Automatic sampling moisture detection device and automatic sampling detection method for belt conveyor

A tape conveyor, automatic sampling technology, applied in measuring devices, sampling devices, weighing by removing certain components, etc., can solve problems such as affecting the accuracy of test data, detrimental to the physical and mental health of employees, and easy changes in moisture, etc. High degree of automation, high work efficiency, and the effect of liberating labor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

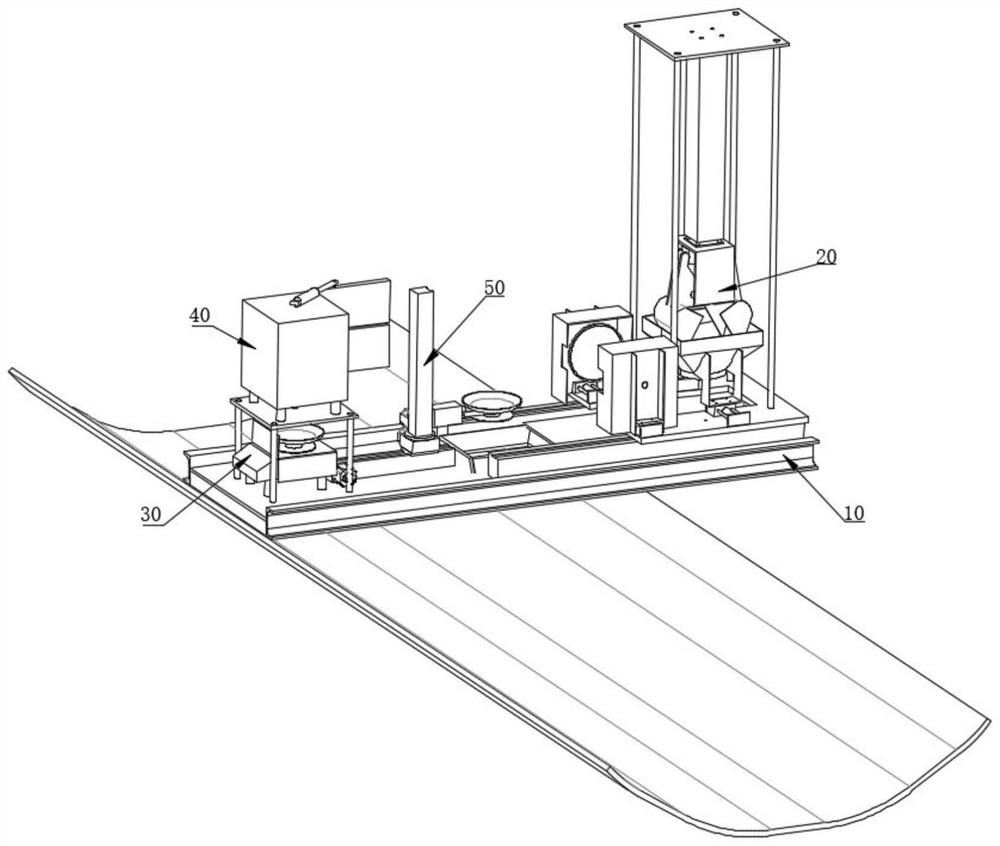

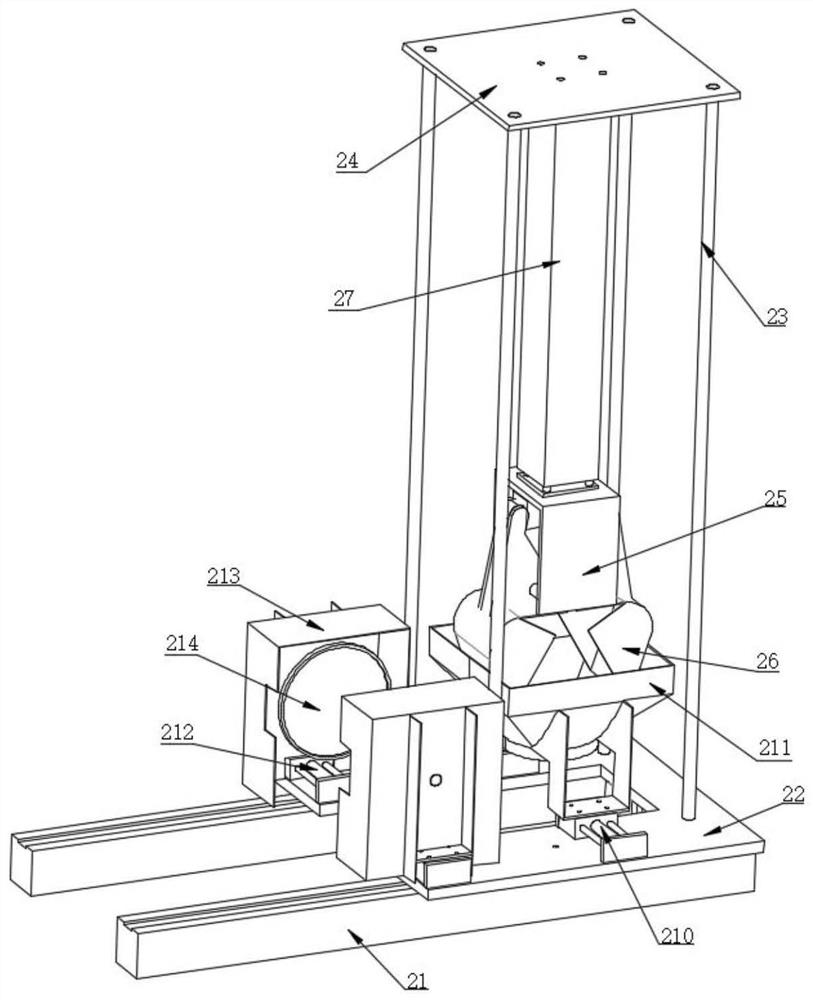

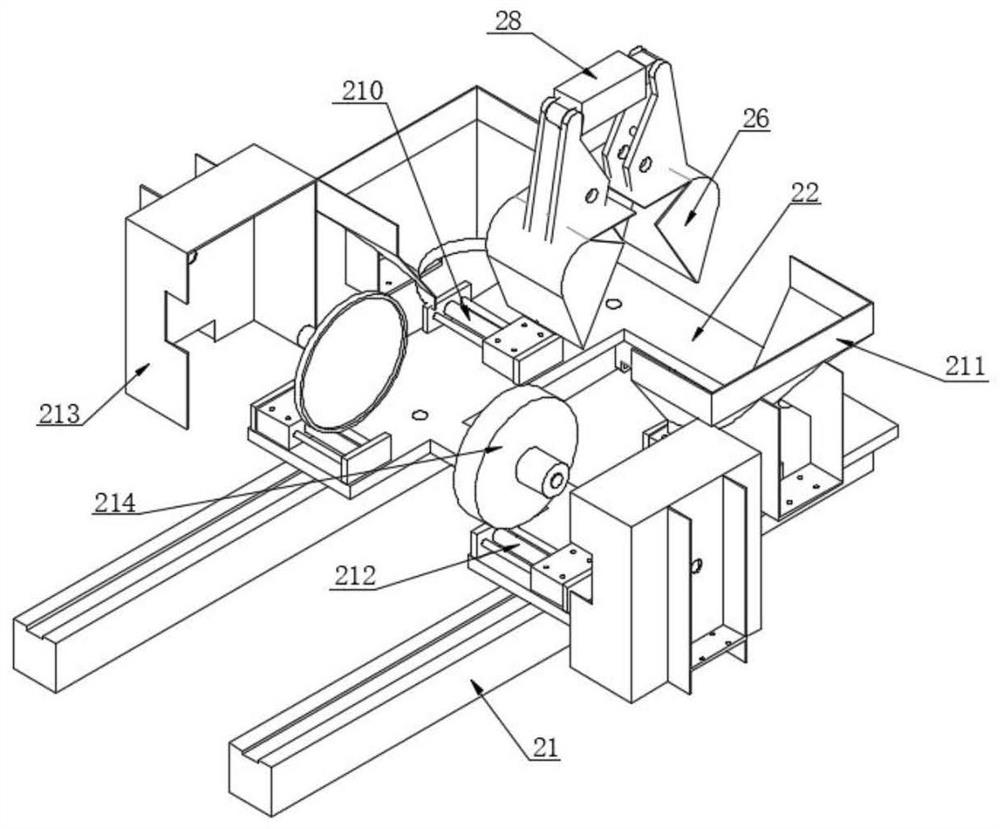

[0087] Example: such as figure 1 As shown, the automatic sampling moisture detection device of the belt conveyor includes: a base module 10 located above the conveyor, the base module 10 is a frame composed of a base frame and a base substrate, and the base frame is welded by grooved or I-shaped steel, The material of the base substrate is aluminum alloy, and the reclaiming module 20 , the weighing module 30 , the drying module 40 and the receiving and transferring module 50 installed on the base module 10 . It can realize the automatic moisture detection process of automatic taking, transferring, weighing, drying, reweighing and returning materials from the belt conveyor.

[0088] The material taking module 20 adopts a traditional sampling device, the weighing module 30 adopts a traditional weighing device (pan scale), the drying module 40 adopts a traditional drying furnace, and the receiving and transferring module 50 can adopt an existing six-axis manipulator.

[0089] W...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com