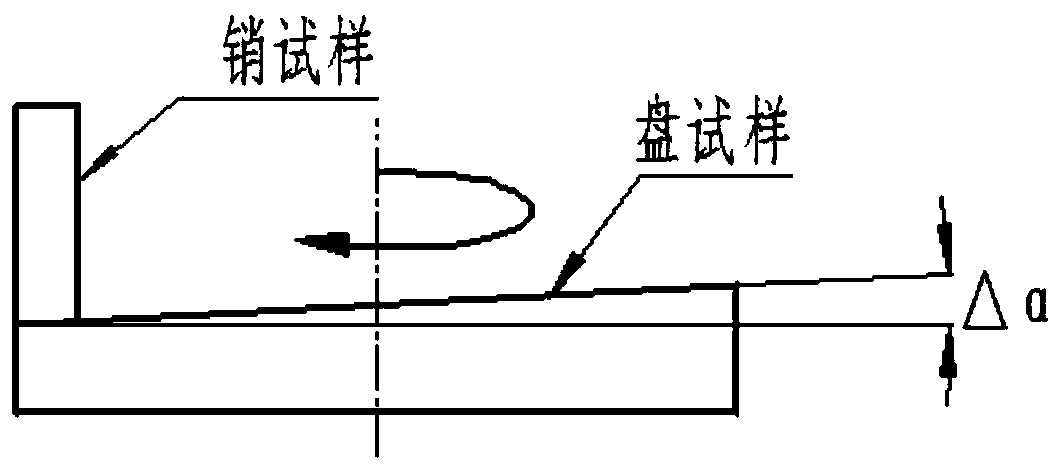

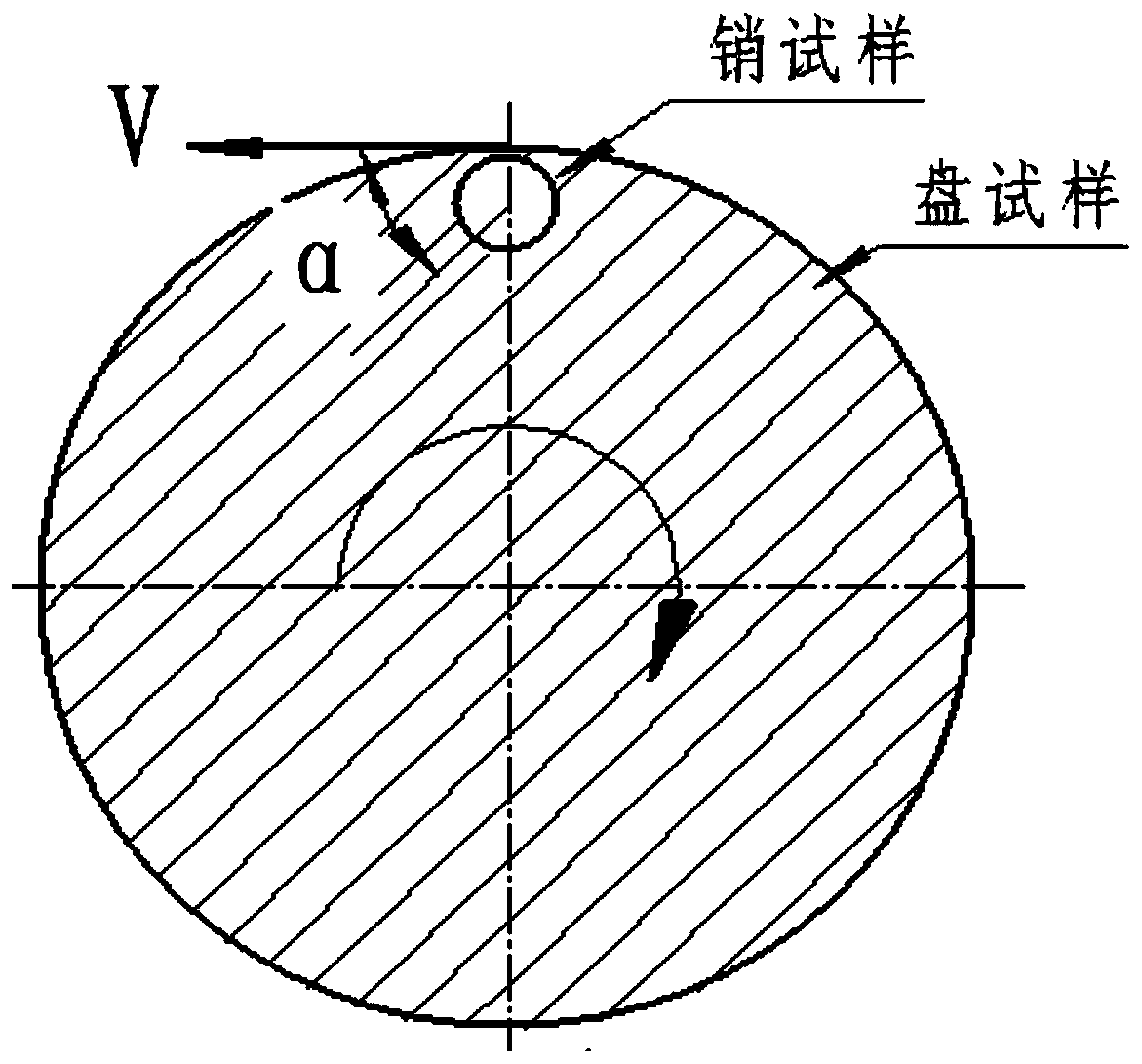

Constant-speed friction and wear experiment data measurement method and testing machine

ActiveCN110243711AEliminate detection errorsImprove detection accuracyUsing mechanical meansInvestigating abrasion/wear resistanceData acquisitionEngineering

The invention discloses a constant-speed friction and wear experiment data measurement method, and the method comprises the following steps: step 1, manufacturing an experiment material into a fixed test piece and a moving test piece according to the specification of an experiment, and respectively installing the fixed test piece and the moving test piece on a fixed clamp and a moving clamp of a testing machine; step 2, setting test parameters such as applied load, temperature, time and the like according to the test requirements; step 3, setting the motion speed of the constant-speed friction testing machine, so that the motion frequency f1 of the moving clamp of the constant-speed friction testing machine and the sampling frequency f2 of a sensor of the constant-speed friction testing machine are in a multiple relation; step 4, starting the constant-speed friction testing machine to carry out a friction and wear experiment, and collecting experiment data through the sensor; and step 5, analyzing the friction and wear performance of the test piece according to the acquired data. According to the method, the relative position of the test piece is fixed at the data acquisition moment, so that the problem of inaccurate detection result caused by processing errors or installation errors is solved, and the detection precision is improved.

Owner:DALIAN JIAOTONG UNIVERSITY

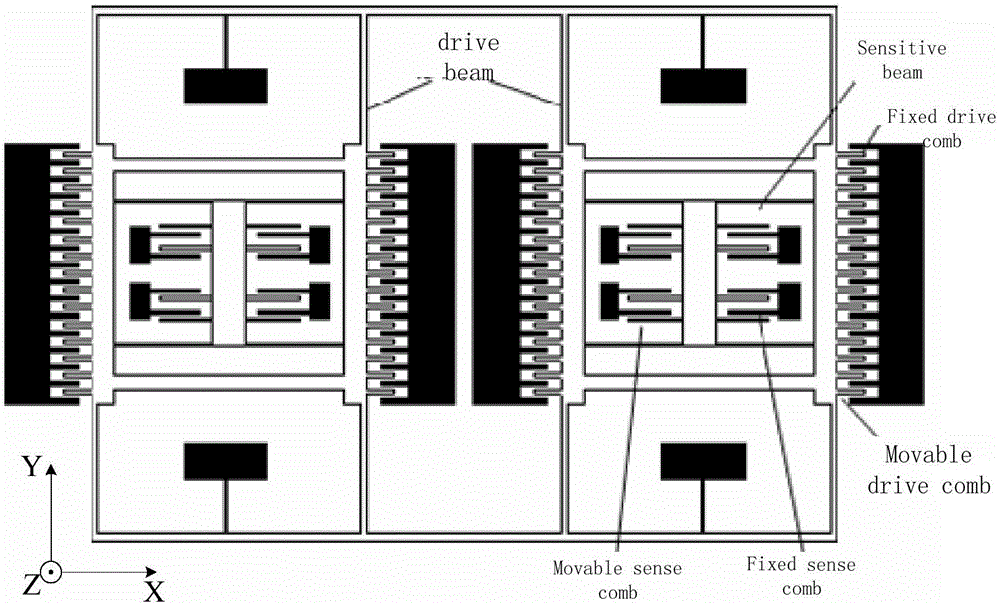

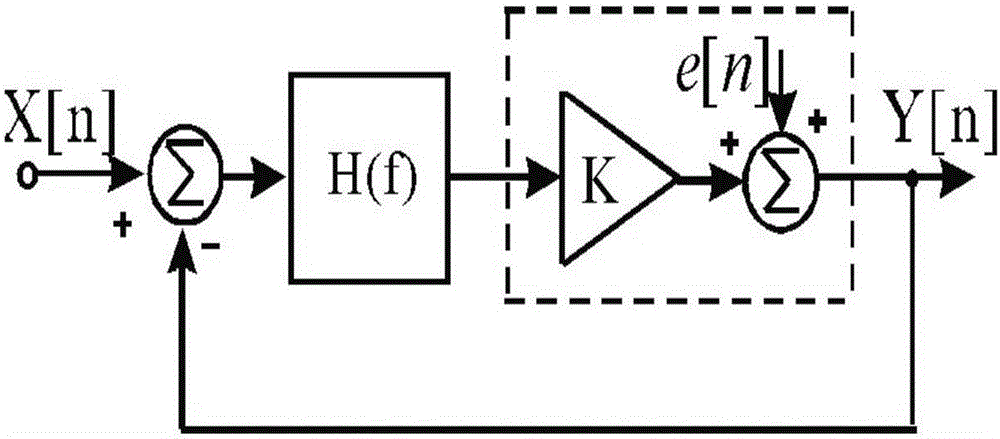

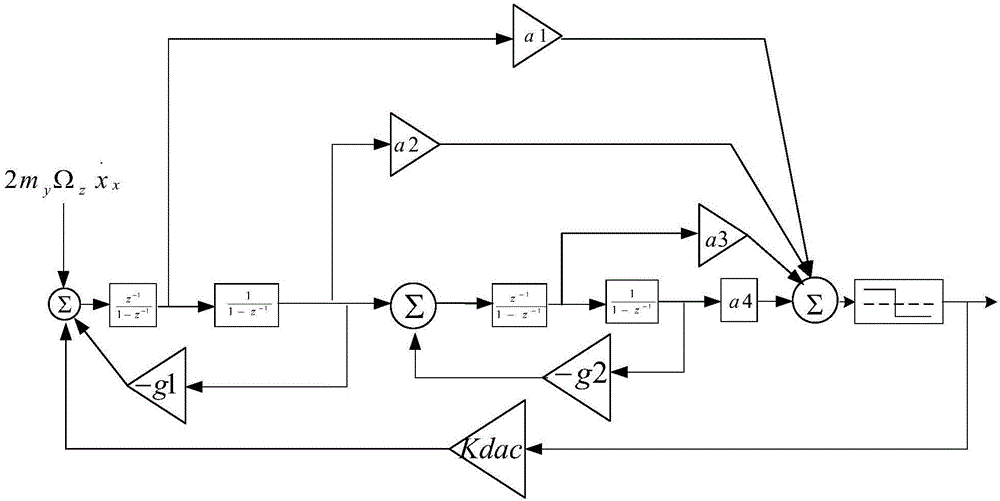

Bandpass sigma-delta closed-loop detection circuit of silicon micro gyroscope

ActiveCN106323263AEliminate detection errorsDesensitizationSpeed measurement using gyroscopic effectsGyroscopes/turn-sensitive devicesCapacitanceSignal-to-noise ratio (imaging)

