Patents

Literature

44results about How to "Avoid weighing errors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Roller washing machine and inertia detection method and device thereof

ActiveCN103966799AReduce detection errorEliminate detection errorsOther washing machinesControl devices for washing apparatusControl theoryElectromagnetic torque

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

Adhesive and preparation method

InactiveCN108485594AReduce hardnessGood weather resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesAdhesiveHardness

The invention relates to the technical field of adhesives, in particular to an adhesive. The adhesive is prepared from the following components: one or more of 10 to 90 weight parts of a silica gel substrate, 10 to 90 weight parts of a modified epoxy glue substrate and 10 to 90 weight parts of acrylate adhesive; 0 to 20 weight parts of a crosslinking agent, 0 to 10 weight parts of a platinum compound, 0 to 15 weight parts of an additive, 0 to 10 weight parts of a reaction inhibitor, 0 to 50 weight parts of a reinforcing material and 150 to 500 weight parts of a conductive filler. By selectionof one or more of the silica gel substrate, the modified epoxy glue substrate and the acrylate adhesive, the hardness of the adhesive can be reduced, and the weather fastness of the adhesive can be improved; meanwhile, the adhesive has the advantage of high disperse stress and is excellent in adhesiveness and protectiveness for an adhered material with low intensity. Furthermore, by use of the conductive filler, the cost of the adhesive can be effectively reduced.

Owner:点馨(上海)实业有限公司

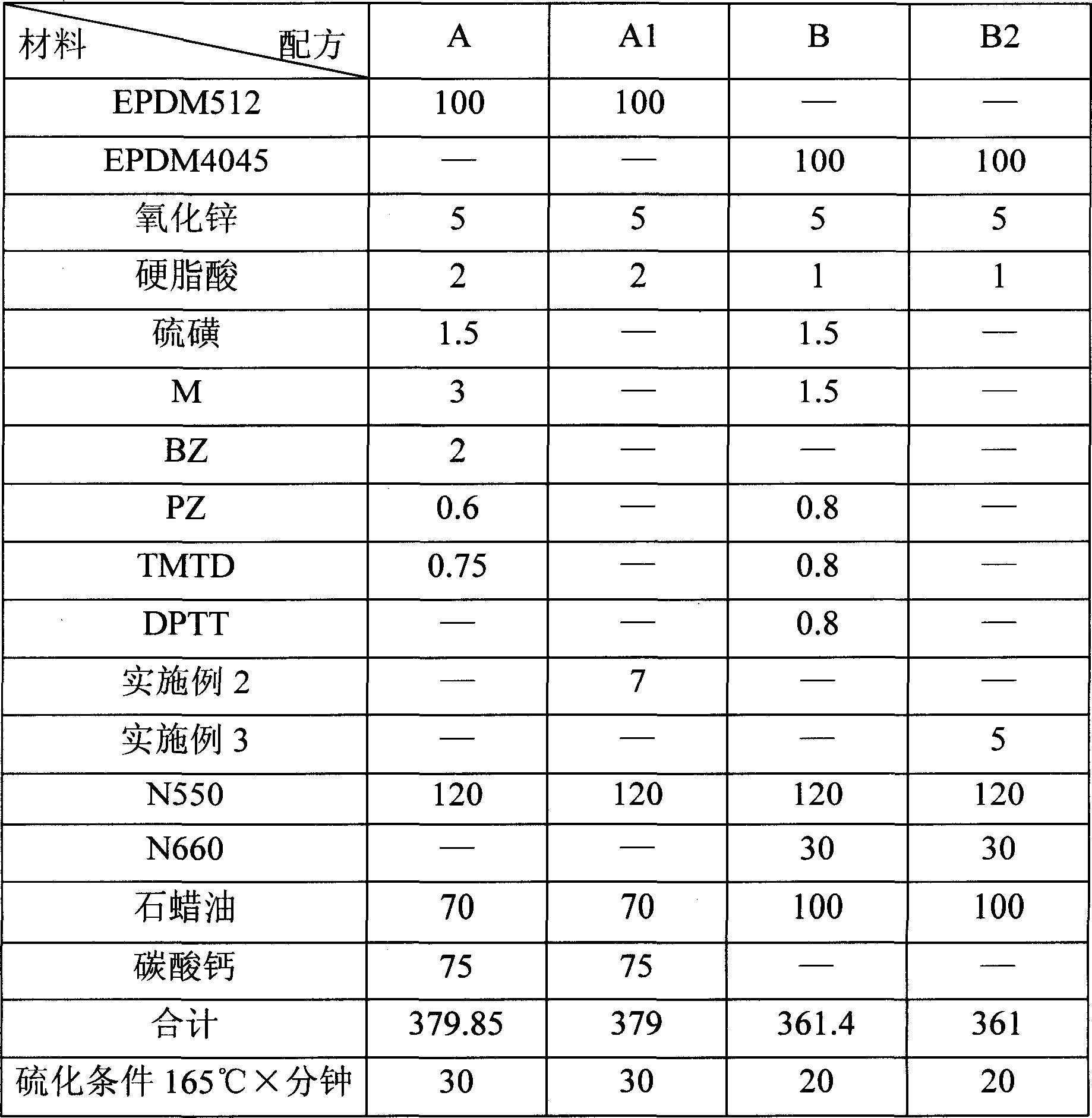

Special curing agent of 3-element EPR

This invention discloses a kind of vulcanizer especially for ethylene propylene diene monomers, which uniquely has a mass-fraction composition as follows: 5~60% sulphur, 1~50% peroxide, 1~70% thiazole, 3~50% thiuram, 1~50% dithiocarbamate, 1~25% amine and condensate of aldehyde and amine and 1~25% ethanolamine. The interaction of coexisting enhancers and vulcanizers is adequately utilized and the amount of enhancers is reasonably controlled within a range for frost spray inhibition. Therefore, the vulcanization speed of ethylene propylene diene monomers can be promoted by almost 30% and frost spray on product surfaces can be well solved, which significantly improves the physical and mechanical properties of the vulcanizate. This invention is applicable for several tens of ethylene propylene diene monomers and there requires no large amount of experimental comparison for a single specie. Therefore, the label strength of the technologists is lowered and the production efficiency is raised.

Owner:戴近禹

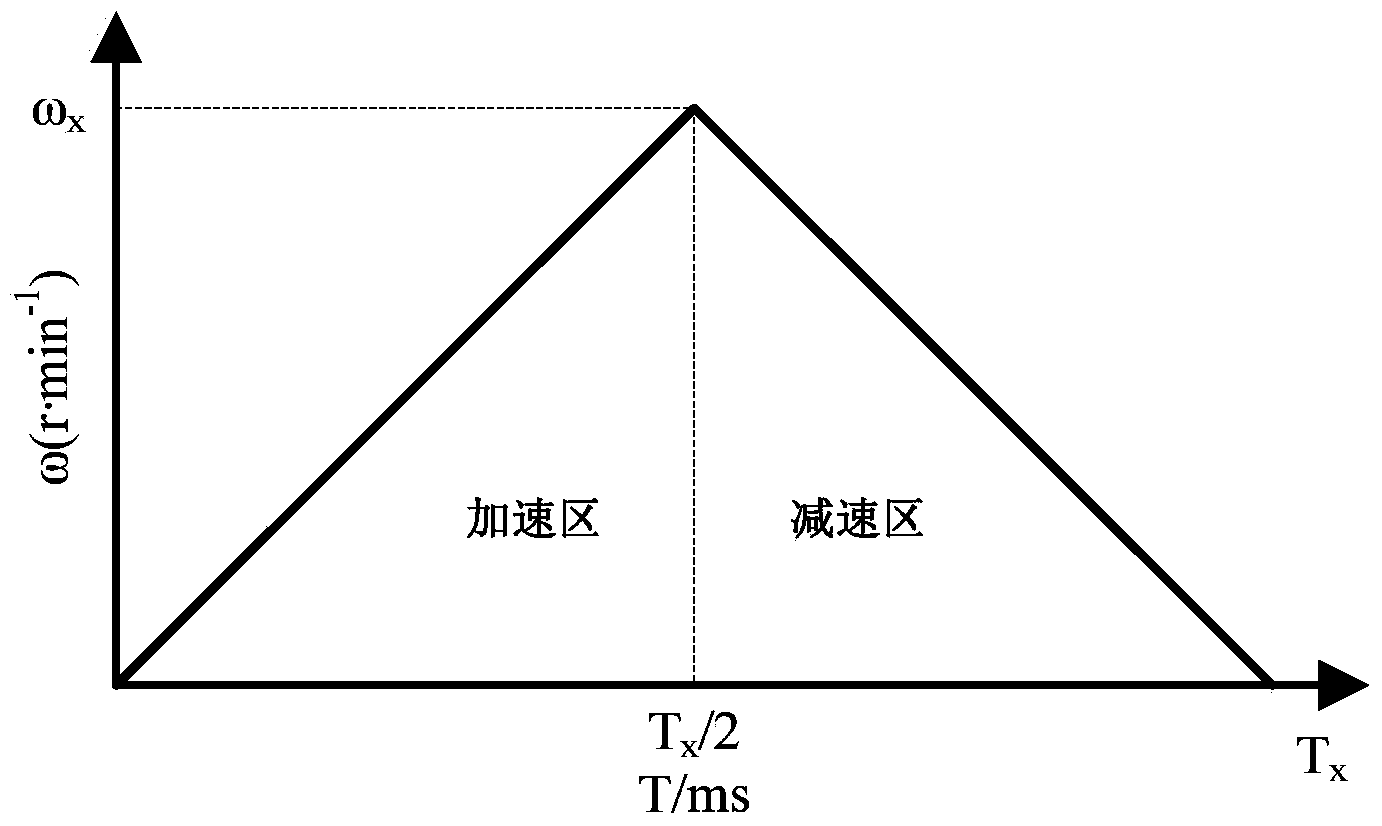

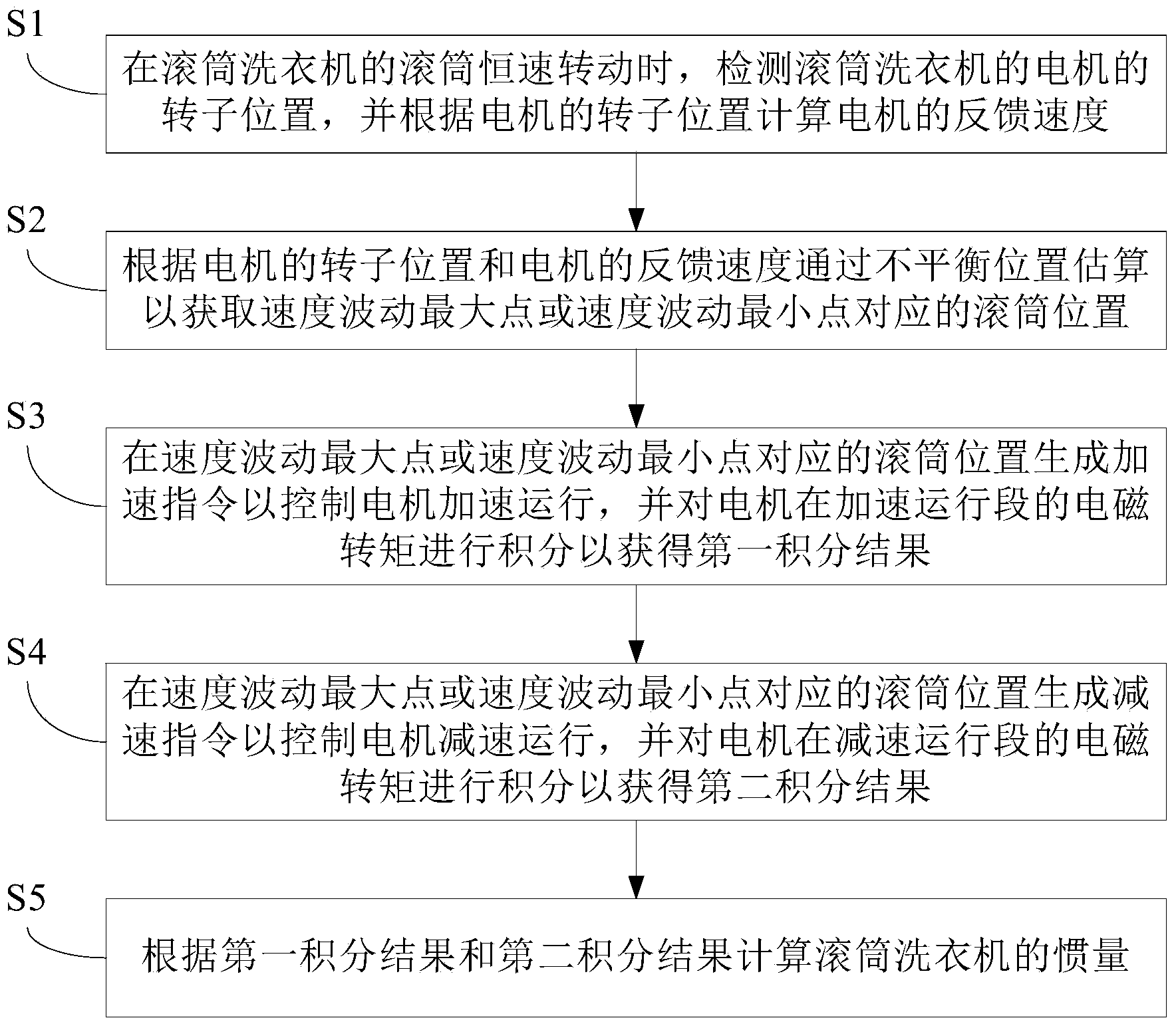

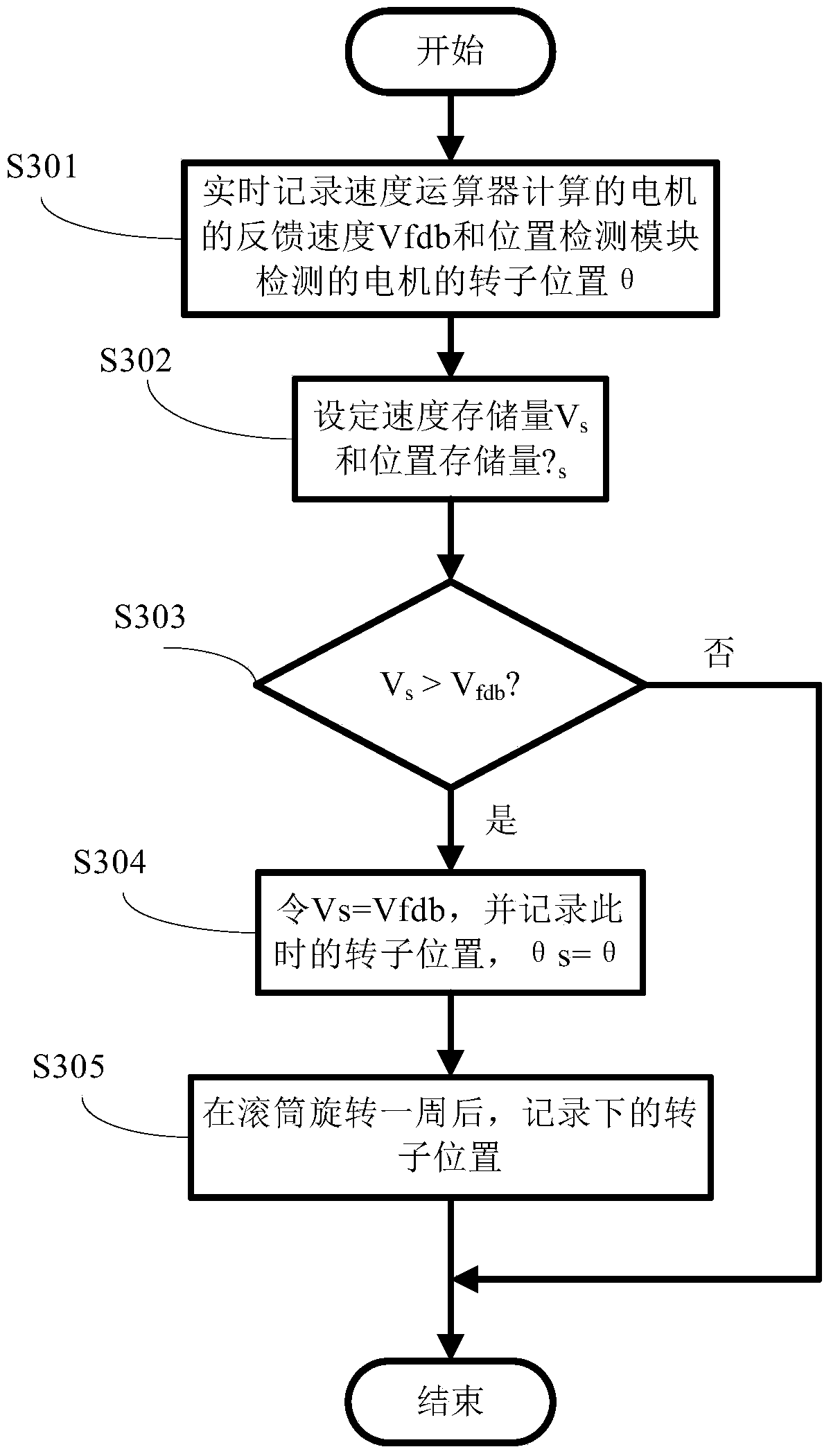

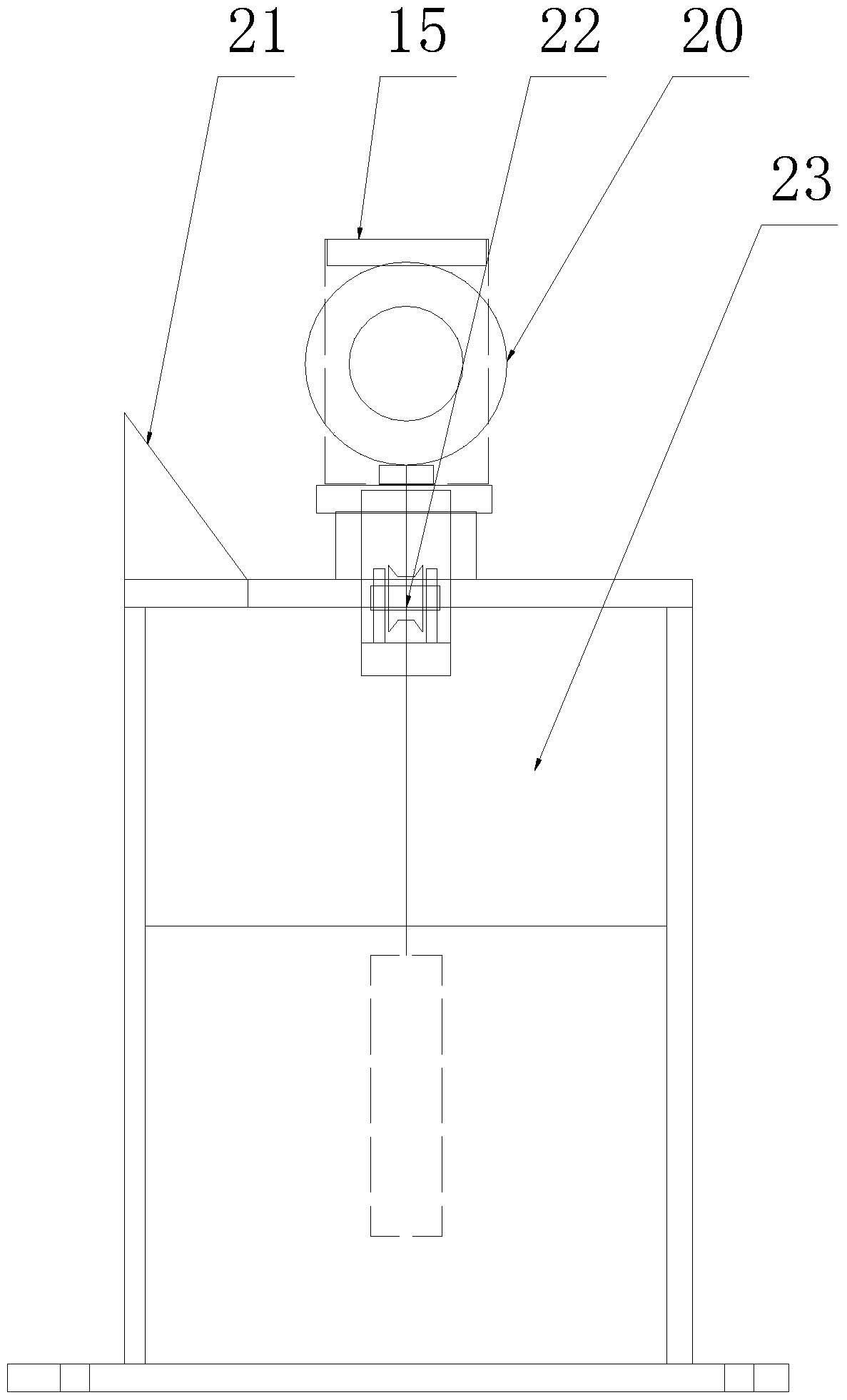

Roller washing machine and inertia detection method and device thereof

ActiveCN103966804AAccurate inertia detectionAvoid weighing errorsOther washing machinesStatic/dynamic balance measurementControl theoryElectromagnetic torque

