Constant-speed friction and wear experiment data measurement method and testing machine

A friction testing machine, friction and wear technology, applied in the direction of measuring devices, testing wear resistance, using mechanical devices, etc., can solve the problems of inaccurate friction and wear detection, achieve the effect of eliminating detection errors and improving detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

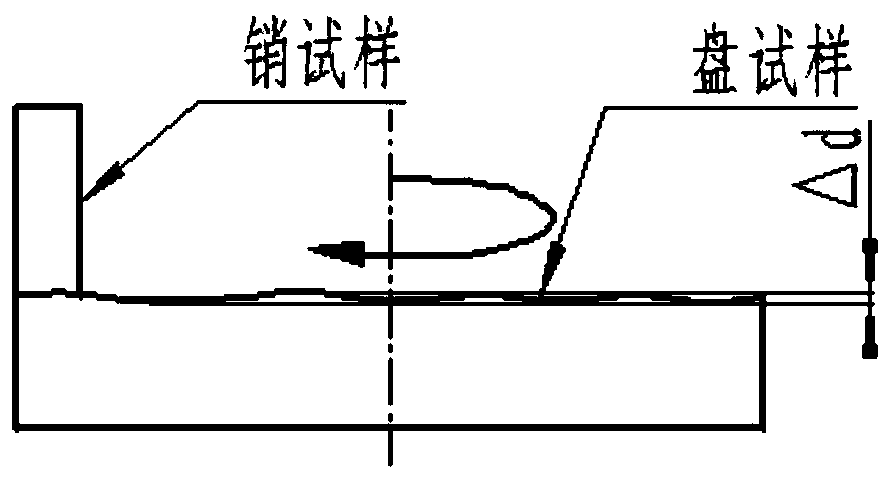

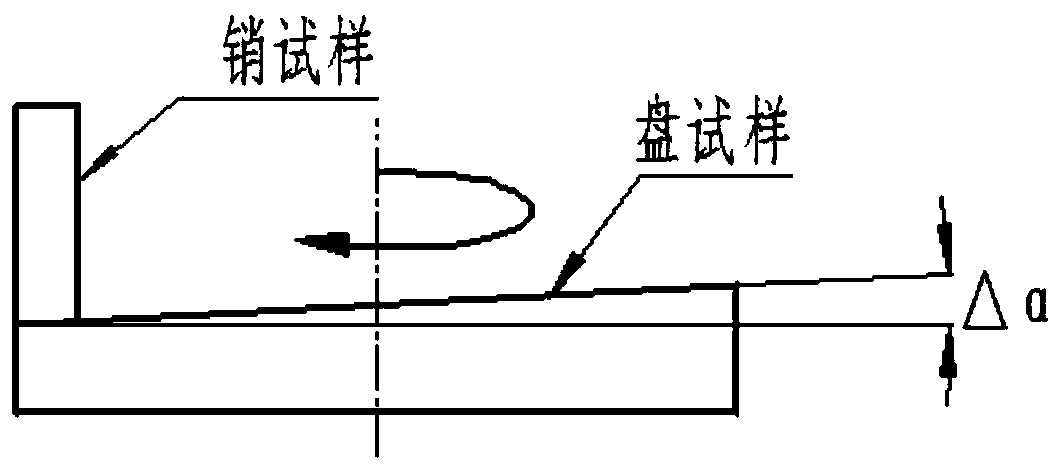

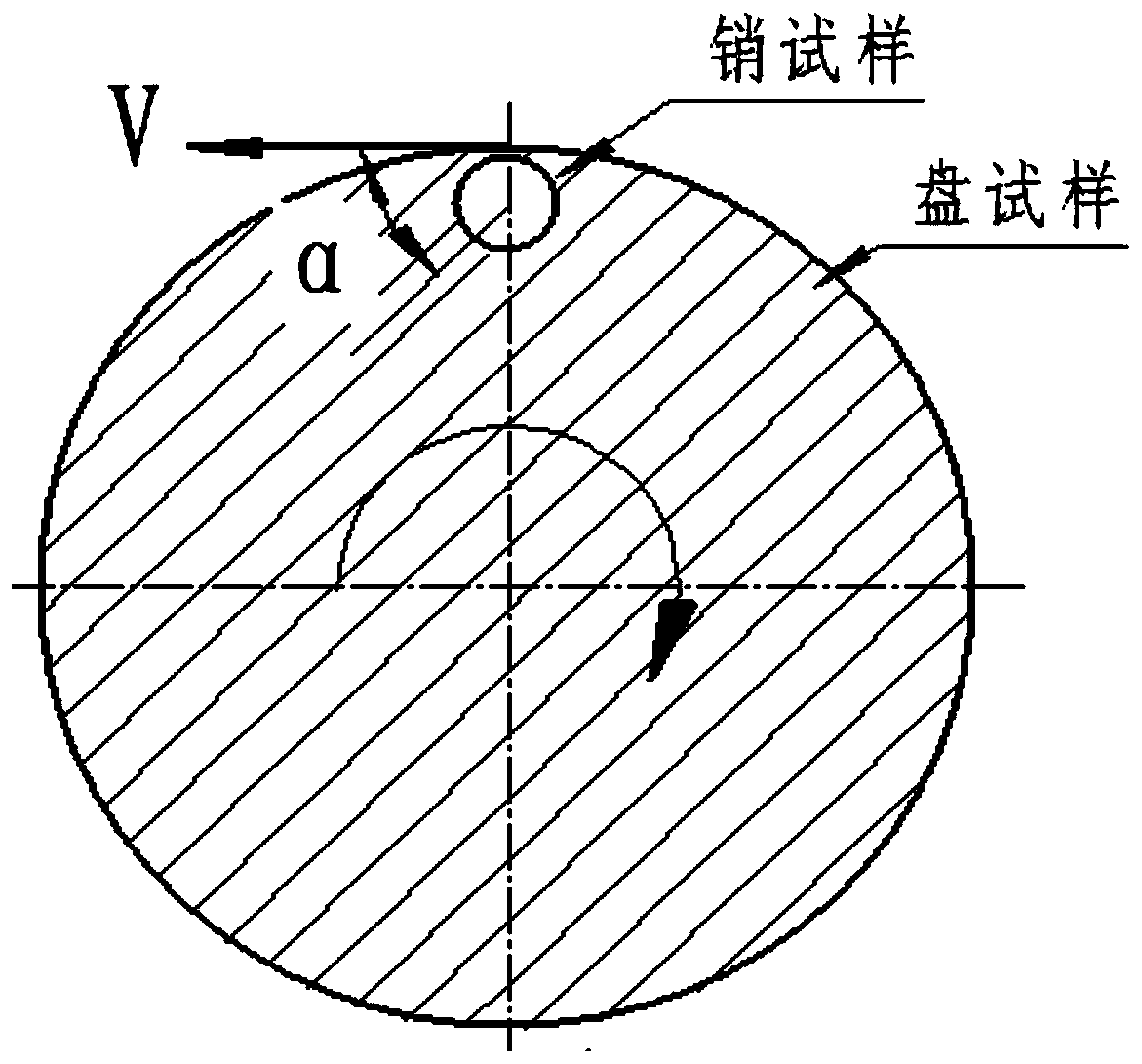

[0038] like Figure 4 Shown is the constant-speed friction and wear experimental data measurement method disclosed in the present invention, comprising the following steps:

[0039] Step 1. Make the experimental material into a fixed test piece and a moving test piece according to the provisions of the friction and wear test, and install the fixed test piece and the moving test piece on the fixed and moving fixtures of the constant-speed friction testing machine respectively;

[0040] Step 2. Set the applied load, temperature and time of the constant speed friction tester according to the experimental requirements;

[0041] Step 3. Set the motion speed of the constant speed friction testing machine so that the motion frequency f of the moving fixture of the constant speed friction testing machine 1 Sampling frequency f with the sensor of the constant speed friction tester 2 is a multiple relationship;

[0042]Step 4. Start the constant-speed friction testing machine, carry ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com