The invention relates to a bandpass sigma-delta closed-loop detection circuit of silicon micro gyroscope. The circuit comprises connected SMG capacitance / voltage conversion circuits, pre-amplifier circuit, modulus converter, digital resonator, one-digit quantizer and one-digit DAC circuit; the closed-loop detection circuit can effectively eliminate detection error arising from error in mechanical processing, eliminate the sensitivity of detection output to the error in gyroscope and enhance the bandwidth of the whole detection circuit; it can also effectively performs noise shaping for the subsequent one-digit round and enhance the signal to noise ratio of the whole detection loop.

Owner:SUZHOU GST INFOMATION TECH CO LTD

Bearing assembly high-size detection instrument

InactiveCN112050744AImprove detection accuracyAvoid problems that affect work and even safety performanceUsing optical meansPhysicsLinear actuator

The invention provides a bearing assembly high-size detection instrument, which belongs to the field of bearing detection, and comprises a detection platform, an upper tool, a lower tool, a pressure sensor, a linear actuator and a loading platform. The lower tool is arranged on the detection platform, the loading platform vertically slides on the detection platform, and the loading platform is driven by the linear actuator. The upper tool is arranged at the bottom of the loading platform, and the pressure sensor is located between the upper tool and the loading platform. A first distance detection sensor and a second distance detection sensor are further arranged at the bottom of the loading platform, the detection end of the first distance detection sensor is arranged downwards and is opposite to the upper end face of a to-be-detected bearing placed on the lower tool, and the detection end of the second distance detection sensor is arranged downwards and is opposite to the upward endface of the lower tool located on the same horizontal plane with the lower end face of the to-be-detected bearing. According to the invention, the assembly high-size measurement difference caused by small axial load can be avoided, the qualified rate of a bearing is improved, and the processing cost is reduced.

Owner:C&U CO LTD +1

Steel rail flatness and torsion detection device and method

InactiveCN108106565AImprove detection accuracyImprove detection efficiencyUsing optical meansEngineeringSurface geometry

The present invention discloses a steel rail flatness and torsion detection device and method. The device comprises a plurality of spectral confocal displacement sensors and a plurality of linear laser contour sensors. The spectral confocal displacement sensors are symmetrically arranged at two sides of a steel rail and two sides of the bottom portion of the steel rail to measure distances from the side of a rail head of the steel rail and measured points at the bottom portion of the steel rail to the sensors; the linear laser contour sensors are put at the top portion of the rail head of thesteel rail to collect a steel rail tread curve; and the spectral confocal displacement sensors and the linear laser contour sensors are connected with a data collection storage to perform analysis andprocessing to obtain the flatness and torsion of the steel rail. The detection method mainly employs the spectral confocal displacement sensors and the linear laser contour sensors to collect geometrical parameters of the surface of the steel rail to obtain flatness and torsion of the steel rail through data analysis and calculation.

Owner:NANJING INST OF ADVANCED LASER TECH

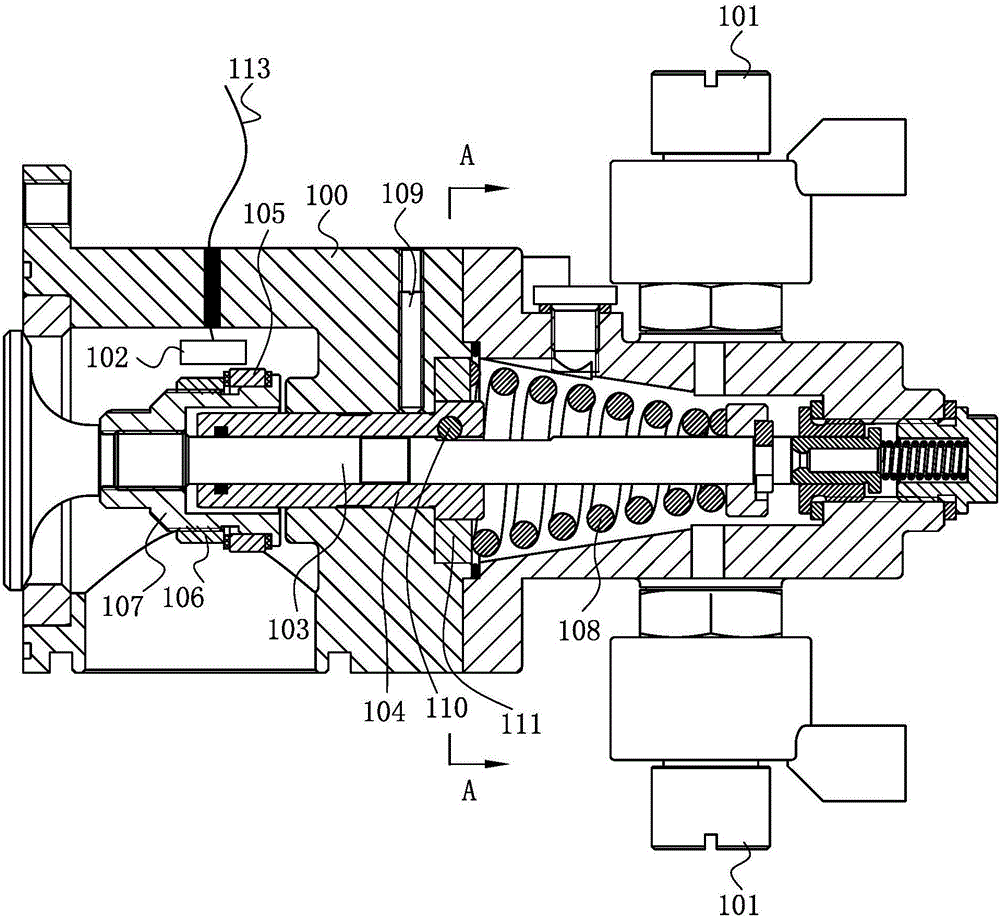

Hydraulically powered gas injection valve

ActiveCN106678426AAccurate opening controlEliminate detection errorsOperating means/releasing devices for valvesInternal combustion piston enginesEngineeringElectromagnetic valve

The invention discloses a hydraulically powered gas injection valve which comprises a valve body and a valve element, wherein a valve bush is arranged in the valve body; an electromagnetic valve communicating with an inner cavity of the valve body is mounted at the external part of the valve body; a valve rod of the valve element and the valve bush are in sliding fit; the valve rod is provided with a first stretching part and a second stretching part stretching out of the valve bush; the first stretching part of the valve rod is fixedly connected with a magnet through a magnet seat; a magnetic field sensor is fixed in the valve body and corresponds to the magnet in position; and a sliding guiding device is arranged between the valve rod and the valve bush. The magnet is fixed with the valve element through the magnet seat and moves along with the valve element, and the magnetic field sensor detects variation of a magnetic field to sense the stroke of the valve element so as to accurately control opening of the valve element; and through the sliding guiding device, the valve element is enabled not to rotate during axial movement, so that detection error brought to the magnetic field sensor by magnetism difference of the magnet in the circumferential direction is eliminated, and measurement accuracy is improved.

