Bearing assembly high-size detection instrument

A technology for dimension detection and bearing assembly, applied in instruments, measuring devices, optical devices, etc., can solve problems such as slipping easily, achieve the effects of reducing slipping, improving pass rate, and reducing processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

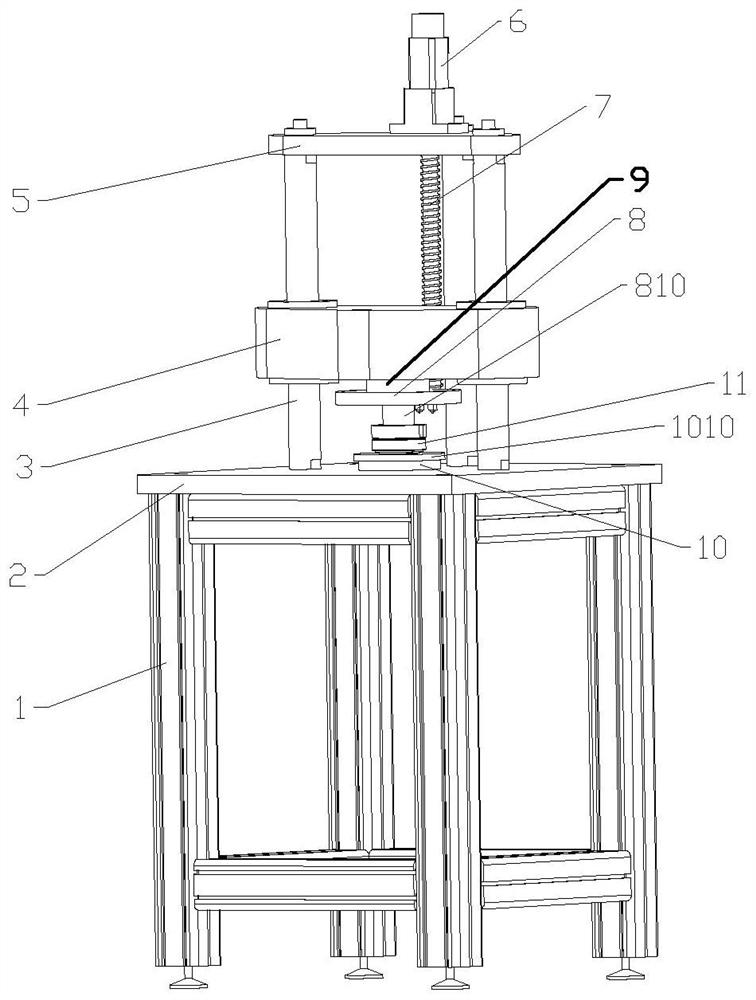

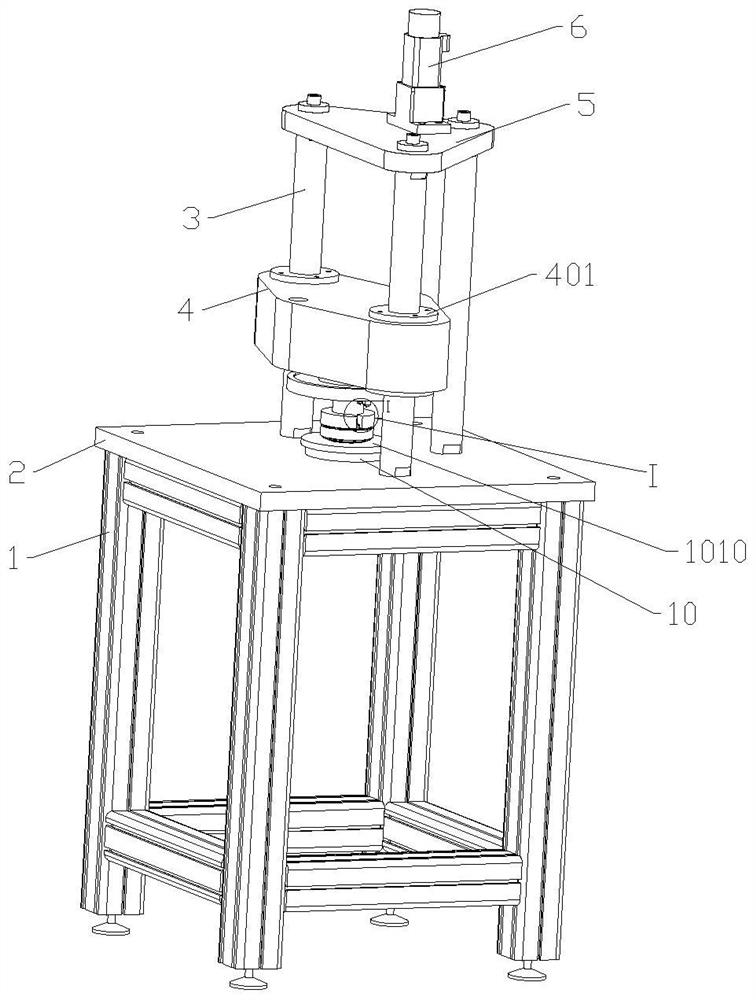

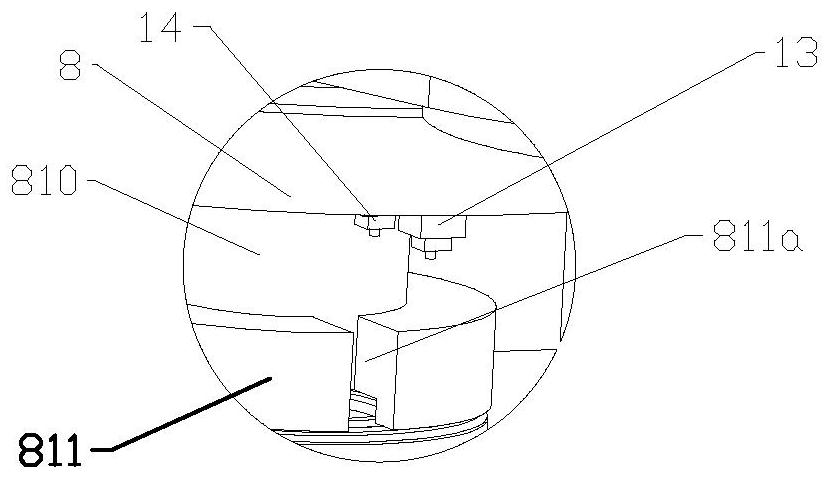

[0026] Embodiment 1 This embodiment provides a high-dimensional detection instrument for bearing assembly, including a detection platform 2, an upper tooling 810 and a lower tooling 1010 set oppositely, an upper tooling seat 8 and a lower tooling seat 10, a pressure sensor 9, a loading platform 4, Install the platform 5, the first ranging detection sensor and the second ranging detection sensor. A support 1 is provided at the bottom of the detection platform 2, and the support 1 has a certain height to raise the detection platform 2 to a designated processing height. The center of the detection platform 2 is provided with a threaded groove, and the lower end of the lower tool seat 10 is a threaded connection end protruding downwards and is fixed in the detection platform 2 by rotating connection. The upper end of the lower tooling base 10 is provided with a positioning shaft 1001 protruding upwards, and the center of the lower tooling 1010 is provided with an opening suitable ...

Embodiment 2

[0044] Embodiment 2 The difference between this embodiment and Embodiment 1 is that the first ranging sensor 13 and the second ranging sensor 14 are sensors with a data display function, and the pressure sensor 9 is also a sensor with a data display function. sensor. In this embodiment, the output end of the pressure sensor 9 is directly connected to the controller of the servo motor 6 . The controller of the servomotor 6 autonomously controls the work of the servomotor 6 according to the data detected by the pressure sensor 9 and preset values and programs. When the applied load reaches the target value, the loading platform 4 stops moving, and the readings of the first distance measuring sensor 13 and the second distance measuring sensor 14 are manually read and calculated.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com