Patents

Literature

50results about How to "Guaranteed precision control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

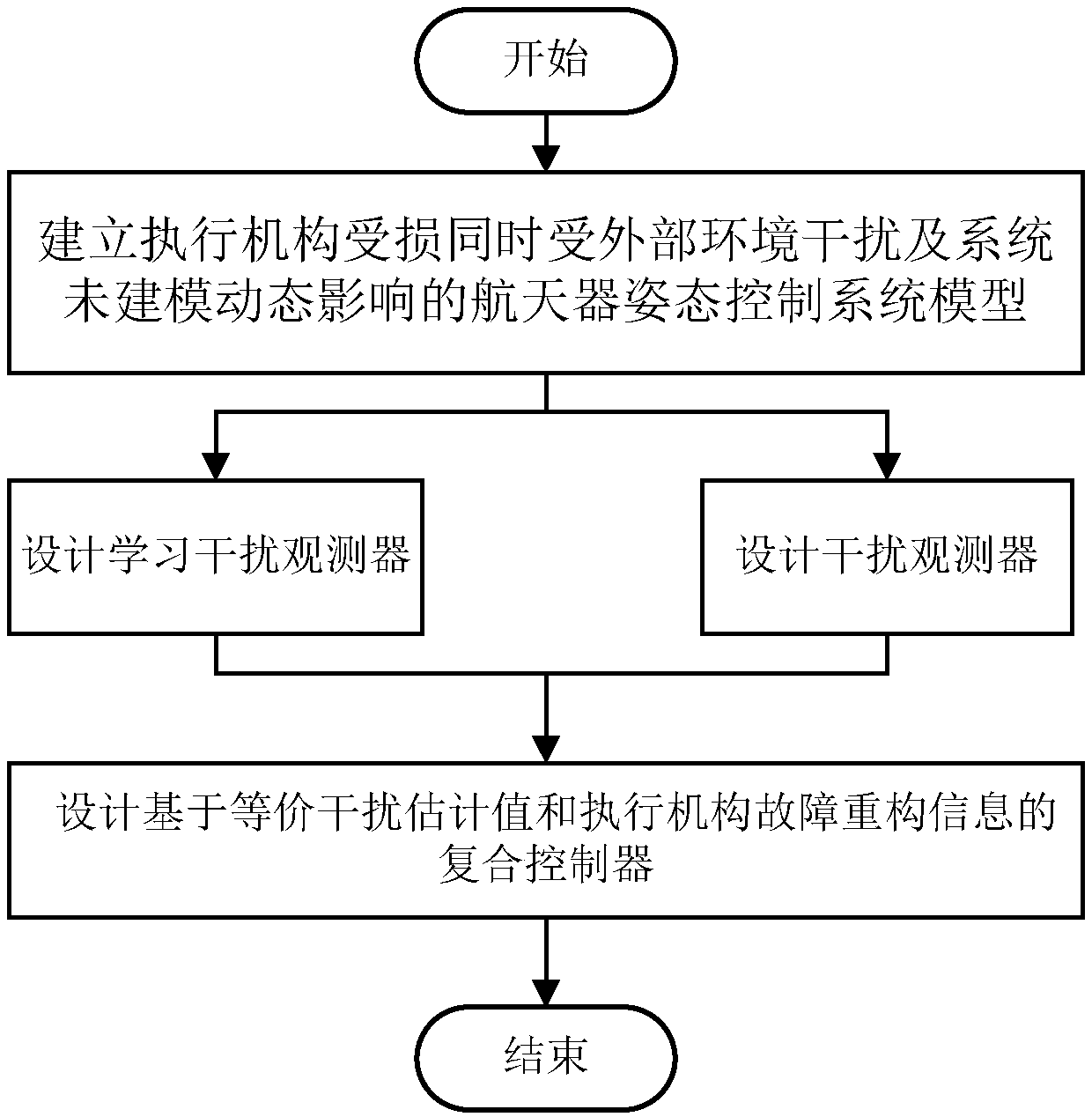

Spacecraft anti-interference attitude control method in condition of damaged actuating mechanism

ActiveCN108415255AGuaranteed accuracyGuaranteed reliabilityCosmonautic vehiclesCosmonautic partsModel dynamicsSpacecraft attitude control

The invention relates to a spacecraft anti-interference attitude control method in a condition of a damaged actuating mechanism. The method provides a spacecraft anti-interference attitude control system for conditions that a spacecraft actuating mechanism is physically attacked by an opponent in a space confrontation and a spacecraft platform has an external environment interference and a systemnon-modeling dynamic influence. The method includes: firstly, establishing a spacecraft attitude control system model in conditions of the damaged actuating mechanism, the external environment interference and the system non-modeling dynamic influence; then designing an interference observer, and estimating an equivalence interference caused by the external environment interference and the systemnon-modeling dynamics; designing a learning observer for an actuating mechanism failure fault, caused by an attack, of the actuating mechanism, and reconstructing the actuating mechanism fault; and finally designing a composite controller according to an equivalence interference estimate and actuating mechanism fault reconstruction information, and constructing the spacecraft anti-interference attitude control method in the condition of the damaged actuating mechanism. The method is applicable to high-precision and high-reliability control of the spacecraft attitude control system.

Owner:BEIHANG UNIV

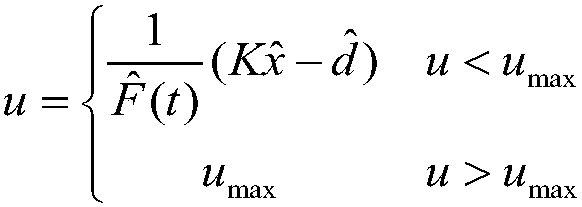

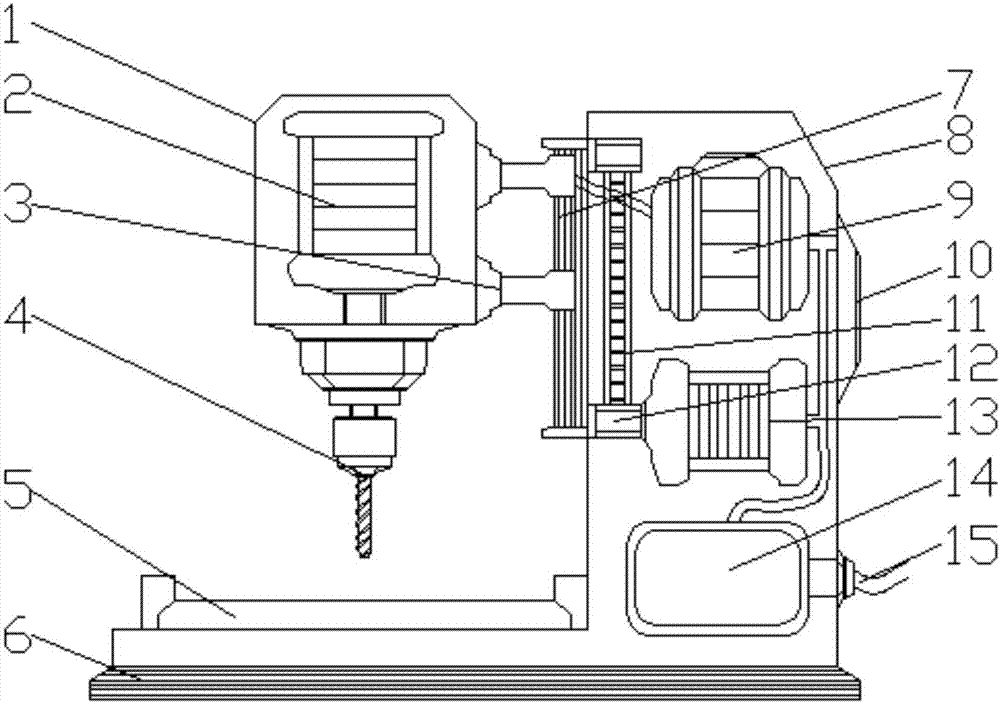

Lathe tailstock hole grinding fixture

The invention relates to a lathe tailstock hole grinding fixture. The fixture comprises a core shaft (1); a tapered guide sleeve (2) is arranged in the middle of the core shaft (1); a taper sleeve (3) is arranged on the guide sleeve (2); the taper sleeve (3) consists of three taper sleeve blocks; a grinding spiral groove (4) is formed on the surface of each of the three taper sleeve blocks, a spring mounting groove (6) is formed on each of the front and rear sides of each grinding spiral groove (4), a spring (5) is arranged in each spring mounting groove (6), and the three taper sleeve blocks are fixed through the springs (5); a washer (9) and an adjusting nut (10) are arranged at each of the front end and the rear end of the taper sleeve (3); and grinding sand (7) is arranged on the surface of the taper sleeve (3). The lathe tailstock hole grinding fixture is simple in structure and convenient to operate, can be used for lathes of the same model, is low in manufacturing cost and high in grinding efficiency, and can effectively ensure the precision control of surface roughness, roundness, cylindricity and the like of a lathe tailstock hole.

Owner:CHENGXI SHIPYARD

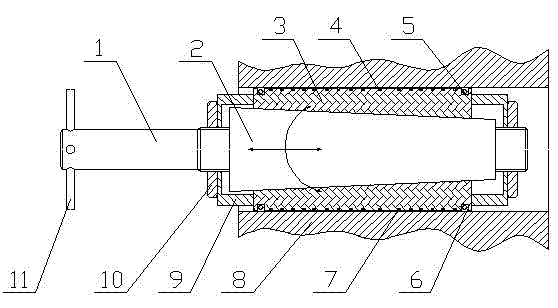

Three-dimensional printing method with arrangement of reference point

InactiveCN104290324AImprove pass rateGood for controlling printing accuracyNetwork modelComputer science

The invention brings forward a three-dimensional printing method with the arrangement of a reference point. A print head operates in a static state, and a workbench carries out three-dimensional motion and can rotate. Specific work steps are as follows: selecting a point which always remains motionless relative to the workbench as a reference point; adding the reference point into a three-dimensional network model; computing three-dimensional distance from each feature point in the three-dimensional network model to the reference point; slicing the three-dimensional network model for layering and acquiring molding information at each layer; moving the workbench to adjust relative position between the workbench and the print head, and carrying out layered printing; and acquiring a printing model. The invention brings forward the three-dimensional printing method with the arrangement of a reference point. By the method, printing deviation can effectively be reduced and printing precision and efficiency can be raised.

Owner:HEFEI SKE INTELLIGENT TECH

Method for quickly and accurately positioning bolt

PendingCN106500677AFast and efficient bolt positioning measurementGuaranteed bolt measurement accuracy controlActive open surveying meansTotal stationPrism

The invention discloses a method for quickly and accurately positioning a bolt. The method comprises the following steps of manufacturing a prism support; fixing the prism support on the bolt to be measured through an upper nut and a lower nut; fixing a prism on a prism substrate; fixing the prism substrate on the support through a prism substrate fixing bolt; adjusting the prism substrate to enable the center of the prism to be aligned to the center of the bolt; and using a total station to measure the position of the bolt. According to the method, the bolt can be positioned and measured quickly and efficiently, accuracy control for bolt measuring can be guaranteed, and besides, the measuring control efficiency is greatly improved.