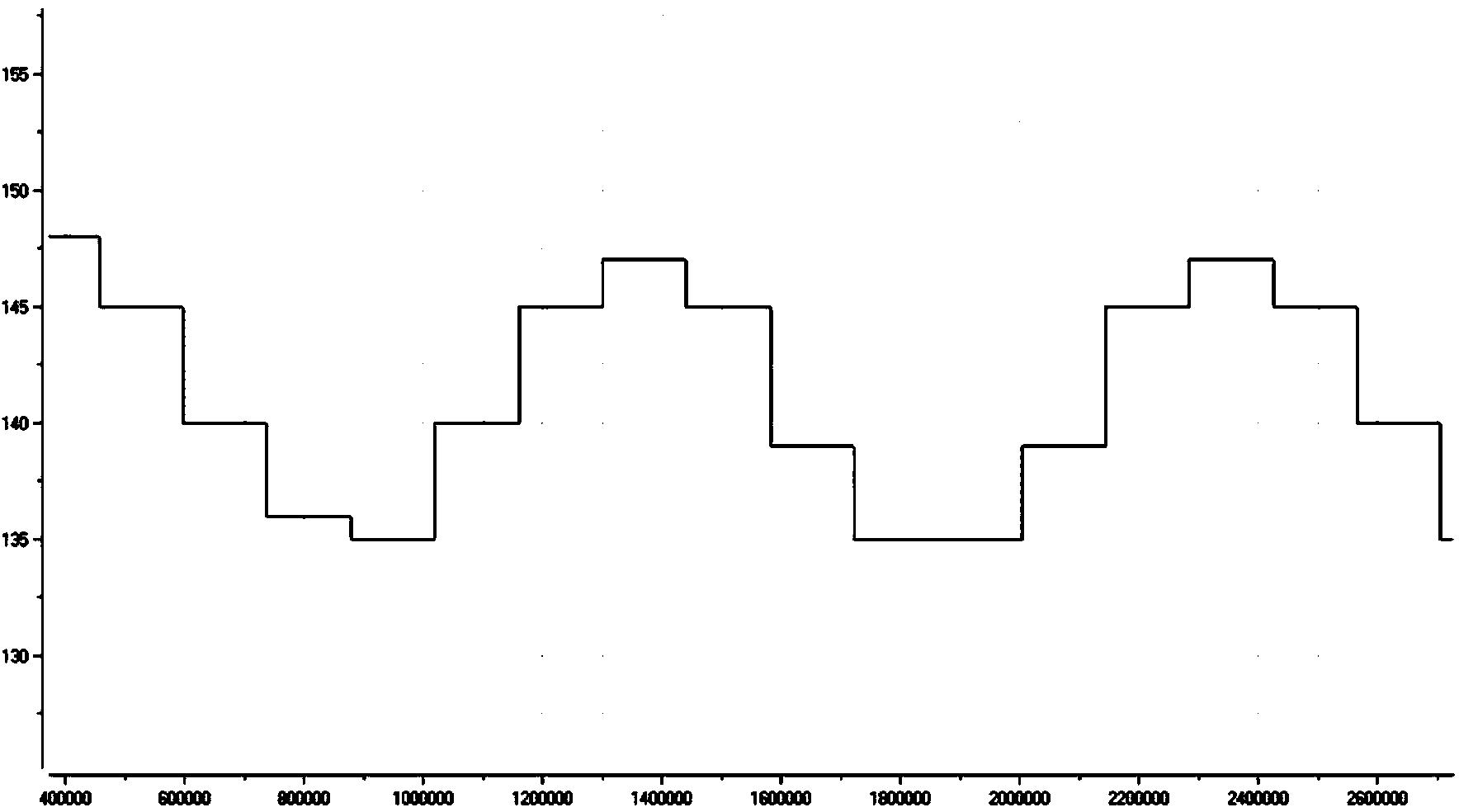

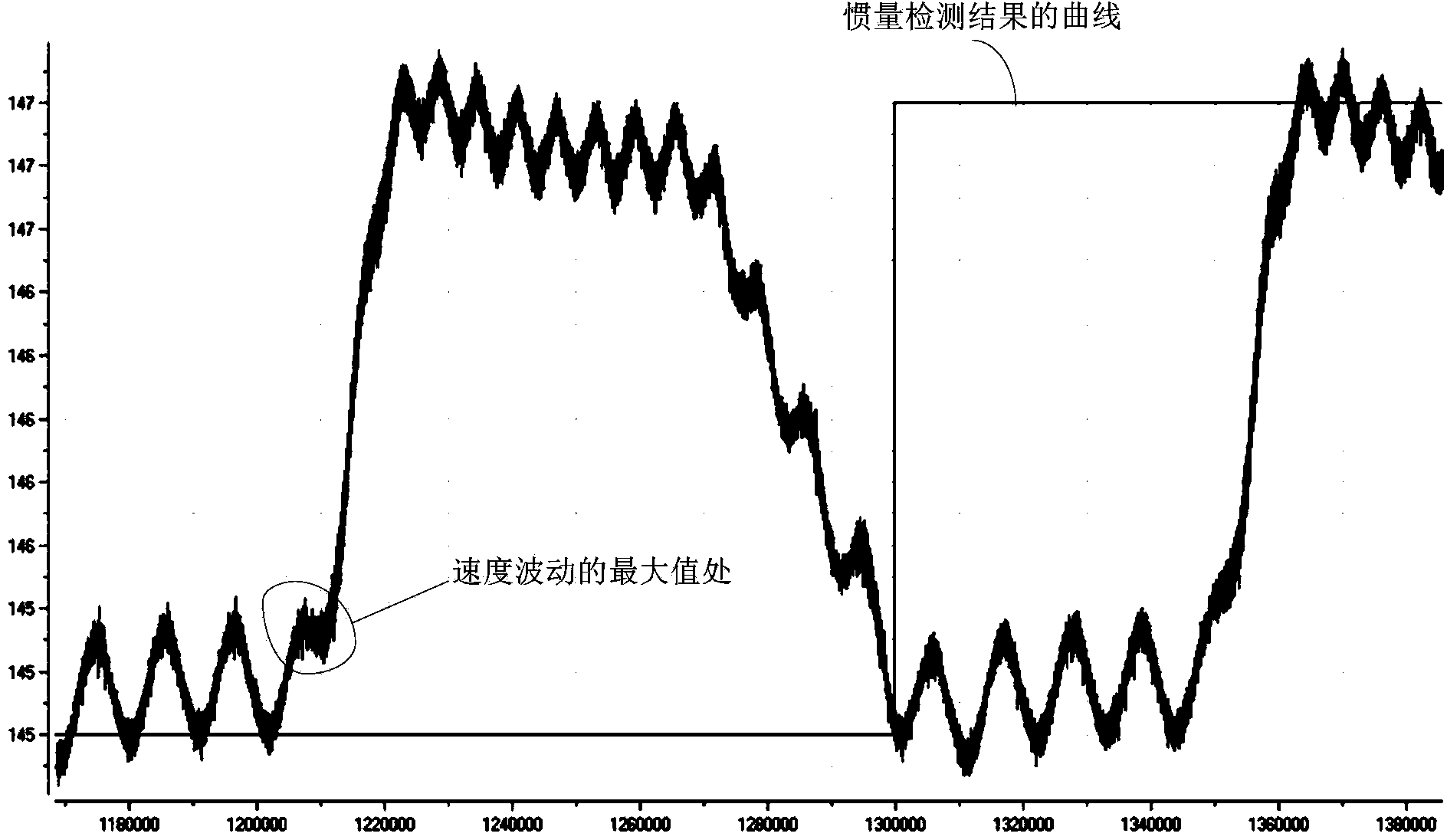

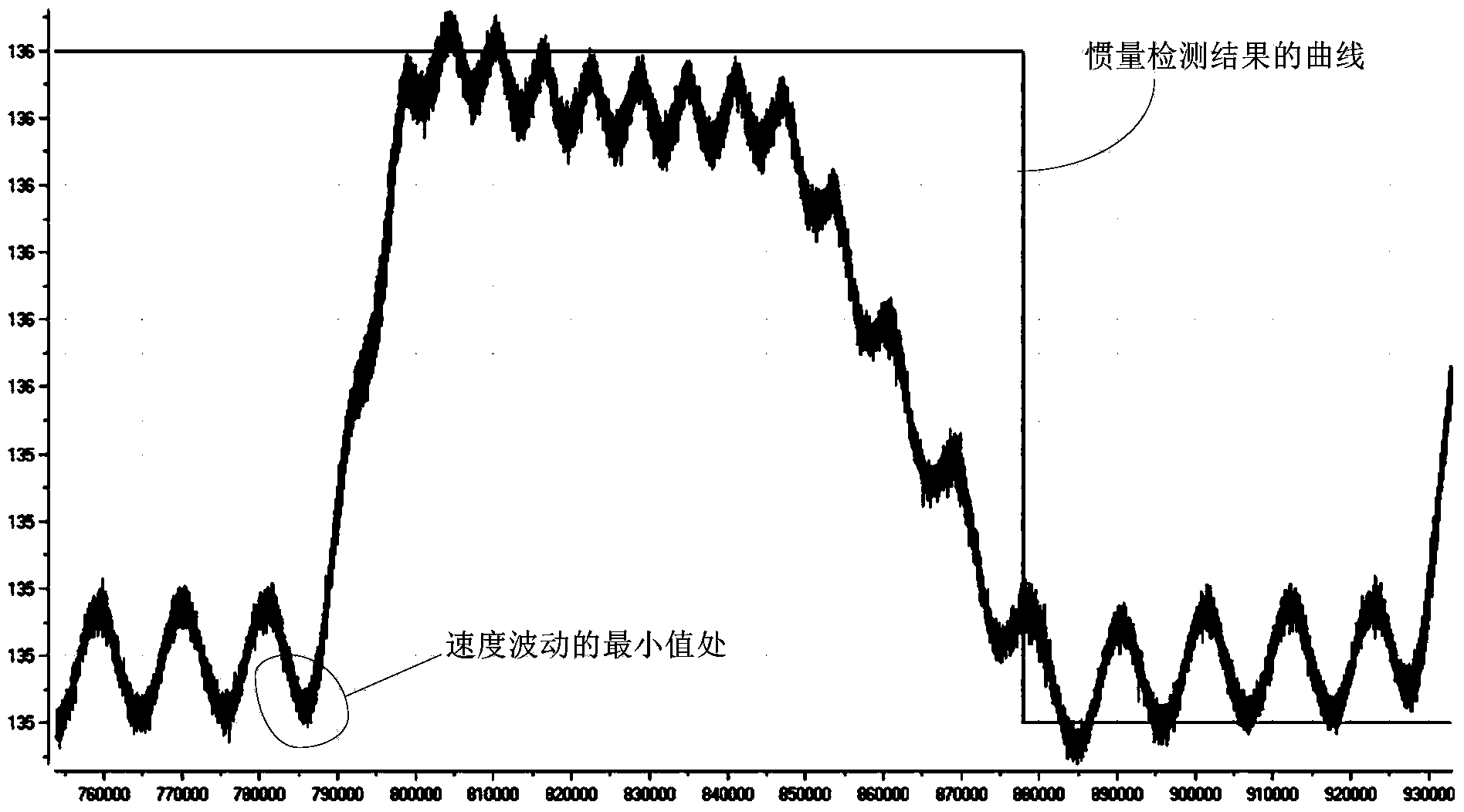

The invention discloses a roller washing machine and an inertia detection method and device of the roller washing machine. The inertia detection method includes the following steps that the position of a rotor of a motor is detected when a roller rotates at constant speed, and feedback speed of the motor is calculated according to the position of the rotor; according to the position of the rotor and the feedback speed, the roller position corresponding to the maximum speed fluctuation point or the minimum speed fluctuation point is obtained through unbalance position estimation; an acceleration instruction is generated at the roller position corresponding to the maximum speed fluctuation point or the minimum speed fluctuation point to control the motor to operate in an accelerated mode, and integration is performed on electromagnetic torque on an acceleration operation section to obtain a first integration result; a deceleration instruction is generated at the roller position corresponding to the maximum speed fluctuation point or the minimum speed fluctuation point to control the motor to operate in a decelerated mode, and integration is performed on electromagnetic torque on a deceleration operation section to obtain a second integration result; according to the first integration result and the second integration result, the inertia of the roller washing machine is calculated. According to the method, influences of load unbalance can be considered, so that detection precision is improved.

