Online detection method for deviation of hot-rolled strip steel

A detection method, hot-rolled steel strip technology, applied in image data processing, instruments, calculations, etc., can solve problems such as frame drift, edge damage, stacking steel accidents, etc., to achieve the effect of ensuring stability and high detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

[0054] The invention provides an online detection method for hot-rolled strip deviation.

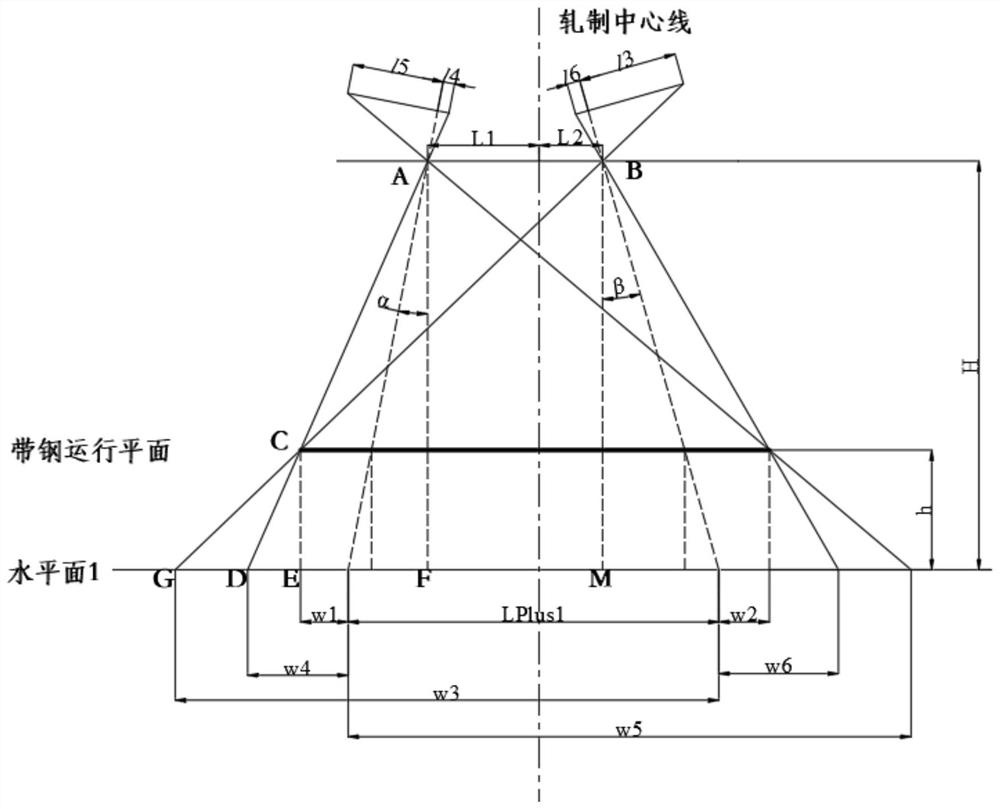

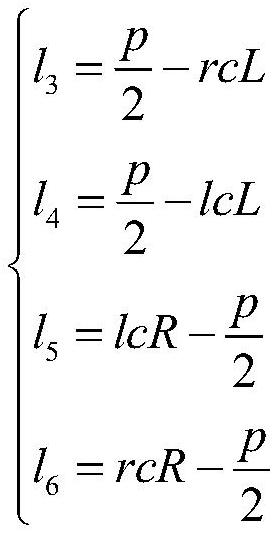

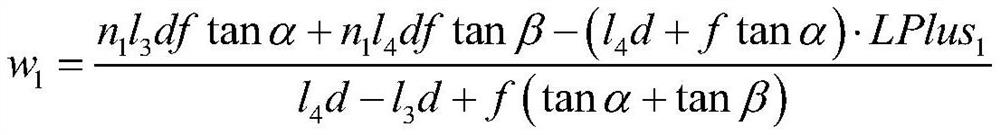

[0055] This method adopts machine vision technology, uses a binocular line array camera to collect real-time images of the strip steel, calculates the real-time width and deviation of the strip steel, and effectively eliminates the influence of the looper angle swing on the detection results. Camera error compensation ensures detection accuracy.

[0056] The specific steps are as follows:

[0057] S1: Distortion correction and calibration of the camera:

[0058] Optimize the distortion correction algorithm of the area array camera to obtain the distortion correction model of the line array camera, use the black and white stripe pattern to correct the distortion o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com