Owner:中国人民解放军63926部队

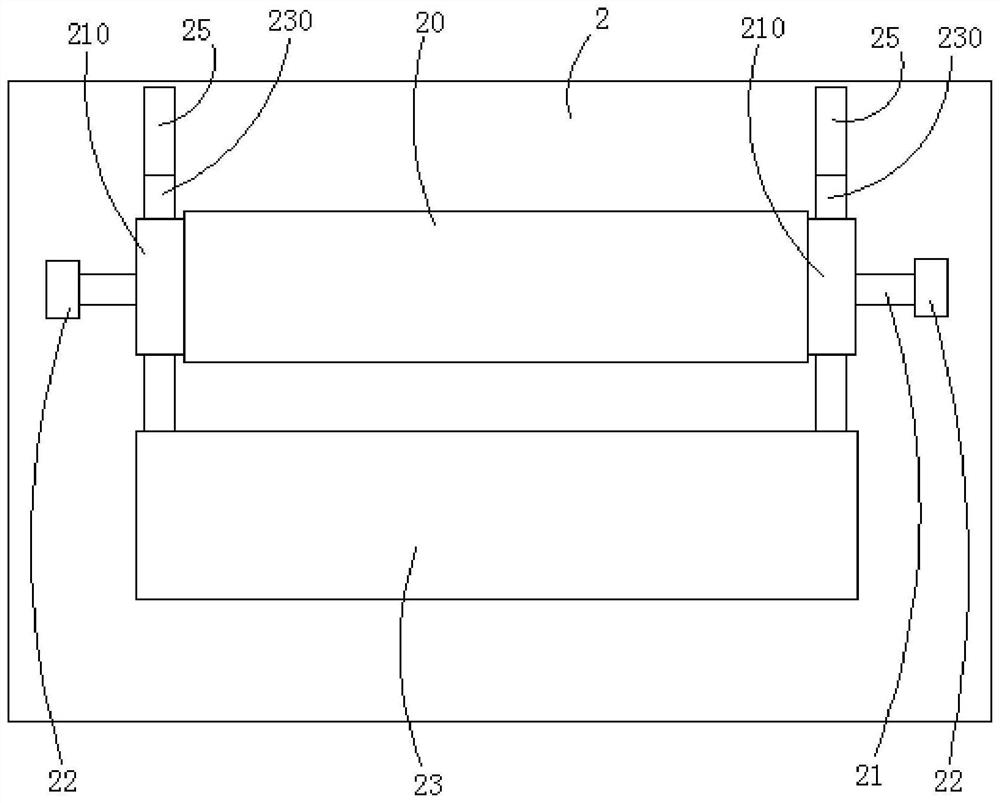

Three-dimensional printing machine with multi-dimensional motion workbench

The invention provides a three-dimensional printing machine with a multi-dimensional motion workbench. The three-dimensional printing machine comprises a base, first rails, a first supporting frame, second rails, a second supporting frame, a telescopic rod, a workbench, a spraying head bracket, one or multiple printing spraying heads, one or multiple material boxes and the like, wherein the first rails are mounted on the base; the first supporting frame is mounted on the first rails and can move along the length direction of the first rails; the second rails are mounted on the first supporting frame and are perpendicular to the first rails; the second supporting frame is mounted on the second rails and can move along the length direction of the second rails; the workbench is mounted on the second supporting frame through the telescopic rod and can move in the height direction; the spraying head bracket is mounted on the base; the printing spraying heads are mounted on the spraying head bracket and are positioned above the workbench; the material boxes are mounted on the base; the printing spraying heads are connected with the material boxes in a one-to-one correspondence manner. The printing spraying heads of the three-dimensional printing machine are fixedly mounted, so that the continuity of printing material outputting is kept, and the printing effect can be enhanced.