Owner:GUANGDONG WELLING ELECTRIC MACHINE MFG +1

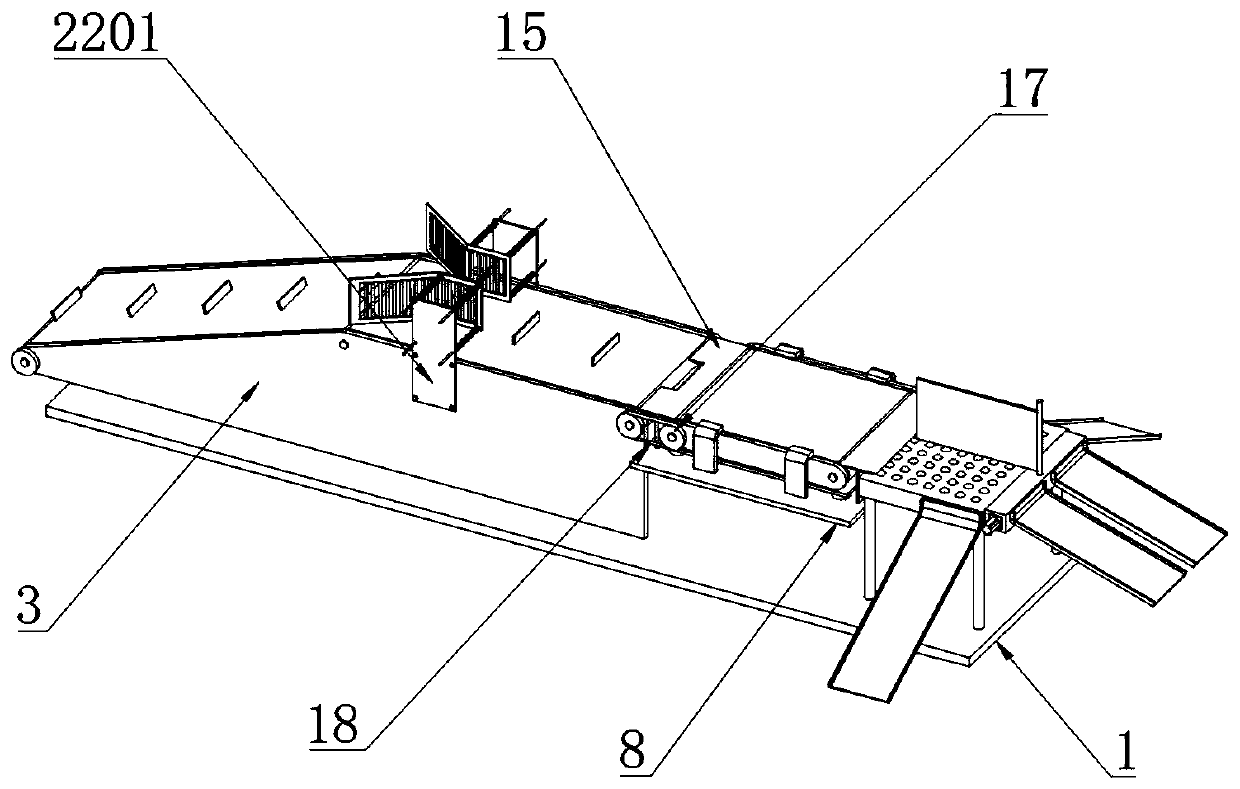

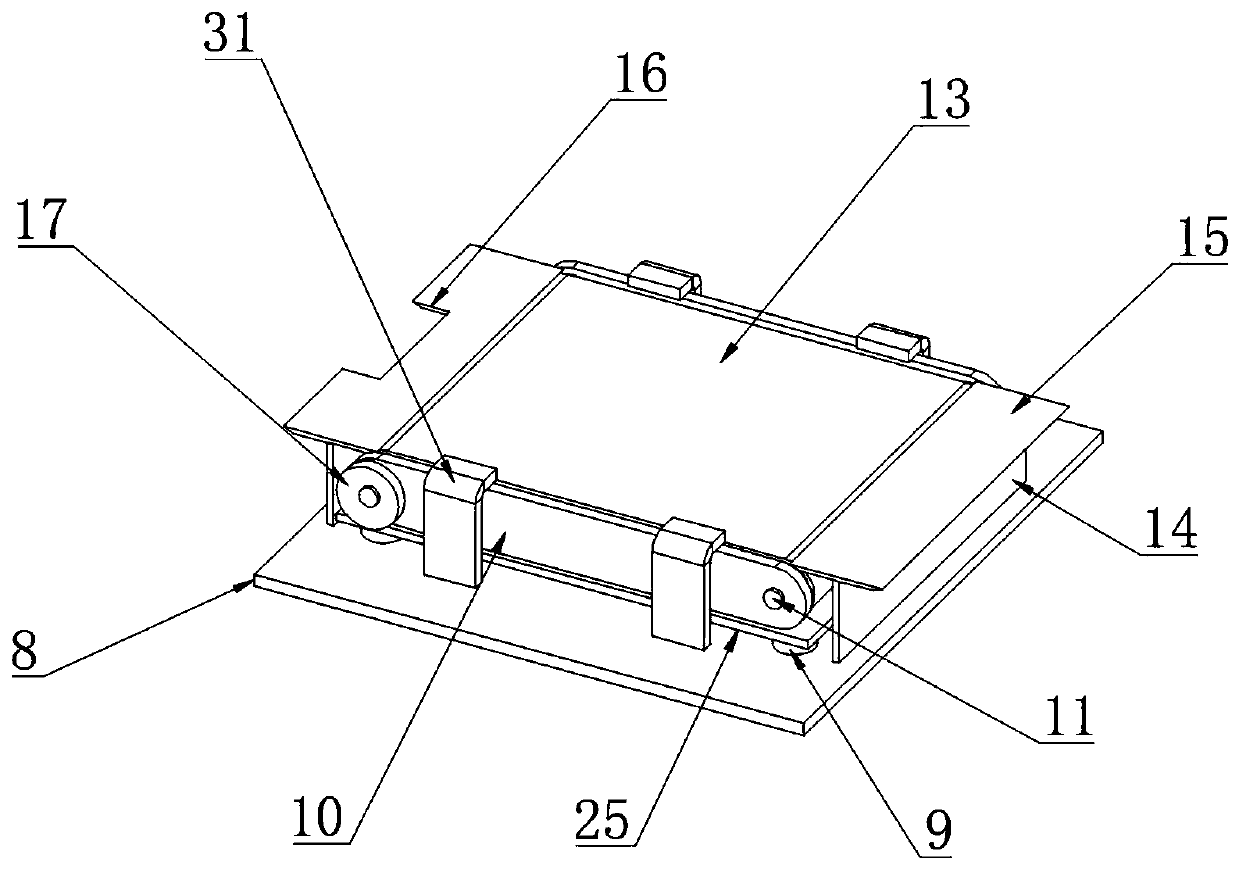

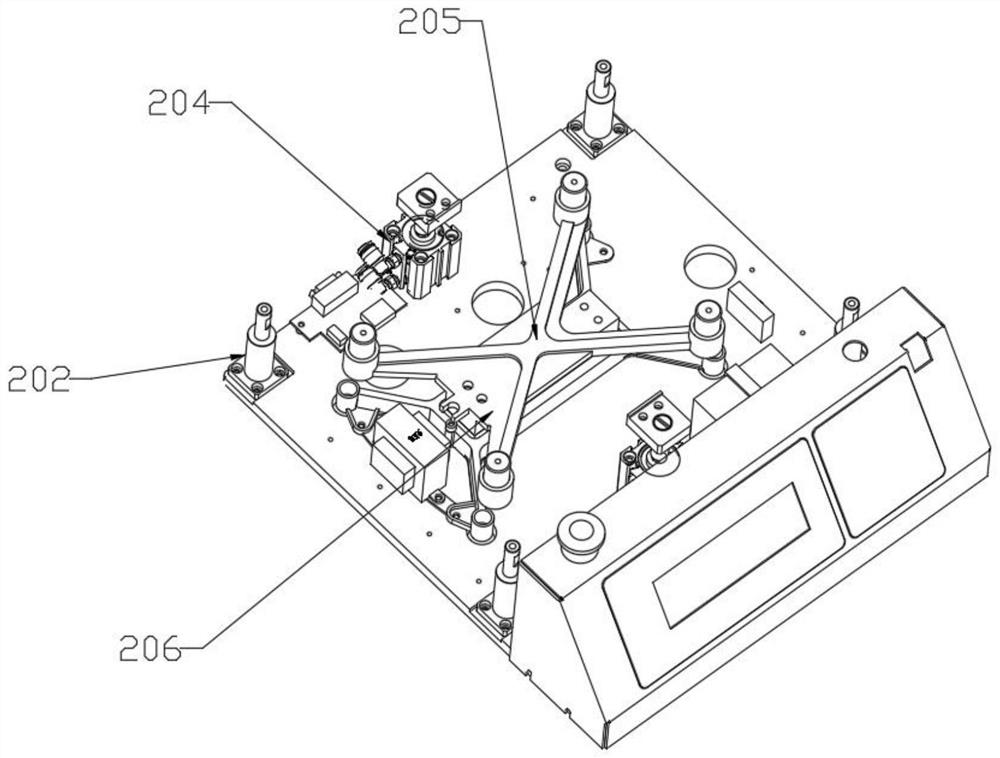

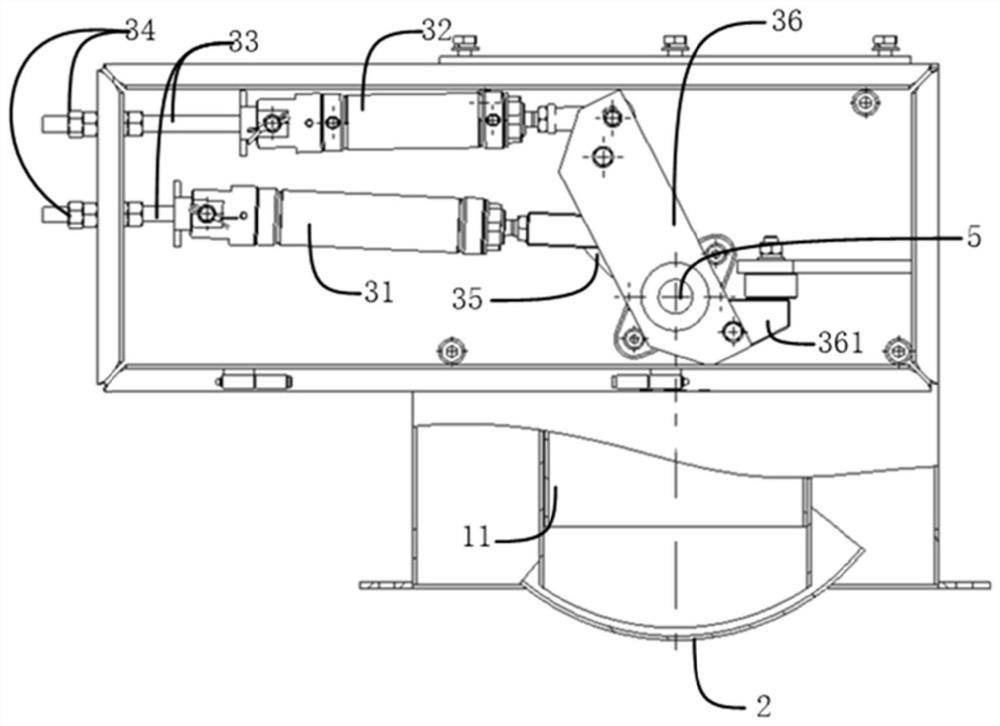

Dynamic weighing and sorting integrated device for logistics

Owner:XUZHOU UNIV OF TECH +1

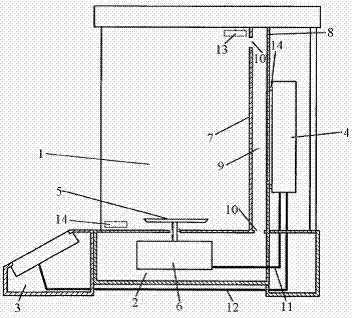

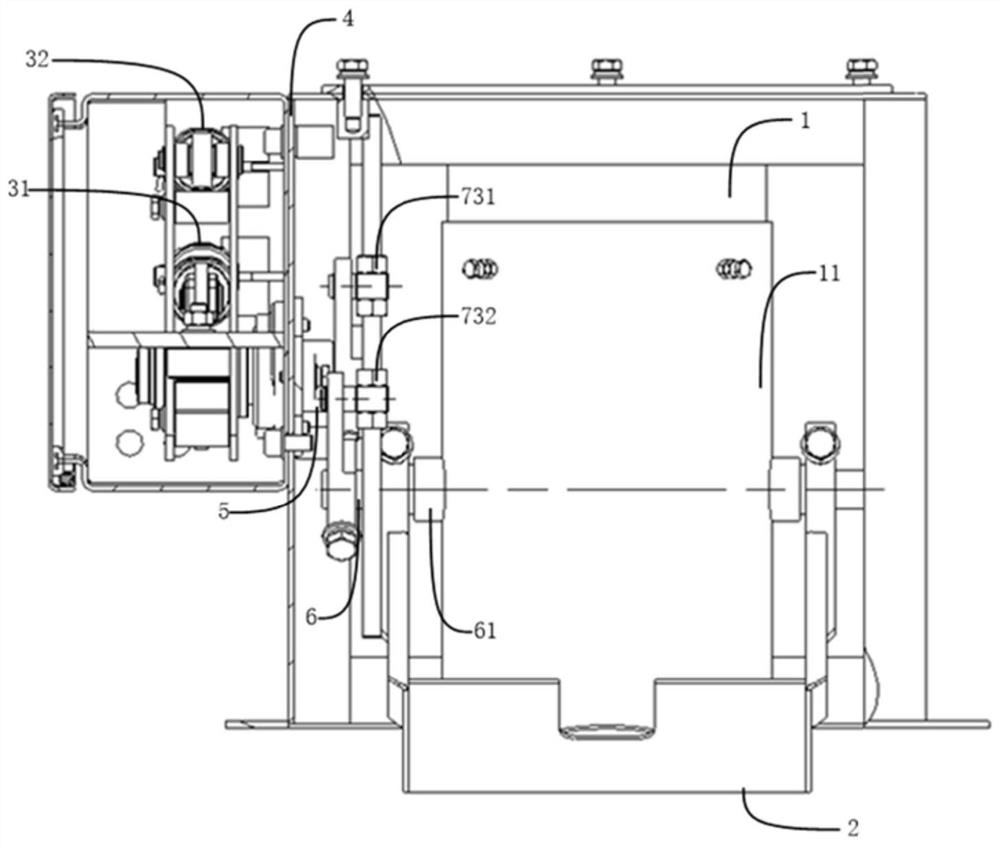

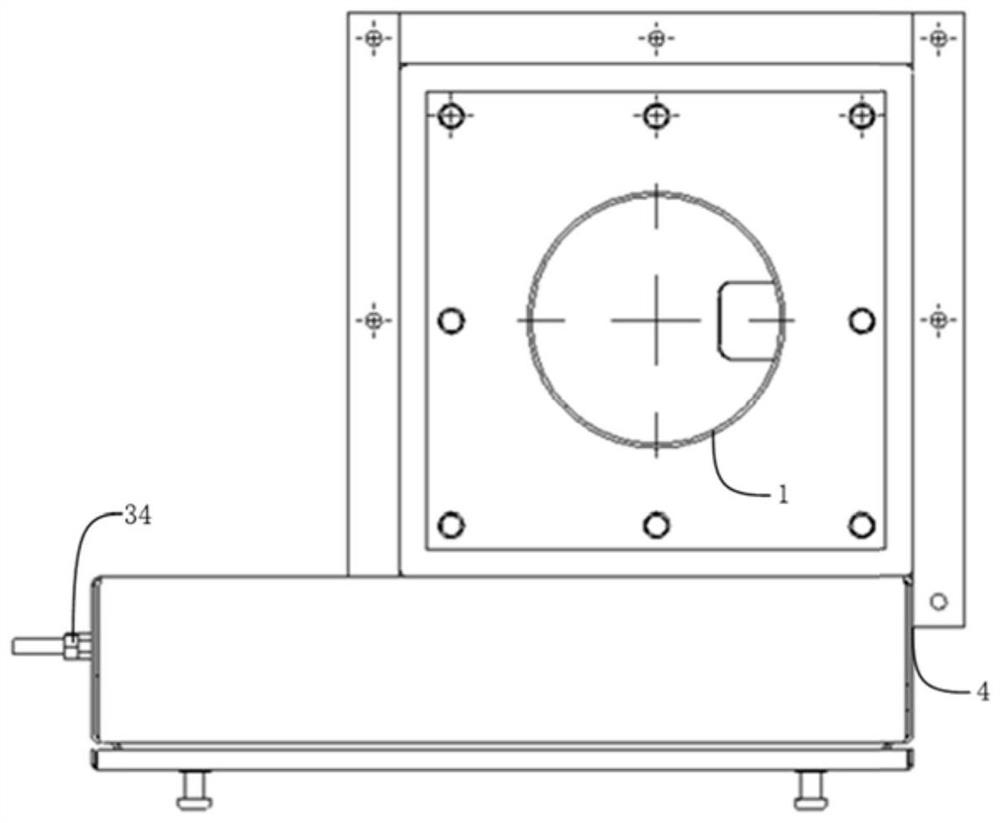

Electronic balance capable of preventing air convection

InactiveCN102778278AHot and cold layered stabilityAvoid Weighing ErrorsWeighing auxillary devicesPneumatic pressureEngineering

The invention discloses an electronic balance capable of preventing air convection. The electronic balance comprises a first compartment, a second compartment, a display device and a processing device, wherein weighing trays are arranged inside the first compartment, a weighing device is arranged inside the second compartment, the first compartment is separated from the processing device by a front wall and a rear wall, the processing device is hung on the rear wall, a cavity is formed between the front wall and the rear wall, the second compartment is pneumatically connected with an upper part of the first compartment through the cavity, and a cooling device is arranged at a lower part of the first compartment. Through the manner, the electronic balance capable of preventing the air convection provided by the invention, a weighing error caused by the air convection around the weighing trays can be prevented and weighing accuracy of the electronic balance can be increased.

Owner:昆山旭虹精密零组件有限公司

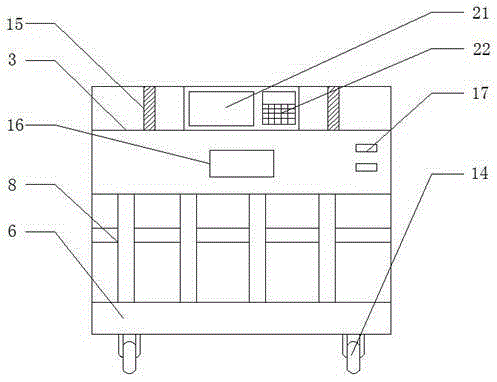

Foldable electronic scale

The invention discloses a foldable electronic scale, which comprises an alarm, an operation and control panel, a display screen, a button, a scale body, a first folding plate, a supporting plate, a hinge bolt, a second folding plate, non-slip mats, a bracket, a fixed bolt, a movable bolt, a first jack, a first fixing plate, a second jack, a second fixing plate, a supporting rod, a rotating mechanism, a steel sheet, a sleeve, a connecting rod, a printer, a stepper motor driving module, a thermal print head, a battery, a single chip microcomputer, a pressure sensor and a filter. The rotatable and foldable supporting rod is adopted to be connected with the operation and control panel and the scale body, inclination of different degrees of the supporting rod can be realized, an overlarge weighing object can be prevented from squeezing and abutting against the supporting rod, and damage of the supporting rod and weighing errors can be prevented on one hand, and on the other hand, reading is facilitated; the operation and control panel adopts a rotatable form, reading at a different angle through rotation can be realized, and the use is convenient; and besides, the scale body can be folded, and an article with a large volume can be placed on the scale body.

