Detection method for true density of iron-containing powder

A detection method and true density technology, which is applied in the direction of measuring devices, specific gravity measurement, and analytical materials, can solve the problems of poor accuracy of true density and achieve the effects of reducing weighing errors, eliminating detection errors, and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

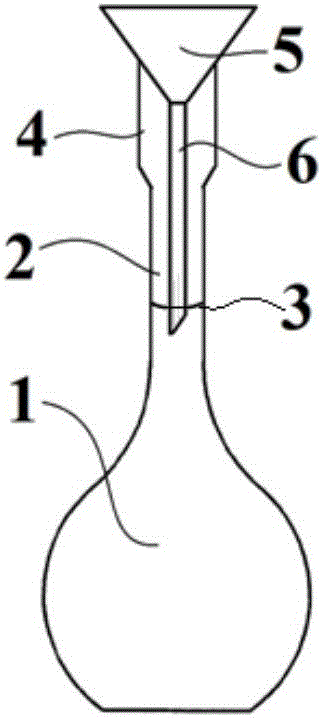

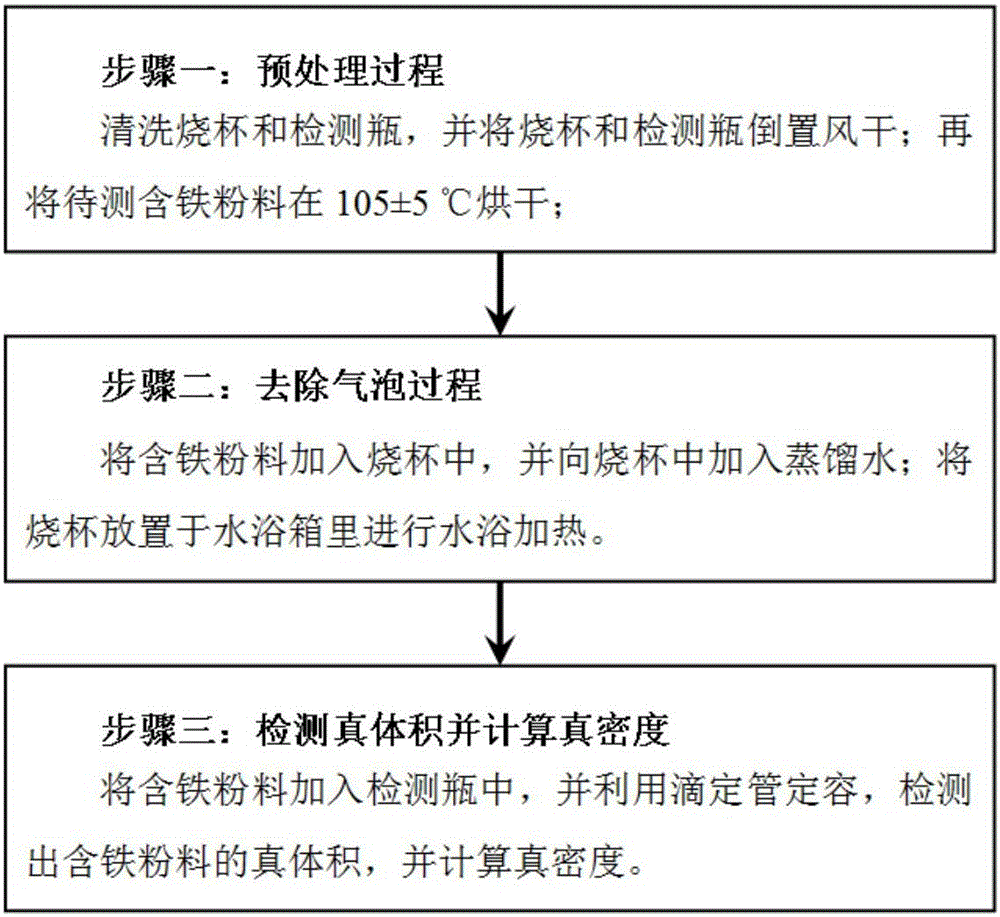

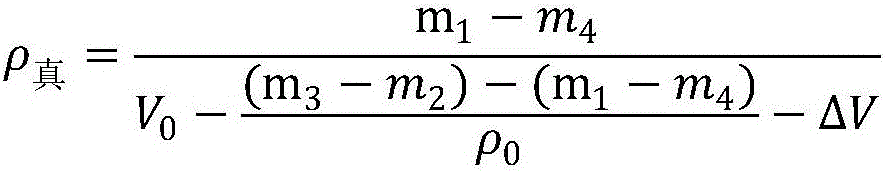

[0041] combine figure 1 and figure 2 As shown, a method for detecting the true density of iron-containing powder in this embodiment, the detection device includes a detection bottle and a funnel 5, the detection bottle is composed of a bottle body 1, a bottleneck 2 and a bottleneck 4, and the bottleneck 2 is located at The upper part of the bottle body 1, the bottleneck 2 is provided with a constant volume scale line 3, the top of the bottleneck 2 is provided with a bottleneck 4, the upper part of the bottleneck 4 of the detection bottle is equipped with a funnel 5, and the bottom of the funnel 5 is provided with a Funnel neck 6, the bottom outlet of the funnel neck 6 is located at the lower part of the constant volume scale line 3, so that when the iron-containing powder is added into the detection bottle from the funnel 5, the iron-containing powder is not easy to adhere to the constant volume scale line 3 of the volumetric bottle The upper area reduces the detection error...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com