Owner:HEFEI SKE INTELLIGENT TECH

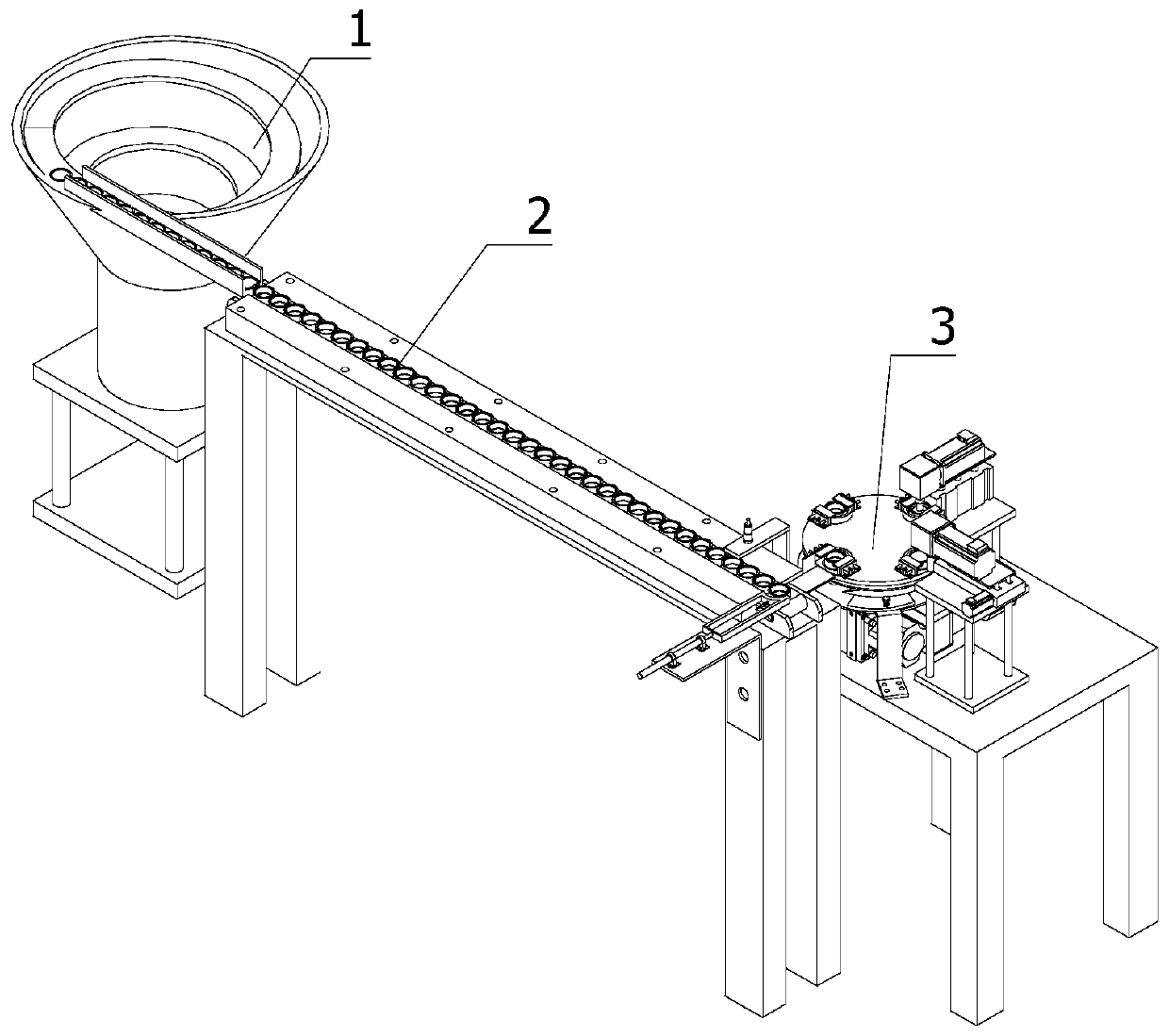

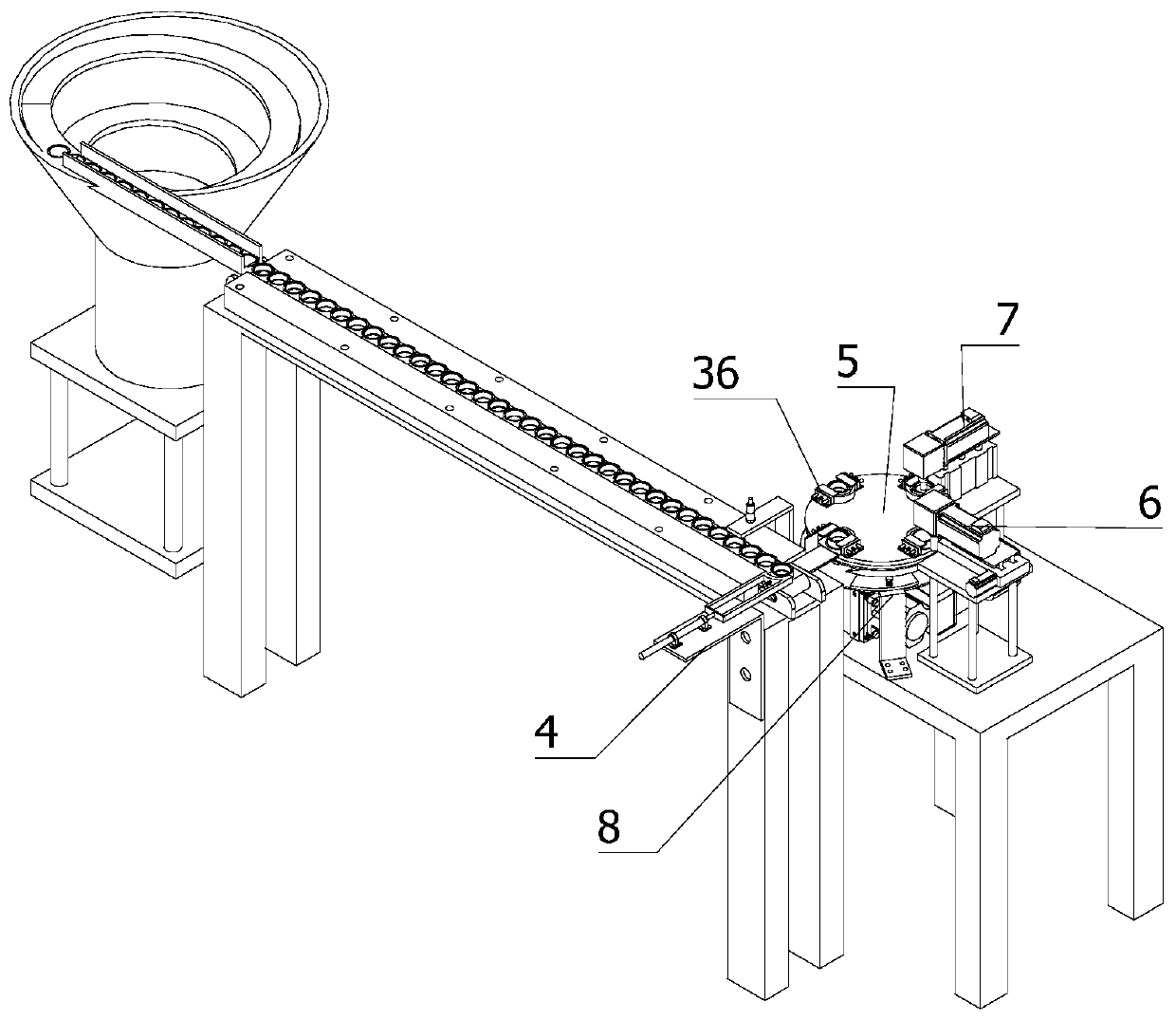

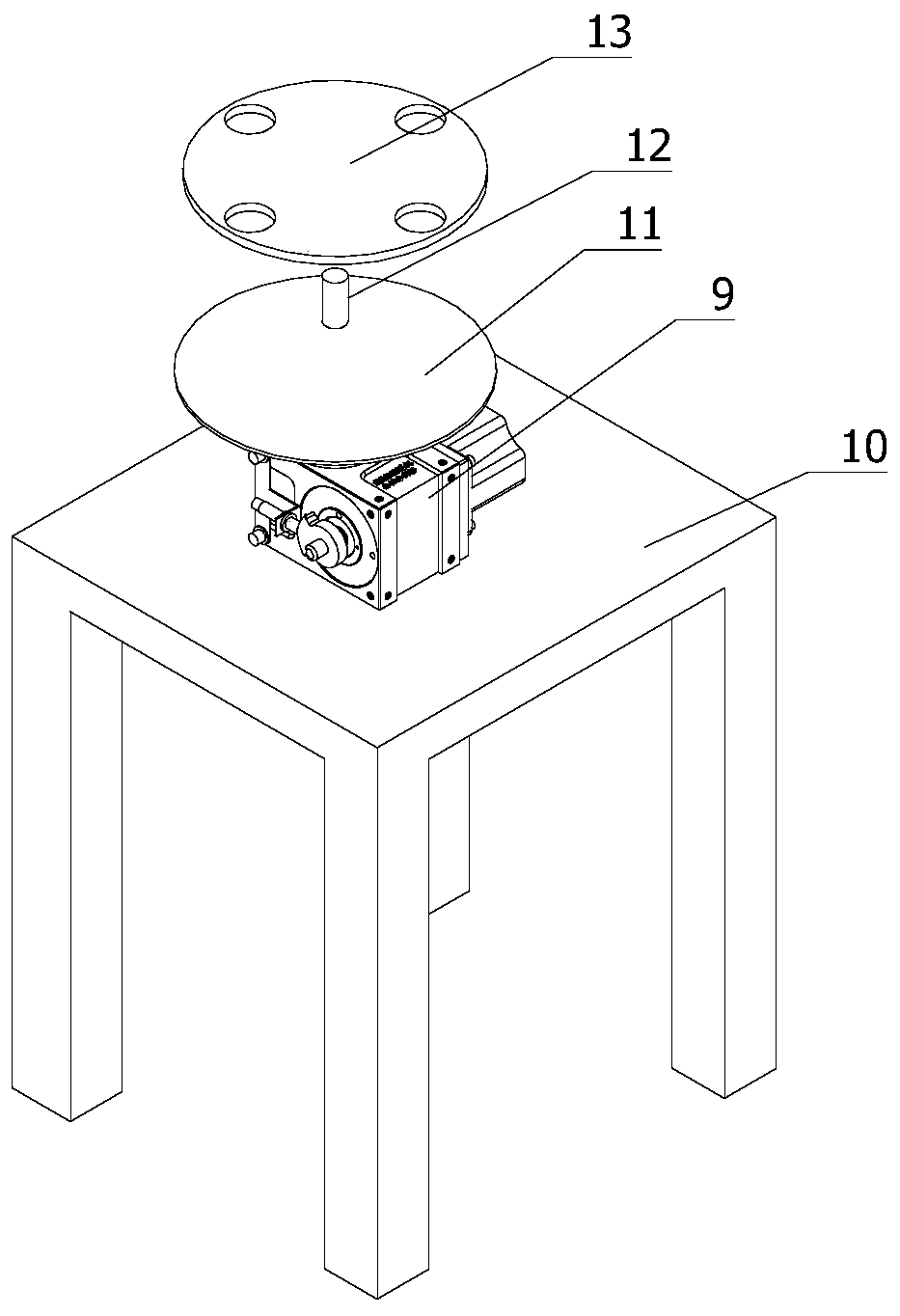

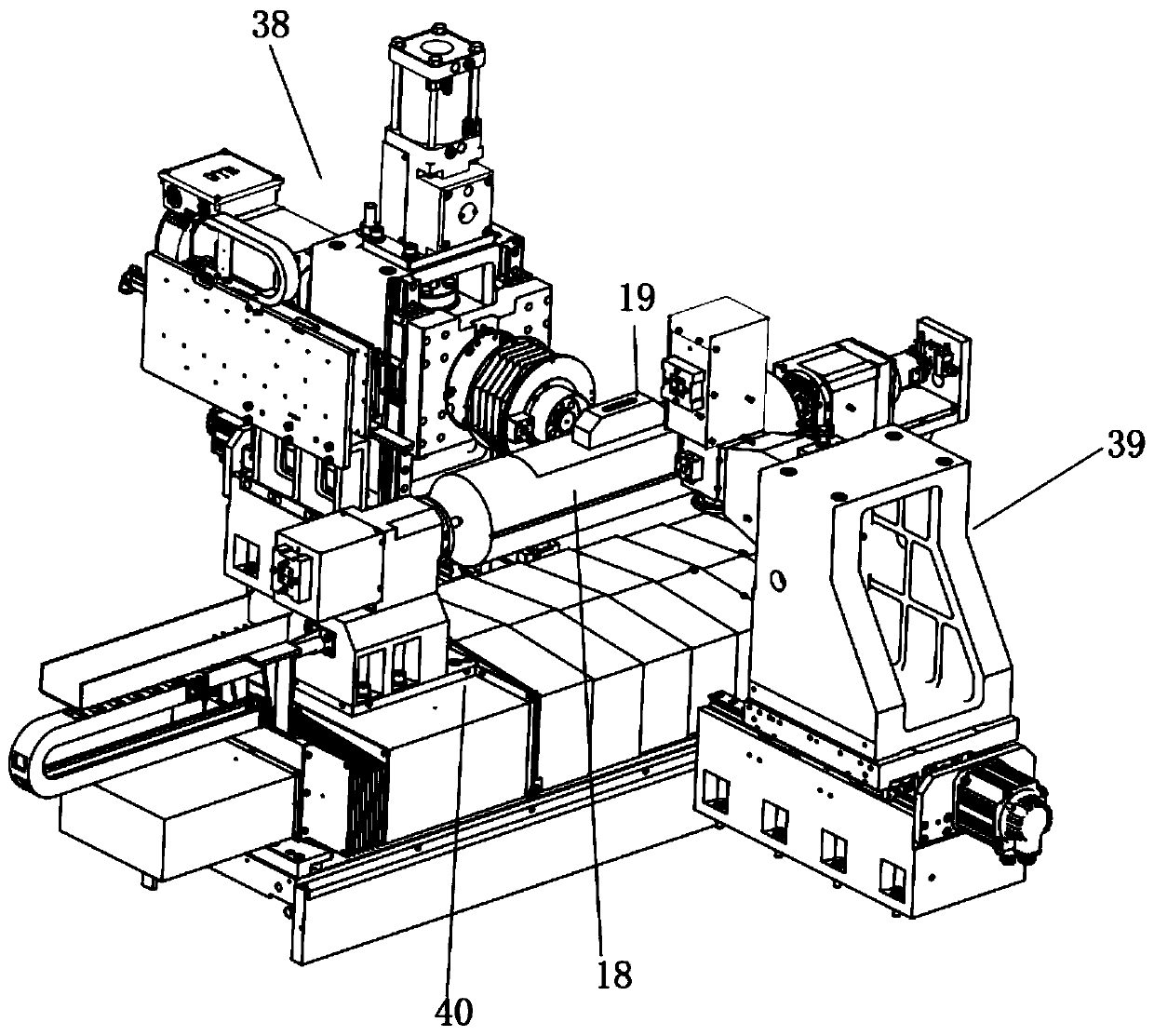

Automatic machining equipment for bearing outer ring

ActiveCN110315428AReduce gapReduce wasteRevolution surface grinding machinesGrinding drivesCamEngineering

The invention relates to the field of bearing machining, in particular to automatic machining equipment for a bearing outer ring. The equipment comprises a vibration disc, a conveying belt and a machining mechanism, wherein the end, far away from the vibrating disc, of the conveying belt is provided with a pushing mechanism, the machining mechanism comprises a rotating mechanism, a ring grinding mechanism, a groove grinding mechanism and a pushing mechanism, the rotating mechanism comprises a cam cutting machine, a first supporting frame, a rotating disc, a rotating rod and a rotating table, the rotating disc is arranged at the top of the cam cutting machine, the rotating rod is fixedly arranged at the top of the rotating disc, the pushing mechanism is located between the rotating disc andthe rotating table, and the pushing mechanism, the ring grinding mechanism and the groove grinding mechanism are sequentially distributed along the circumferential direction of the rotating table. According to the automatic machining equipment for the bearing outer ring, outer ring grinding and outer groove grinding are simultaneously conducted by adopting the mechanism, the waste of a large quantity of area of sites is reduced, the automatic feeding mode of the vibrating disc and the mode of automatic alignment of conical ejector pins are adopted, so that the precision of feeding is controlled, and the machining precision of the bearings is more accurate.

Owner:苏州市东挺河智能科技发展有限公司

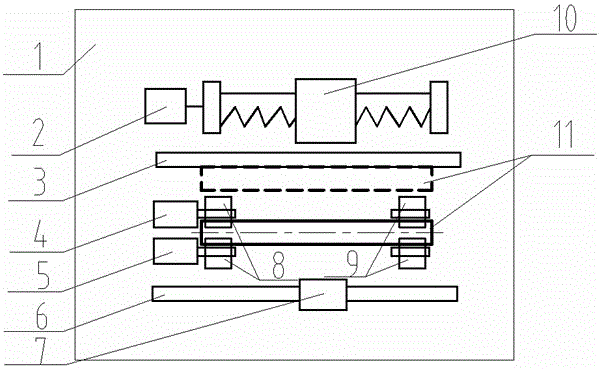

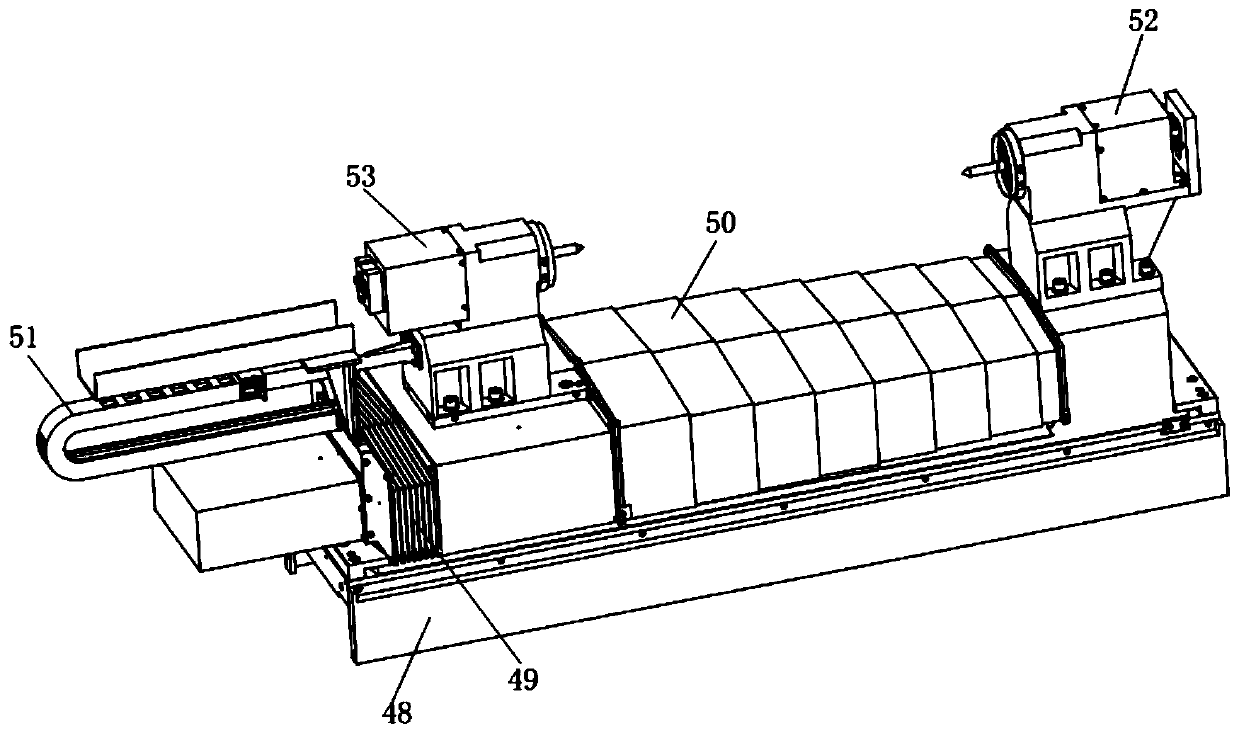

Simple detection device of circularity and linearity of bar stock

InactiveCN105783677AGuaranteed precision controlImprove performanceAngles/taper measurementsMechanical counters/curvatures measurementsLinear motorMaximum difference

The present invention provides a simple detection device of circularity and linearity of bar stock. Four parallel guide rails are installed on a platform, consisting of a linear motor work guide rail, a guide rail 1, a speed regulation motor work guide rail and a guide rail 2. The linear motor work guide rail is provided with a linear motor and a gauge stand 2; the speed regulation motor work guide rail is provided with a speed regulation motor 1 and a speed regulation motor 2, a double-row cylindrical roller bearing 1 is connected with the speed regulation motor 1 and the speed regulation motor 2, and a double-row cylindrical roller bearing 2 is arranged at a corresponding bearing pedestal; the gauge stand 1 is arranged on the guide rail 2; when rod materials to be detected are putted on the double-row cylindrical roller bearing 1 and the double-row cylindrical roller bearing 2, a dial indicator is arranged on the gauge stand 1, the dial indicator and the position of the rod materials to be detected are observed, the rod materials to be detected begin to rotate, and the maximum difference of pointer bouncing is recorded; and the dial indicator is arranged on the gauge stand 2, the rod materials to be detected are contacted with the guide rail 1, and the reading difference during the movement of the pointer is recorded. The simple detection device of circularity and linearity of bar stock is rapid, accurate in detection, low in cost, simple in operation, high in rechecking efficiency and saved in both time and labor.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

