Corrosion on-line monitoring system for reinforced bar in concrete

A technology for steel corrosion and monitoring systems, which is applied in the directions of weather resistance/light resistance/corrosion resistance, measuring devices, instruments, etc. It can solve the problems of complicated wiring structure of sampling signal processing circuit, failure of monitoring system, and large size of sampler device. , to achieve the effect of improving accuracy and sensitivity, good anti-corrosion, and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0021] Such as Figure 8 As shown, this embodiment sets 16 corrosion detection points (address numbers are W01~W16), which are installed in the reinforced concrete structure of the inner side wall of the tunnel, and are evenly distributed within the scope of easy-to-corrosion parts. The data conversion circuit 1 communicates with the upper monitoring computer 2 .

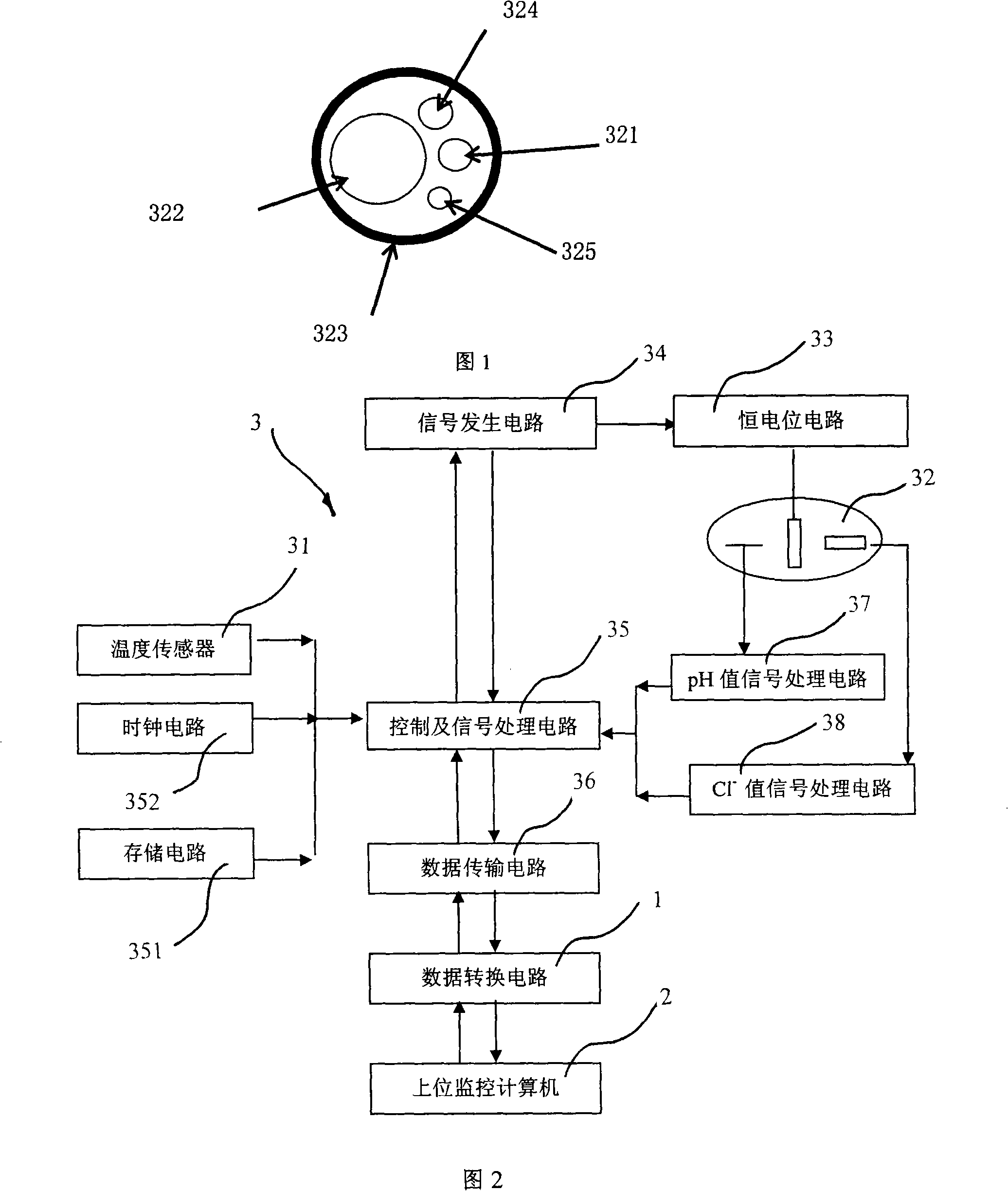

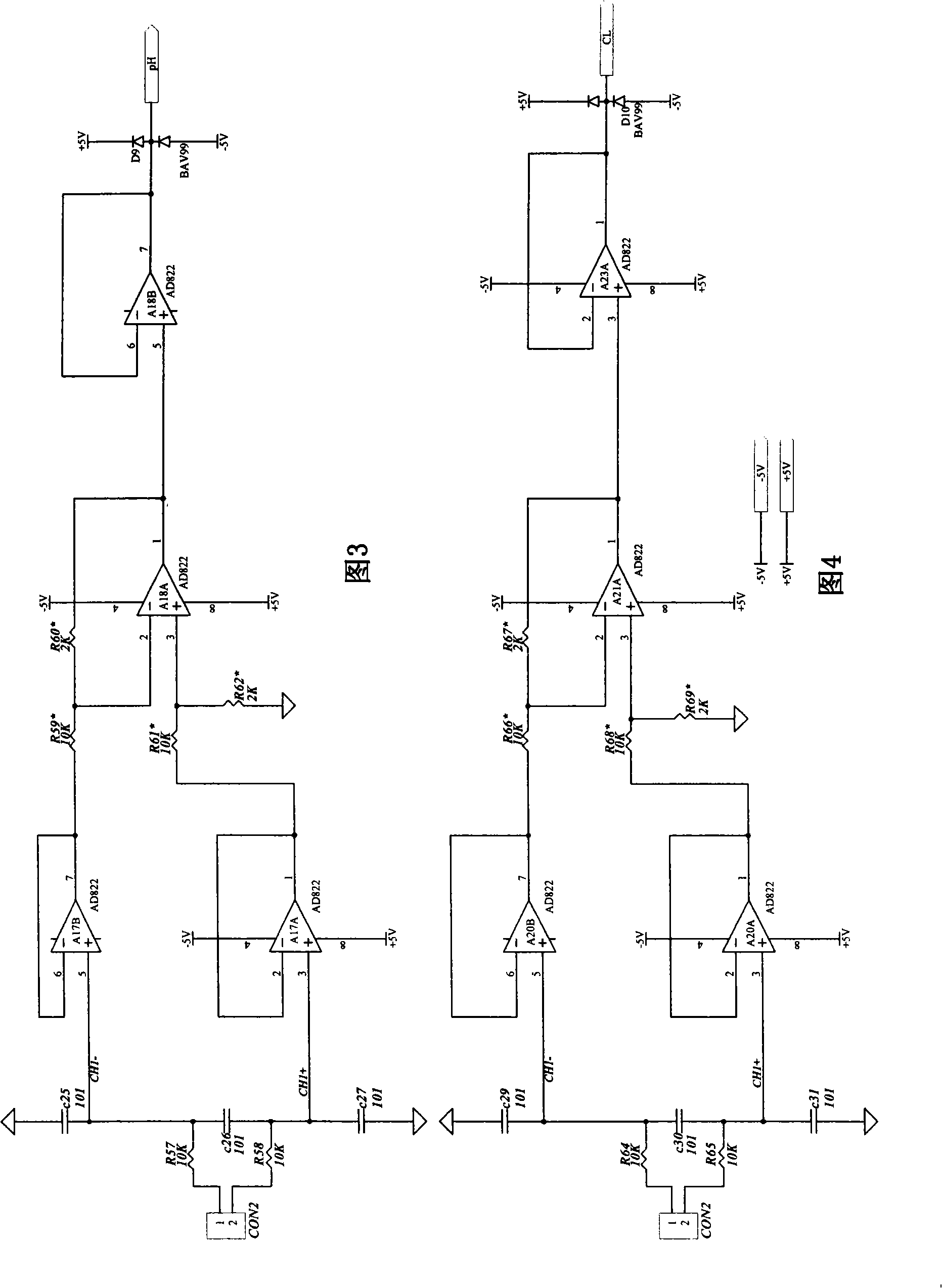

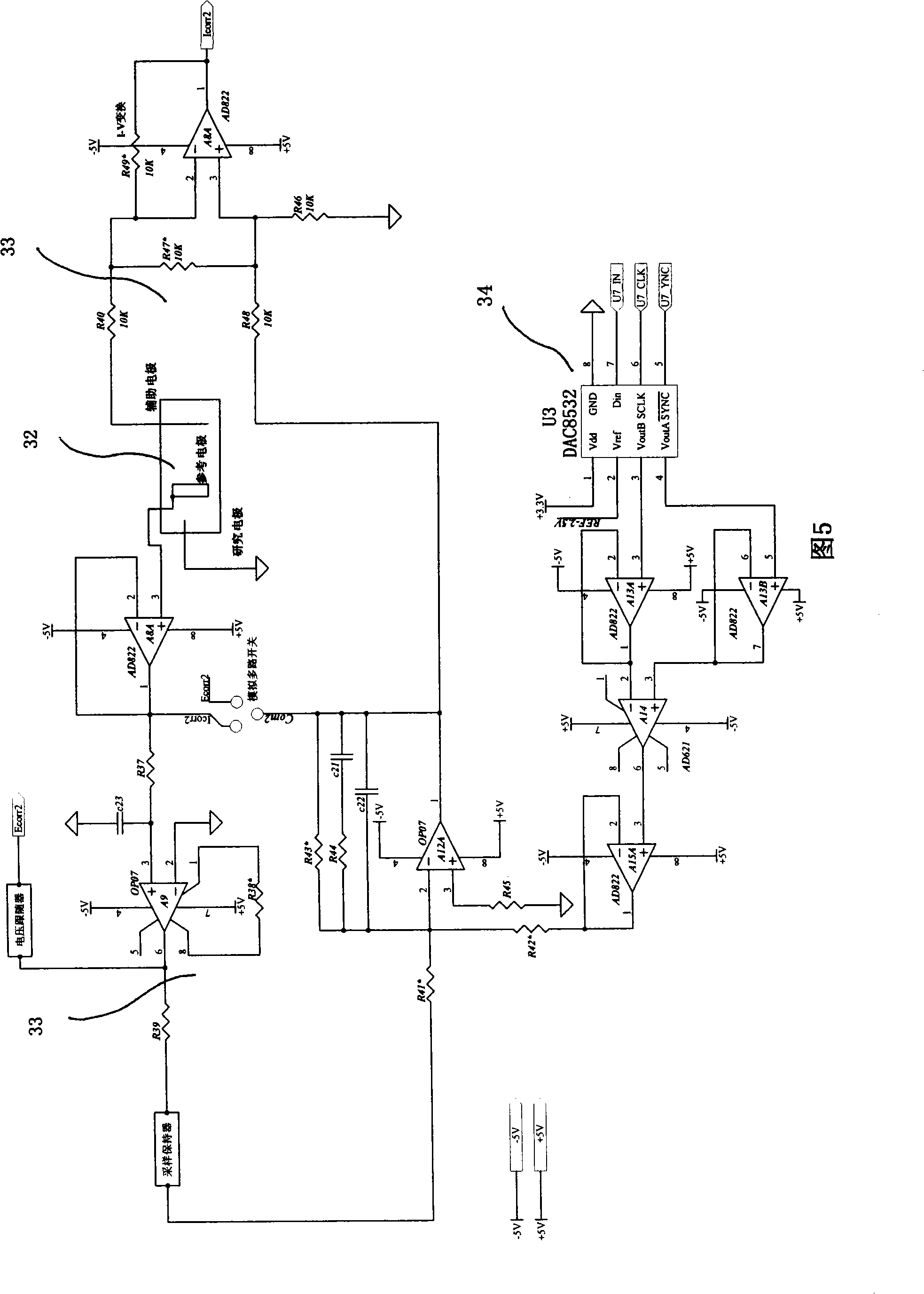

[0022] As shown in Figures 2 to 6, a temperature sensor 31, a composite sensor 32 and a corresponding sampling signal processing circuit 3 are arranged at each detection point, and the composite sensor 32 includes a research electrode 321, a reference electrode 322, Auxiliary electrode 323, pH probe 324 and Cl - Probe 325, research electrode 321, reference electrode 322, pH probe 324 and Cl - The probes 325 are all arranged in the coaxially extending tubular auxiliary electrode 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com