Owner:WEIFANG LICHUANG ELECTRONICS TECH

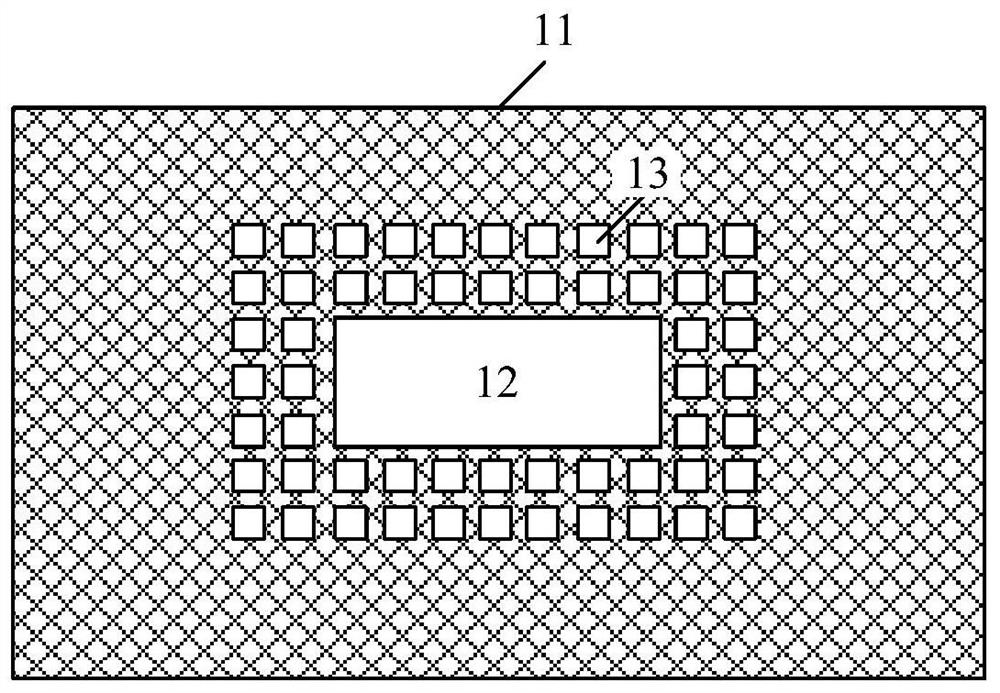

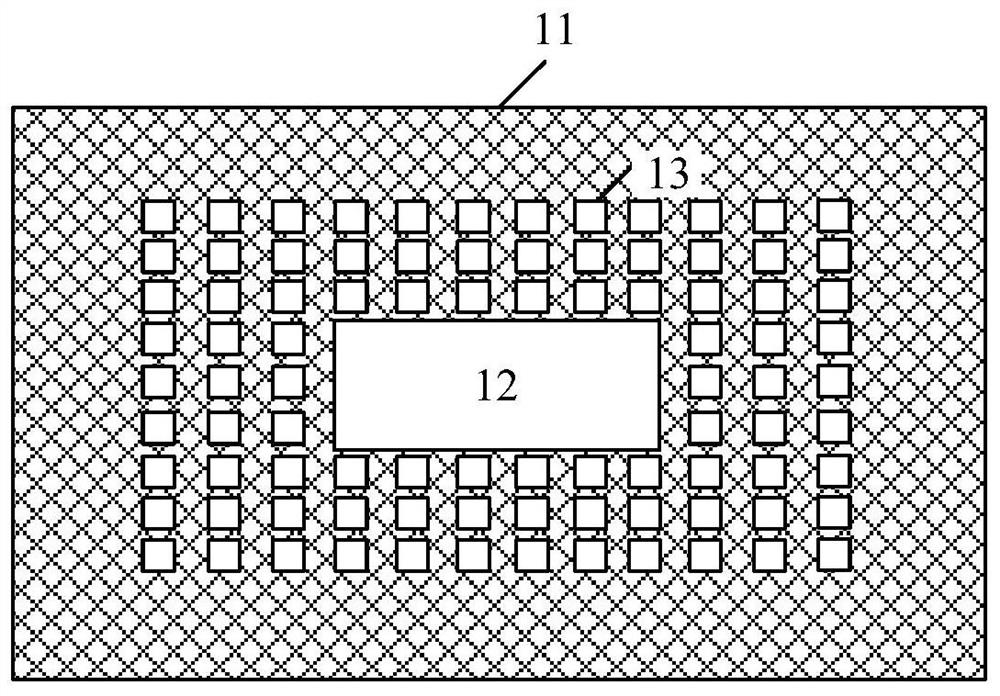

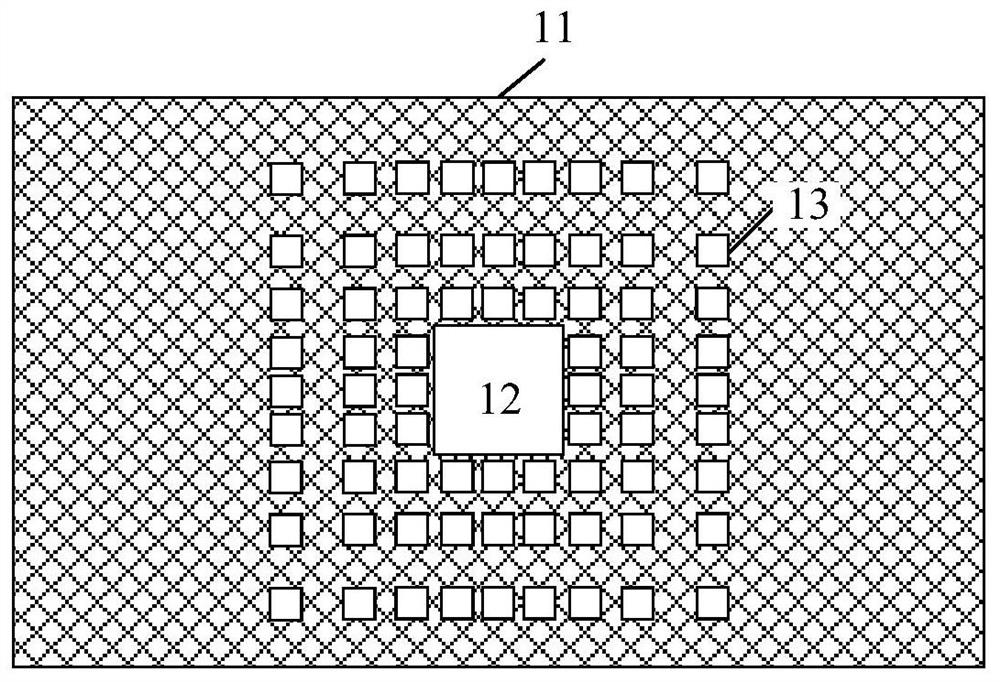

Antenna device and electronic equipment

ActiveCN112542701ASuppression of surface electromagnetic wave transmissionEliminate distractionsIndividually energised antenna arraysAntenna couplingsAntenna polarizationDielectric plate

The embodiment of the invention discloses an antenna device and electronic equipment. The antenna device comprises a non-metal dielectric plate, an antenna and a plurality of electromagnetic band gapunits, wherein the antenna and the plurality of electromagnetic band gap units are arranged on the non-metal dielectric plate, and the plurality of electromagnetic band gap units are arranged around the antenna according to a first array mode; and the electromagnetic band gap units are used for suppressing surface electromagnetic wave transmission of the non-metal dielectric plate. Therefore, by arranging the electromagnetic band gap unit array around the antenna, for all incoming wave directions and antenna polarization directions, the electromagnetic band gap unit array can inhibit surface electromagnetic wave transmission of the non-metal dielectric plate and eliminate interference of surface electromagnetic waves of the non-metal dielectric plate on the antenna, so that detection of anarrival angle is irrelevant to antenna polarization, then the detection error caused by different antenna polarizations is eliminated, and the detection precision of the arrival angle is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Multi-blade collimator blade zero calibration device

ActiveCN112657069AEliminate errorsImprove Zero ConsistencyX-ray/gamma-ray/particle-irradiation therapyPhotoswitchGrating

The invention discloses a multi-blade collimator blade zero calibration device. The device comprises a photoelectric switch assembly, a light path collimation assembly, a blade assembly and a blade driving control assembly which are installed on a multi-blade collimator base. The photoelectric switch assembly is used for forming a detection light beam and feeding back a calibration signal to the driving control assembly; the light path collimation assembly is used for ensuring that the divergence error of the detection light beam in the detection range meets the positioning precision requirement; and a plurality of blades in the blade assembly are respectively driven by the blade driving control assembly to move to the detection light beam for zero calibration. According to the invention, the optical path of one photoelectric switch is segmented and collimated through the light path collimation assembly, trigger errors of different positions of the optical path of the photoelectric switch caused by long-distance transmission scattering are eliminated, the zero consistency of each blade of a multi-leaf collimator is improved, and zero errors caused by inconsistency of the trigger precision and attenuation speed of multiple photoelectric switches are eliminated at the same time.