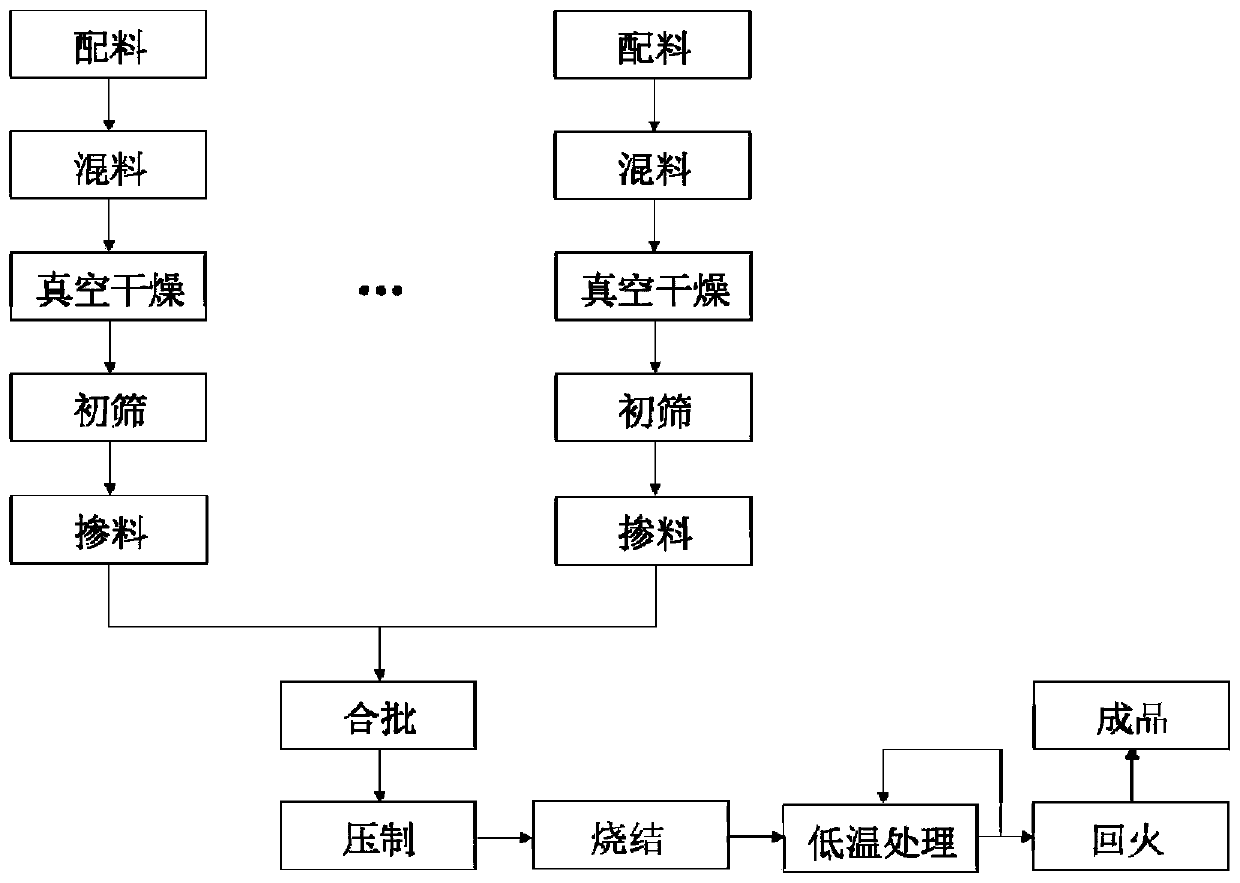

High-performance hard alloy material

The invention discloses a high-performance hard alloy material, and belongs to the field of hard alloy materials. The high-performance hard alloy material is prepared by the following raw materials inparts by weight: 65-80 parts of WC, 5-10 parts of Co, 10-15 parts of TiC, 3-8 parts of Ni, and 0.2-0.7 part of grain growth inhibiting agent; preferentially, the high-performance hard alloy materialis prepared by the following raw materials in parts by weight: 70-75 parts of WC, 7-9 parts of Co, 12-14 parts of TiC, 4-6 parts of Ni, and 0.3-0.5 part of grain growth inhibiting agent; the grain growth inhibiting agent is TaC; and the weights of all the components have the following relations: Ni / (Co+Ni) is not more than 0.4 and not less than 0.3; and (0.06WC+0.2TiC) / (WC+Co+TiC+Ni) is not more than 0.08 and not less than 0.05. Through improvement of the formula, the high-performance hard alloy material reduces adding of such expensive materials as Co and TaC, so that the production cost is reduced; and through reasonable batching, the hardness, the toughness and the cutting performance of the finally prepared high-performance hard alloy material are greatly improved compared with a traditional hard alloy material.

Owner:技锋精密刀具(马鞍山)有限公司

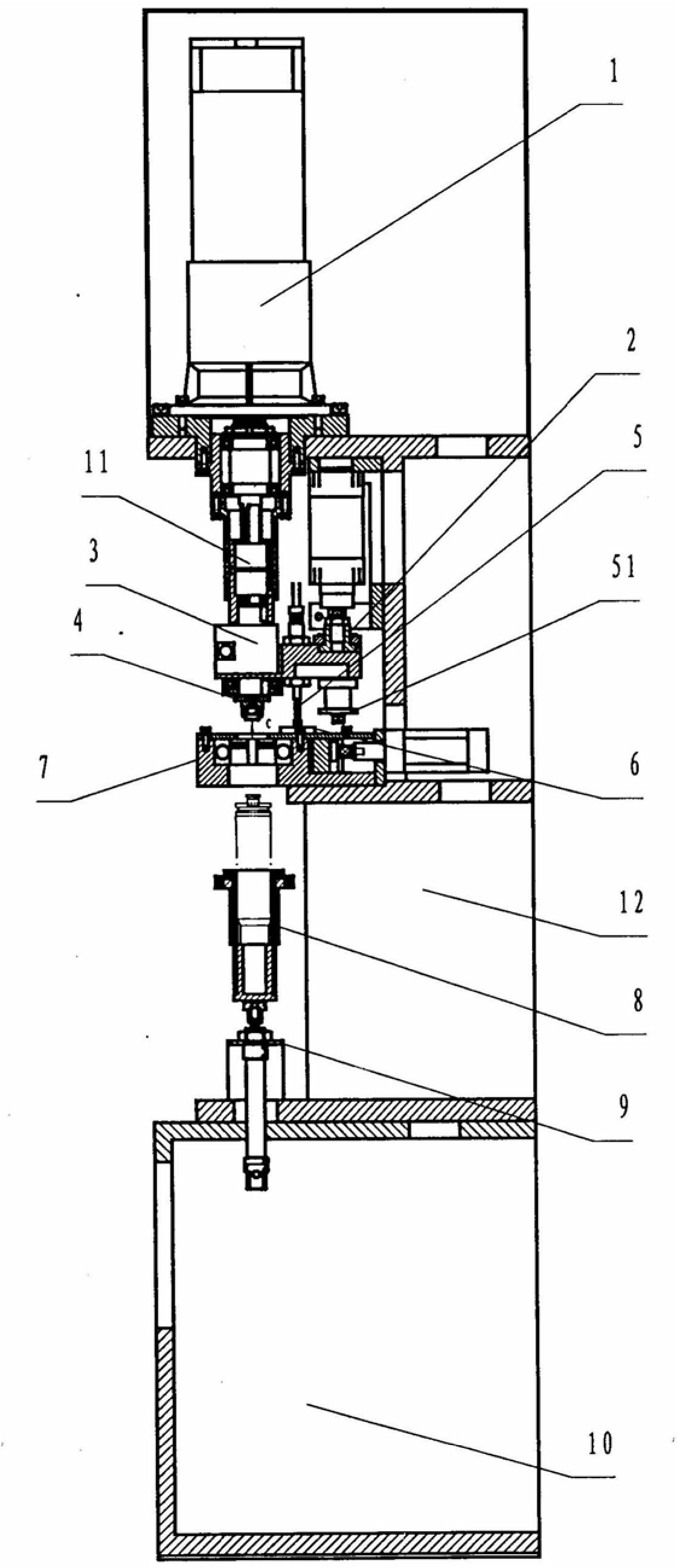

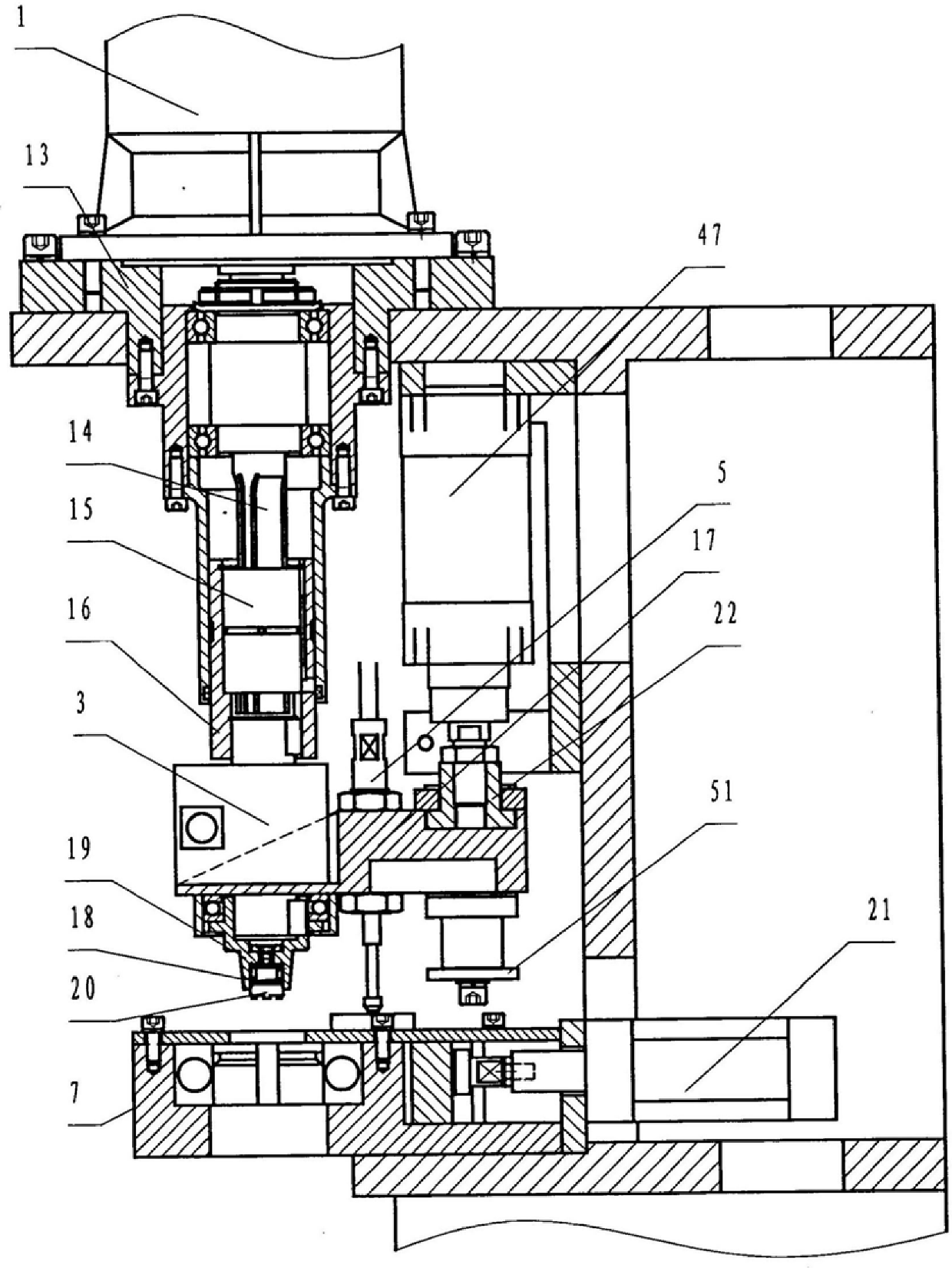

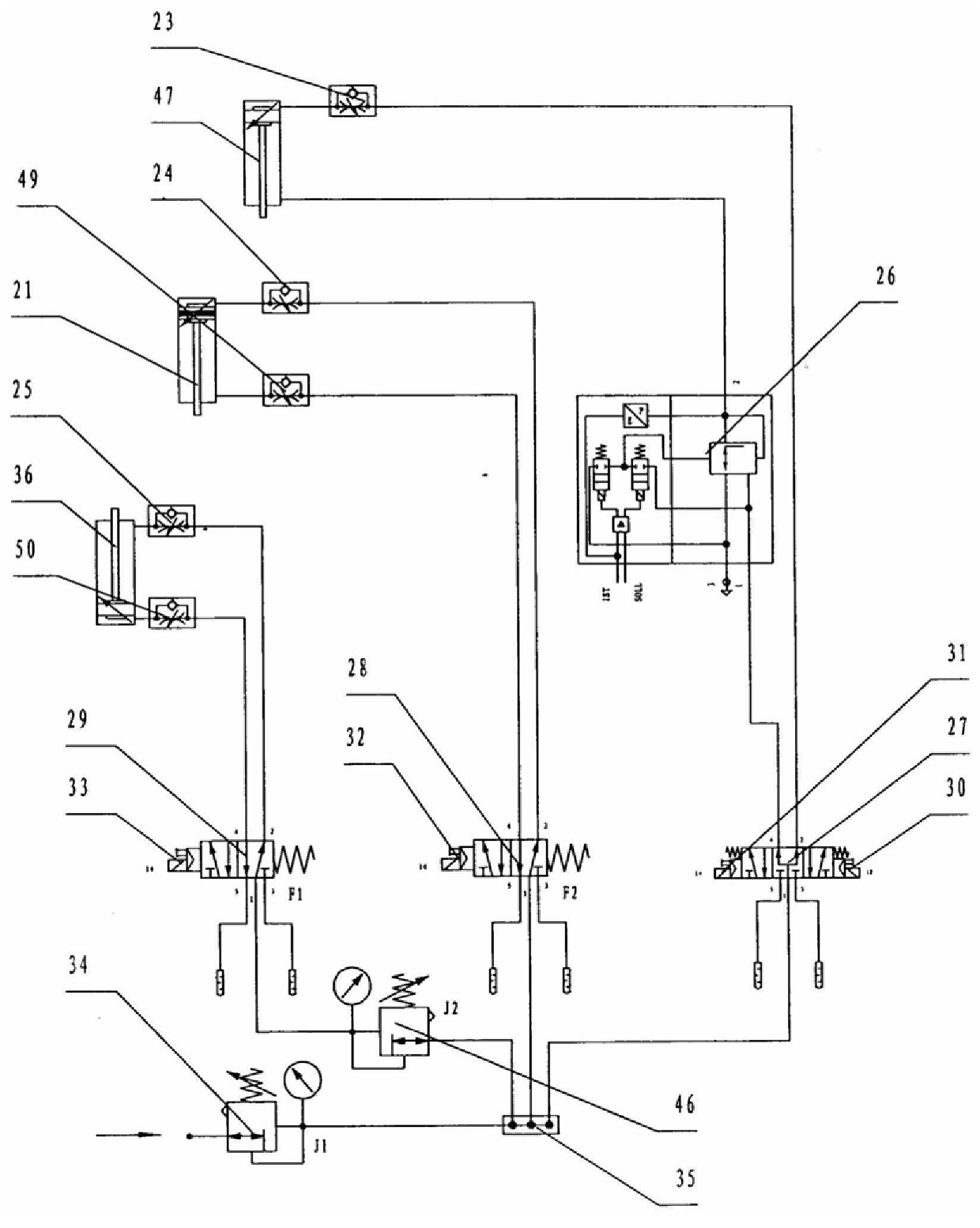

Screw-in electric bottom fire explosion-proof tightening machine

InactiveCN106342168BEnsure safetySolve the pit problemPower driven toolsAmmunition fuzesEngineeringMechanical construction