Owner:长沙玛森教育科技有限公司

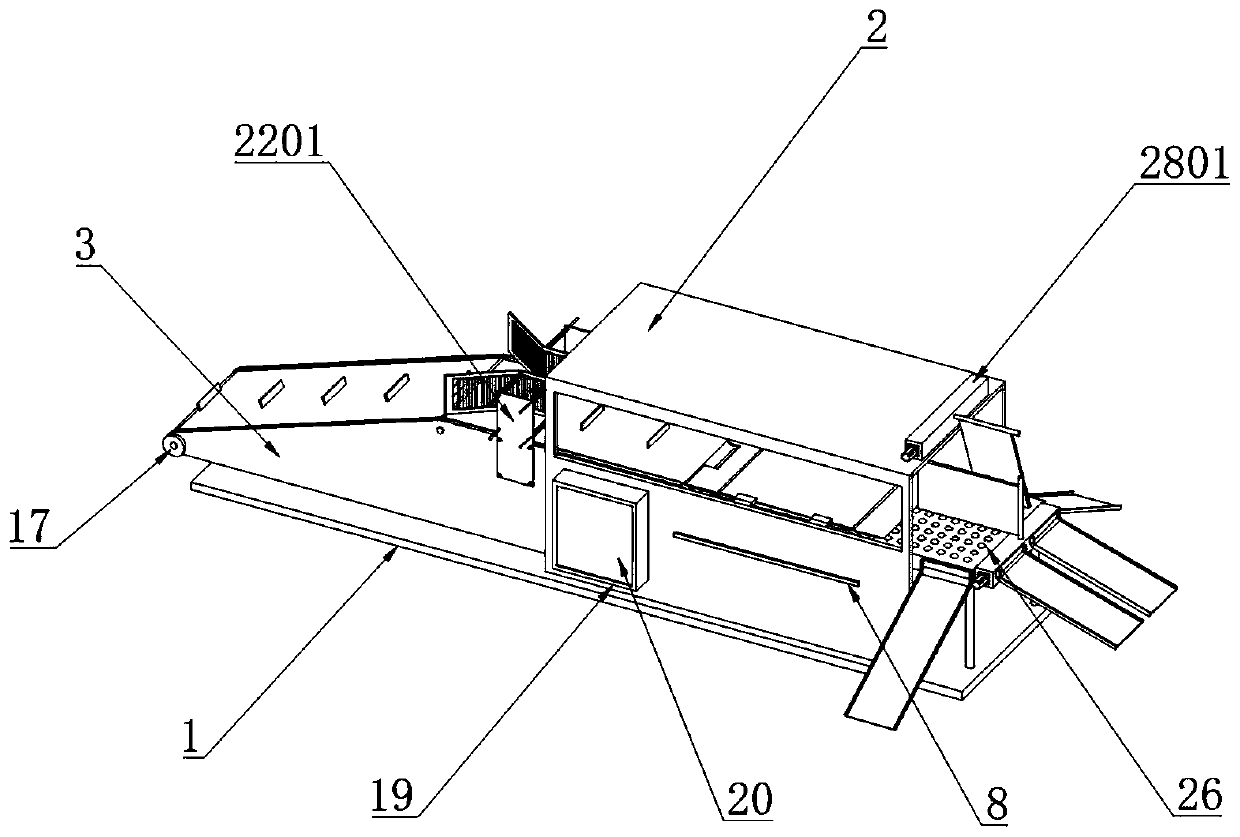

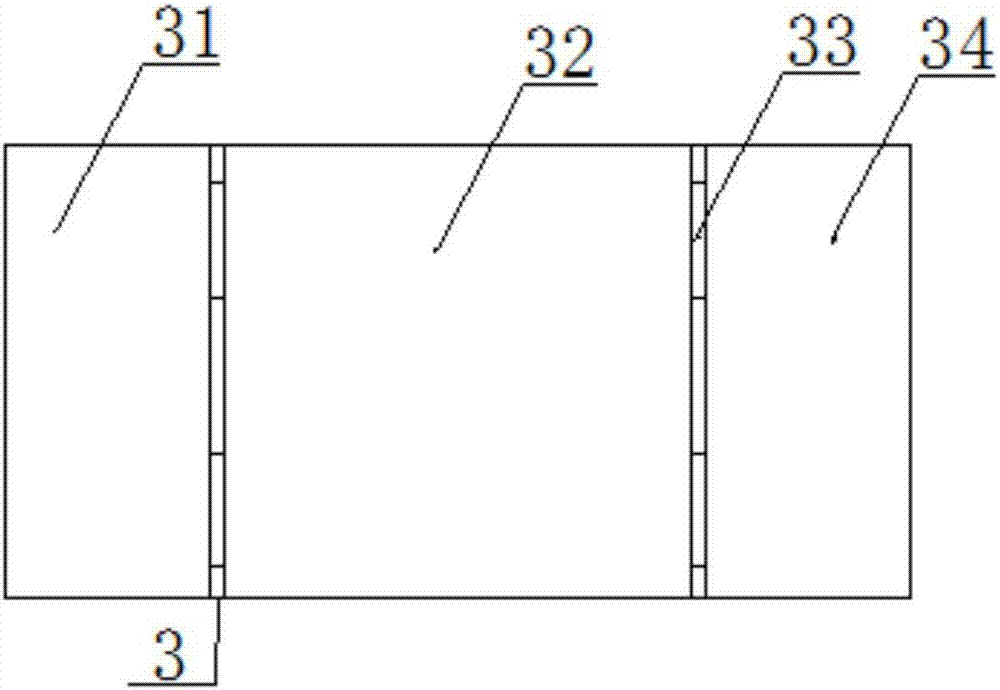

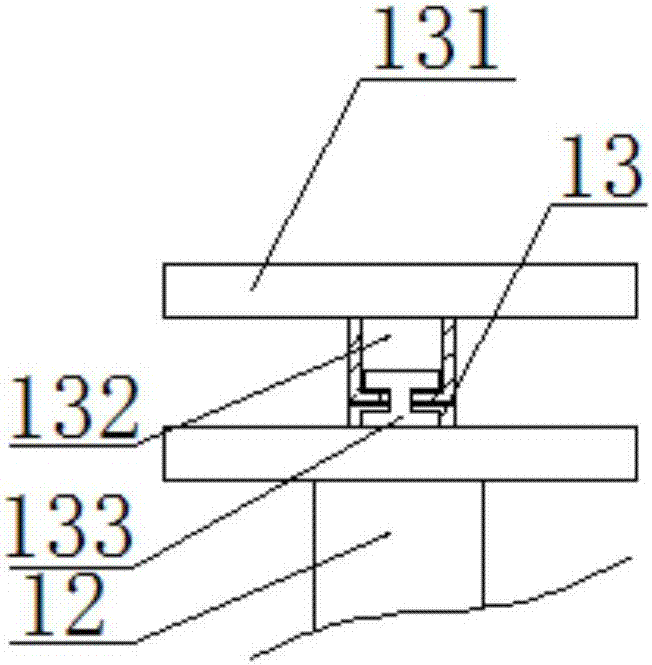

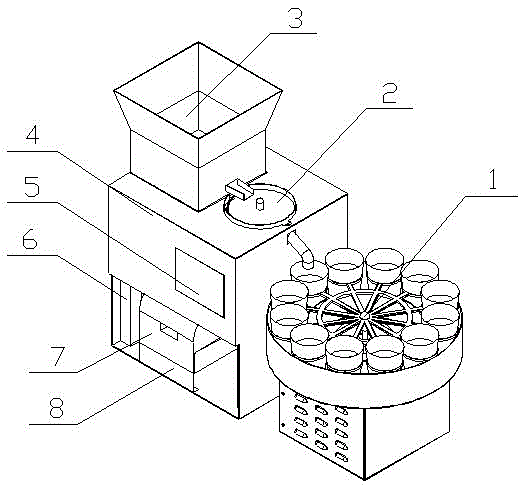

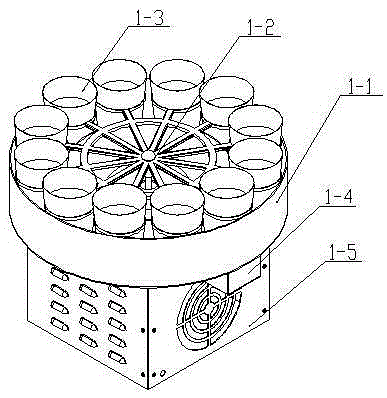

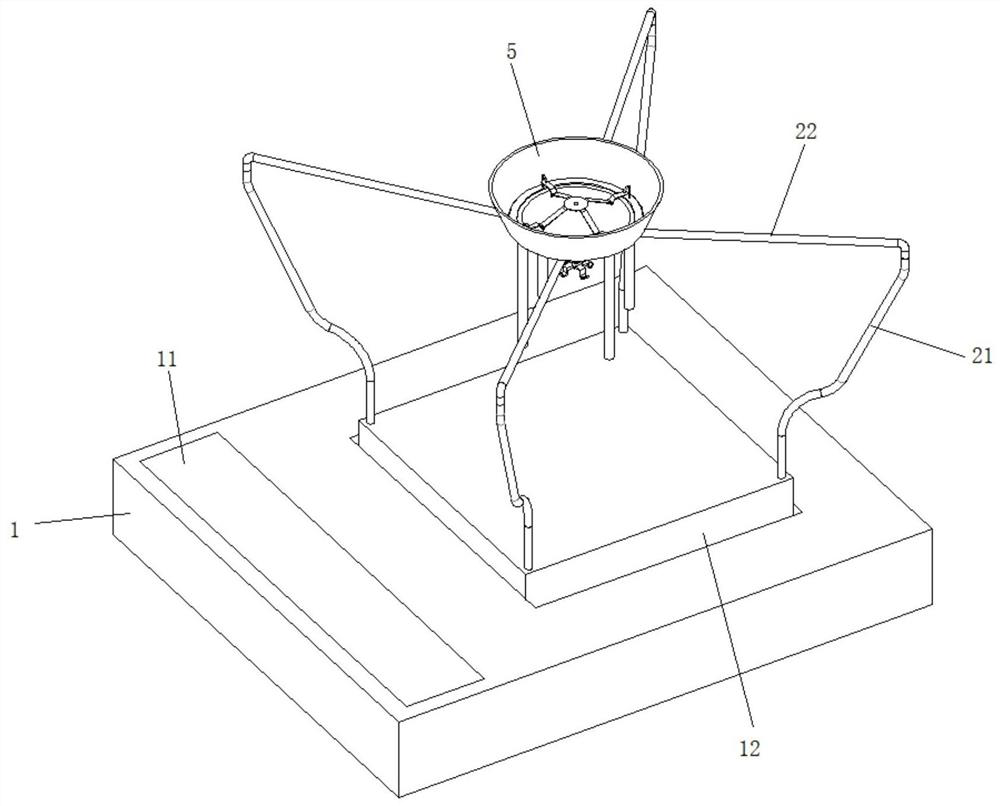

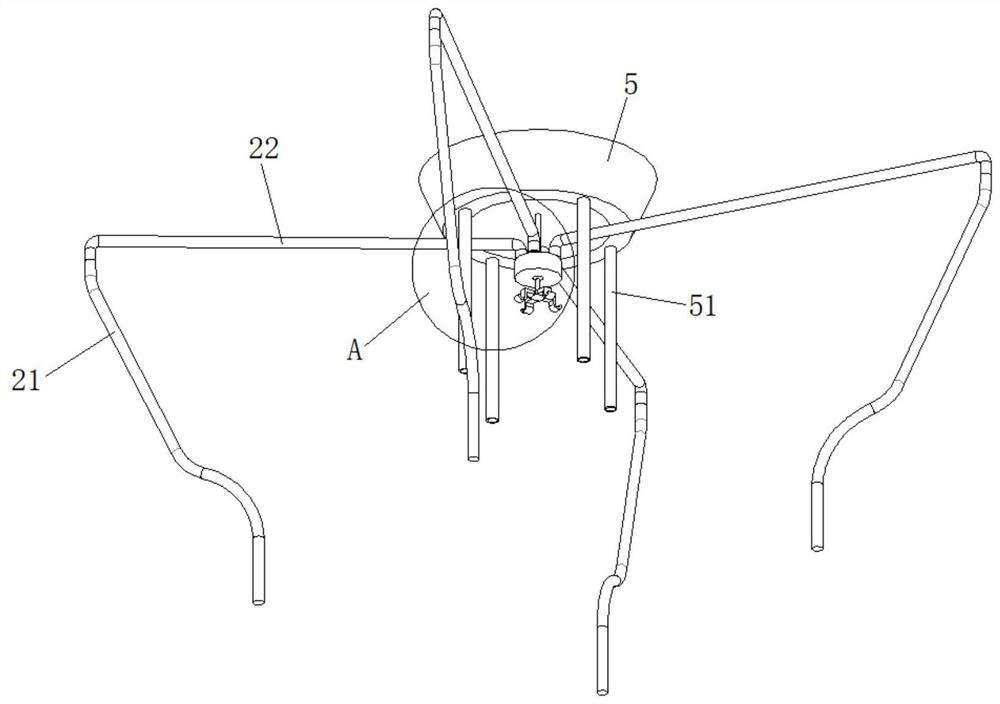

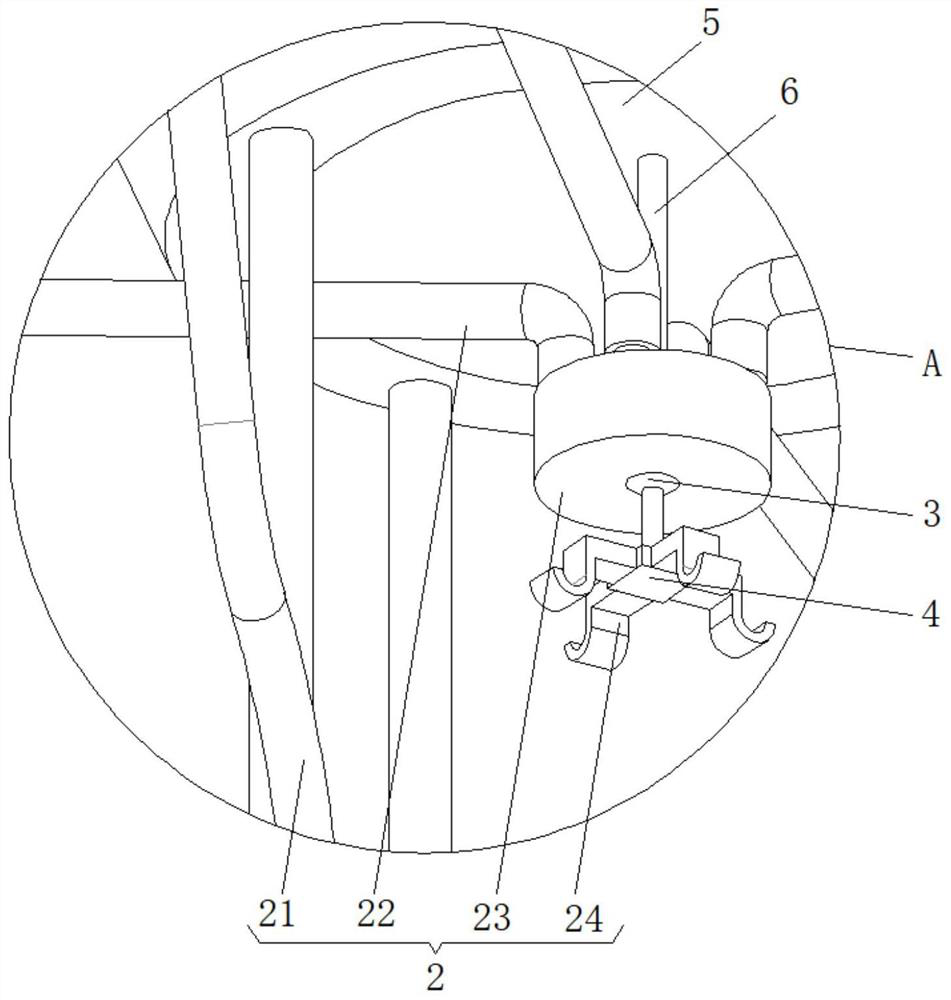

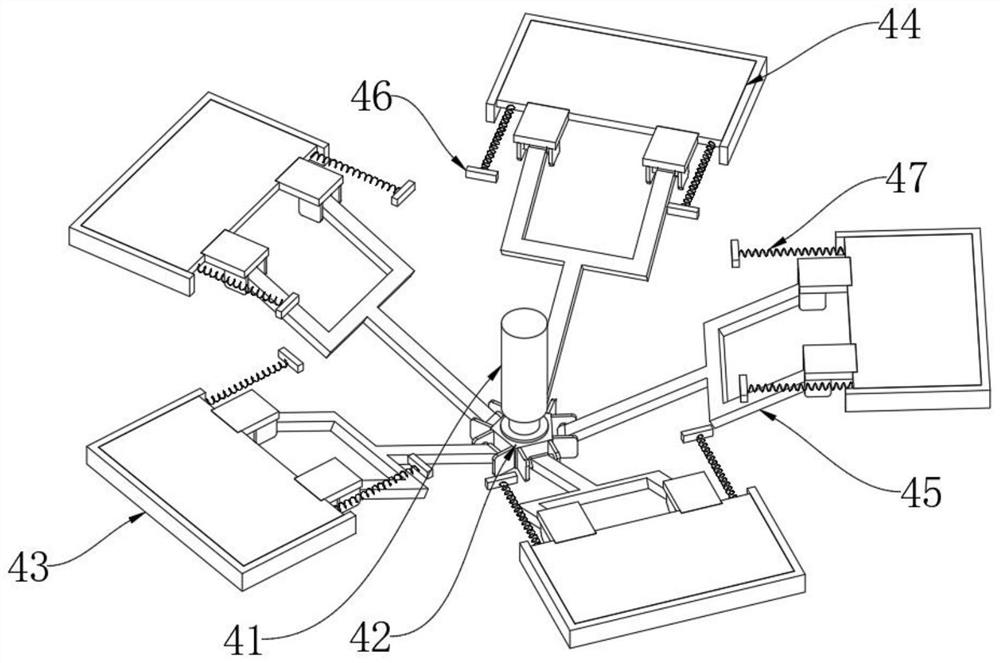

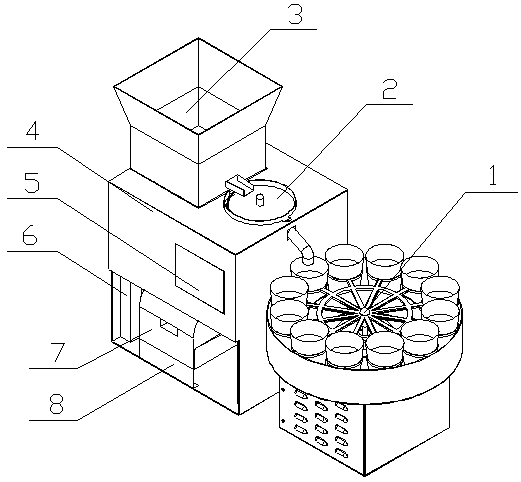

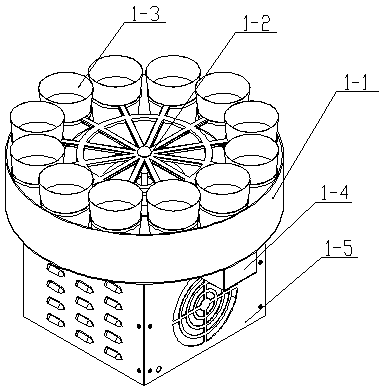

Pre-sowing seed separating device for plot breeding

ActiveCN105292530ARealize mechanical automatic packagingHigh measurement accuracySolid materialEngineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery and discloses a pre-sowing seed separating device for plot breeding. The pre-sowing seed separating device comprises a vibratory feeding device, a counting device and a separated packaging device. The vibratory feeding device and the counting device are installed on the upper surface of a machine frame, the discharge port of the vibratory feeding device is formed above the counting device, the separated packaging device is installed on one side of the machine frame, and the material outlet of the counting device is formed above the separated packaging device. The separated packaging device comprises a support, a round rail is arranged at the top end of the support, a tooth part is arranged in the round rail, a plurality of ring trays are uniformly distributed on the edge of the tooth part, and a material cup is arranged on each ring tray. According to the invention, through linkage of the vibratory feeding device, the counting device, the separated packaging device and an information code printing device, integrated line production of counting, weighing, packaging, code printing and the like of seeds is achieved, mechanical and automatic separated packaging is achieved in pre-sowing seed separation for plot breeding, and therefore the time and the labor are saved and the measuring accuracy of seed separation is greatly improved.

Owner:JIUQUAN OK SEED MACHINERY

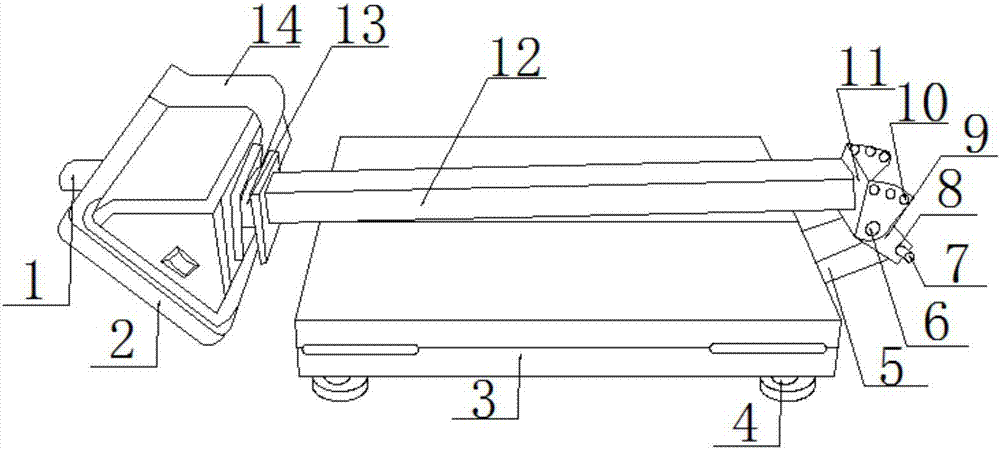

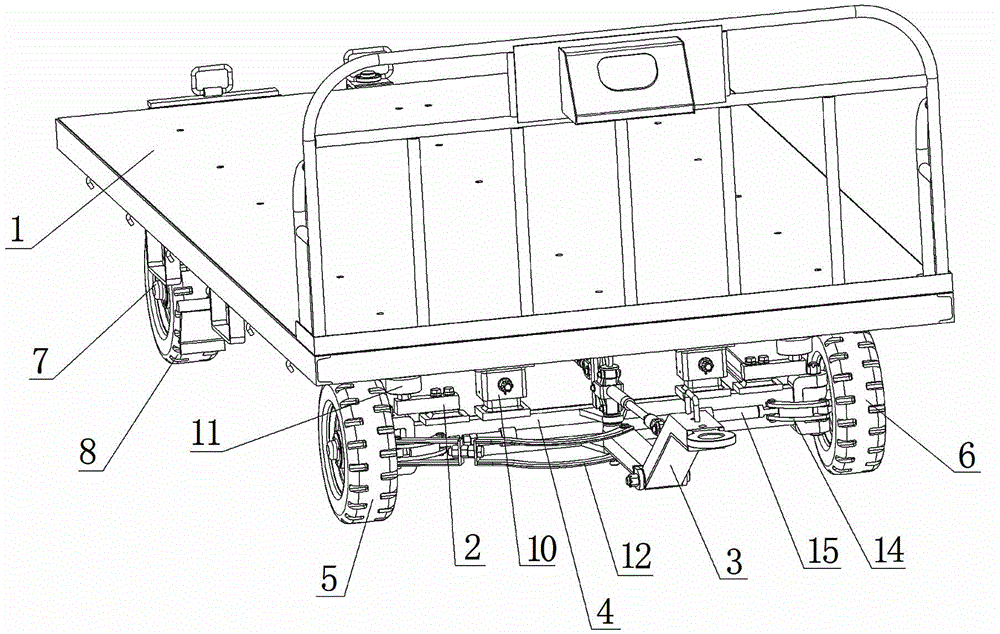

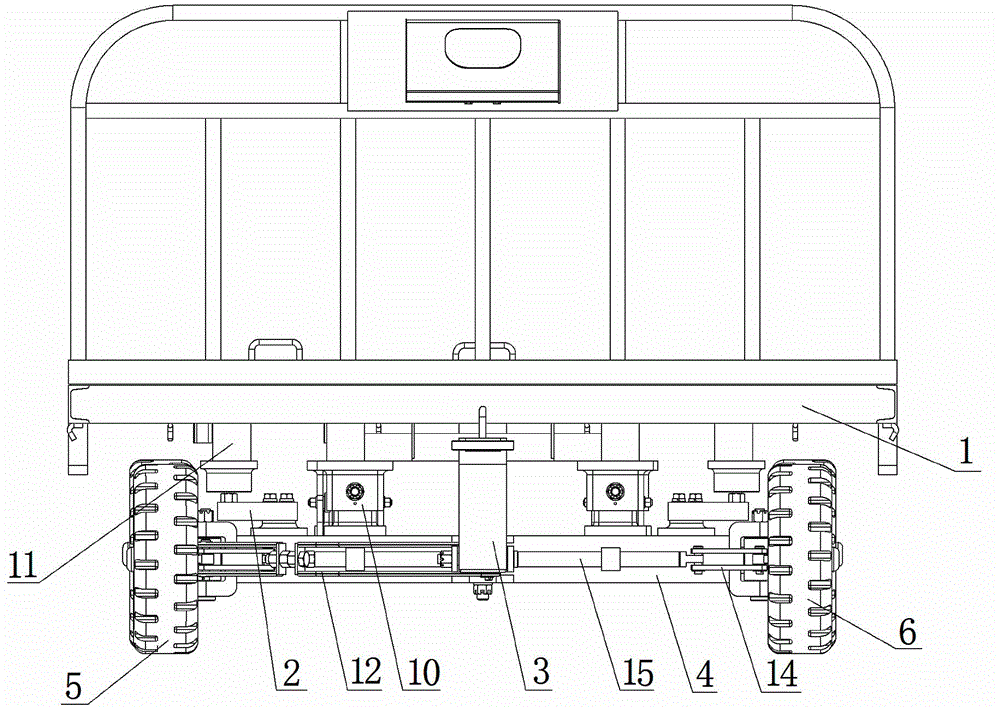

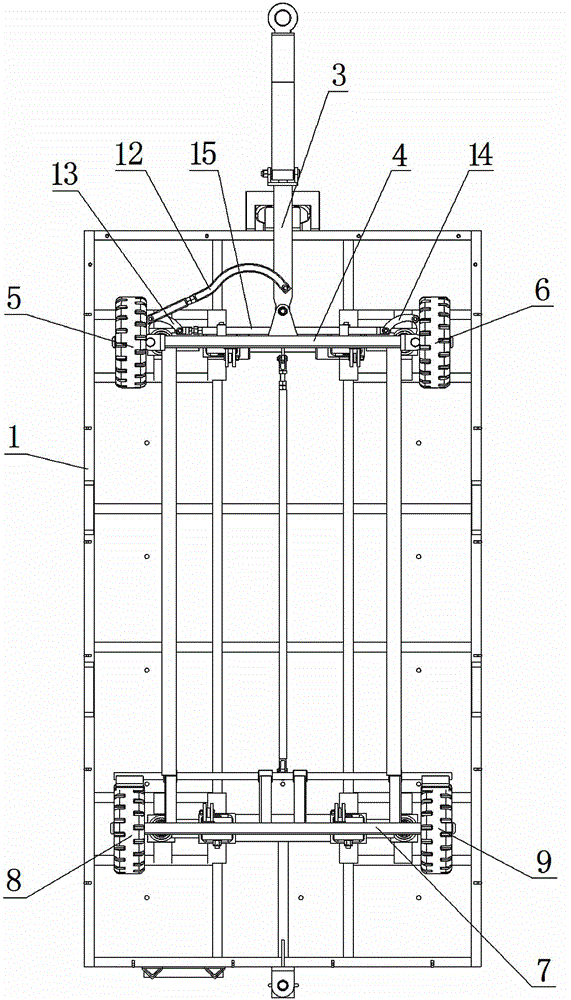

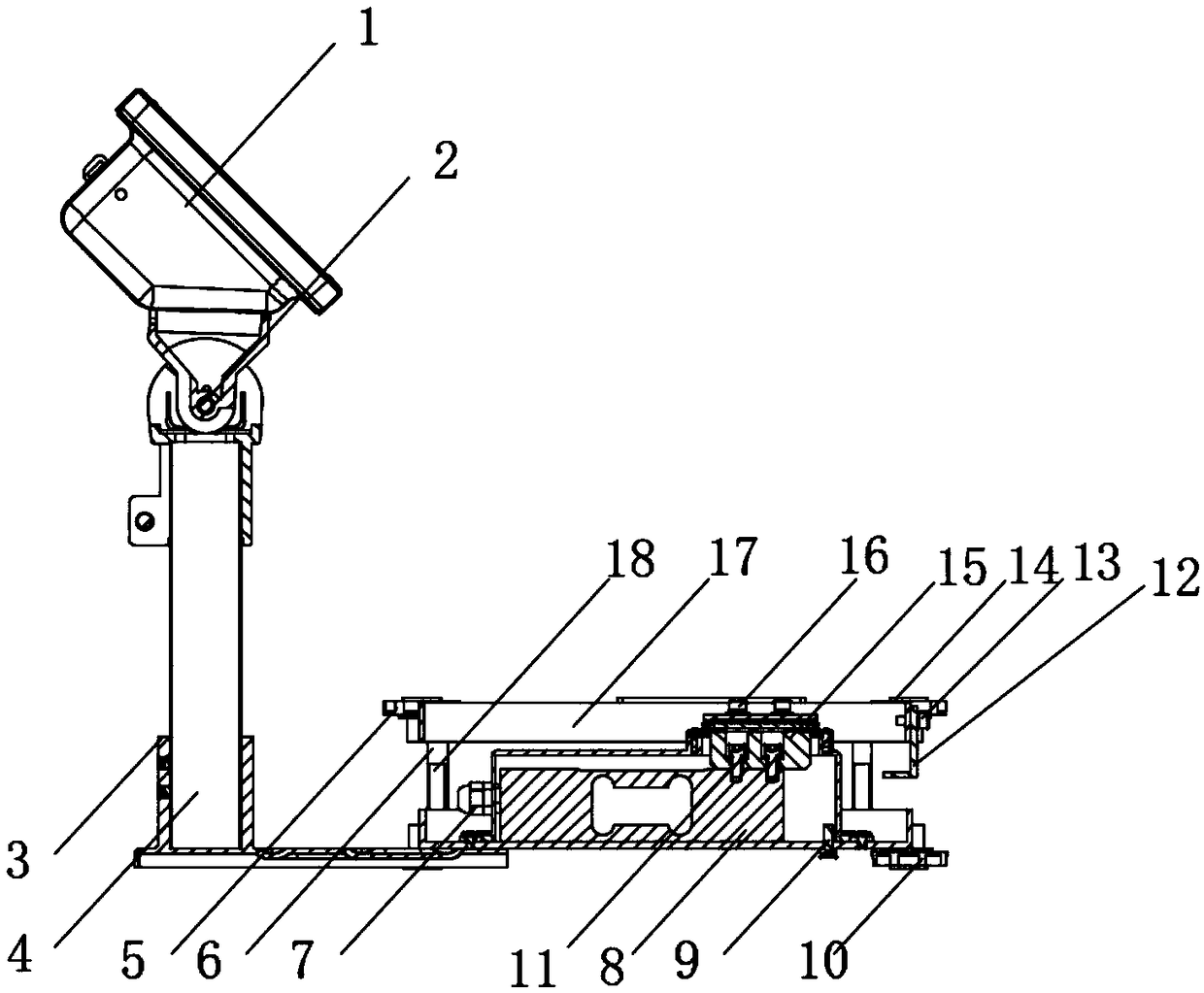

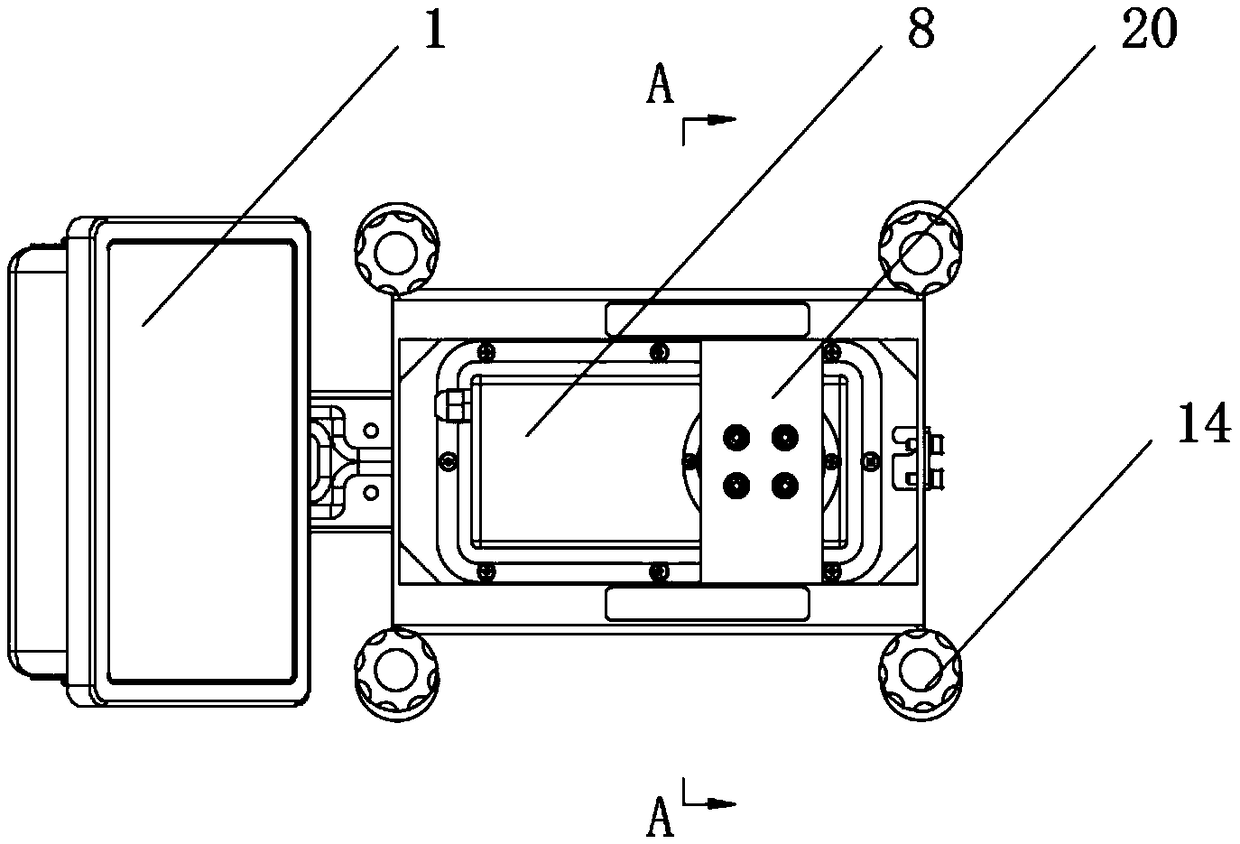

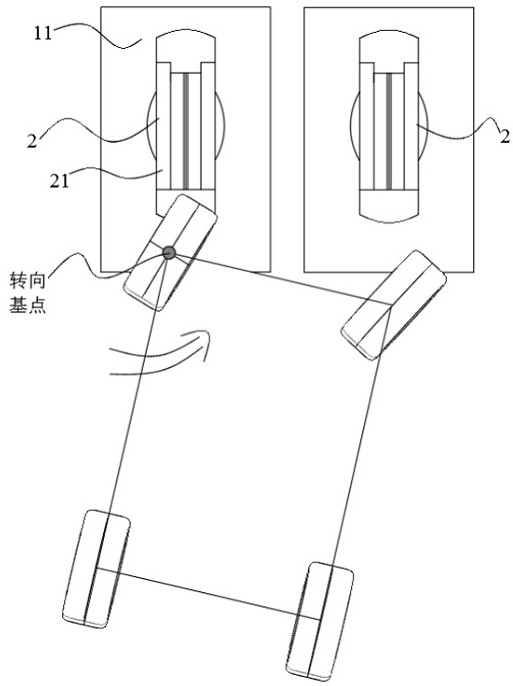

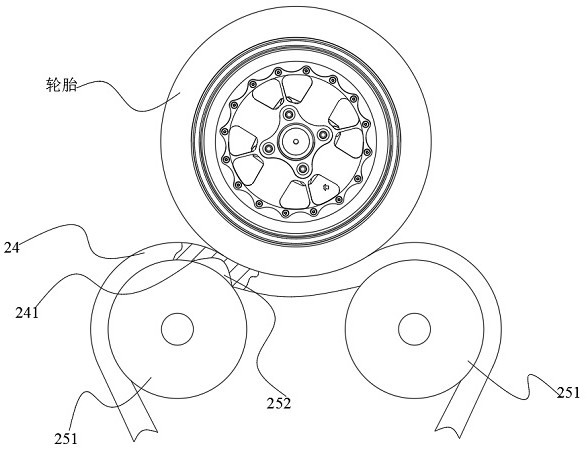

Moving type weighing platform trailer

ActiveCN104859692AAvoid weighing errorsEasy to dragHand carts with multiple axesHand cart accessoriesEngineeringPressure sensor

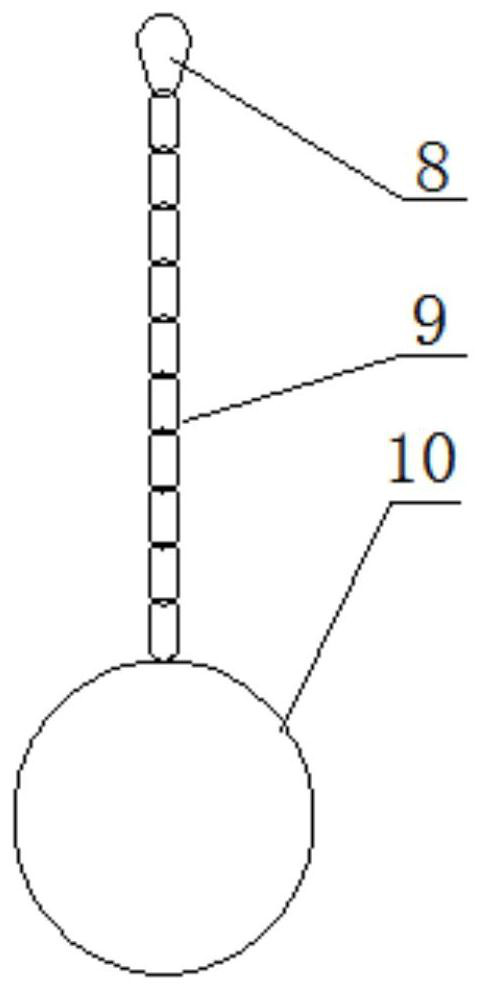

The invention discloses a moving type weighing platform trailer which comprises a trailer bottom plate (1), a steering mechanism, vertical guiders I (10), vertical guiders II (11), pressure sensors (2), a controller, a mop (3), as well as a front axle assembly and a rear axle assembly arranged below the trailer bottom plate (1), wherein the rear axle assembly is composed of a main shaft II (7), a rear left wheel (8) and a rear right wheel (9); the rear left wheel (8) and the rear right wheel (9) are mounted at two ends of the main shaft II (7) in a rotary manner; two pressure sensors (2) and two vertical guiders I (10) are arranged on the top surface of each of a main shaft I (4) and the main shaft II (7); the vertical guiders II (11) are arranged on the tops of the four pressure sensors (2); the four pressure sensors (2) are connected with the controller. The moving type weighing platform trailer has the following benefits: the weight of cargos and luggage can be accurately weighed when the platform trailer is in the moving state or on a slope, so that airport staff can conveniently drag the cargos or luggage.