Owner:江苏海明医疗器械有限公司

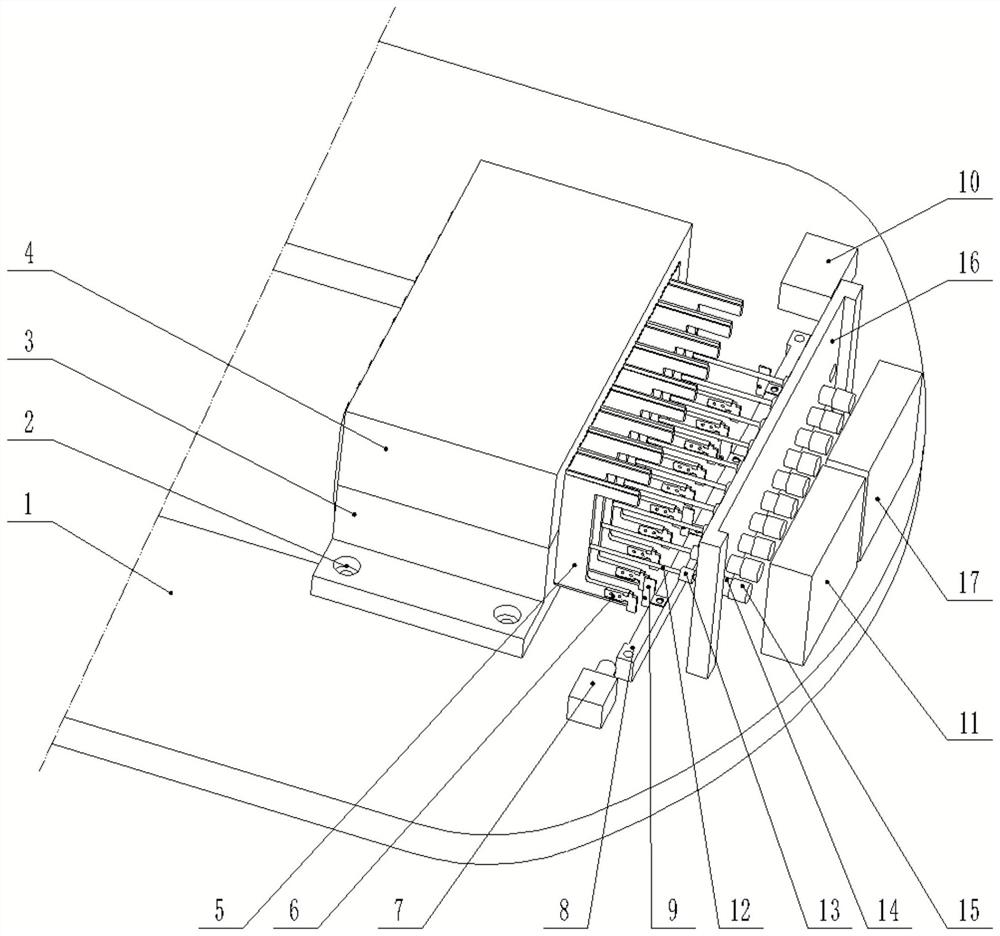

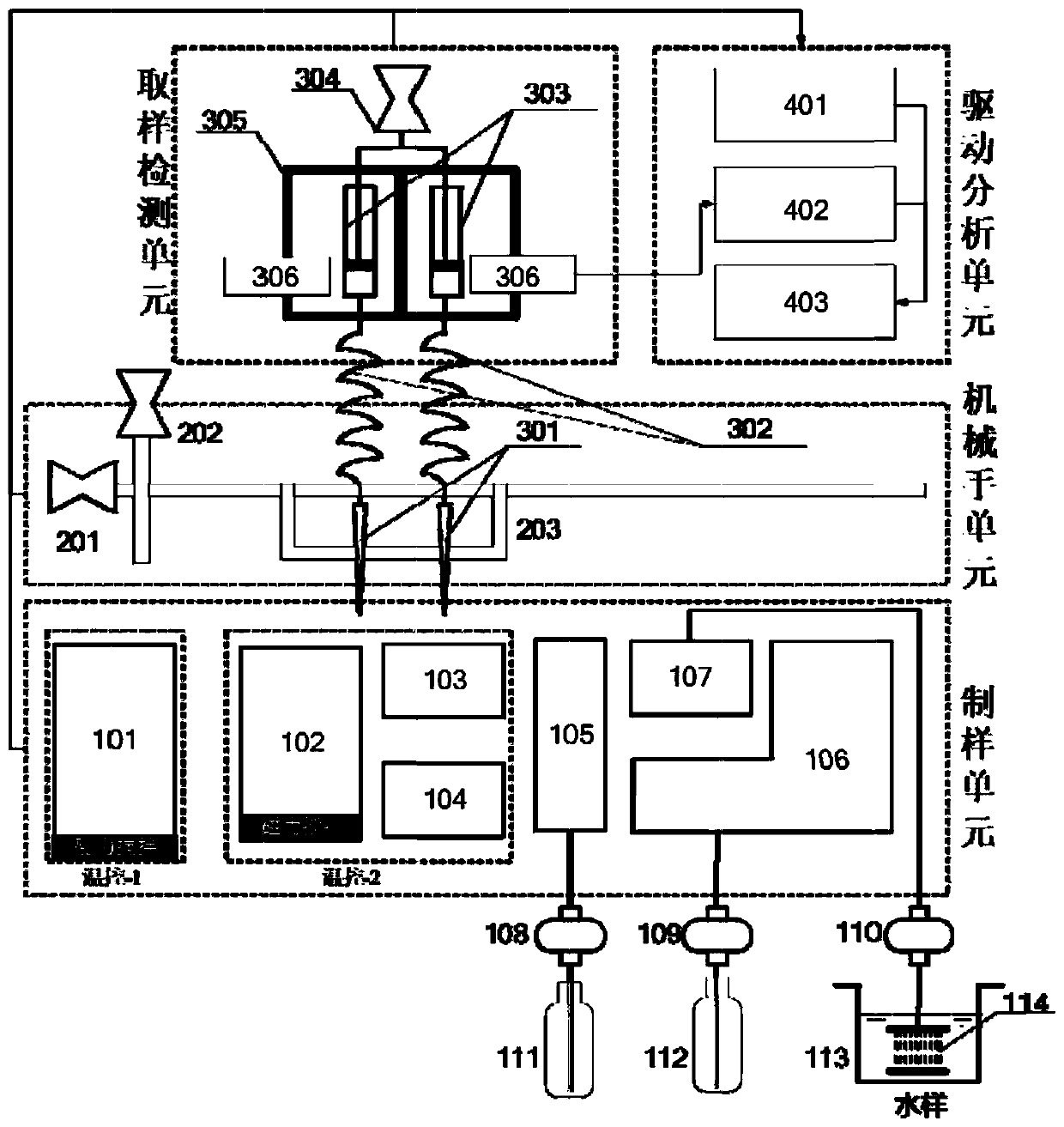

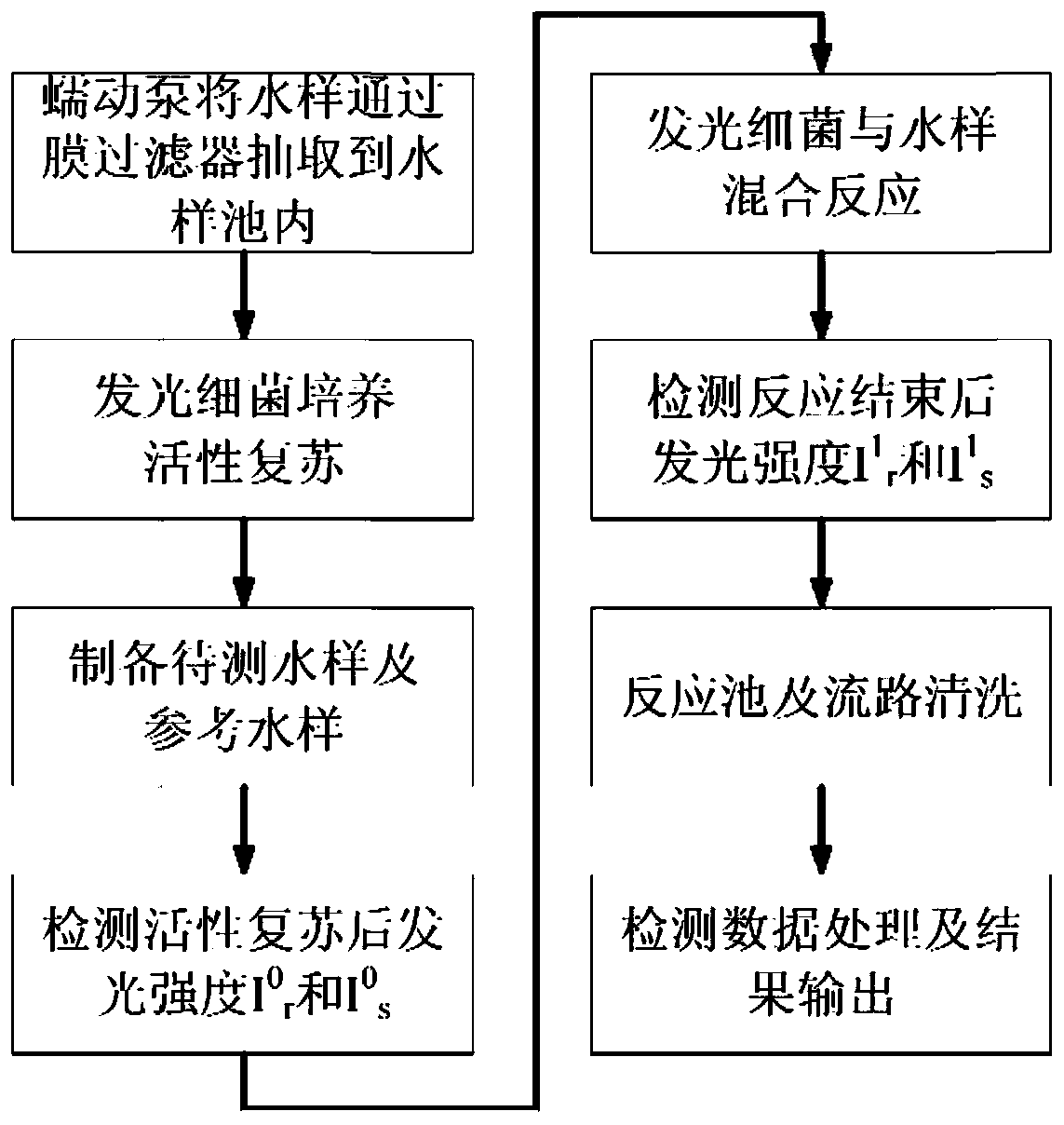

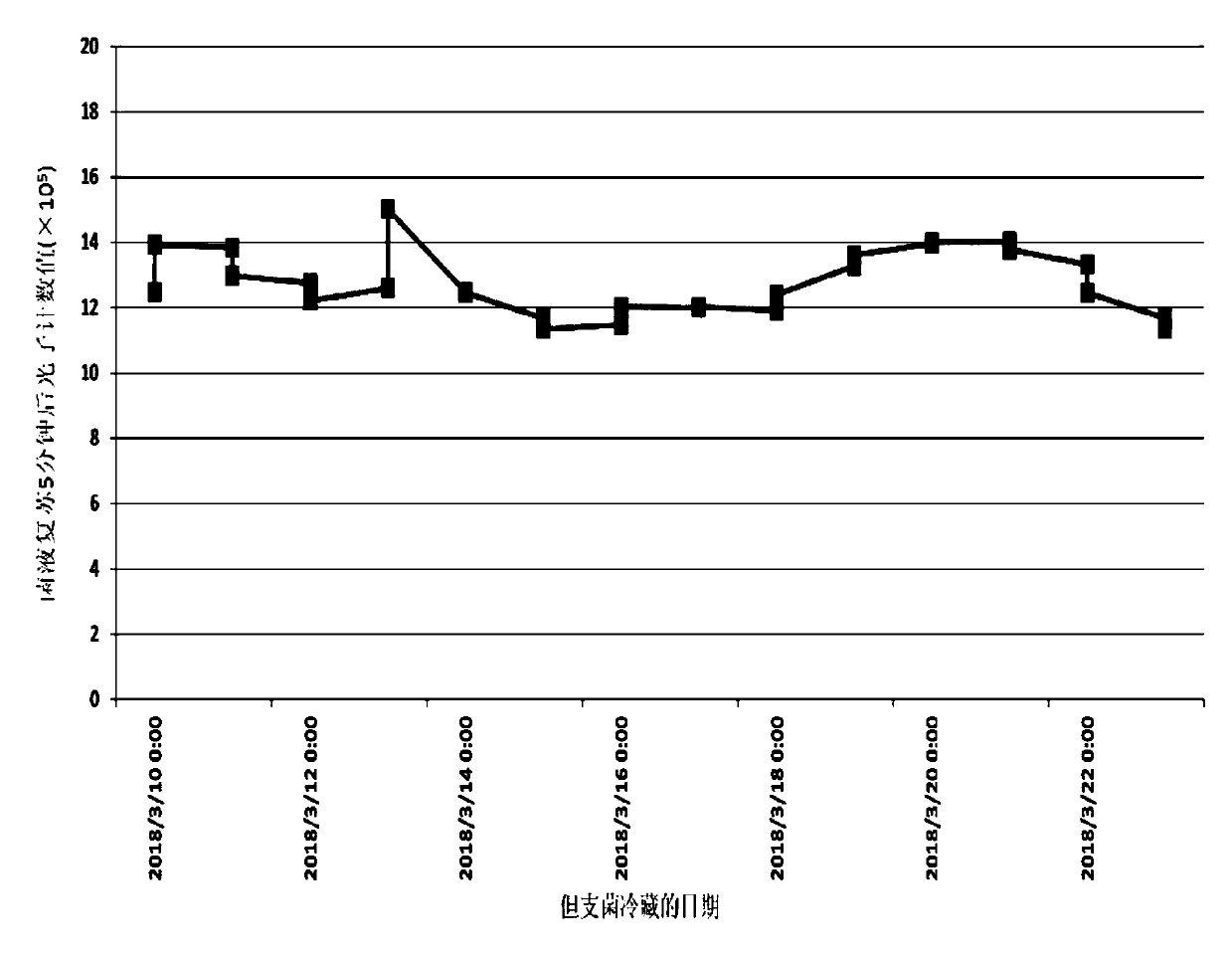

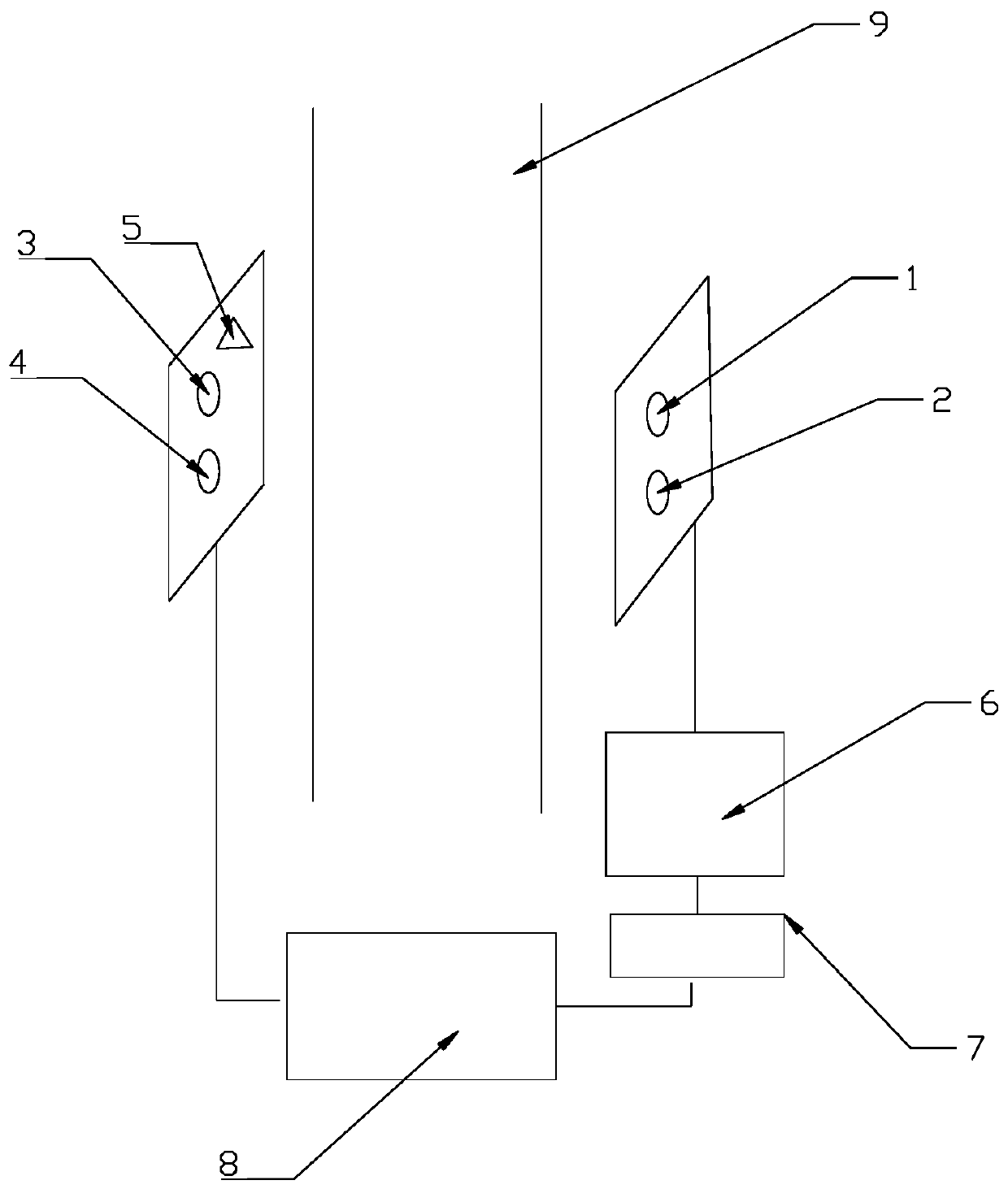

Device for on-line detection of water-quality biotoxicity

InactiveCN109856121AEliminate the effects of distracting factorsRealize automatic dilutionChemiluminescene/bioluminescenceWater sourceWater quality

Provided in the invention is a device for on-line detection of water-quality biotoxicity. The device comprises a sample preparation unit including a water sample pretreatment unit, a mechanical arm unit, a sampling detection unit and a drive analysis unit. The sample preparation unit and the sampling detection unit employ the parallel two-channel technical solution to realize simultaneous measurement of a reference water sample and a to-be-detected water sample and eliminate a system error and a measurement deviation. The device has advantages of simple operation, great convenience in maintenance, high automation degree, flexible configuration and the like and is especially suitable for real-time online water-quality toxicity detection of the surface water, the drinking source water, and various waste water.

Owner:廊坊市慧璟科技有限公司

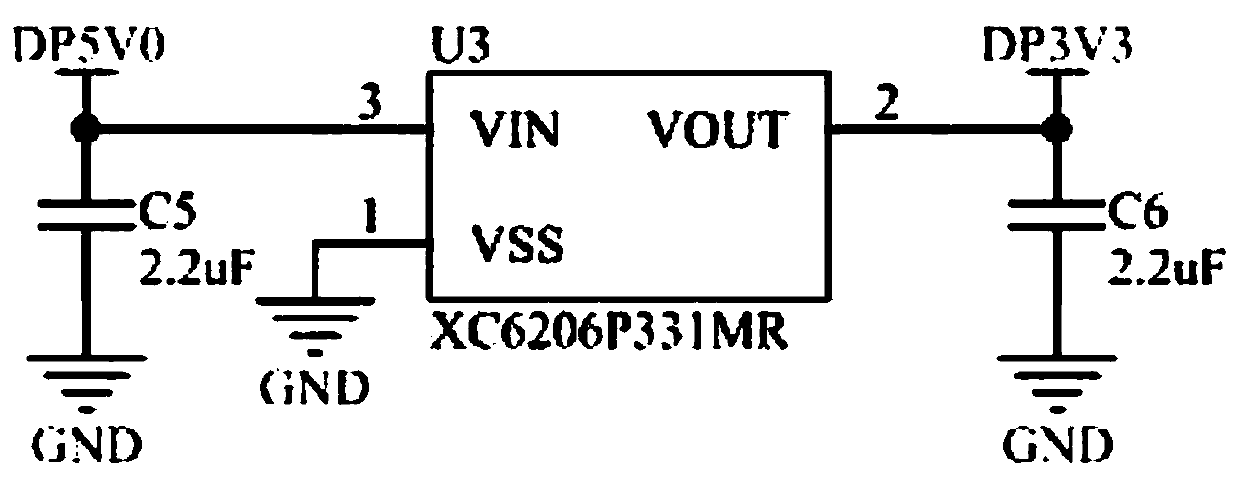

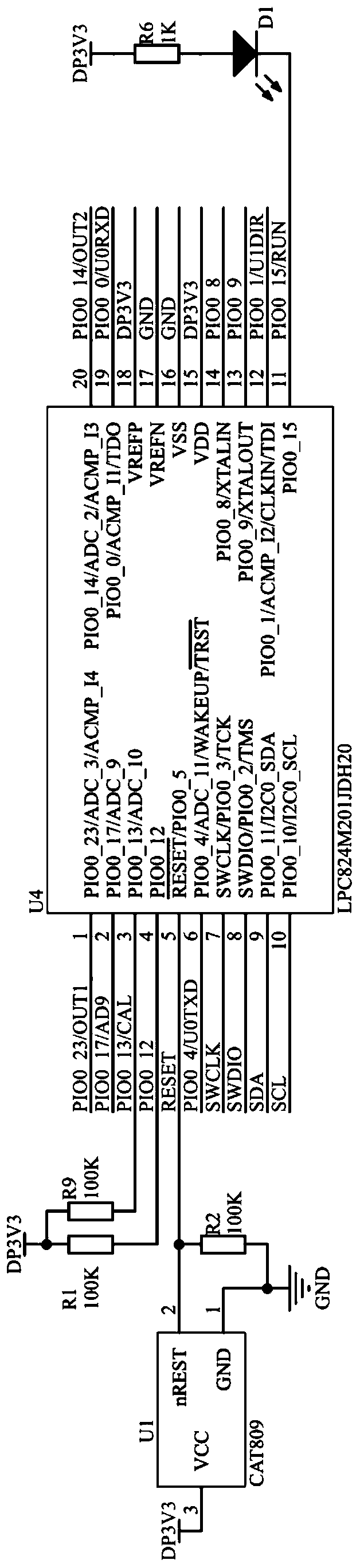

Blood leakage detection device for extracorporeal circulation line

PendingCN110749405AHigh sensitivityReduce false alarm rateOther blood circulation devicesDialysis systemsExtracorporeal circulationMicrocontroller

The invention discloses a blood leakage detection device for an extracorporeal circulation line, and the device comprises a power module, a microcontroller, a light source control module, a temperature measurement module, and a storage module, wherein the power output terminal of the power module is connected to the power input terminals of the microcontroller, the light source control module, thetemperature measurement module and the storage module; the signal input and output terminal of the microcontroller is communicatively connected to the signal input and output terminal of the light source control module, and is communicatively connected to the signal input and output terminal of the temperature measurement module; and signal input and output terminal of the microcontroller is communicatively connected to the signal input and output terminal of the storage module. According to the ingenious design of the circuit, the light sensor is digital and directly outputs digital signals,thereby avoiding errors generated in the signal amplification process and analog-to-digital conversion process, and making the leak detection device have higher sensitivity and lower false alarm rate.