The invention belongs to the field of assembly of small-caliber bullets, and in particular relates to a screw-in type electric primer explosion-proof screwing machine used in the assembly of small-caliber bullets. A screw-in type electric primer explosion-proof tightening machine of the present invention includes a cartridge cup, a jacking mechanism, a positioning and clamping mechanism, a pit device for automatically pressurizing and searching for a screw-in type electric primer, an air circuit system, a control part and controlling software. The jacking mechanism of the screw-in electric primer explosion-proof screwing machine is installed on the machine base, the cartridge cup is located above the jacking mechanism, and the positioning and clamping mechanism, automatic pressurization and the pit device for finding the screw-in electric primer are located in the cartridge in turn. The top of the cylinder cups are installed on the rack. The air source, valve, air pipe and the pneumatic actuators of the above mechanical parts form an air circuit system. The control software is set in the controller of the control part, and the controller and the control software control the operation of the above-mentioned mechanical structure. The screw-in electric primer explosion-proof tightening machine of the present invention can automatically complete the screwing of the screw-in electric primer, it solves the problem of automatically finding the pit on the screw-in electric primer, and can ensure the precision control of the screw-in electric primer tightening depth , to ensure product quality, realize the separation of man and machine, and ensure the safety of production personnel.

Owner:SICHUAN MIANYANG SOUTHWEST AUTOMATION INST

High-precision electric punching machine

InactiveCN107538048AEasy to replaceWide range of workBoring/drilling componentsElectric machineryDrive motor

The invention discloses a high-precision electric punching machine, which includes a driving motor, a punching device, a processor and a circuit box. frame, the support frame is fixed with a rail connected to the casing, a driving motor is arranged above the puncher, a workbench is connected below the puncher, and an operation panel is installed on the right side of the casing and a power cord, and an operation panel is fixed above the power cord, a transmission chain is installed on the left side of the processor, a running wheel is fixed on the upper and lower ends of the transmission chain, and a host motor is installed on the right side of the running wheel . This high-precision electric punching machine has installable and detachable bolts on the puncher, which is more convenient to replace. The movement stroke is 0-20, the working range is wide, and there are many types of processing materials. There are scales and fixers on the workbench. device, accurate precision control, high work efficiency, and avoid processing defects.

Owner:朱炎康

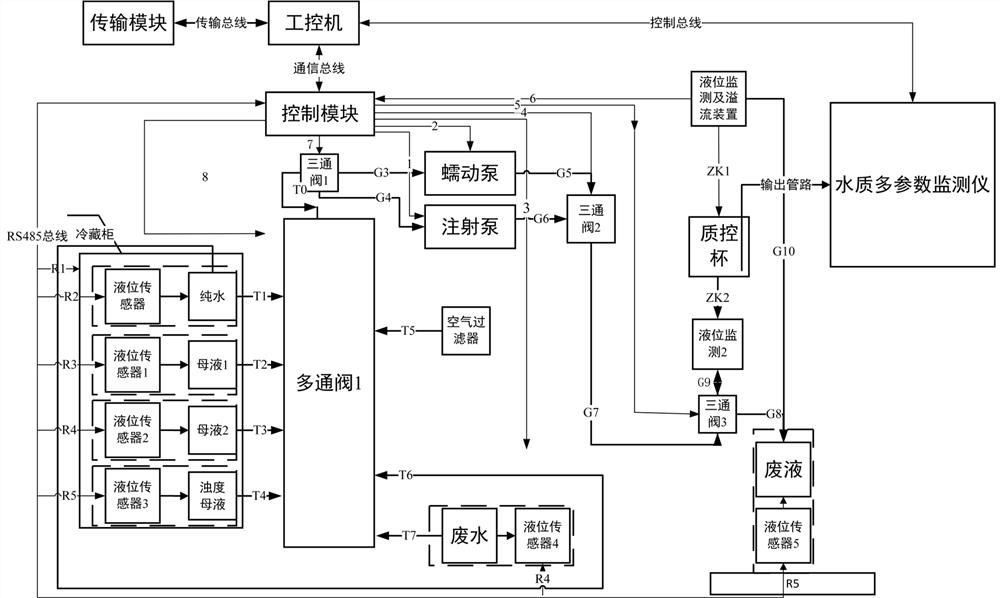

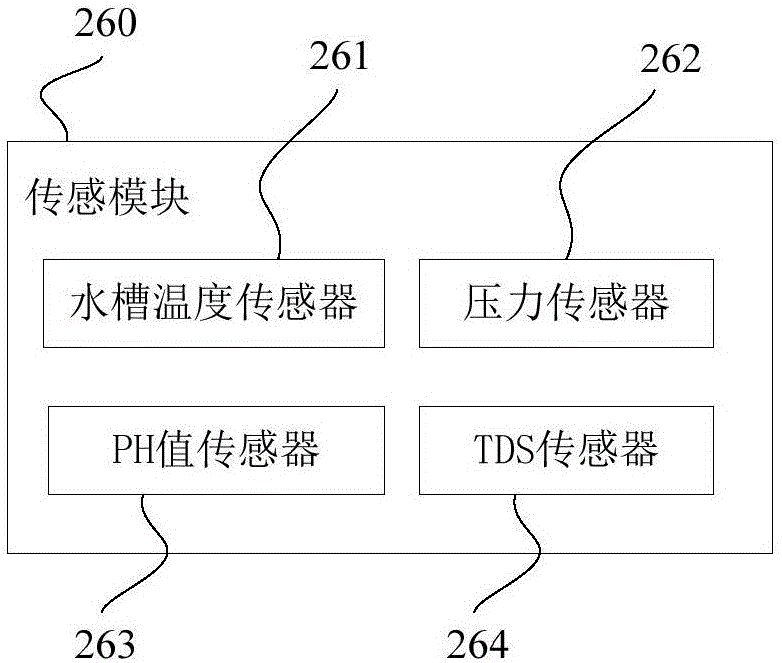

Remote quality control system suitable for water quality multi-parameter monitor and using method

PendingCN111879905AReduce complexityReduce operation and maintenance workloadTesting waterMachines/enginesPeristaltic pumpAir filter

The invention provides a remote quality control system suitable for a water quality multi-parameter monitor and a using method. The remote quality control system comprises the water quality multi-parameter monitor, a quality control cup, a multi-way valve, a peristaltic pump, an injection pump, a control module, an industrial personal computer, an air filter, a pure water bottle and a plurality ofmother liquor bottles. The pure water bottle, the mother liquor bottles and the air filter are respectively connected to the multi-way valve, the multi-way valve is connected to the quality control cup through a switchable peristaltic pump passage and an injection pump passage, a monitoring pipeline of the water quality multi-parameter monitor is connected to the quality control cup, and a liquidlevel monitoring and overflowing device is arranged in the quality control cup. A second interface at the tail end of the multi-way valve is connected with the pure water bottle; The industrial personal computer communicates with the control module, a quality control system with more complex components is formed, configuration of quality control liquid with various parameters can be provided, solution dosage reminding can also be provided, one system is used, different quality control requirements are met, and the remote quality control system is designed to be modular and easy to expand.

Owner:HENAN HANWEI ELECTRONICS

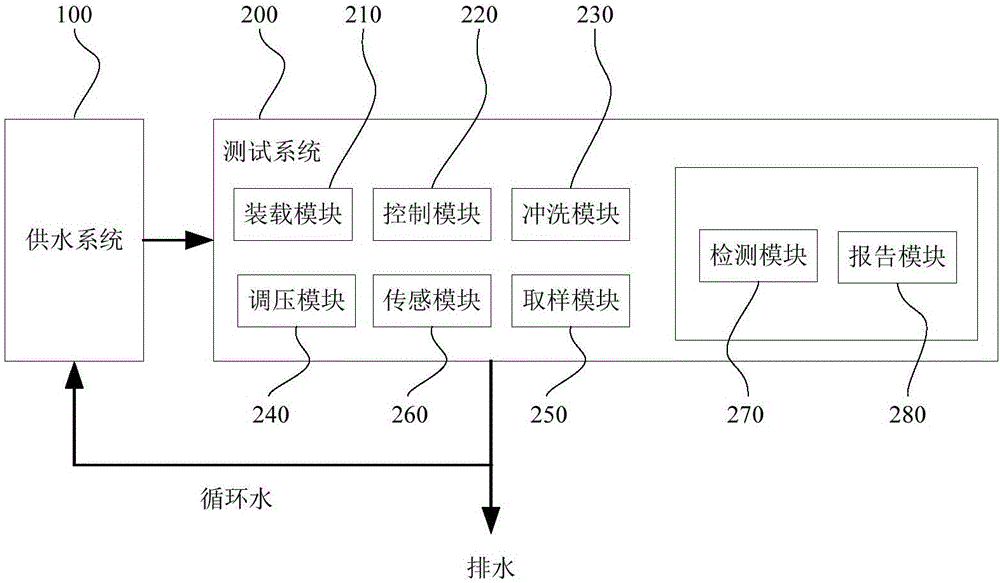

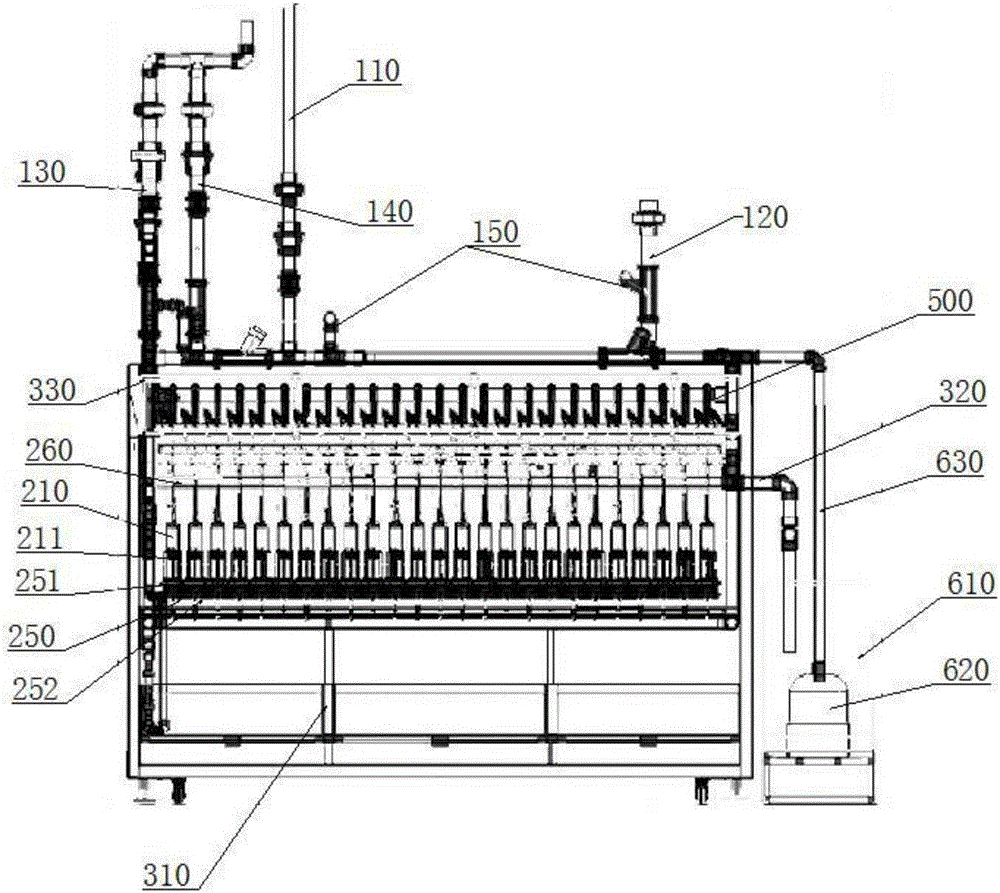

Integral filter element testing system

InactiveCN106198085AImprove test efficiencyAccurate controlStructural/machines measurementData transmissionEngineering

The invention discloses an integral filter element testing system. The integral filter element testing system is composed of a water supply system and a testing system, wherein the water supply system supplies water to the testing system through a main water supply pipe, the testing system comprises a loading module, a control module, a flushing module, a pressure regulating module, a sampling module, a sensing module, a detecting module and a reporting module, the control module is used for regulation process control, and the reporting module conducts data transmission, reception and computing analysis on various parameters, data, control states and the like and displays the parameters, data, control states and the like. A stable, repeatable and efficient testing environment can be provided for performance testing of a filter element, multiple filter elements can be tested simultaneously or independently, testing efficiency is improved greatly, testing environment and testing regulation can be precisely controlled, testing precision can be controlled more accurately, testing water can be recycled by 70% or more through matching of the water supply system and the testing system, more energy is saved, and environment friendliness is better realized.