Owner:MEISHAN DEXIN AVIATION EQUIP

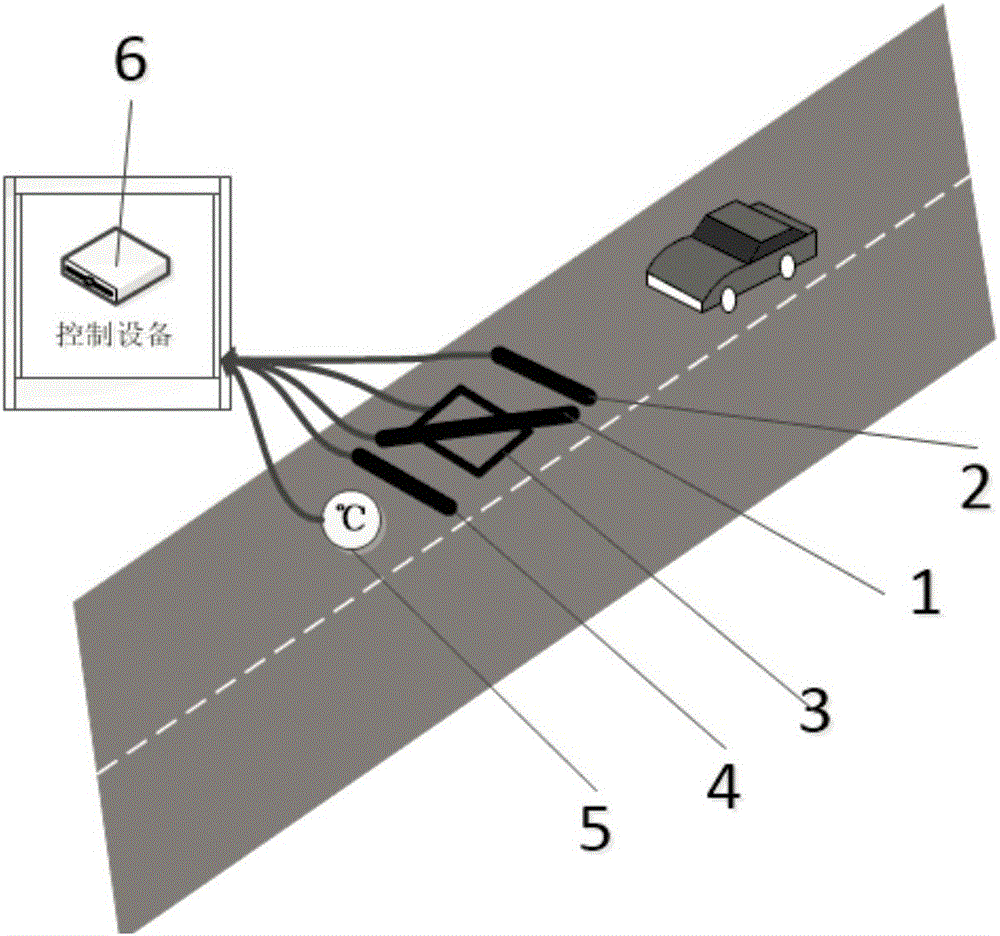

Vehicle weighing system

ActiveCN102538927AAvoid weighing errorsEasy to implementSpecial purpose weighing apparatusAutomotive engineeringDynamic balance

The invention discloses a vehicle weighing system which comprises two weighing sensors respectively arranged on a left half lane and a right half lane; the location area of a vehicle which passes through the lane can be detected by a position sensor arranged nearby the weighing sensors; correction factors are selected to correct the weight of the whole vehicle measured by the weighing sensors according to the different areas; and the vehicle weighing system solves the problem that the difference of the vehicle eccentric load area can not be well corrected in the existing design, so that the weighing error can be caused. The vehicle weighing system is simple in implementation way and installation, low in project difficulty and capable of meeting the dynamic balance technical regulation requirements with low cost.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

Special-purpose load weighing device of pig slaughter house

InactiveCN105300492AScientific and reasonable structureEasy to useWeighing apparatus for materials with special property/formTransducerEngineering

The present invention discloses a special-purpose load weighing device of a pig slaughter house. The special-purpose load weighing device comprises a memory, a controller, hand-pushing supports, a bearing base plate, bending force bearing plates, fences, safe protective doors, pressure transducers and bearing wheels. The fences are installed over the bearing base plate; the hand-pushing supports are disposed at the left side on the fences; the controller, hand holding rods, a battery pack and data interfaces are arranged on the hand-pushing supports; the memory is installed in the hand-pushing supports; the safe protective doors are installed at the front and the back of the fences and connected with the fences through the hinges; the right ends of the safe protective doors is provided with a fastening lock; the pressure transducers are installed in the bearing base plate; and the bending force bearing plates and the bearing wheels are arranged at the bottom of the bearing base plate. The special-purpose load weighing device of a pig slaughter house has scientific and reasonable structure, the bottom of the bearing base plate is provided with a groove, and bearing wheels are packed up at weight through electric power spring valves so that the damaging of the bearing wheels is avoided at weight.

Owner:CHONGQING MINGGAO FOOD CO LTD

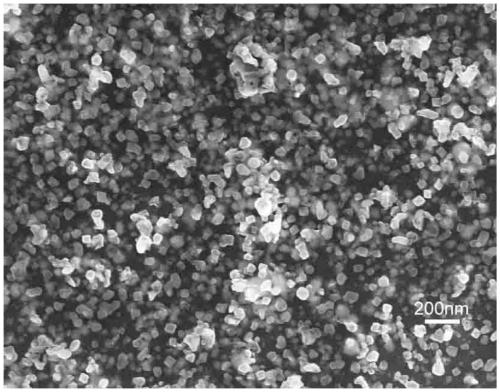

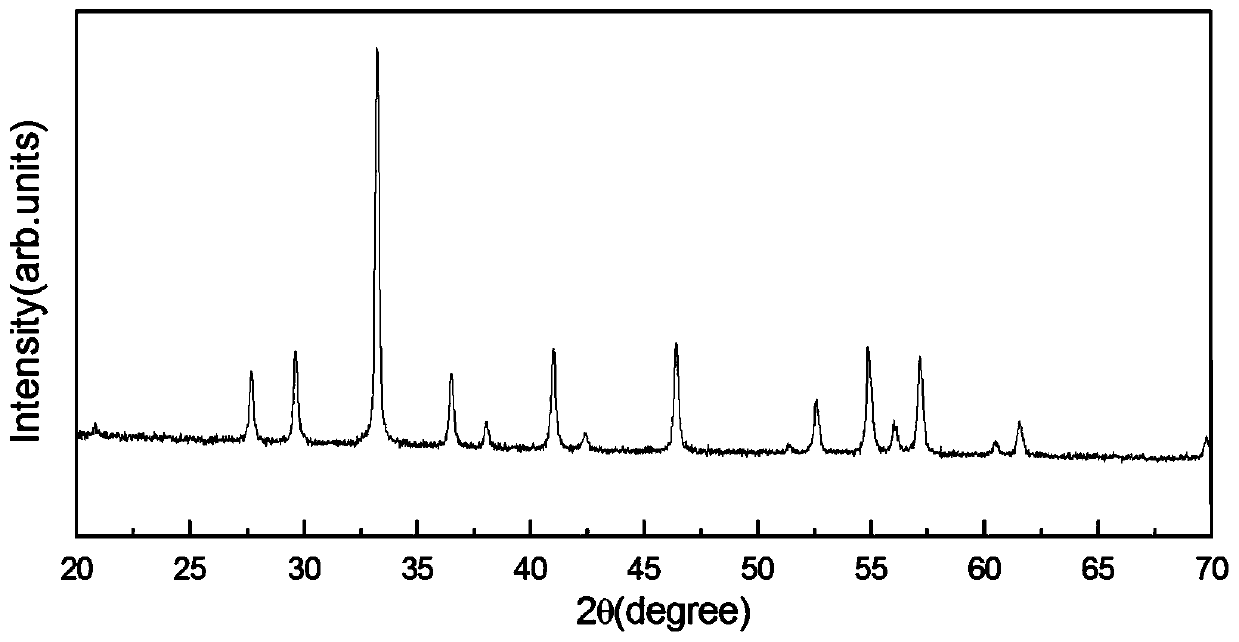

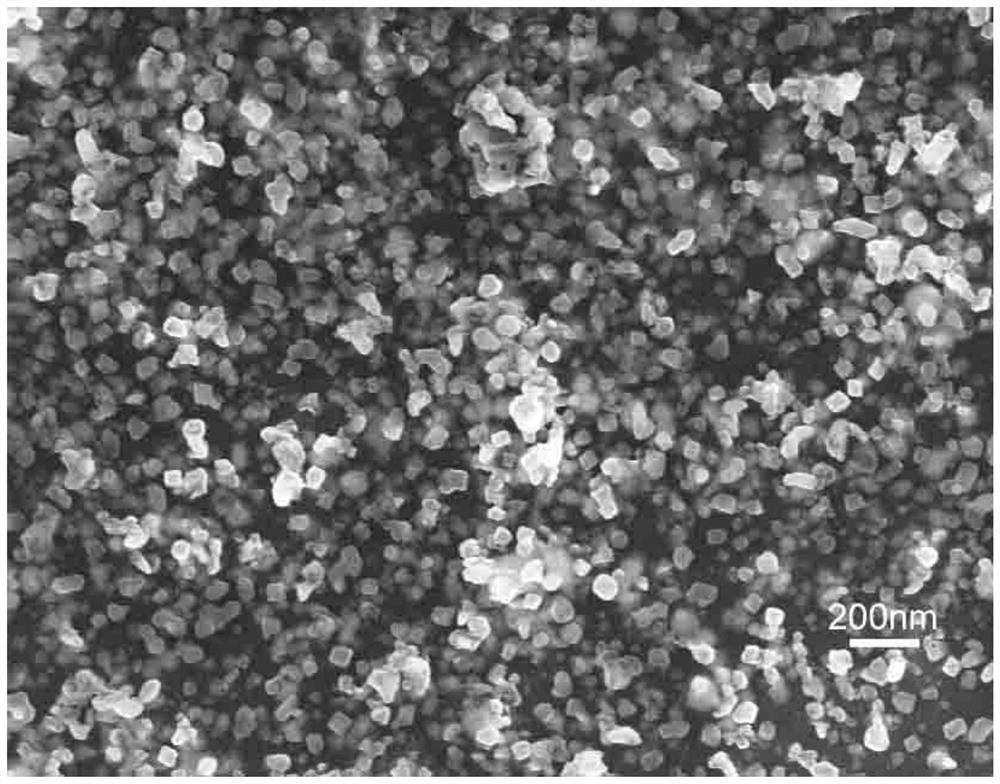

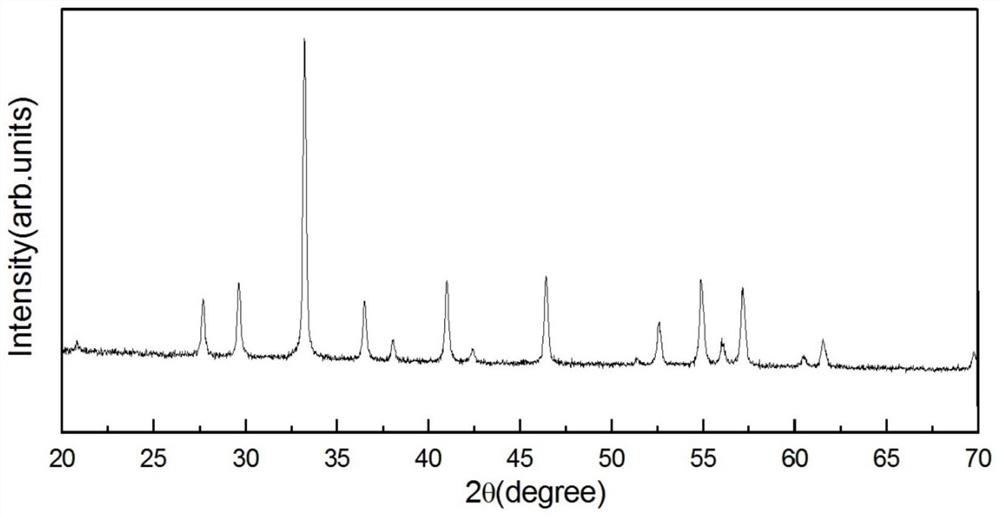

Method for preparing yttrium aluminum garnet powder

ActiveCN111574215AReduce consumptionReduce pollutionRare earth metal compoundsCrystallographyPhysical chemistry

The invention discloses a method for preparing yttrium aluminum garnet powder. The chemical formula of yttrium aluminum garnet is Y3Al5O12. The preparation method comprises the steps of solution preparation, precipitation, washing, mixing, hydrolysis, hydrothermal reaction, filtration, drying and calcination. The prepared yttrium aluminum garnet polycrystalline powder has the advantages of high purity, accurate stoichiometric ratio, uniform composition and uniform dispersion.

Owner:PUTIAN UNIV

Mechanical electronic scale chassis

InactiveCN109186732AGuaranteed comfortGuaranteed stabilityWeighing apparatus detailsEngineeringDisplay device

The invention discloses a mechanical electronic scale chassis, which comprises a display assembly. A main damping rotating shaft is embedded to the bottom of the display assembly; a first connecting shaft is sleeved to the bottom of the main damping rotating shaft; a first shaft sleeve is sleeved to the bottom of the first connecting shaft; an upper force-bearing truss is arranged on the outer part of one side of the first connecting shaft; a first fixed disc is arranged on one side of the upper force-bearing truss; a second fixed disc is arranged on the other side of the upper force-bearing truss; a main centering stud is sleeved in the middle of the second fixed disc; a first balance rod is arranged on one side of the upper force-bearing truss; and a second balance rod is sleeved to thetail end of the first balance rod. In the mechanical electronic scale chassis in the invention, a novel structure is used and a design of multiple sets of balance rods is adopted so that the whole electronic scale is ensured to be located at a horizontal position and the horizontal position of the electronic scale is avoided from deviation; meanwhile, multiple sets of limiting pins are adopted sothat inner components of the electronic scale can be ensured to be completely fixed, thereby avoiding moving and ensuring the accuracy of use of the electronic scale.