Owner:北京哈特凯尔医疗科技有限公司

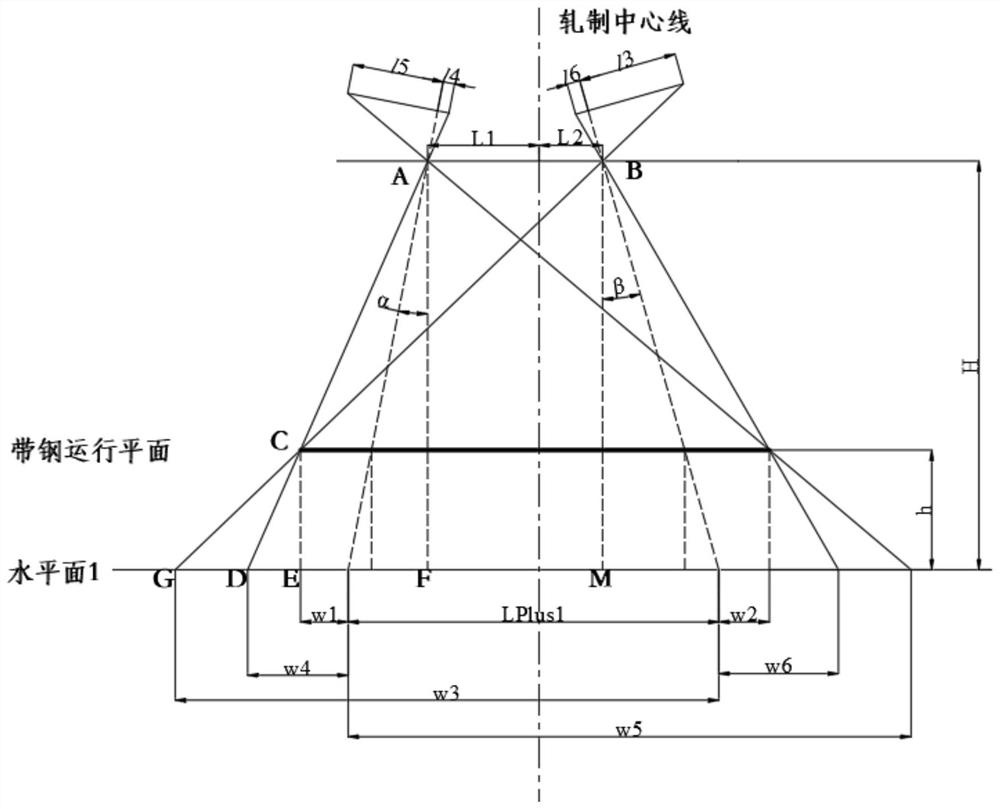

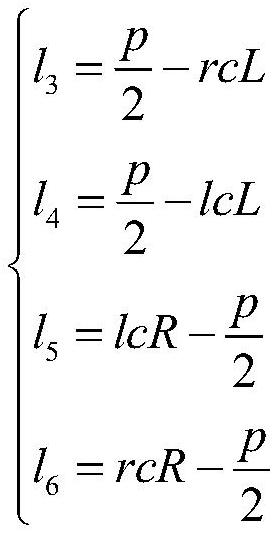

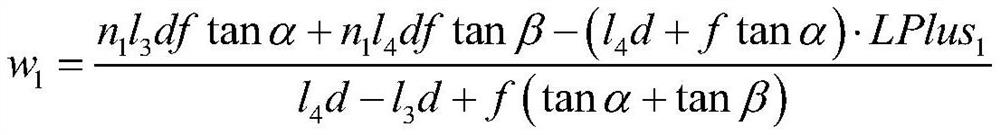

Online detection method for deviation of hot-rolled strip steel

PendingCN112801966AImprove detection accuracyGuaranteed stabilityImage enhancementImage analysisEngineeringLinear array

The invention provides an online detection method for deviation of hot-rolled strip steel, and belongs to the technical field of plate and strip rolling automation. According to the method, a machine vision technology is adopted, a binocular linear array camera is used for collecting strip steel images in real time, the real-time width and deviation amount of the strip steel are calculated through means such as edge detection, the influence of loop angle swing on a detection result is effectively eliminated, and finally camera error compensation is added to guarantee the detection precision. According to the strip steel deviation amount detected through the method, the deviation detection precision of the strip steel can be improved to the millimeter level, and a reliable basis is provided for follow-up strip steel deviation control.