Owner:苏州科尔净净化科技有限公司

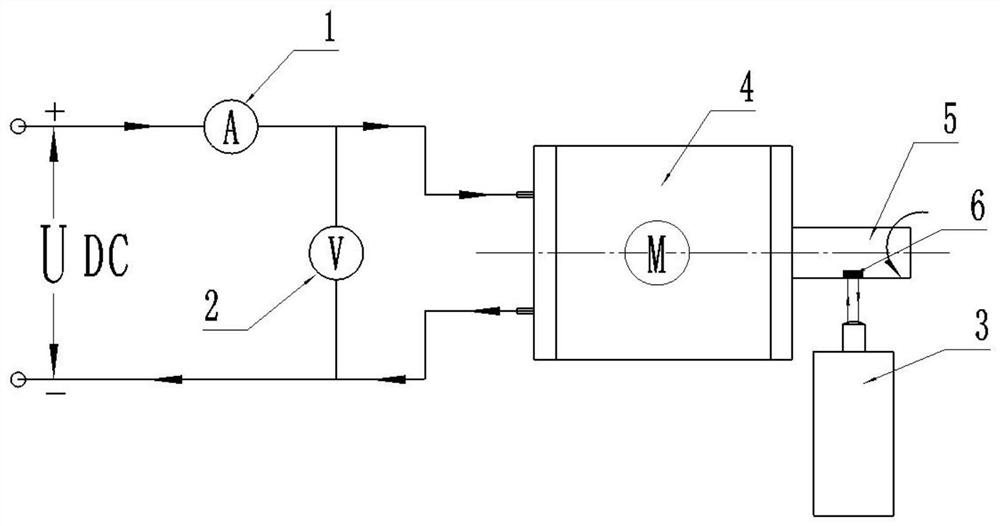

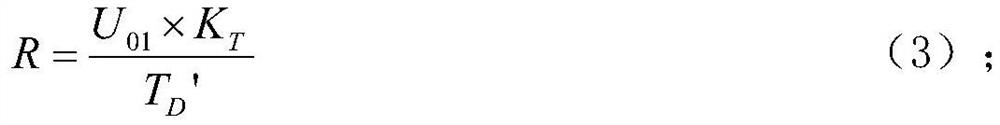

Steady-state no-load test method for mechanical characteristics of motor

PendingCN113985278AEasy to testReduce testing costsDynamo-electric machine testingElectric machineLoad torque

The invention discloses a steady-state no-load test method for mechanical characteristics of a motor. The method comprises the steps: S1, applying a rated voltage U01 to a motor, and measuring the no-load current I01 and the no-load rotating speed n01 of the motor when the motor operates to a steady state; S2, applying a voltage U02 to the motor, and when the motor operates to a steady state, measuring the no-load rotating speed n02 of the motor, wherein the voltage U02 is smaller than the rated voltage U01; S3, obtaining an expression that the current I, the rotating speed n, the output power P2 and the efficiency eta of the motor change along with the load torque T; and S4, obtaining the locked-rotor torque TD of the motor, selecting a plurality of values with the load torque T being 0-TD, and substituting into the expression of S3 to obtain a mechanical characteristic curve of the motor. The method has the advantages that the method can adapt to testing of more types of motors, the testing mode is simple, the testing cost is low, and compared with an acceleration torque transient mechanical characteristic testing method, the accuracy is better controlled, and the obtained characteristic curve is more accurate.

Owner:江苏旭泉电机股份有限公司

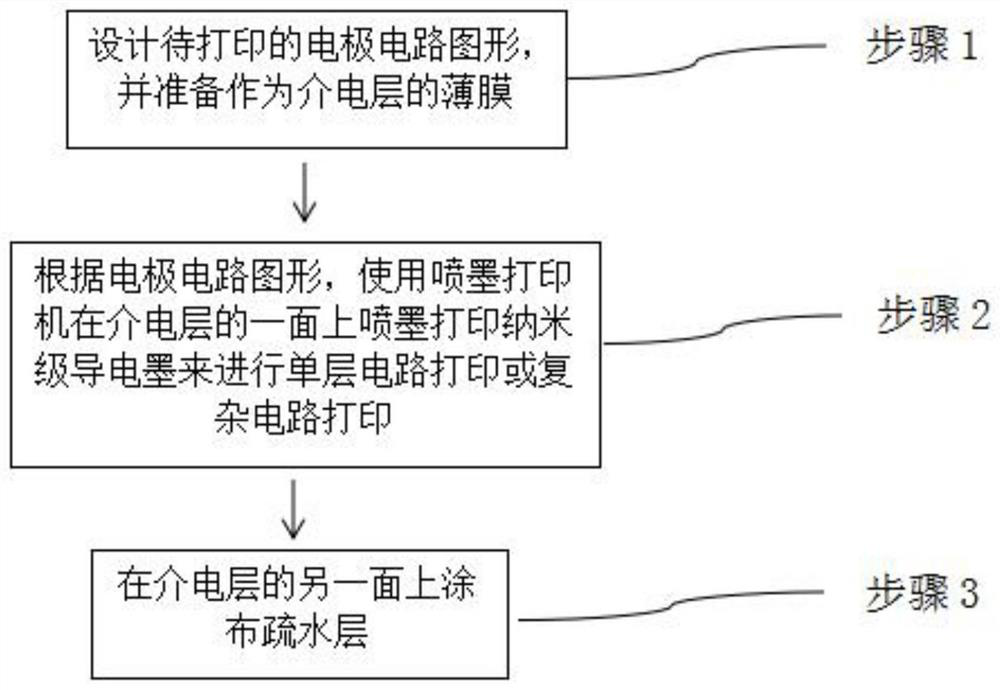

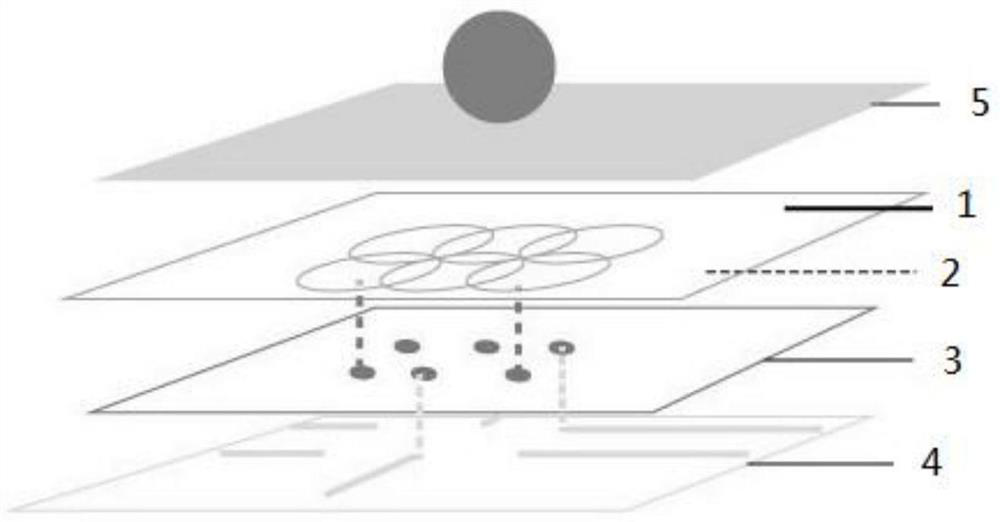

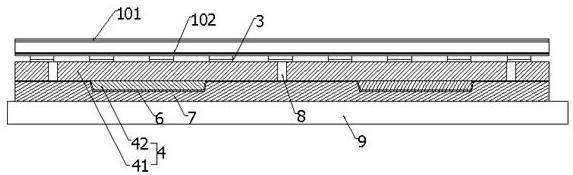

Manufacturing method of ink-jet printing digital micro-fluidic chip

InactiveCN113304791AAvoid bumpy wavy ladder rulerInhibit electrolysisLaboratory glasswaresPrintingComputer printingInk printer

The invention provides a manufacturing method of an ink-jet printing digital micro-fluidic chip, which comprises the following steps of: 1, designing an electrode circuit pattern to be printed, and preparing a thin film serving as a dielectric layer; 2, according to the electrode circuit pattern, using an ink-jet printer for carrying out ink-jet printing of nanoscale conductive ink on one face of the dielectric layer so as to carry out single-layer circuit printing or complex circuit printing; and 3, coating the other surface of the dielectric layer with a hydrophobic layer. According to the manufacturing method of the ink-jet printing digital micro-fluidic chip, high-precision resolution ink layer control is carried out by utilizing ink jet of an ink-jet printer, the problems that steps are generated in an electrode gap and liquid is blocked are solved, the problem of separation of an electrode and a lead is solved, and the influence of short circuit in a complex circuit design is effectively avoided. The ink-jet printing process is relatively simple, low in cost and high in precision, is suitable for repeated test requirements of the digital micro-fluidic chip in the research field, can greatly improve the working precision and efficiency of the digital micro-fluidic chip, and has practicability.