Owner:合肥昌燎科技有限公司

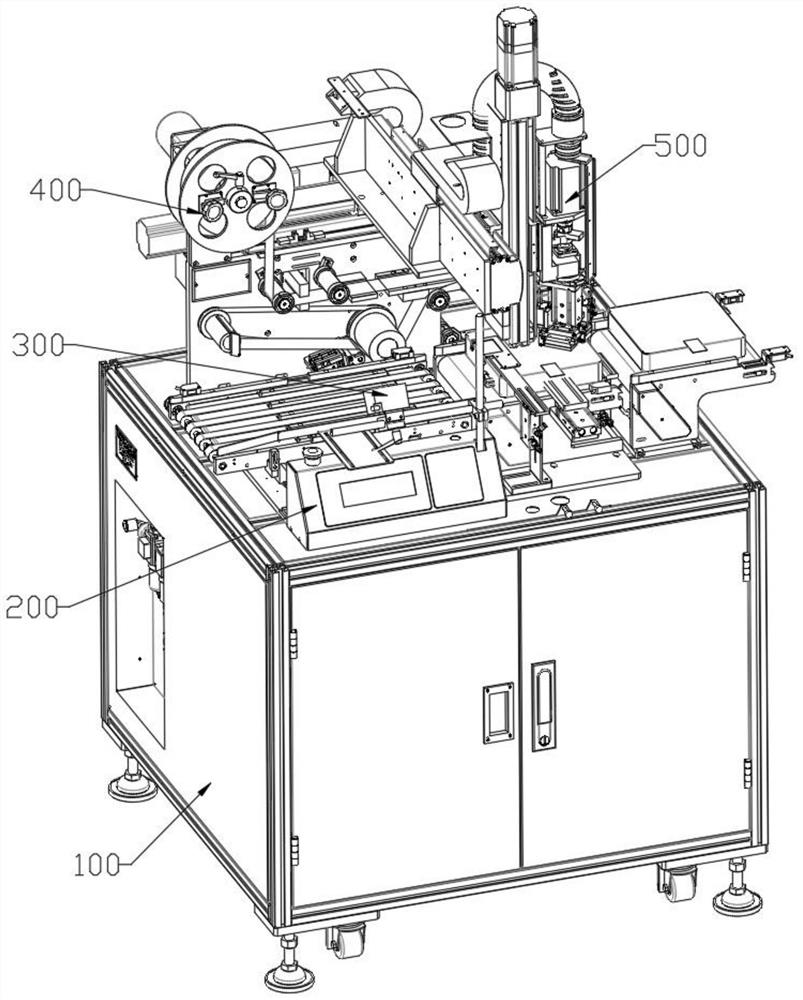

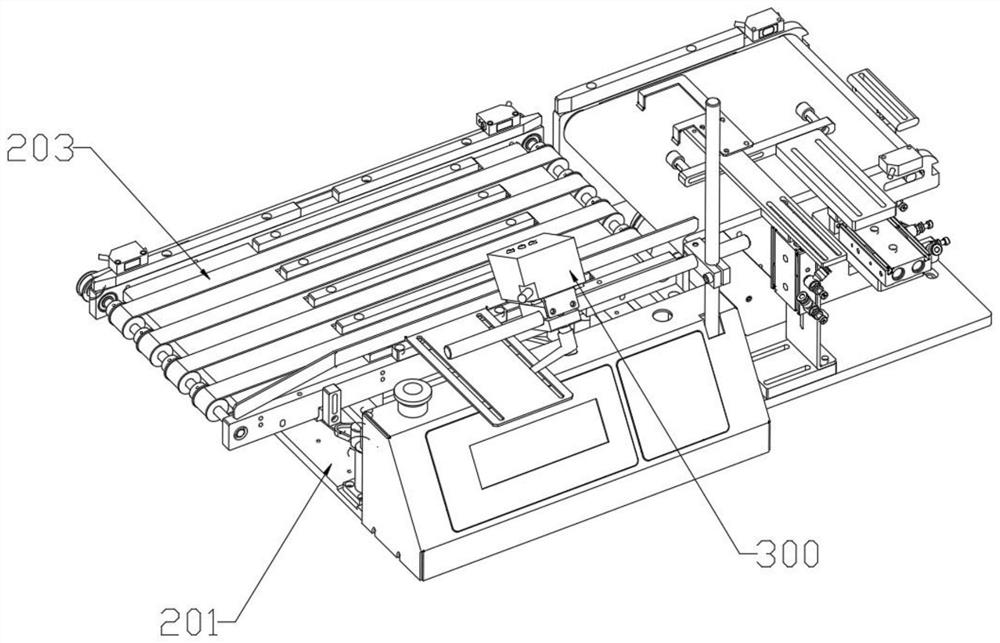

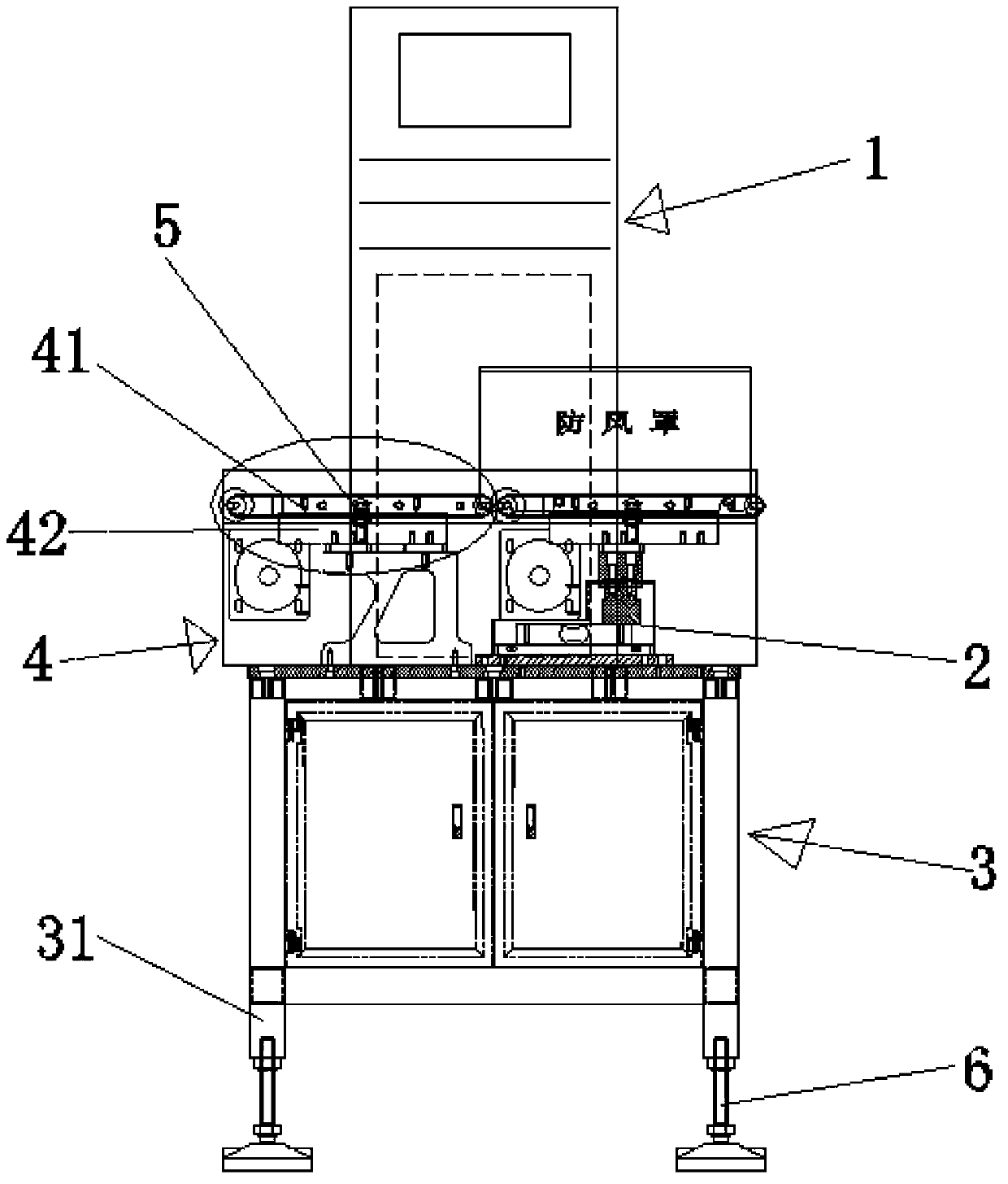

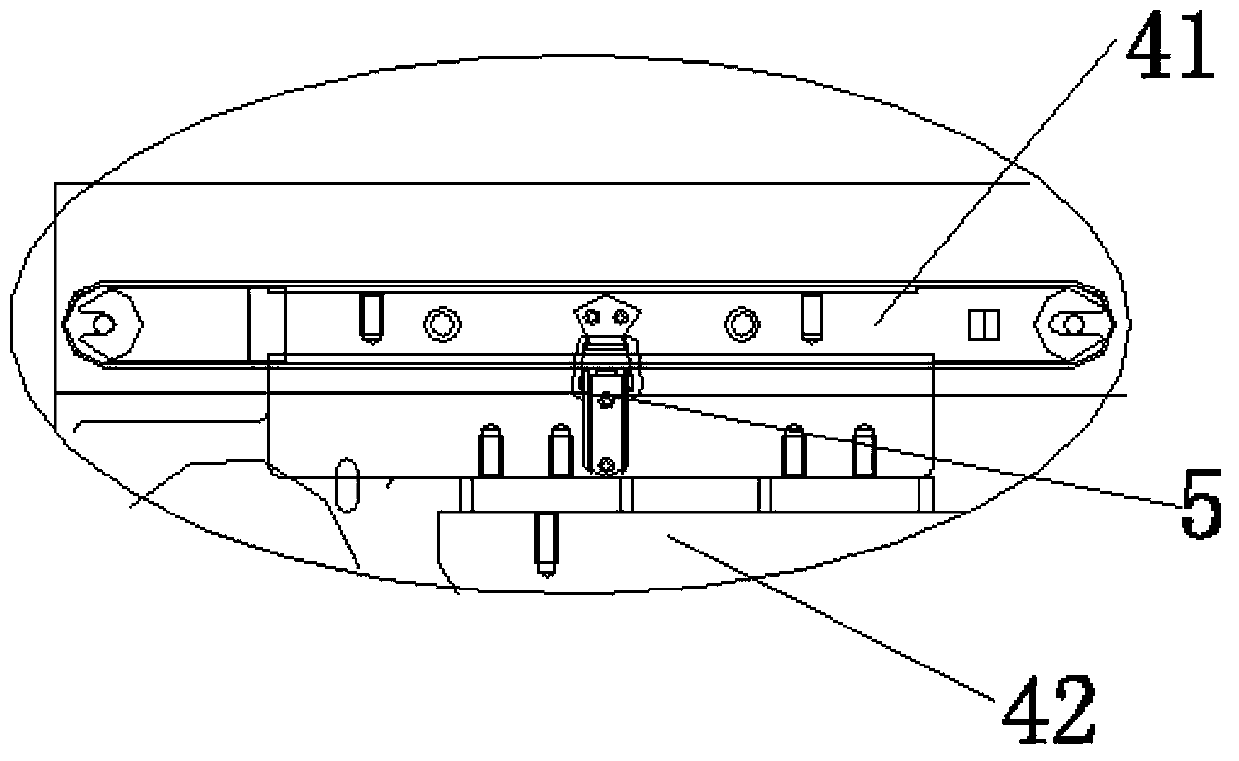

Automatic weighing, code scanning and labeling equipment

PendingCN112572940AImprove efficiencyImprove work efficiencySortingWeighing auxillary devicesProcess engineeringMechanical engineering

The invention discloses automatic weighing, code scanning and labeling equipment. The equipment comprises a rack, and a weighing mechanism, a code scanning mechanism, a label stripping mechanism, a labeling mechanism and a runner mechanism which are all arranged on the rack. The weighing mechanism comprises a weighing device and a weighing conveying belt arranged above the weighing device. The code scanning mechanism is arranged beside the weighing mechanism and is used for scanning codes of boxes with qualified weights and uploading information; the label stripping mechanism is arranged beside the weighing mechanism and is used for separating labels in a label material belt; the labeling mechanism comprises a moving module, a labeling assembly arranged on the moving module, and a protection assembly arranged between the moving module and the labeling assembly, and is used for pasting a label separated from the label stripping mechanism on a box; and the automatic weighing, code scanning and labeling device can automatically perform weighing, code scanning and labeling, and has the advantages of high working efficiency and high accuracy compared with a conventional manual manner.

Owner:东莞长城开发科技有限公司

Platform-surface-quickly-detachable high-precision automatic checkweigher

InactiveCN103630218AQuick releaseImprove parallelismWeighing apparatus with automatic feed/dischargeEngineeringLoad cell

Owner:KUNSHAN LIGU WEIGHING IND

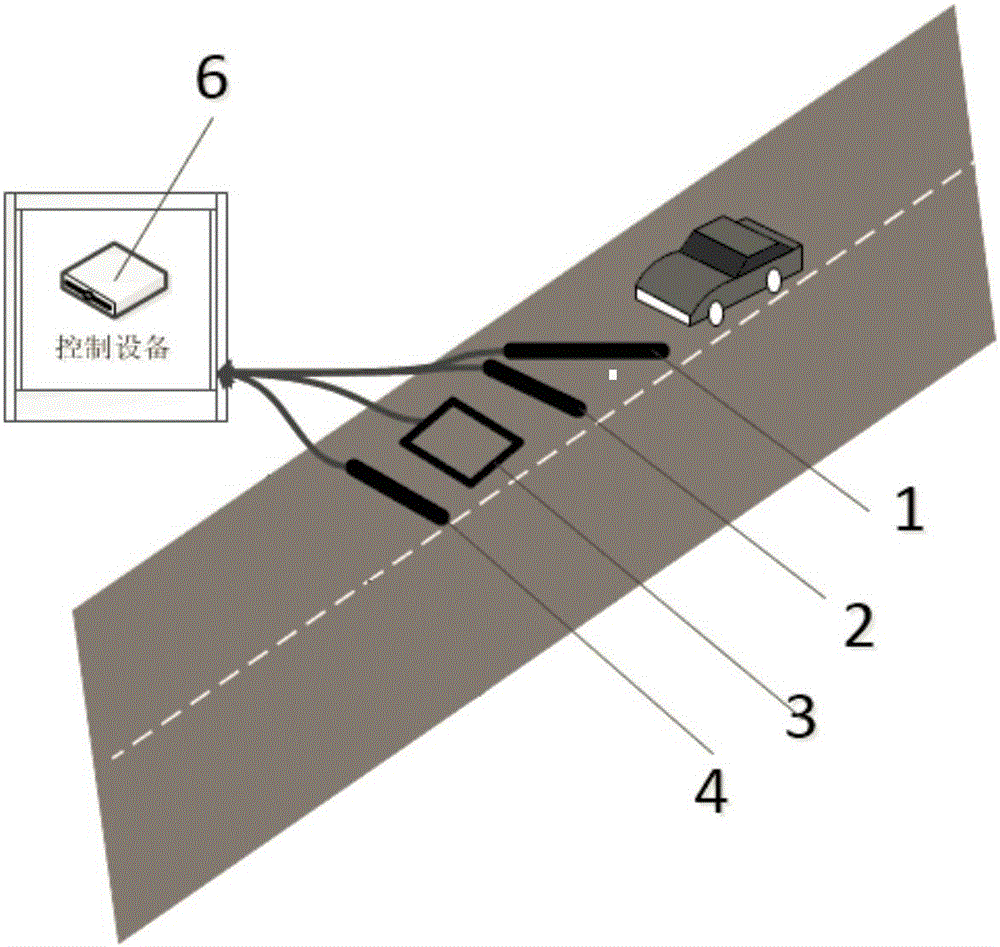

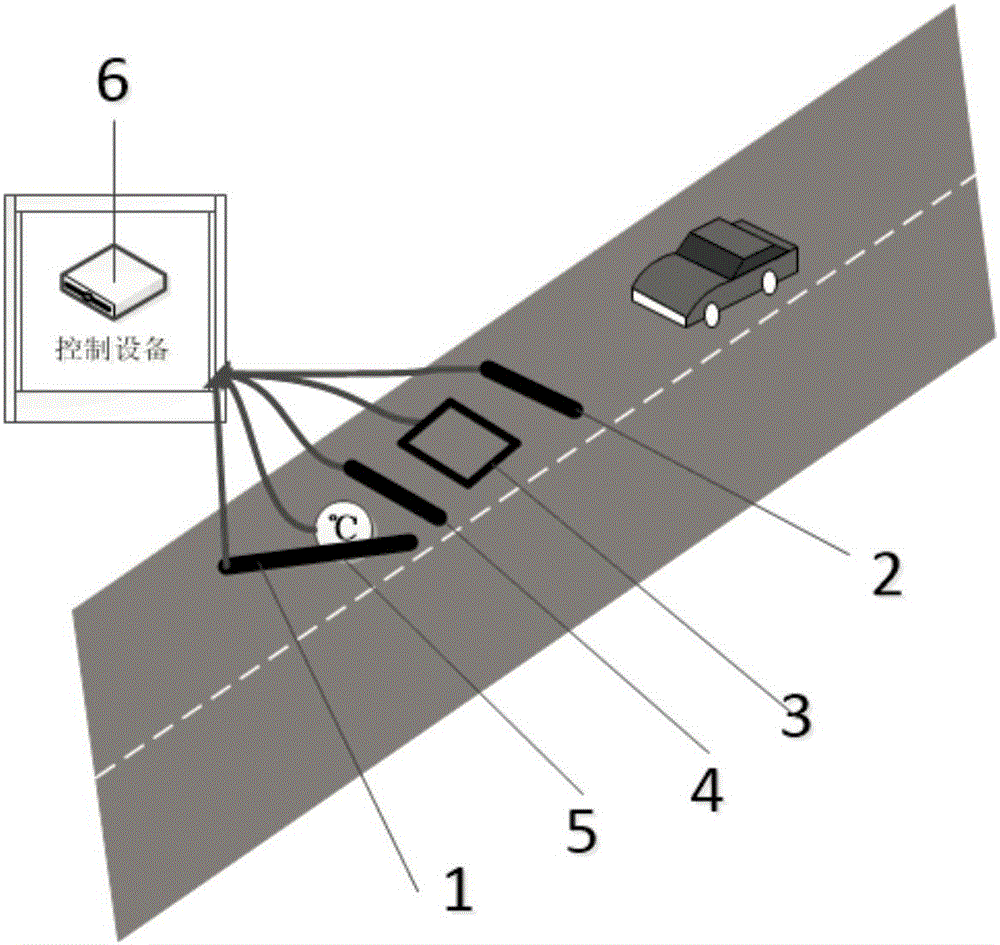

Diagonal axis type dynamic weight measurement system and diagonal axis type dynamic weight measurement method

InactiveCN106644007AEasy to correctHigh precisionWeighing apparatus testing/calibrationSpecial purpose weighing apparatusEngineeringTruck

The invention provides a diagonal axis type dynamic weight measurement system and a diagonal axis type dynamic weight measurement method. The system comprises a diagonal piezoelectric axis, a driving-in speed piezoelectric axis and a driving-out speed piezoelectric axis which are arranged in a weight measurement area, and a control device which is connected with the diagonal piezoelectric axis, the driving-in piezoelectric axis and the driving-out speed piezoelectric axis. The control device calculates the weight of a truck according to electrical signals output by the diagonal piezoelectric axis, the driving-in piezoelectric axis and the driving-out speed piezoelectric axis, and displays the weight of the truck. The method comprises the following steps: the time difference is calculated according to two voltage curve peaks obtained when the two front wheels of a truck in a measurement area drive into the driving-in speed piezoelectric axis and the driving-out speed piezoelectric axis, and the speed of the truck is determined; the positions of the wheels are calculated according to the time difference between the two peaks of the front wheels obtained when the two front wheels drive into the diagonal piezoelectric axis; and the control device establishes a relevant database based on the peak area, truck speed, wheel position and ambient temperature obtained through integration of the voltage curve peaks acquired by the two front wheels, the driving-in speed piezoelectric axis and the driving-out speed piezoelectric axis, and a voltage curve is calculated and corrected to get the weight of the truck. The system and the method are used in traffic overweight detection and industrial park anti-theft detection.

