Platform-surface-quickly-detachable high-precision automatic checkweigher

A high-precision, automatic inspection technology, applied in the direction of automatic feeding/discharging weighing equipment, measuring devices, instruments, etc., can solve the problem that the parallelism of the table is not very accurate, unfavorable for mechanical debugging and electrical debugging, and affects the checkweigher Accuracy and other issues, to achieve the effect of shortening disassembly and assembly time, easy mechanical debugging and electrical debugging, and improving weighing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

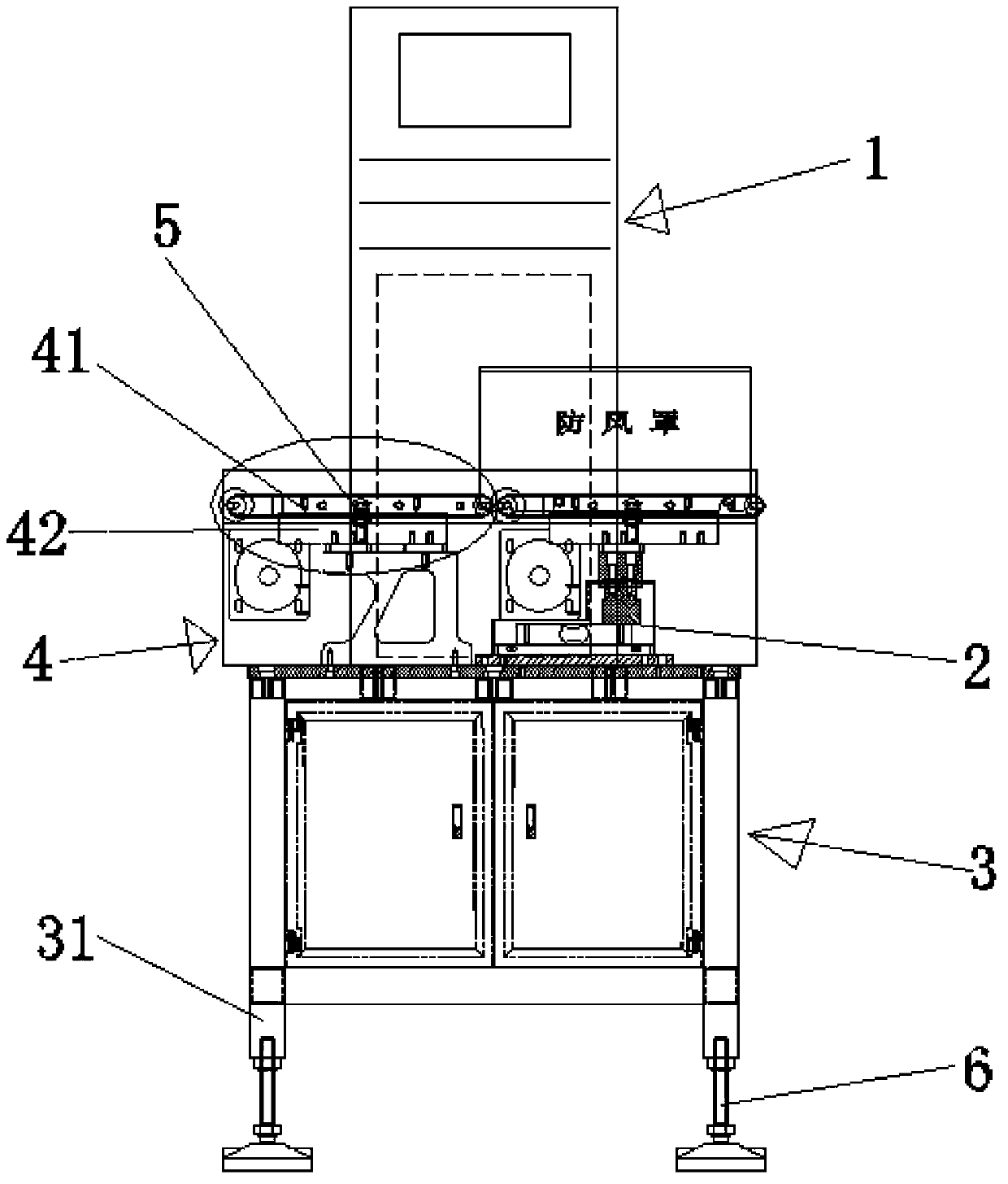

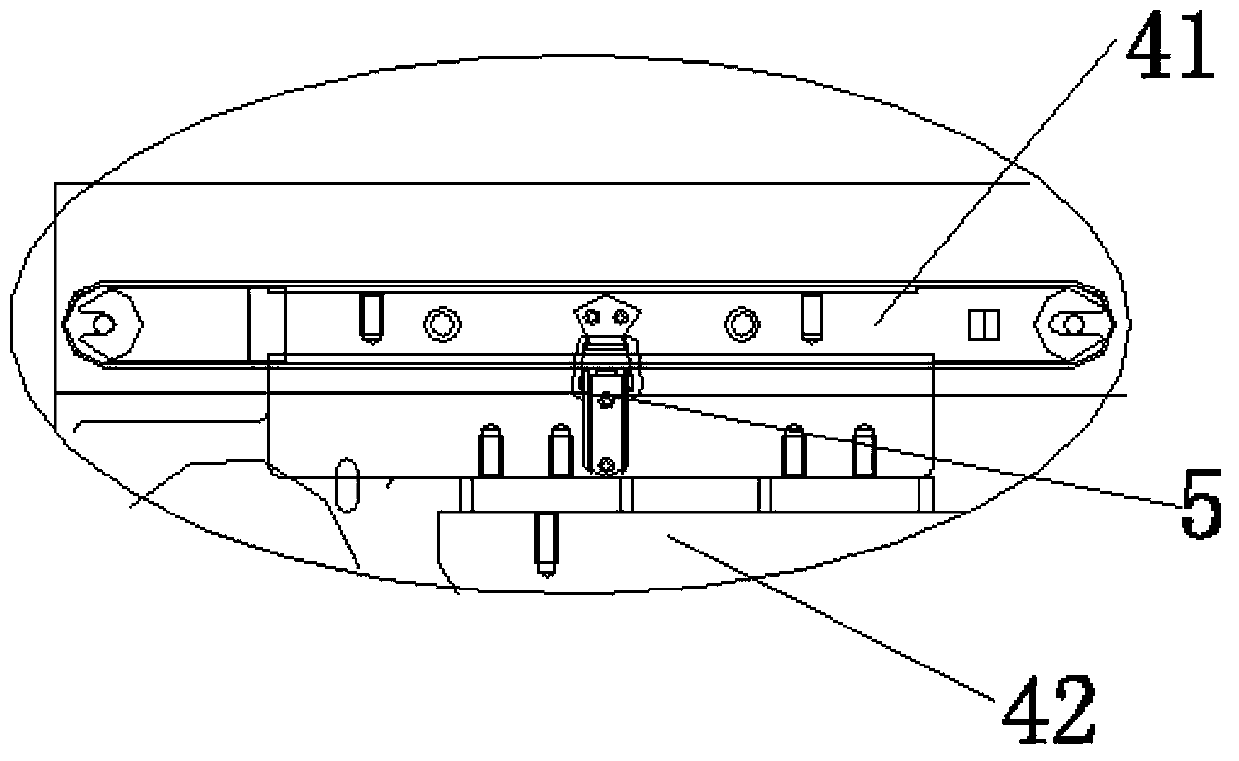

[0019] like figure 1 and figure 2 As shown, a high-precision automatic checkweigher whose table top can be quickly disassembled includes an electric box 1, a load cell 2, a frame 3 and at least one weighing platform 4 located on the frame, and the weighing platform It includes a platform 41 and a table top 42, the table is fixed on the frame, the table is horizontally fixed on the table through several buckle devices 5, and the electric box is located on one side of the table. side, and is fixedly connected with the frame, the load cell is arranged on the frame, and is electrically connected with the electric box, and the side of the frame facing away from the weighing platform is provided with several a foot 6, the foot can adjust the table top to be horizontal, so that the table top can be quickly buckled on the weighing platform through the buckle device, and when maintenance is required, the table top can be quickly disassembled, It is convenient for mechanical and elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com