Owner:北京科技大学设计研究院有限公司

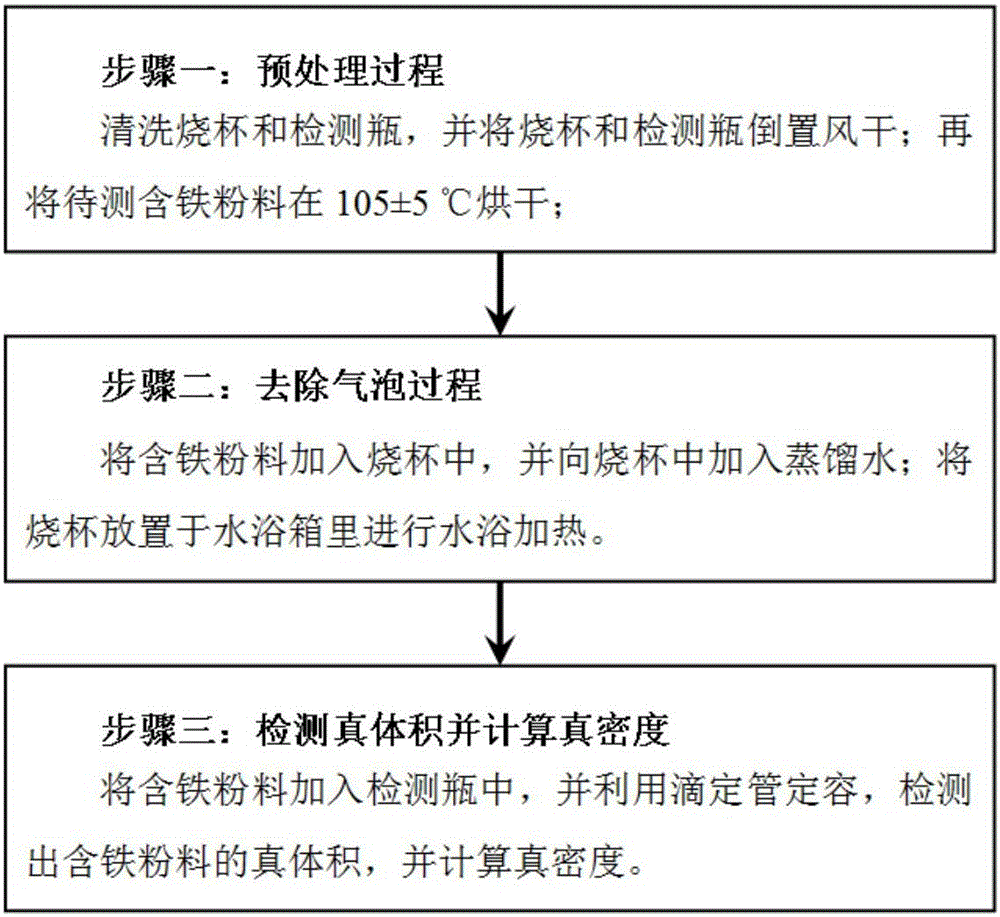

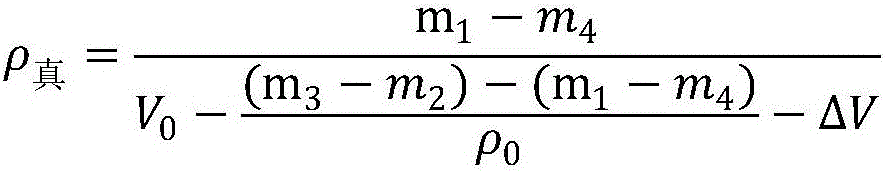

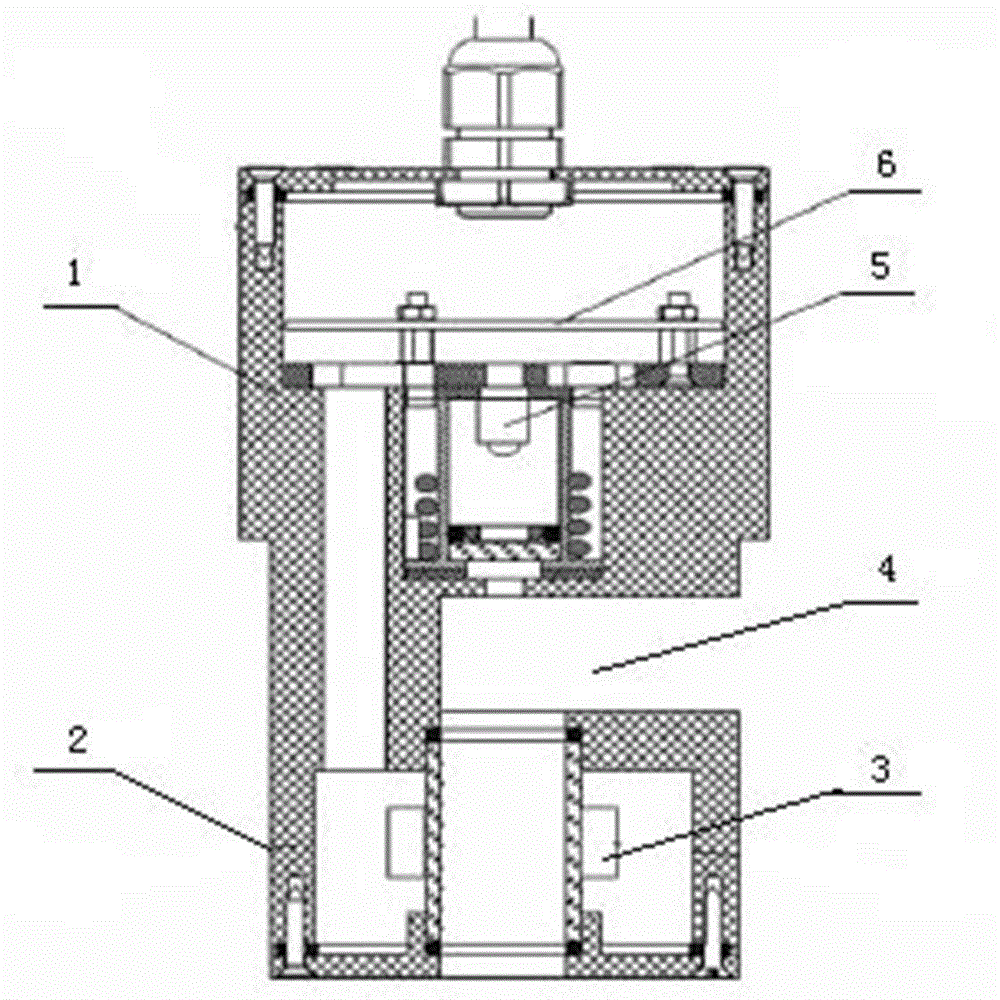

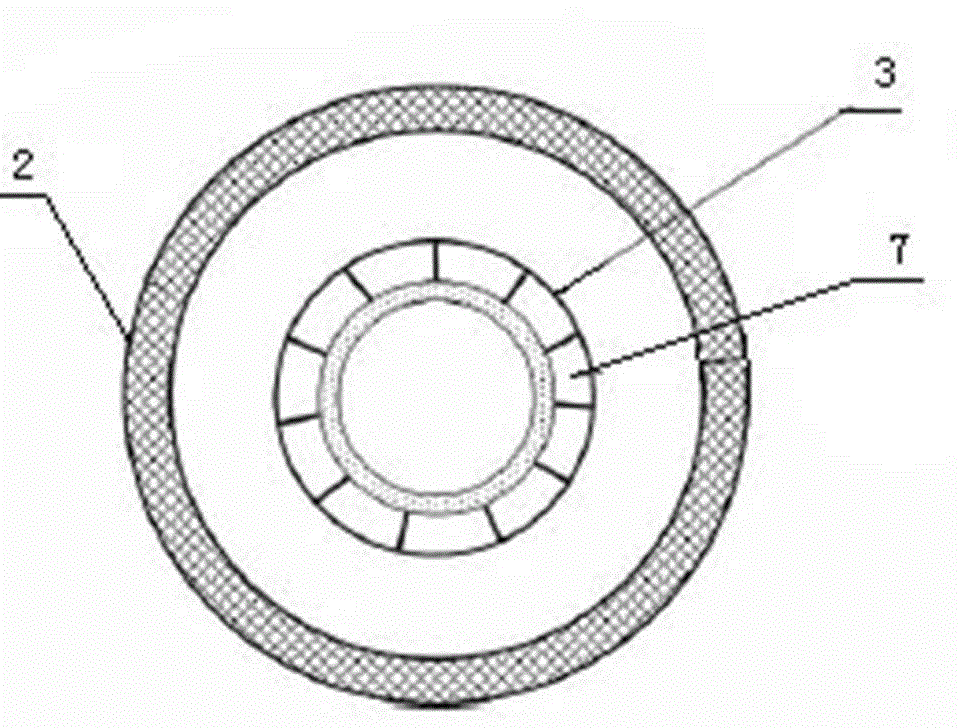

Detection method for true density of iron-containing powder

InactiveCN106596330AAccurate detectionAvoid volumeSpecific gravity measurementWater bathsIron powder

The invention discloses a detection method for the true density of iron-containing powder, belonging to the technical field of detection of the basic performance of metallurgical iron-containing powder. The detection method comprises the following concrete steps: step 1, pretreatment: drying to-be-detected iron-containing powder at 105 + / - 5 DEG C; step 2, removal of bubbles: heating the iron-containing powder in a water bath to remove bubbles in the iron-containing powder; and step 3, detection and calculation of true density: adding the iron-containing powder into a detection bottle, fixing a volume by using a burette and calculating the true density. According to the invention, the whole process is controlled, and bubble removal of the iron-containing powder is carried out in a beaker, so the volume of the detection bottle is prevented from influence by heat at high temperature; the burette is employed for volume fixation, so weighing frequency and errors are reduced; and thus, the true density of the iron-containing powder is accurately detected.

Owner:从俊强

Super-low range turbidity sensor

InactiveCN105527250AImprove signal-to-noise ratioEliminate detection errorsScattering properties measurementsIntegrated circuitLight source

The invention relates to a super-low range turbidity sensor. According to the invention, a heating element is added on a light source part, a lens of the light source part is kept at constant temperature, Atomized condition of the light source part can be overcome, and detection accuracy of the turbidity sensor is increased. The turbidity sensor comprises an upper housing, a lower housing, a detection control integrated circuit, a light source and a photoelectric converter member; the photoelectric converter member comprises several photoelectric conversion monomers, the photoelectric conversion monomers are connected in series to form a ring; the light source and light-transmission through holes are arranged in the upper housing, a water channel pipe as a water body turbidity detection area is arranged in the lower housing; a transversely penetrated recess cavity is arranged between the upper housing and lower housing, and an open-type isolation region is arranged between the upper housing and the lower housing by the recess cavity.