Owner:SHANGHAI PUBLISHING & PRINTING COLLEGE

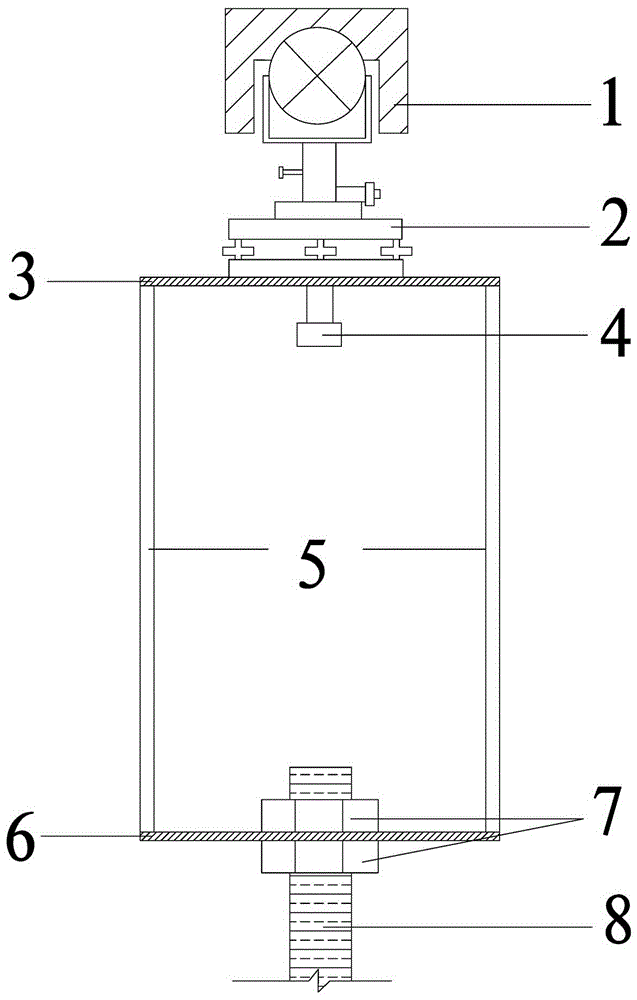

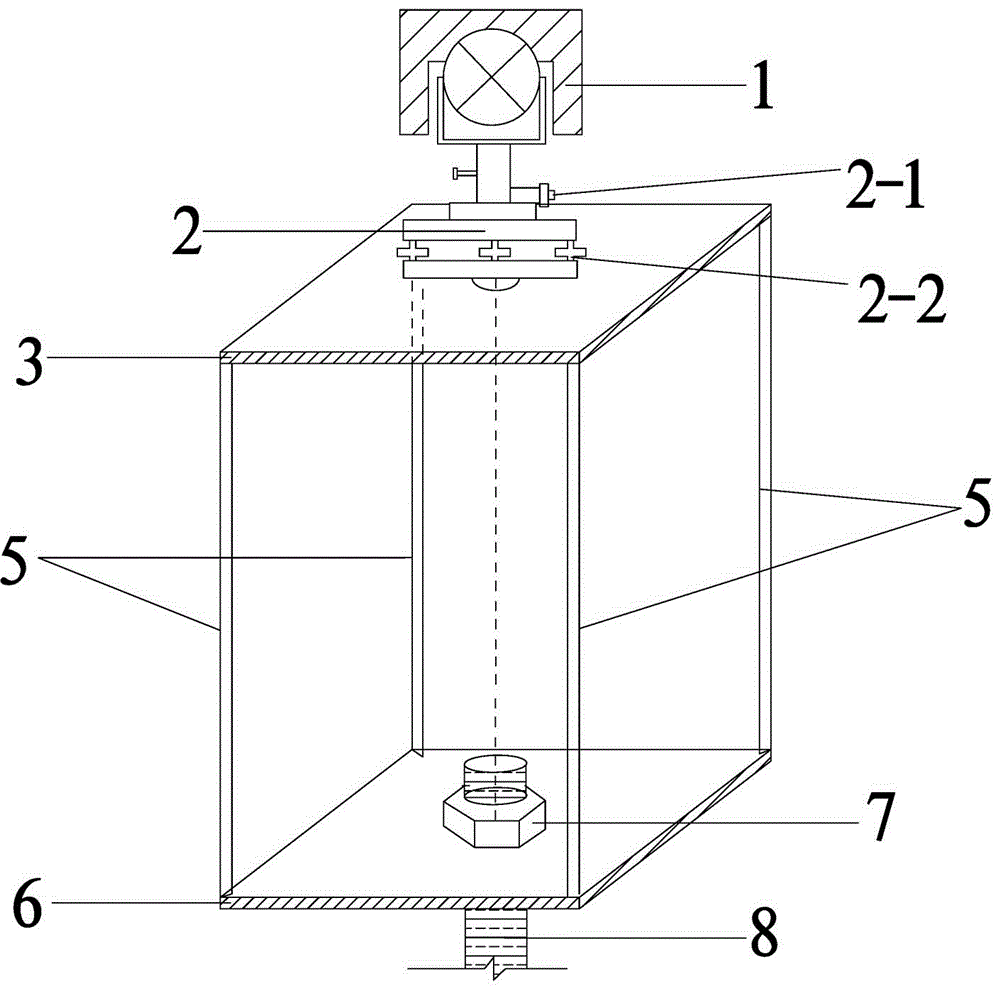

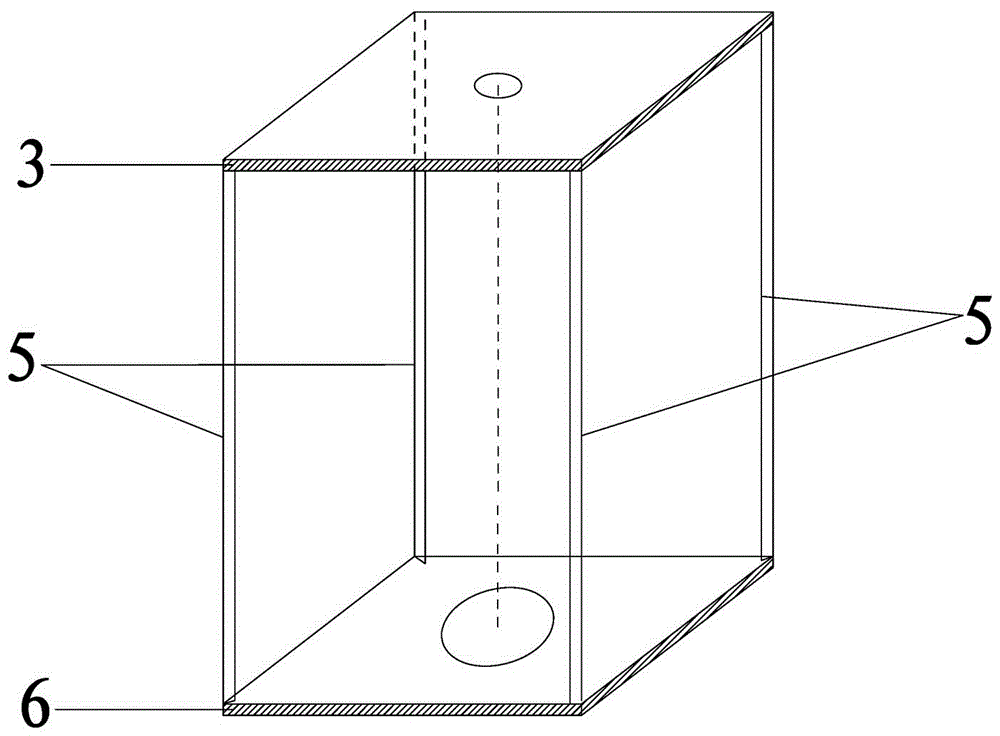

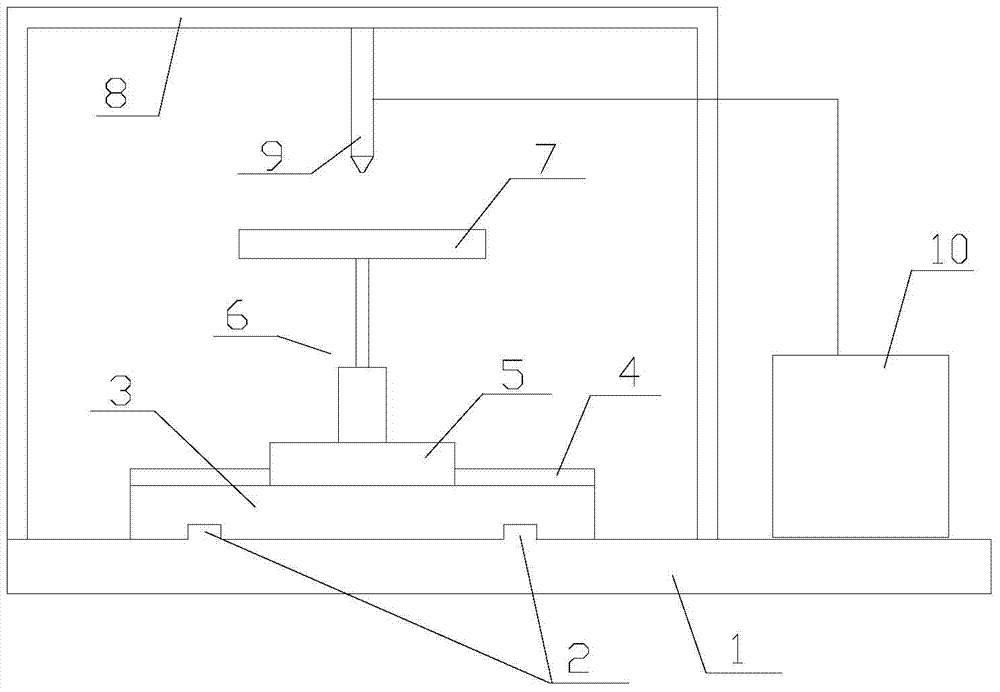

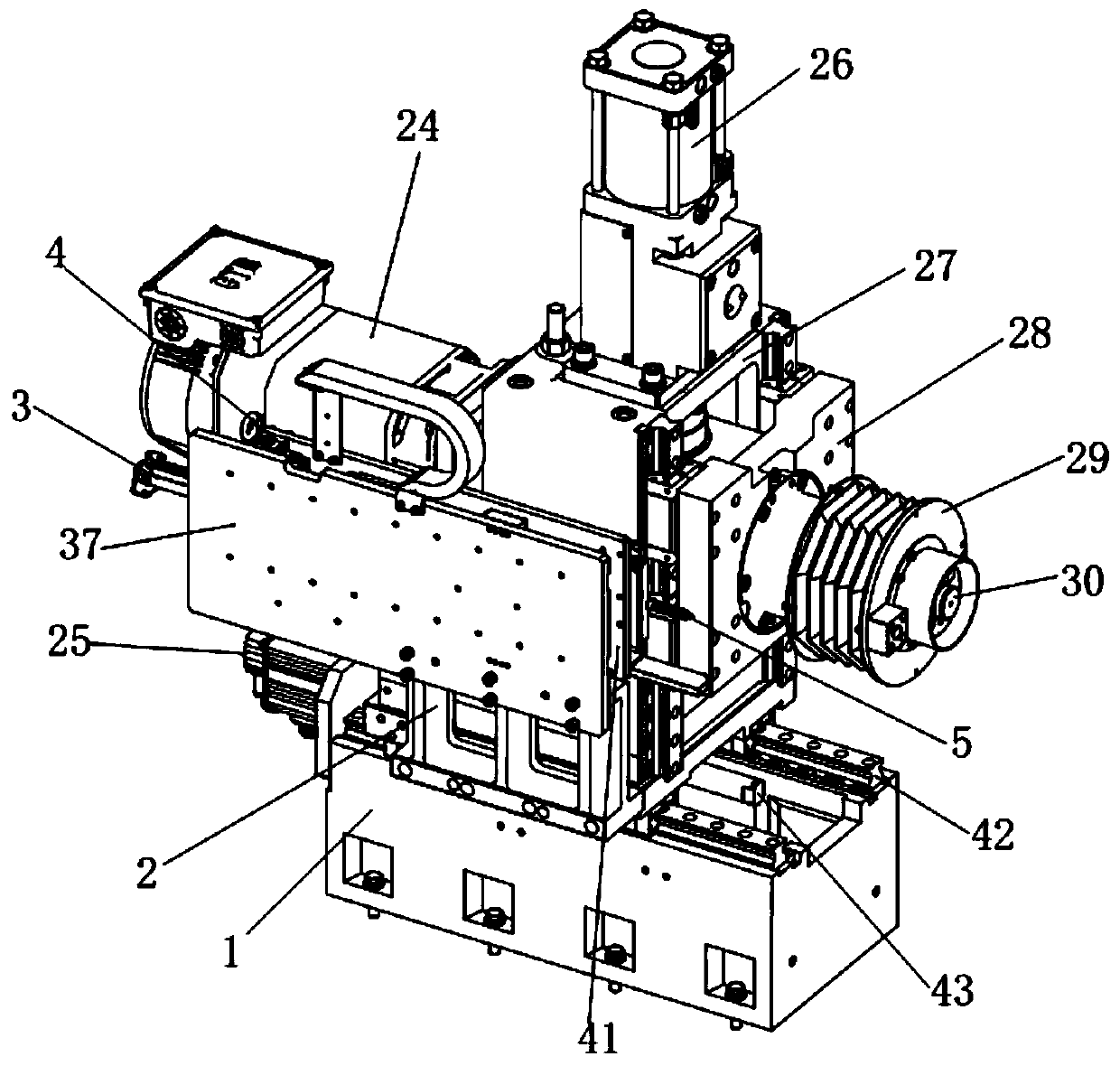

Semiconductor crystal rod Notch forming center calibration device and method

PendingCN110587428ASimple installationThe calibration method worksGrinding drivesGrinding feed controlMeasurement deviceEngineering

The invention belongs to the technical field of silicon rod machining and particularly relates to a semiconductor crystal rod Notch forming center calibration device comprising a clamping device, a center measurement device and a V groove grinding device, and the center measurement device and the V groove grinding device are arranged on the two sides of the clamping device correspondingly. The invention further relates to a calibration method. Firstly, center calibration is conducted through the center measurement device and a high-precision center calibration rod, and then center calibrationis conducted through the V groove grinding device and the high-precision center calibration rod. Through the semiconductor crystal rod Notch forming center calibration device and method, the problem that when a Notch groove is formed in a semiconductor crystal rod, semiconductor grinding equipment cannot be calibrated by a tool is solved, and the method for calibration through the calibration device is convenient and reliable and is an effective method for fast calibrating the Notch groove.