Owner:辉因科技(北京)有限公司

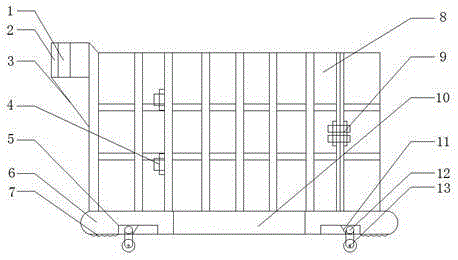

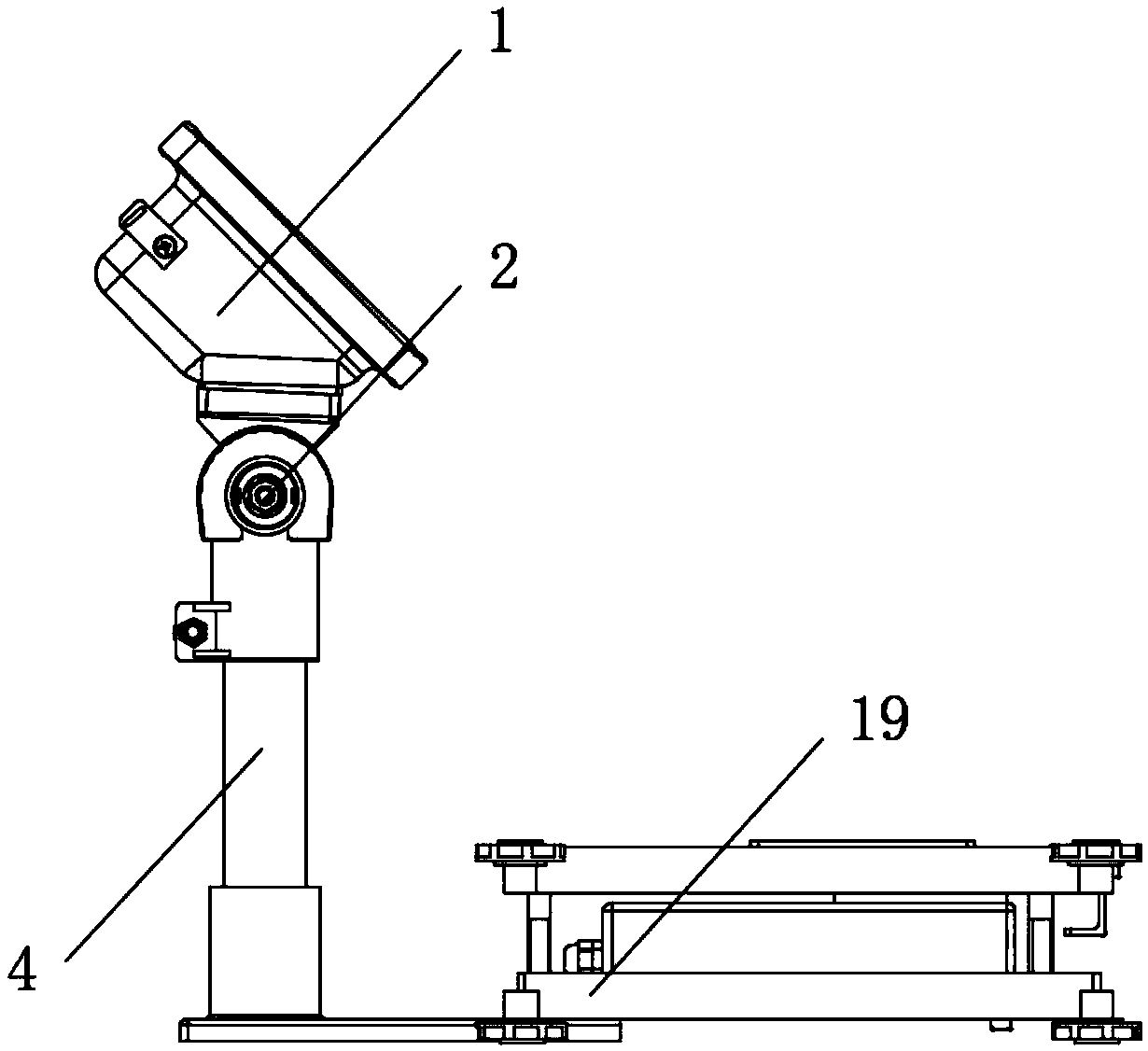

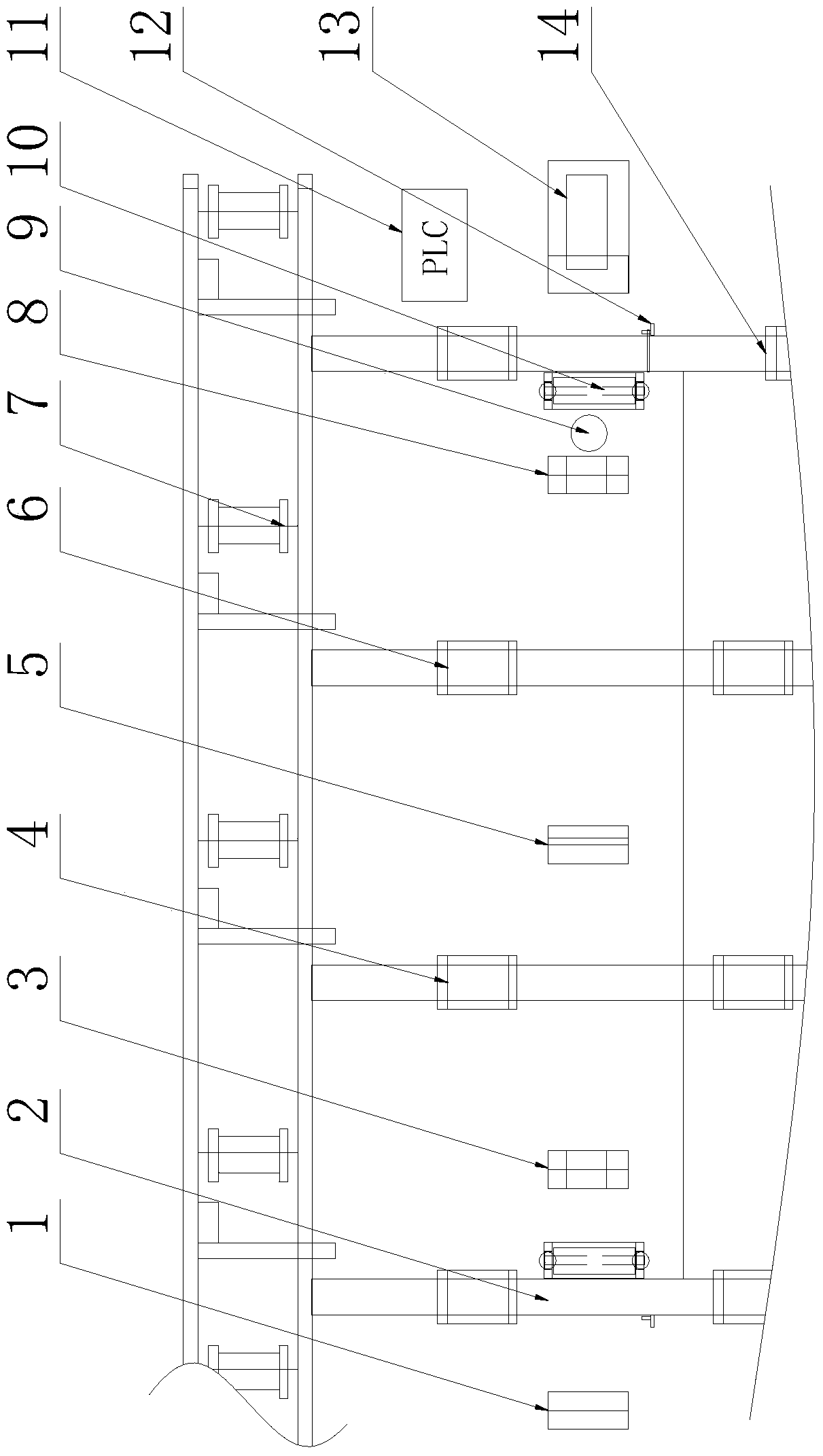

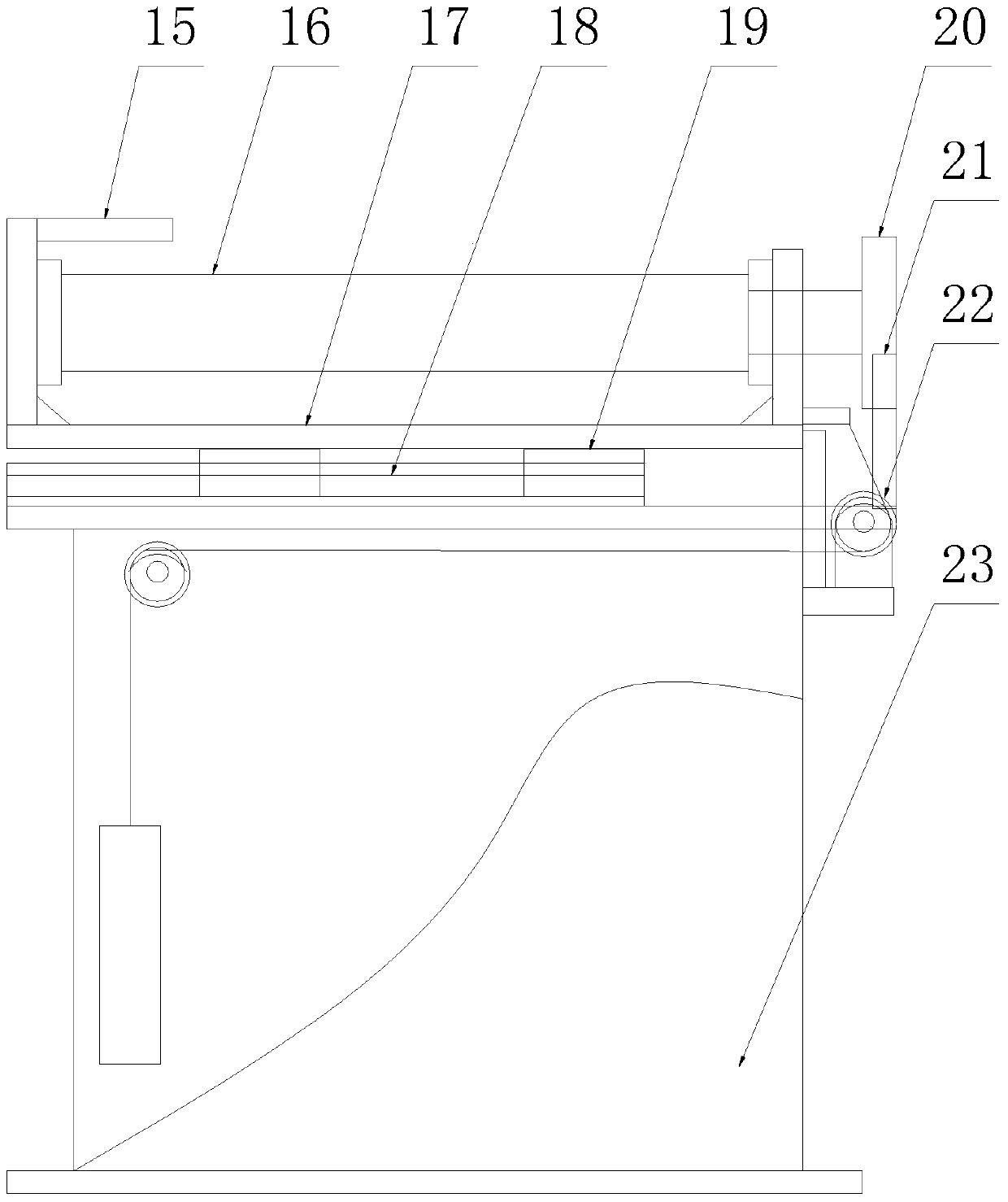

An automatic length measuring and weighing system for high frequency welded pipe

ActiveCN104990506BImprove efficiencySave human effortUsing optical meansWeighing apparatus for materials with special property/formSystems designSemi automatic

The invention belongs to the technical field of high-frequency welded pipe processing, and relates to an automatic length measurement and weighing system for high-frequency welded pipes. The device is fixed on the cooling bed frame, a part of the longitudinal positioning device is relatively fixed on the ground on both sides of the cooling bed frame, and a part is symmetrically fixed on the cooling bed frame, the length measuring device is fixed on the longitudinal positioning device, and the weighing device Relatively fixed on the ground inside the cooling bed frame, one part of the control device is arranged inside the cooling bed frame, and the other part is arranged outside the cooling bed frame and is respectively connected with the longitudinal positioning device, the length measuring device and the weighing device. The high-frequency welded pipe automatic length measurement and weighing system has a scientific and reasonable structure design, adopts semi-automatic control, and can measure and weigh the steel pipe online. It has the advantages of saving manpower, high speed, high efficiency, and high safety. Convenient, accurate measurement and other advantages, with high innovation.

Owner:TIANJIN UNITED STEEL PIPE

A kind of method for preparing yttrium aluminum garnet powder

ActiveCN111574215BReduce consumptionReduce pollutionRare earth metal compoundsPhysical chemistryHydrolysis

The invention discloses a method for preparing yttrium aluminum garnet powder, the chemical formula of the yttrium aluminum garnet is Y 3 Al 5 o 12 ; The preparation method includes solution preparation, precipitation, washing, mixing, hydrolysis, hydrothermal reaction, filtration, drying and calcination. The yttrium aluminum garnet polycrystalline powder prepared by the invention has the advantages of high purity, precise stoichiometric ratio, uniform components and uniform dispersion.

Owner:PUTIAN UNIV

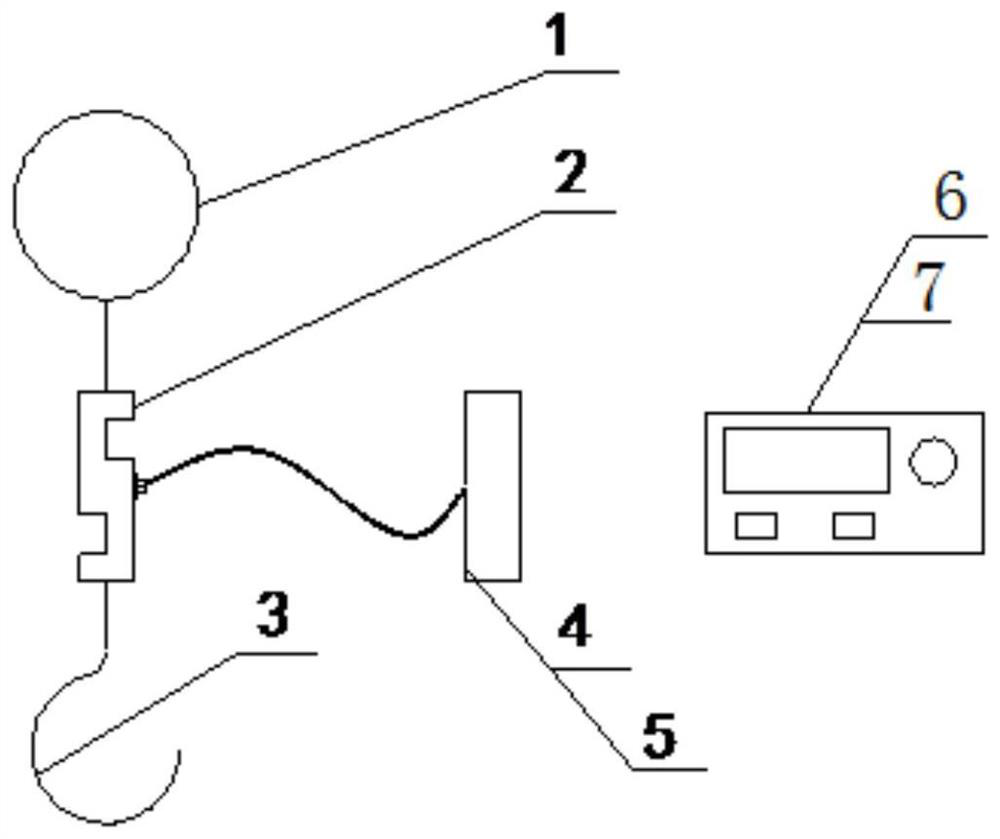

Instrument with placing hanger

InactiveCN113959544AWill not affect the weighing effectAvoid weighing errorsWeighing apparatus for materials with special property/formWeighing auxillary devicesEngineeringGravity center

The invention discloses an instrument with a placing hanger, and relates to the technical field of instruments. The instrument with the placing hanger comprises a scale body, the top of the scale body is provided with a display screen and a weighing tray, the cross section of the weighing tray is square, and the top of the weighing tray is provided with a placing hanger body. According to the instrument with the placing hanger, a plastic bag containing liquid can be fixed by arranging the hooks, so that the plastic bag containing the liquid can be stably stored at the top of the weighing tray, meanwhile, solid objects can be placed at the top of the weighing tray, and the weighing effect on other objects cannot be affected; the four hooks can measure a plurality of to-be-measured products at the same time, the measuring efficiency is improved, the universal connecting shafts are arranged, the positions of the hooks can be adjusted according to the weights of the to-be-measured products, the gravity centers of the to-be-measured products are made to be located on the central axis of the weighing tray all the time, and therefore weighing errors caused by position deviation of the to-be-measured products are prevented.

Owner:黄冰莹

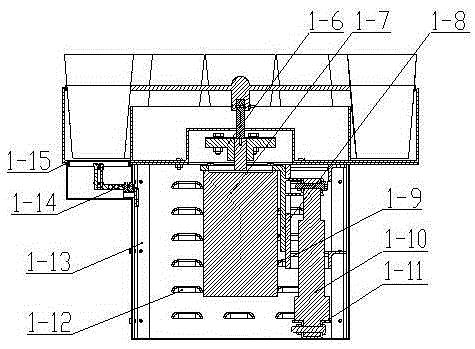

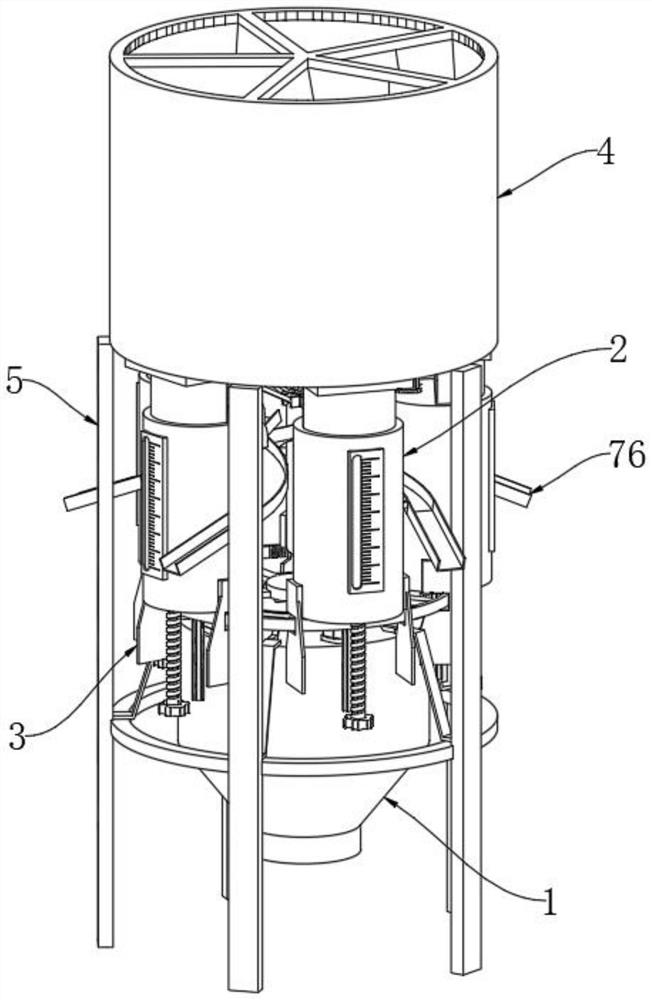

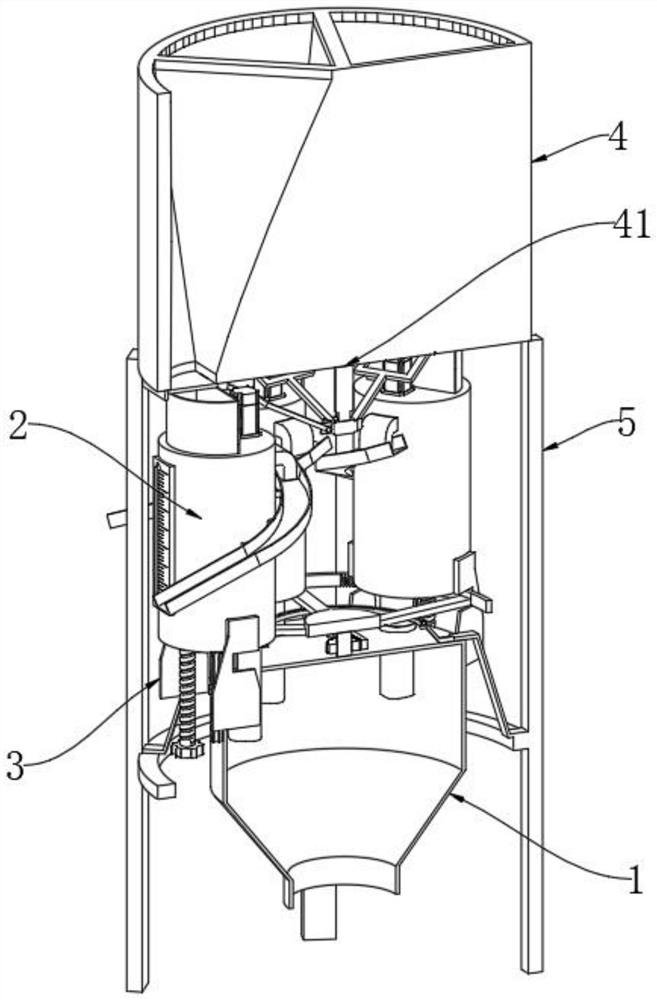

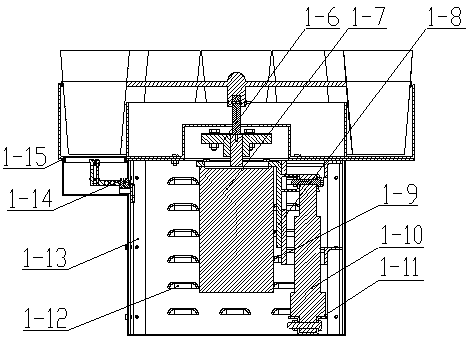

Melting furnace feeding device with automation function

The invention relates to the technical field of feeding devices, in particular to a melting furnace feeding device with an automation function, which comprises a discharging box, and a discharging port is formed in the bottom of the discharging box; the five groups of material distribution boxes are arranged, and the five groups of material distribution boxes are annularly arranged at the top of the discharging box; the material storage box is arranged above the discharging box, and a material storage cavity corresponding to the material distribution box is formed in the material storage box; and the quantity control assembly is arranged in the material distribution box, so that the metal raw materials in the material distribution box are subjected to different proportions through the quantity control assembly. According to the feeding device, the problems that five metal raw materials need to be weighed in proportion during iron core machining, the operation is tedious, weighing errors are prone to being generated, and in addition, when an existing feeding device is used, the metal raw materials still fall from a material opening, and consequently machined iron cores are unqualified are effectively solved.

Owner:南京梦和电子科技有限公司

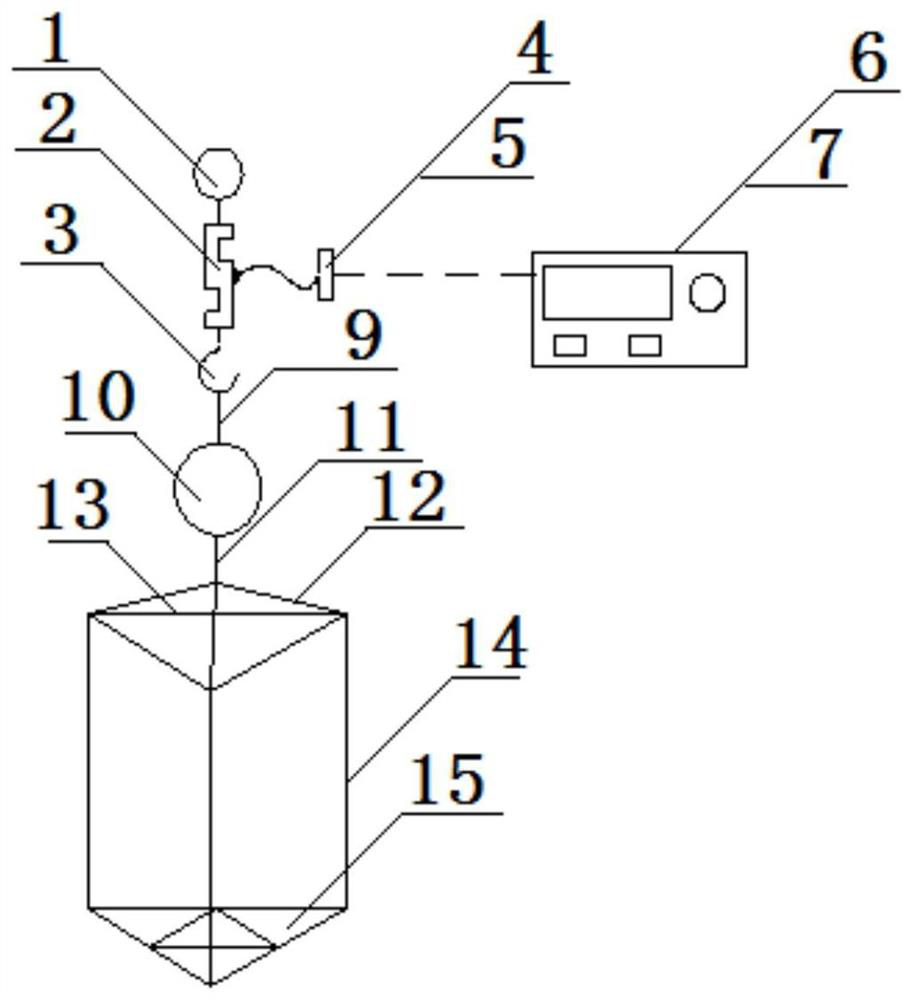

Photovoltaic glass raw material weighing device and method

PendingCN113790782AAvoid weighing errorsPrevent leakageWeighing apparatus testing/calibrationWeighing apparatus for materials with special property/formManufacturing engineeringMaterials science

The invention provides a photovoltaic glass raw material weighing device and method. The photovoltaic glass raw material weighing device comprises: a material weighing cylinder, which is used for pre-loading a photovoltaic glass raw material to be weighed; a detection assembly, which is mounted on the wall of the material weighing cylinder and used for detecting the weight of the photovoltaic glass raw material to be weighed in the material weighing cylinder; and a correcting and weighing assembly, which comprises a hanging piece extending in a gravity direction, wherein the upper end of the hanging piece is connected to the wall of the material weighing cylinder, the lower end of the hanging piece is used for hanging a weight, and the detection assembly is further used for detecting the weight of the weight so as to judge an error range of the weight of the photovoltaic glass raw material to be weighed according to weight of the weight. According to the device and the method, the to-be-weighed photovoltaic glass raw material which is weighed for the first time can be precisely rechecked for the second time, various conditions such as weighing errors, material leakage, excessive material discharge, less material discharge and wrong material distribution can be effectively avoided, a material distribution period is shortened, and normal maintenance and repair of the device are facilitated.

Owner:信义光伏(苏州)有限公司

A pre-sowing seed divider for plot breeding

ActiveCN105292530BRealize mechanical automatic packagingHigh measurement accuracySolid materialEngineeringAgricultural machinery

The invention relates to the technical field of agricultural machinery and discloses a pre-sowing seed separating device for plot breeding. The pre-sowing seed separating device comprises a vibratory feeding device, a counting device and a separated packaging device. The vibratory feeding device and the counting device are installed on the upper surface of a machine frame, the discharge port of the vibratory feeding device is formed above the counting device, the separated packaging device is installed on one side of the machine frame, and the material outlet of the counting device is formed above the separated packaging device. The separated packaging device comprises a support, a round rail is arranged at the top end of the support, a tooth part is arranged in the round rail, a plurality of ring trays are uniformly distributed on the edge of the tooth part, and a material cup is arranged on each ring tray. According to the invention, through linkage of the vibratory feeding device, the counting device, the separated packaging device and an information code printing device, integrated line production of counting, weighing, packaging, code printing and the like of seeds is achieved, mechanical and automatic separated packaging is achieved in pre-sowing seed separation for plot breeding, and therefore the time and the labor are saved and the measuring accuracy of seed separation is greatly improved.

Owner:JIUQUAN OK SEED MACHINERY

Material weighing and feeding device for metal working fluid production

The invention relates to a material weighing and feeding device for metal working fluid production, which comprises an electronic platform scale, a raw material pump, a pipeline and the like. The electronic platform scale, a one-way valve and the raw material pump are respectively connected with a control electric box, and the control electric box is connected with an external power supply. A groove is arranged on the electronic platform scale, a raw material barrel is arranged in the groove, and a material pumping pipe is placed in the raw material barrel. A subtraction feeding method is adopted, material weighing and feeding equipment is additionally arranged, transformation of old equipment is omitted, the production process is simplified, labor is saved, and the working efficiency is improved. The one-way valve is installed on the material pumping pipe, when feeding is stopped, raw materials in the material pumping pipe cannot flow back into the raw material barrel, the raw materials remaining in the pipeline are counted in the feeding amount due to subtraction, the raw materials can be jacked into a stirring kettle when a next raw material is weighed, and due to the fact that all the raw materials are raw materials for producing machining liquid, even if the materials are mixed, the problem of pollution of the material pumping pipeline does not exist.

