Gas storage well shaft detection system based on ultrasonic phased array technology and detection method thereof

An ultrasonic phased array and detection system technology, which is applied to the analysis of solids using sound waves/ultrasonic waves/infrasonic waves, material analysis using sound waves/ultrasonic waves/infrasonic waves, and measurement devices, which can solve the difficulties of pre-test adjustments and scan coverage. low, large detection error and other issues, to achieve the effect of high scanning coverage, high detection accuracy, and convenient use and maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

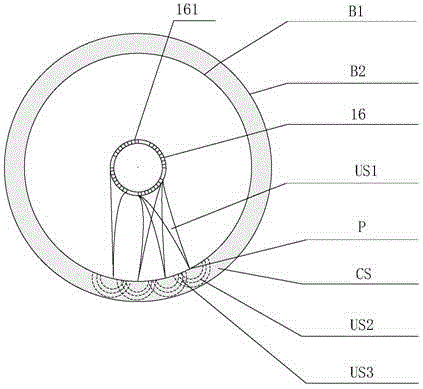

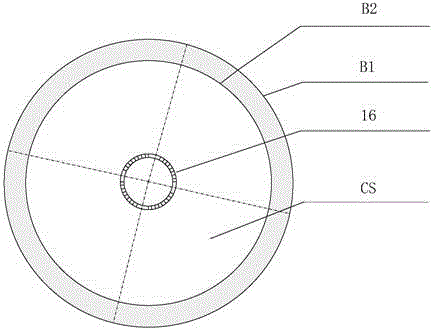

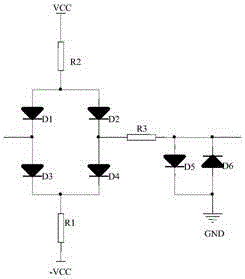

[0054] Such as figure 1 As shown, it is a schematic diagram of an embodiment of a wellbore detection system for gas storage wells based on ultrasonic phased array technology in the present invention. The system includes uphole equipment, downhole equipment and composite cables; uphole equipment includes a system host 1, a control box 3, a wire take-up frame 2, and a fixed pulley 5; an encoder 4 is installed on the fixed pulley 5; downhole equipment includes centralizers 11, Detector 13 and ring probe 16; its composite cable 6 is composed of internal copper wires, optical fibers and outer steel wires; the copper wires supply power to the downhole equipment, the steel wires drag the downhole equipment to work, and the optical fiber is the communication medium between the system host 1 and the downhole equipment. It is characterized by:

[0055...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com