Electric Wechsler hardness tester

A Webster hardness and electric technology, which is applied in the direction of testing the hardness of materials, can solve the problems of lack of digital display equipment and low display accuracy, and achieve the effects of simple and fast instrument calibration, simple and fast operation, and reduced labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

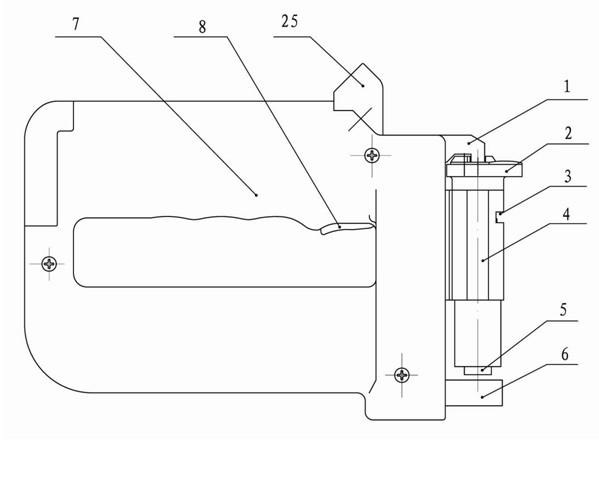

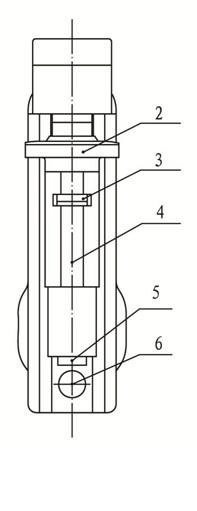

[0035] According to attached figure 1 , figure 2 As shown, the electric Webster hardness tester includes a control system, a power actuator, and a probe device; the control system is connected to and drives the power actuator, and the power actuator is connected to and drives the probe device to be placed on the anvil 6 The test piece 17 is tested for contact pressure hardness.

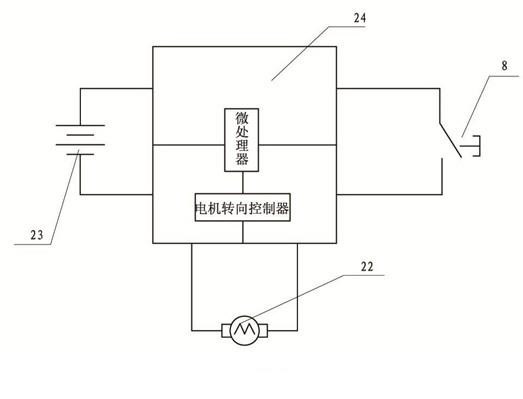

[0036] Figure 5 As shown, the control system includes a power supply battery pack 23, a control board 24, a micromotor 22, the control board is powered by the power supply battery pack connected to it and the control board is connected and controls the work of the micromotor; the control board is also connected with Handle 7 with switch 8. Using a micro motor as the power, you only need to press the switch lightly with your fingers to realize the detection operation, which greatly reduces the labor intensity of the inspectors during batch detection; one-button operation is adopted for the detecti...

Embodiment 2

[0049] According to attached figure 1 , figure 2 As shown, the electric Webster hardness tester includes a control system, a power actuator, and a probe device; the control system is connected to and drives the power actuator, and the power actuator is connected to and drives the probe device to be placed on the anvil 6 The test piece 17 is tested for contact pressure hardness.

[0050] Figure 5As shown, the control system includes a power supply battery pack 23, a control board 24, a micromotor 22, the control board is powered by the power supply battery pack connected to it and the control board is connected and controls the work of the micromotor; the control board is also connected with Handle 7 with switch 8. Using a micro motor as the power, you only need to press the switch lightly with your fingers to realize the detection operation, which greatly reduces the labor intensity of the inspectors during batch detection; one-button operation is adopted for the detectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com