Owner:张学一

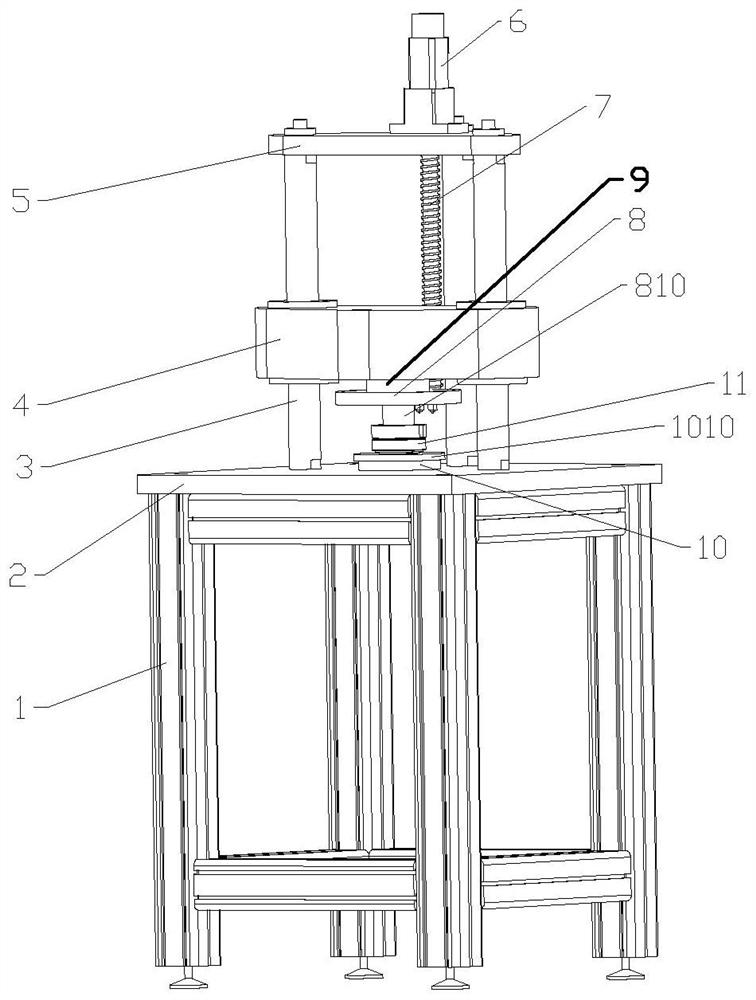

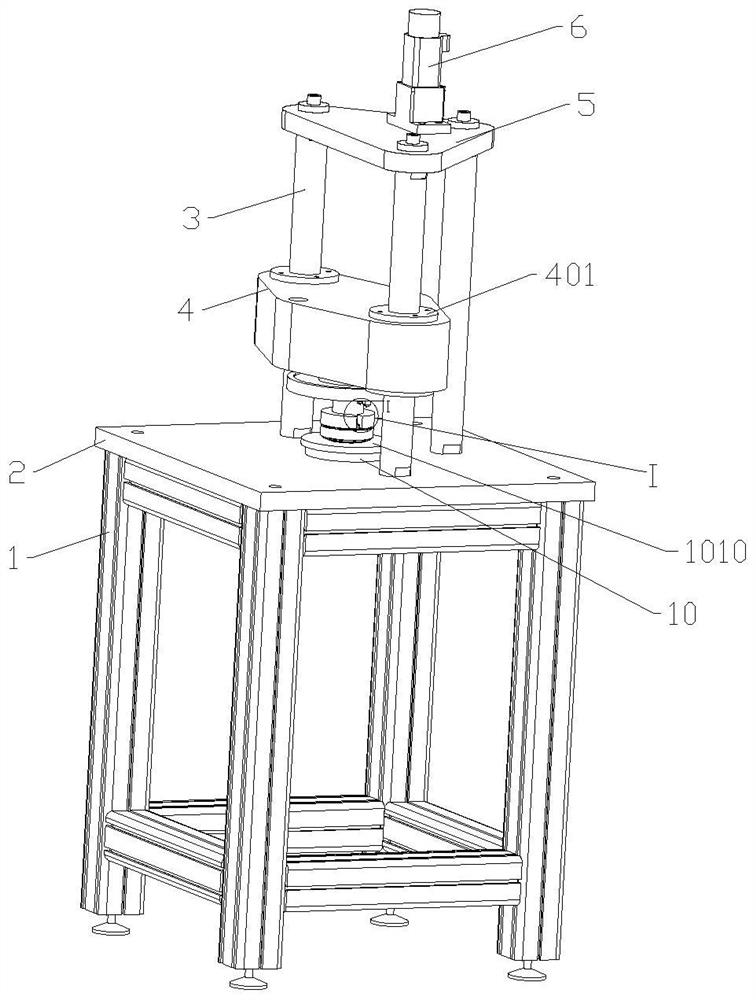

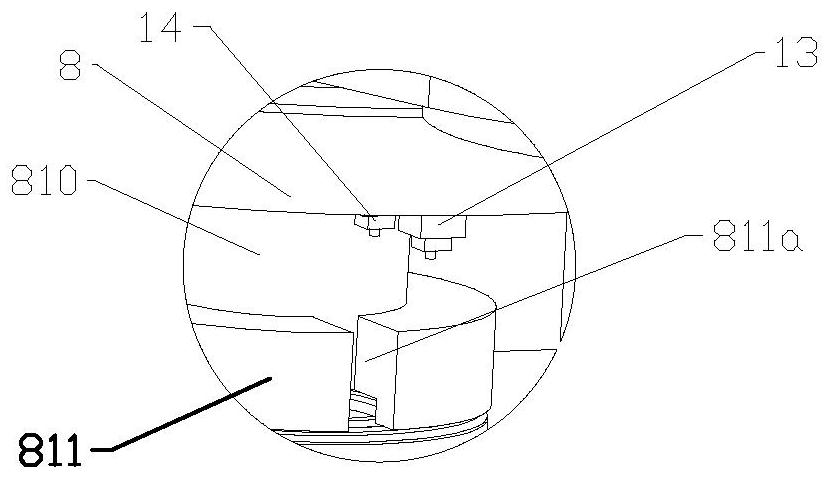

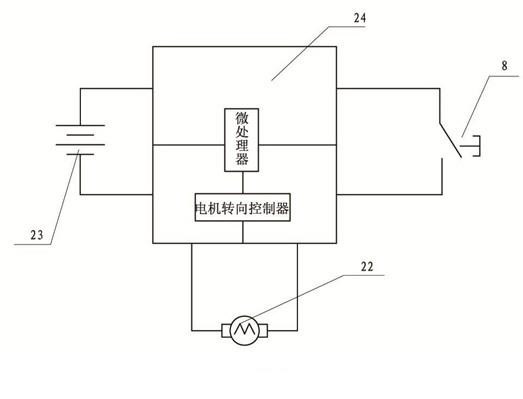

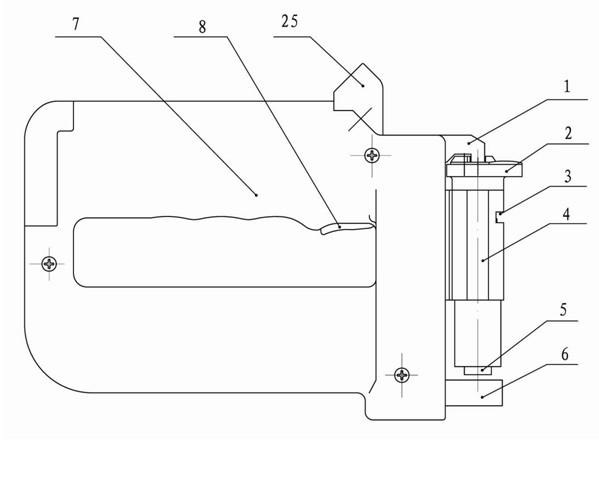

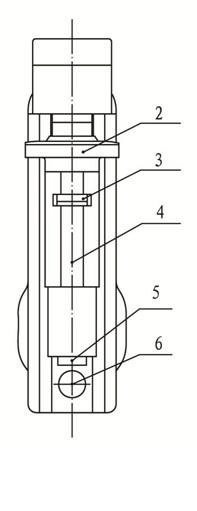

Electric Wechsler hardness tester

InactiveCN102494964AReduce labor intensityEliminate detection errorsInvestigating material hardnessContact pressureControl system

The invention relates to an electric Wechsler hardness tester, which comprises a control system, a power execution mechanism and a measuring head device, wherein the control system is connected with the power execution mechanism and drives the power execution mechanism; and the power execution mechanism is connected with a tested piece and drives the measuring head device to detect the contact pressure hardness of the tested piece arranged on an anvil block. The electric Wechsler hardness tester has the characteristics of high stability, low labor intensity, high measurement accuracy, simple calibration operation, low detection error, high detection precision and the like.

Owner:张天宝

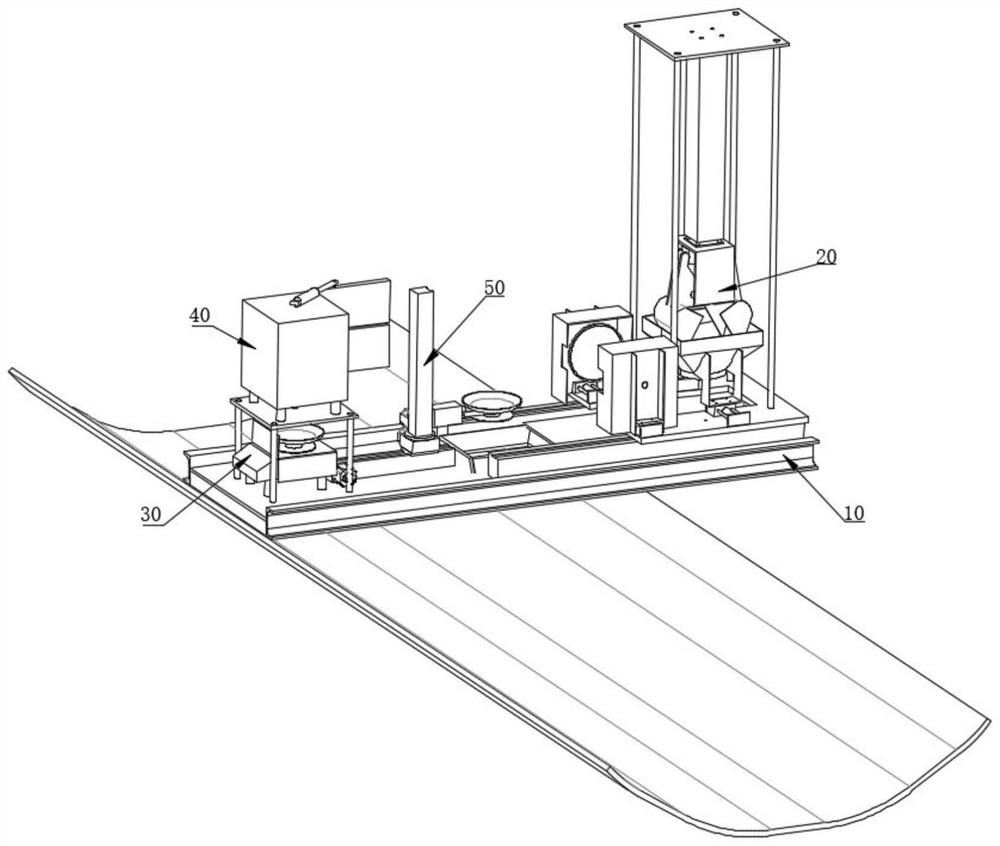

Automatic sampling moisture detection device and automatic sampling detection method for belt conveyor

PendingCN113686721AEasy to detectImprove work efficiencyWeighing by removing componentWithdrawing sample devicesControl engineeringProcess engineering

The invention discloses an automatic sampling moisture detection device and an automatic sampling detection method for a belt conveyor, and belongs to the field of online sample detection. According to the invention, the automatic sampling moisture detection device for the belt conveyor comprises a base module located above the conveyor, and a material taking module, a weighing module, a drying module and a material receiving and transferring module which are mounted on the base module, and the automatic moisture detection method of the device comprises the following full-automatic moisture detection processes of automatic material taking treatment from the belt conveyor, sample tray loading treatment, weighing treatment, drying treatment, re-weighing treatment and sample returning treatment. The whole process does not need manual intervention, full-automatic online sampling and sample moisture value detection are realized through specific operation control logic among module parts and a detected material weighing and data processing method, and the sample moisture detection efficiency is greatly improved.

Owner:马鞍山市安工大智能装备技术研究院有限公司

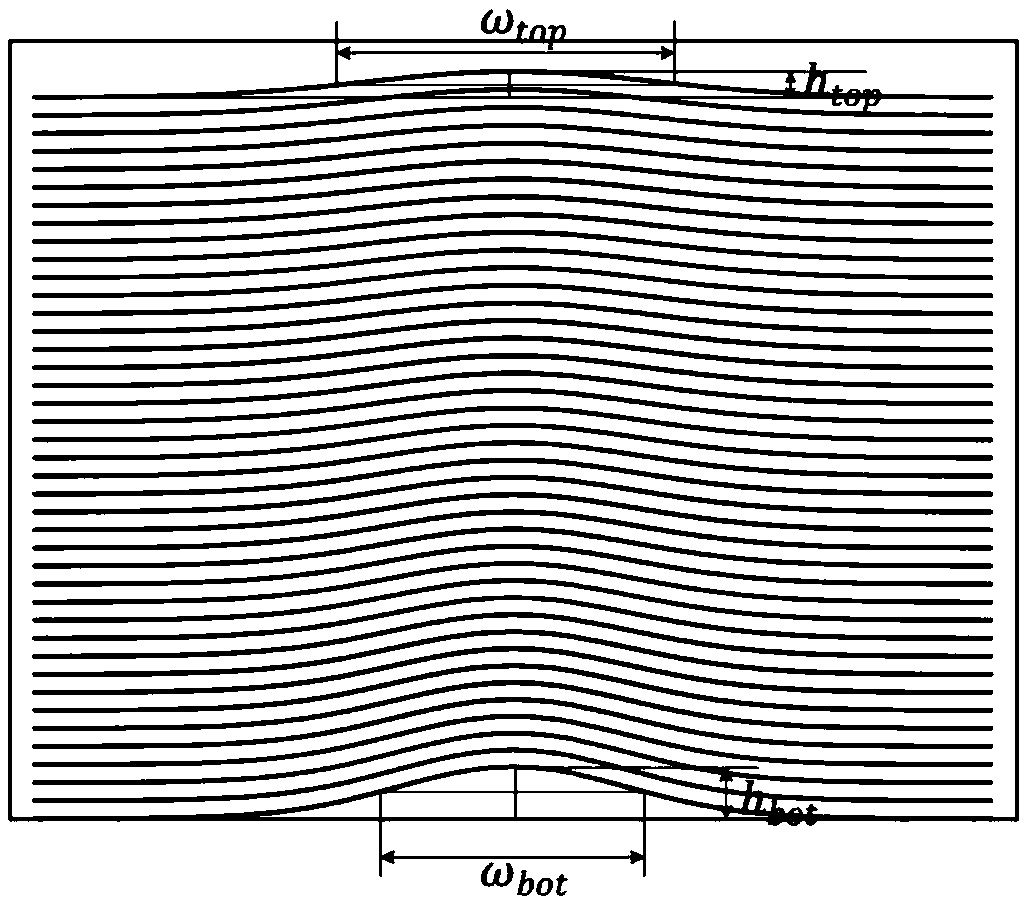

Continuously variable transmission metal belt, process for producing metal ring, and process for measuring shape of metal ring

A method for manufacturing a metal belt and a metal ring for a continuously variable transmission, and a method for measuring the shape of the metal ring, wherein the most protruding part is projected toward the width direction of the side edge of the metal ring (33) of the metal belt for a continuously variable transmission (33c) is located between the radial center surface (C) and the radial inner peripheral surface (I) of the metal ring, the protruding part, the position where it contacts the V-shaped surface (38) of the pulley (5, 7) (P) is closer to the central plane (C) in the radial direction than the inner peripheral surface (I) relative to the radial direction of the metal ring, so as to reduce the bending caused by the bending of the metal ring (33) wound on the pulley The sum of the compressive stress and the Hertzian point contact stress caused by the contact between the protrusion and the V-shaped surface of the pulley can improve the fatigue life of the metal ring compared with the comparative example. In addition, when the metal rings are laminated, recesses for retaining oil are formed between these side edges, and the sliding surfaces of the adjacent metal rings can be effectively lubricated, and the durability can be further improved.

Owner:HONDA MOTOR CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com