Owner:TIANJIN RUNJIE INNOVATION ENVIRONMENTAL PROTECTION TECH

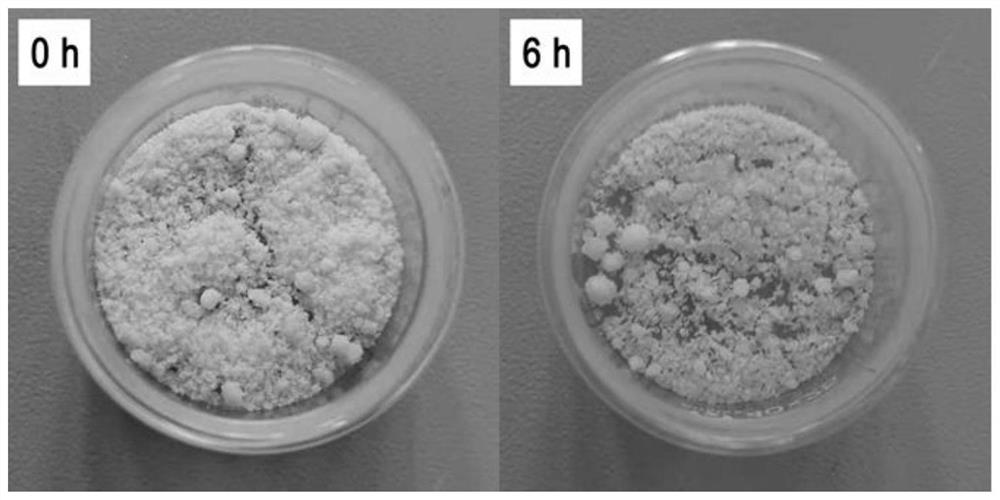

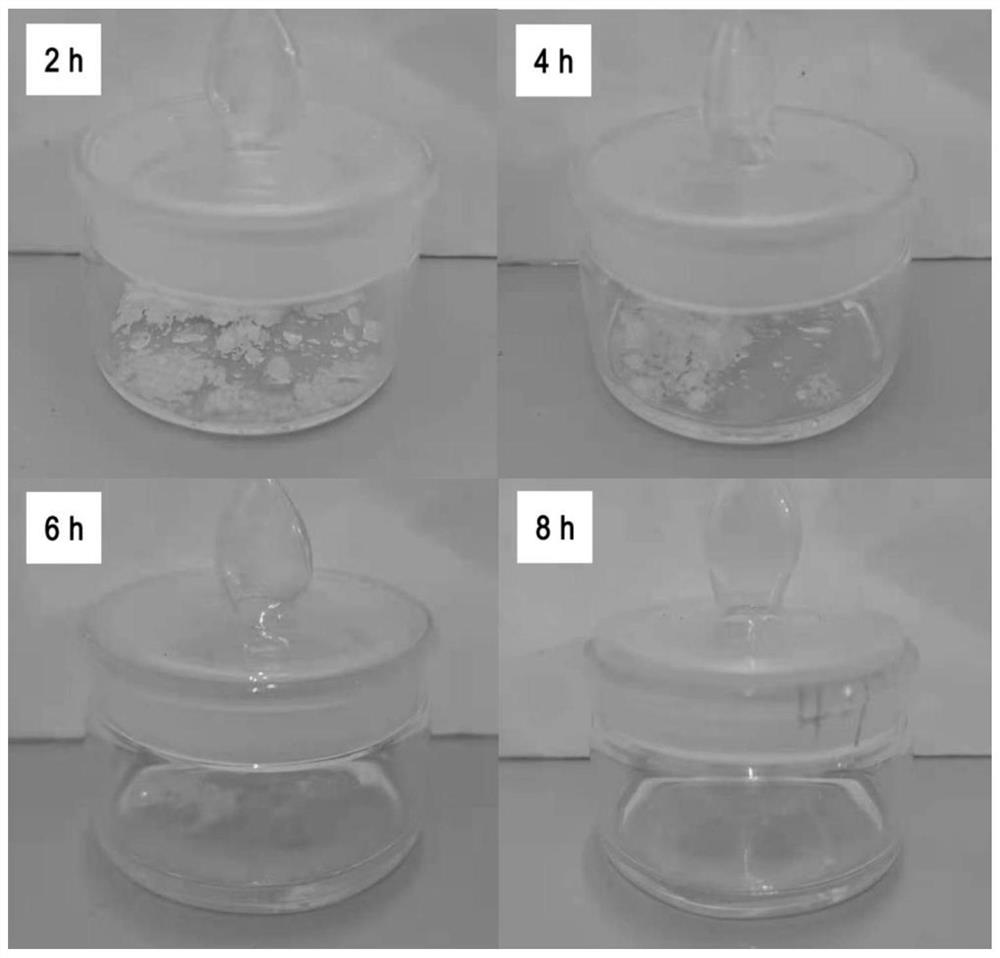

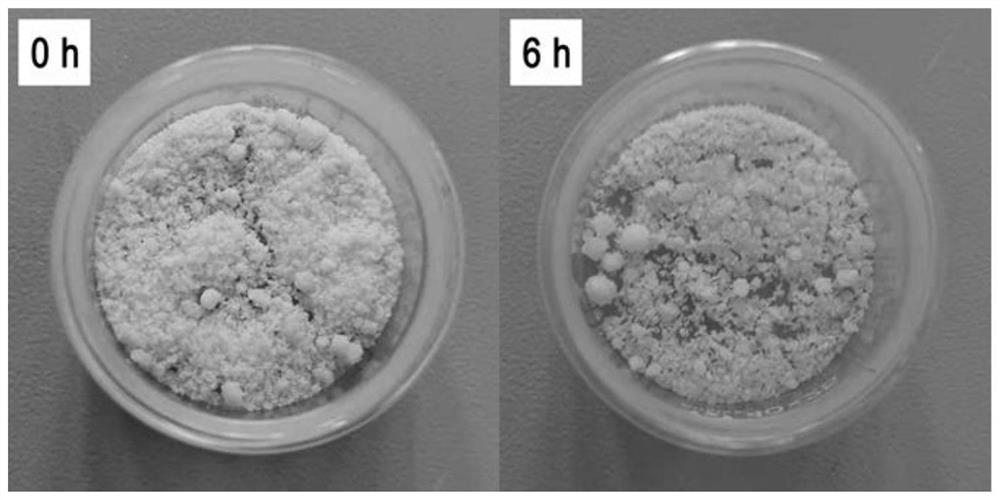

Method for testing hygroscopicity of 3,4-dinitropyrazole

PendingCN113959889AAccurate dataSimple and fast operationChemical analysis using titrationWeighing by absorbing componentMoisture absorptionDrying time

The invention provides a method for testing hygroscopicity of 3,4-dinitropyrazole, which comprises the following steps: drying a 3,4-dinitropyrazole sample to constant weight under a vacuum condition; sampling and measuring the water content of the sample dried in the step 1, and when the mass fraction of water in the sample is greater than 0.02%, continuously drying the sample until the mass fraction of water is less than or equal to 0.02%; sampling the material, carrying out a hygroscopicity experiment under the condition of constant temperature and humidity, and recording the mass and moisture absorption rate of the sample after moisture absorption. The method for testing hygroscopicity of 3,4-dinitropyrazole has the advantages of accurate data and simplicity and convenience in operation. For example, in drying process, the drying time is determined by determining the overall constant weight of a sample in the conventional method, and the specific water content is obtained by titrating a small amount of sample by using a water titrator, so that weighing errors caused by the temperature of the sample are avoided, and meanwhile, specific data of the drying degree of the sample can be obtained.

Owner:ZHONGBEI UNIV +1

Stress and piezoelectric combined weighing device with abnormal driving correction

ActiveCN113295250AAvoid weighing errorsPrevent rolloverWeighing apparatus testing/calibrationSpecial purpose weighing apparatusStructural engineeringSprocket

The invention discloses a stress and piezoelectric combined weighing device with abnormal driving correction, which comprises a frame assembly, a guide device, a correction device, a detection device and a power device, wherein the frame assembly is installed in a roadbed, the frame assembly is movably connected with the guide device, the guide device is connected with the correction device, and the correction device is movably connected with the detection device; the power device is connected with the frame assembly, the power device is in transmission connection with the correction device, the detection device is connected with the frame assembly, the correction device is movably connected with the frame assembly, the frame assembly comprises a frame and a fixed seat, one side of the fixed seat is fixedly connected with one side of the frame, and the guide device comprises a guide seat, a guide plate, a guide chain, a chain wheel assembly and a guide wheel. The guide seat is movably connected with the frame, the guide plate is movably connected with the guide seat, the chain wheel assembly comprises two chain wheels, and the two chain wheels are in transmission connection with guide wheels through guide chains.

Owner:GUANGZHOU JUJIE ELECTRONICS TECH

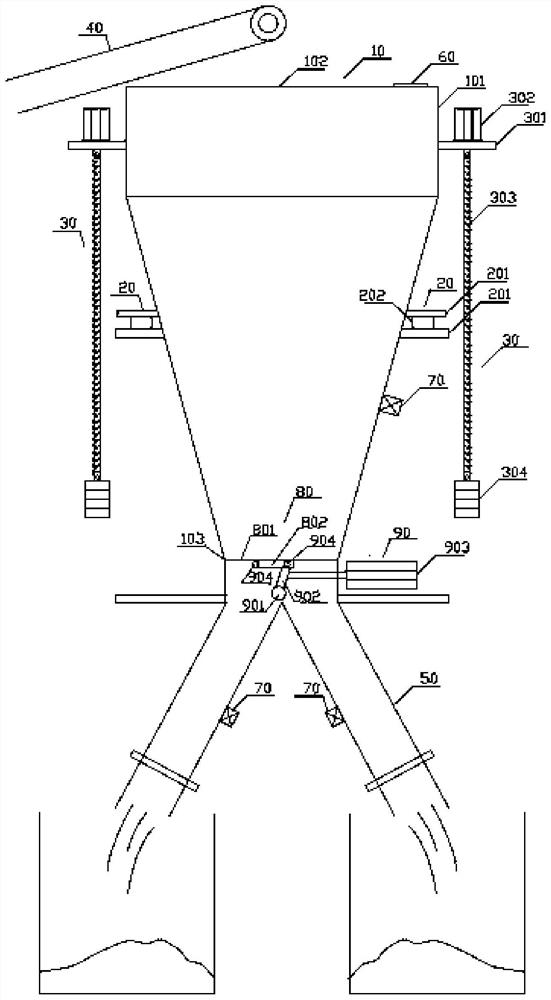

Packaging scale feeding device

PendingCN111846396AAvoid weighing errorsGuaranteed precision controlPackagingAgricultural engineeringMechanical engineering

The invention provides a packaging scale feeding device. The packaging scale feeding device comprises a feeding hopper, a material door, a driving unit and a transmission unit; the feed hopper comprises at least two layers of feed pipes, and the feed pipe at the outermost layer of can move up and down; the transmission unit is respectively connected with the feeding pipe at the outermost layer andthe material door, and the telescopic height of the material door is equally adjusted according to the telescopic height of the feeding pipe at the outermost layer; and the driving unit is connectedwith the transmission unit and is linked with the material door to open and close through the transmission unit. By means of the packaging scale feeding device, weighing errors caused by overlarge drop from the material door to a scale hopper when a packaging scale is fed can be avoided, and feeding and weighing precision control is guaranteed.

Owner:METTLER TOLEDO (CHANGZHOU) MEASUREMENT TECH CO LTD +2

Vehicle weighing system

ActiveCN102538927BAvoid weighing errorsEasy to implementSpecial purpose weighing apparatusLeft halfDynamic balance

The invention discloses a vehicle weighing system which comprises two weighing sensors respectively arranged on a left half lane and a right half lane; the location area of a vehicle which passes through the lane can be detected by a position sensor arranged nearby the weighing sensors; correction factors are selected to correct the weight of the whole vehicle measured by the weighing sensors according to the different areas; and the vehicle weighing system solves the problem that the difference of the vehicle eccentric load area can not be well corrected in the existing design, so that the weighing error can be caused. The vehicle weighing system is simple in implementation way and installation, low in project difficulty and capable of meeting the dynamic balance technical regulation requirements with low cost.

Owner:SICHUAN XINGDA MINKO ELECTR MECHANICAL ENG

Method for preventing highway weighing charge error

InactiveCN105928599ALight weightAvoid weighing errorsSpecial purpose weighing apparatusOperating speedGravitation

The invention discloses a method for preventing highway weighing charge error. According to the method, vehicle driving routes are acquired by a range finding sensor so that using "s"-shaped driving tracks, changing the vehicle center of gravity and reducing weight of the vehicle can be prevented. According to the method, driving speed of the charge measurement process is acquired in real time so that the situation that the weight borne by the wheel axle and the position of the center of gravity are changed by the vehicle though multiple times of braking and the weight is reduced can be prevented. Multiple conventional weighing charge escape modes are detected so that the phenomenon of weighing charge error can be avoided.

Owner:ANHUI WANTONG TECH

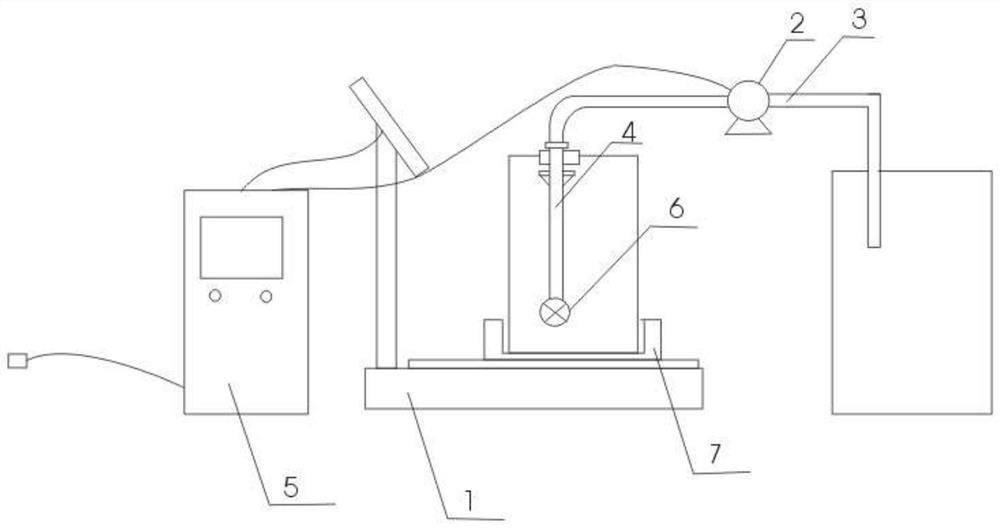

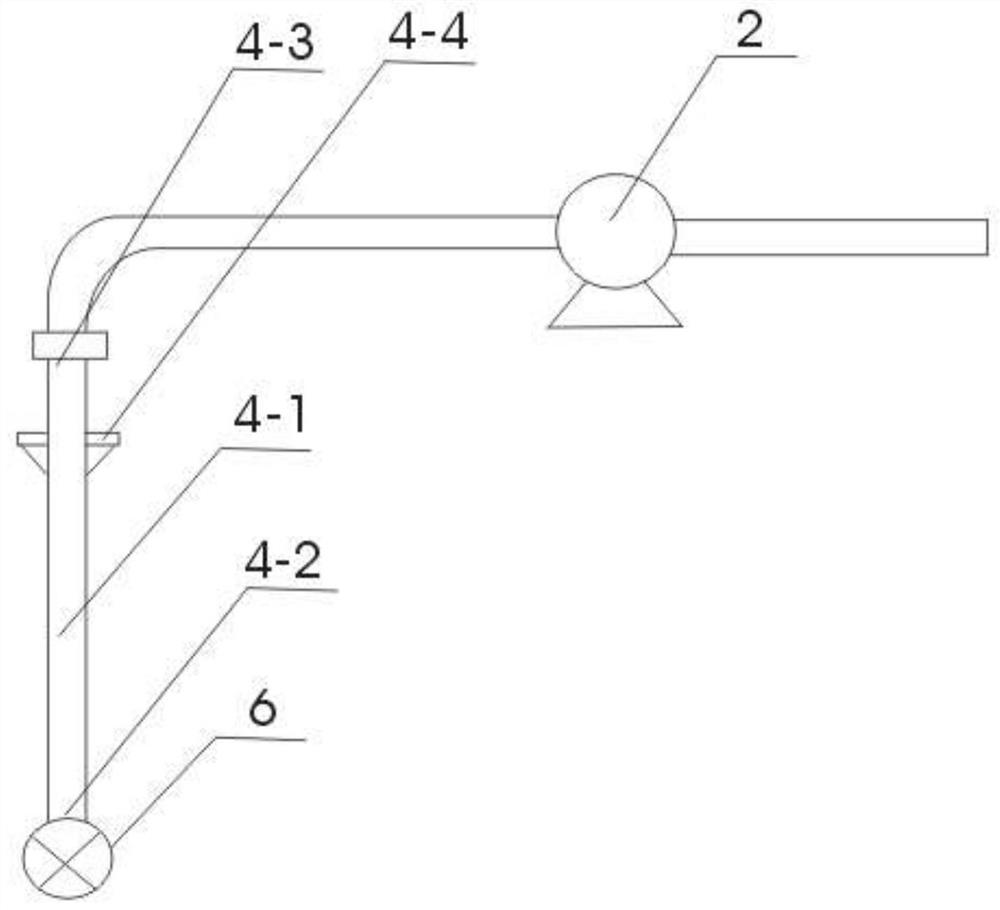

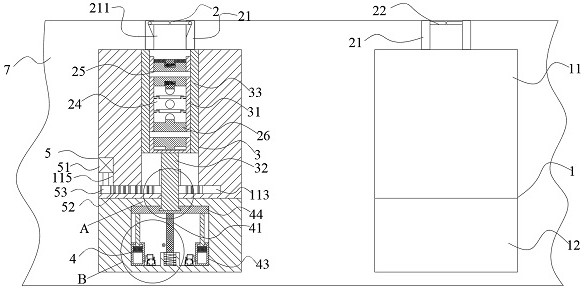

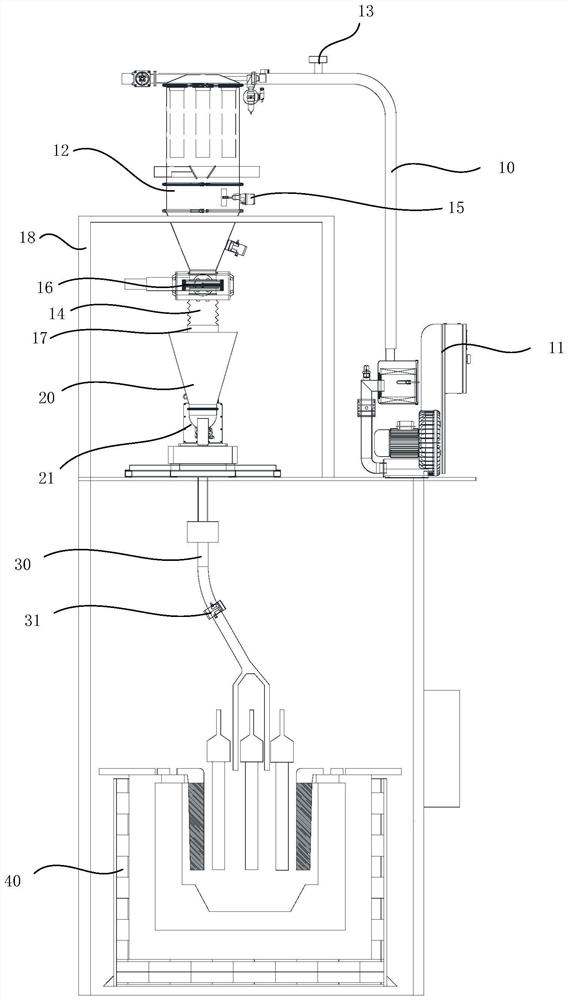

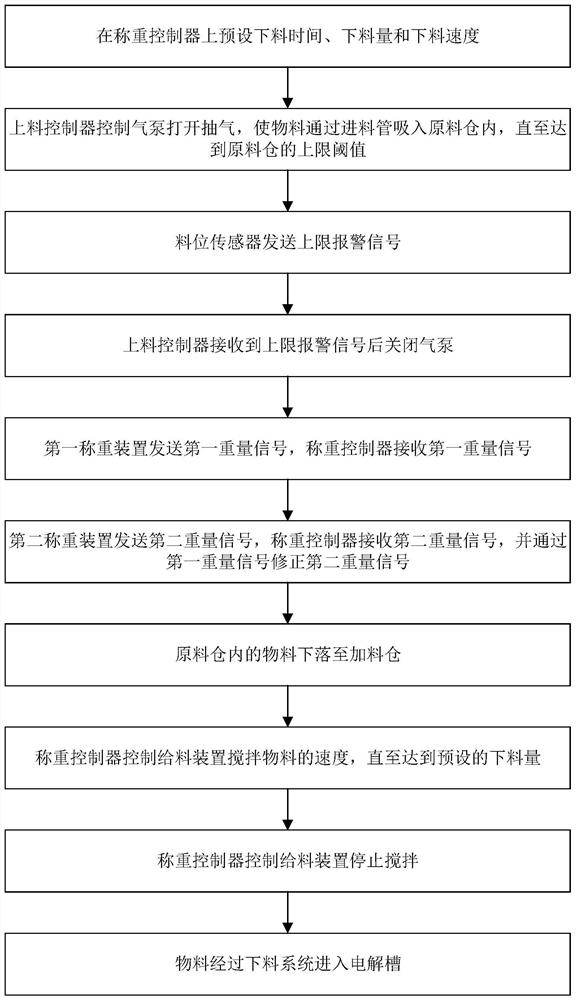

Feeding machine and feeding method for rare earth electrolysis

InactiveCN113061940AGuaranteed airtightGuarantee the direction of airflowElectrolysis componentsElectrolysisAir pump

The invention discloses a feeding machine and a feeding method for rare earth electrolysis. The feeding machine for rare earth electrolysis comprises a vacuum feeding system, a weighing and feeding system and a discharging system which are sequentially connected, wherein the vacuum feeding system comprises a feeding pipe, an air pump and a raw material bin which are connected in a closed mode, and further comprises a feeding control module; a pneumatic butterfly valve, a flexible connecting piece and a first weighing device are sequentially arranged between the vacuum feeding system and the weighing and feeding system; a support is arranged on the periphery of the raw material bin; and the weighing and feeding system comprises a feeding bin, a second weighing device and a feeding device, and further comprises a weighing controller. According to the feeding machine and the feeding method for rare earth electrolysis, an automatic production system is adopted, so that automatic feeding, feeding and discharging are realized, manpower is reduced, and safety is improved; the vacuum feeding system is adopted, and the system is integrally closed, so that pollution is avoided; and the weighing system is adopted, so that timing and quantitative discharging can be realized, discharging is uniform, and product quality is guaranteed.

Owner:包头市金为达稀土材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com