Owner:QINGDAO GAOCE TECH CO LTD

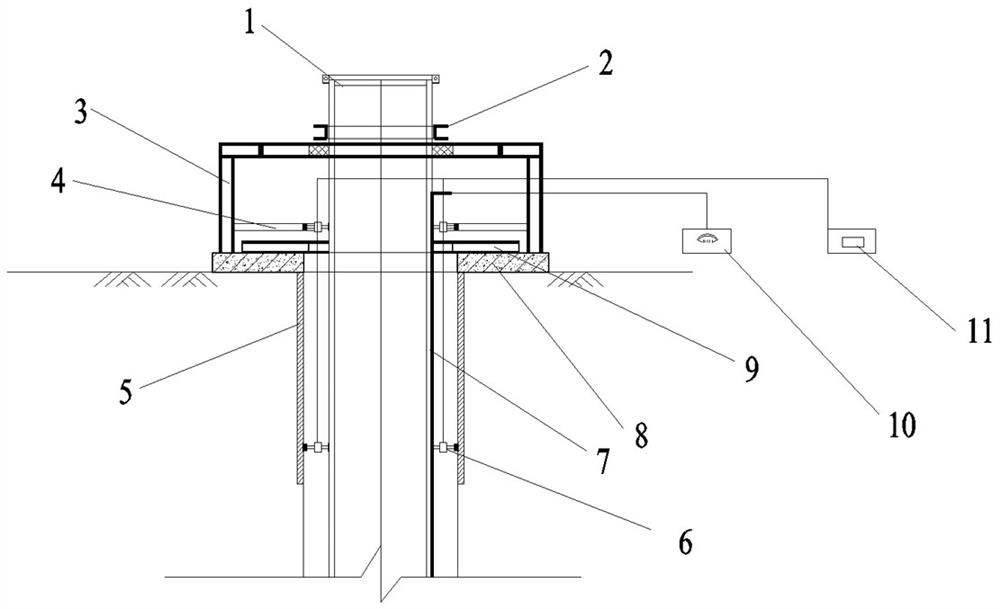

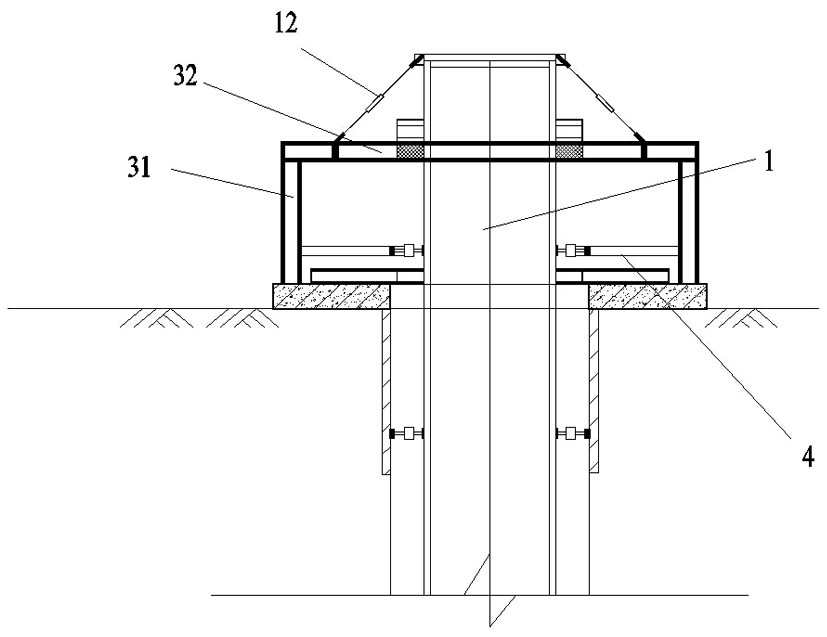

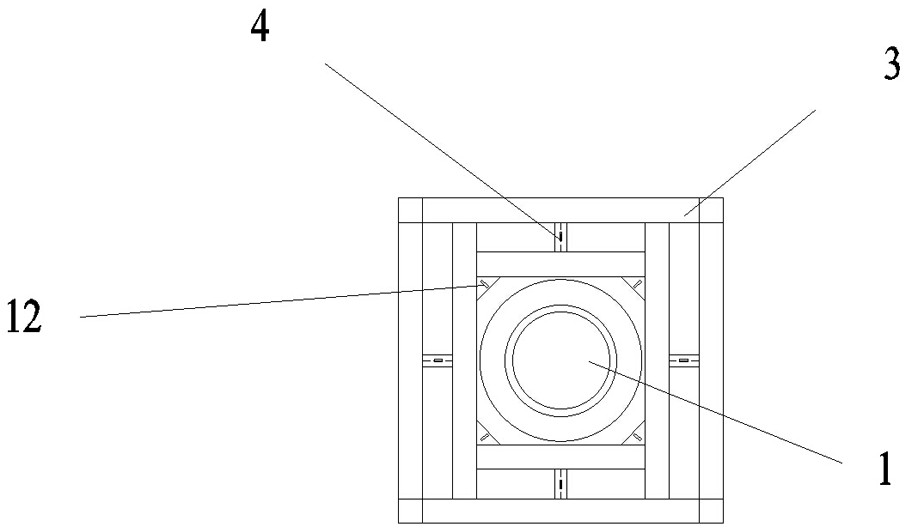

Pile column connection precise positioning pouring system and construction method

The invention discloses a pile column connection precise positioning pouring system and a construction method. The pile column connection precise positioning pouring system comprises a steel stand column, a drilled pile, a control frame connected to a supporting platform, a first jack connected between the control frame and the horizontal direction of the steel stand column, a second jack connected between a protective cylinder and the horizontal direction of the steel stand column, and a feeding pipe inserted into the steel stand column. During construction, by arranging the control frame, the steel stand column can be effectively borne; by arranging the supporting platform, the supporting platform can be fixedly connected through a bearing arm pre-connected to the steel stand column; by arranging the first jack and the second jack, installation is facilitated, and adjustment, clamping and fixing are facilitated; and the first jack and the second jack are jointly controlled through a verticality adjusting controller, so that cooperation and synchronous control are facilitated. Through pouring construction of different grades of concrete, the overall construction of the steel stand column and the drilled pile is guaranteed, and effective construction during concrete grade conversion and precision control in the process are guaranteed.

Owner:CHINA CONSTR SECOND ENG BUREAU LTD

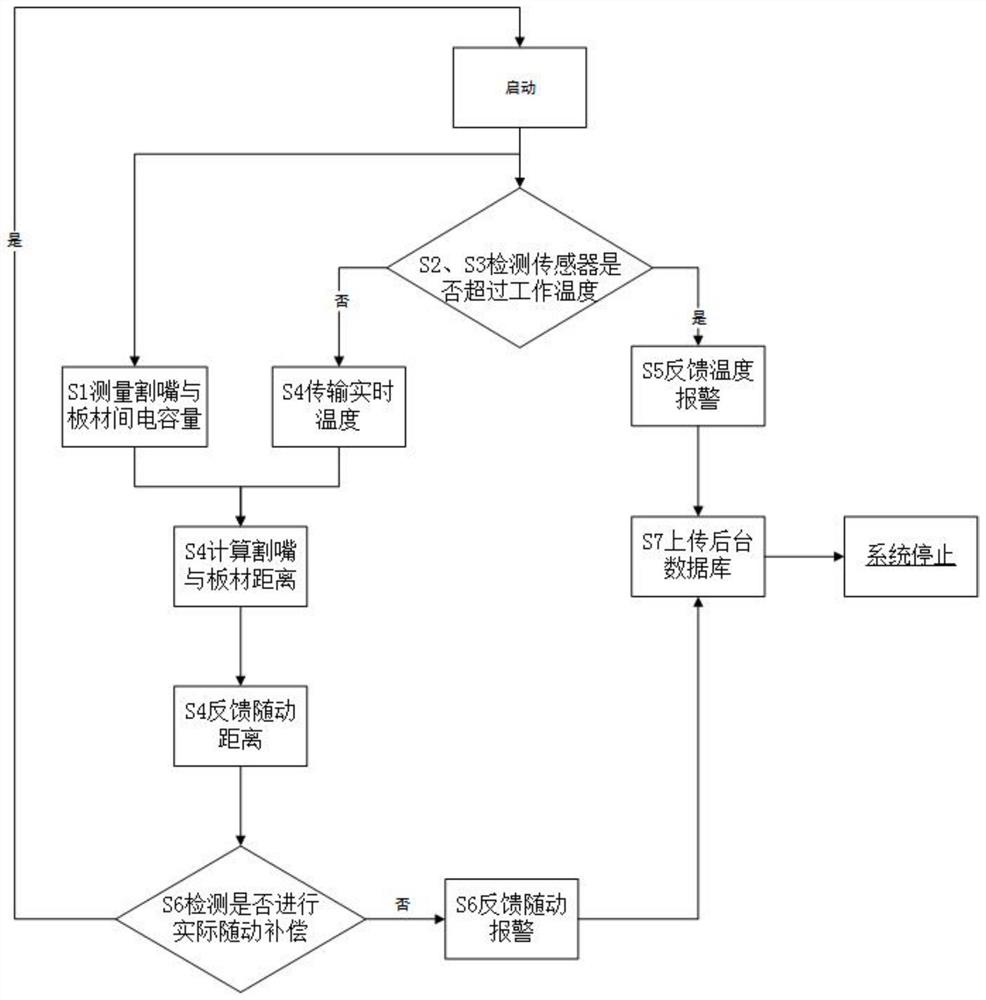

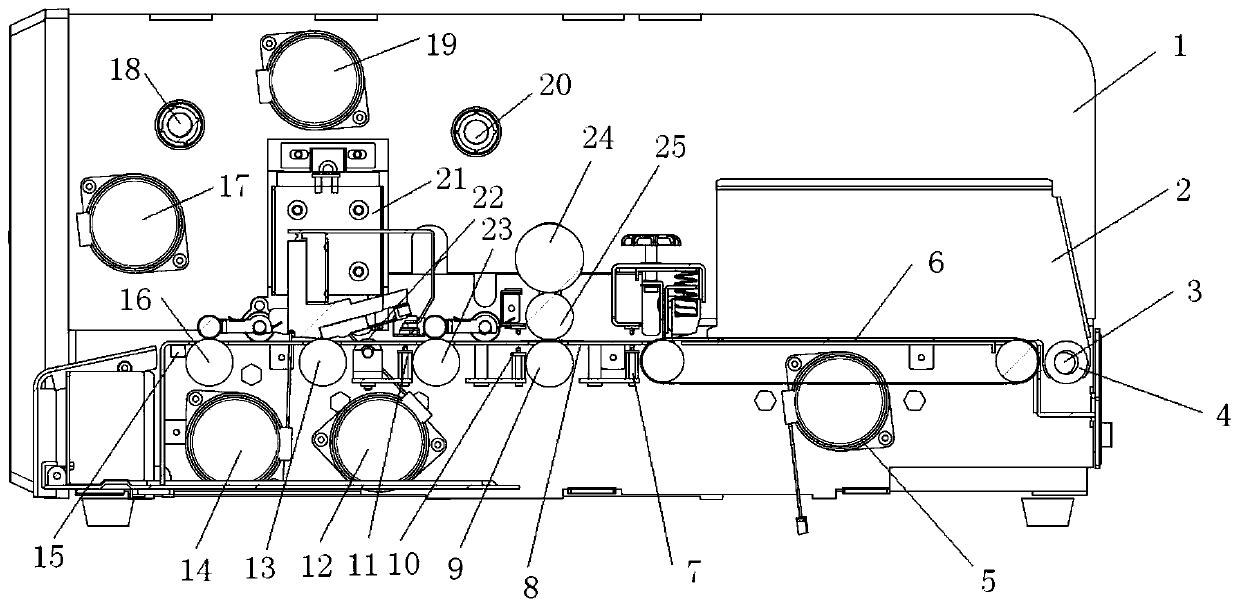

Cutting head follow-up control system and method

ActiveCN112276371AGuaranteed precision controlEasy to storeLaser beam welding apparatusControl systemControl engineering

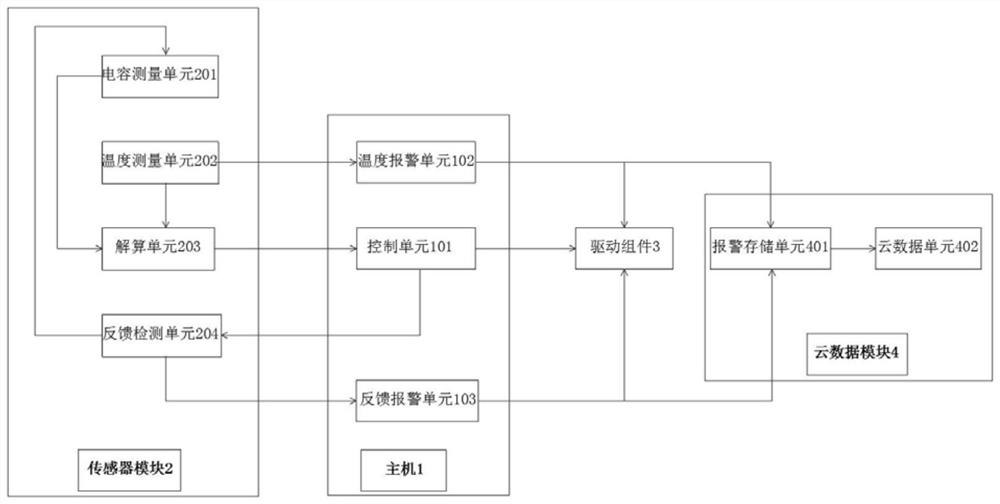

The invention discloses a cutting head follow-up control system. The system comprises a host, a sensor module and a driving assembly, wherein the host is electrically connected with the sensor moduleand the driving assembly separately, the sensor module is used for measuring physical characteristics of a laser cutting head nozzle, converting the physical characteristics into signals and transmitting the signals to the host, the host sends a corresponding control instruction to the driving assembly after receiving the signals, the sensor module comprises a capacitance measuring unit and a temperature measuring unit, the capacitance measuring unit is used for detecting capacitance signal between the laser cutting head nozzle and a to-be-cut workpiece, and the temperature measuring unit is used for detecting the temperature of the capacitance measuring unit. According to the follow-up control system, the follow-up control precision is improved, the follow-up control system can automatically give an alarm and stop in case of abnormal operation, the overall precision of laser cutting operation is guaranteed, an operator can conveniently store, analyze and estimate all data appearing infollow-up control, the use condition of the follow-up control system can be better monitored, and maintenance management in the later period is facilitated.

Owner:HANS LASER TECH IND GRP CO LTD +1

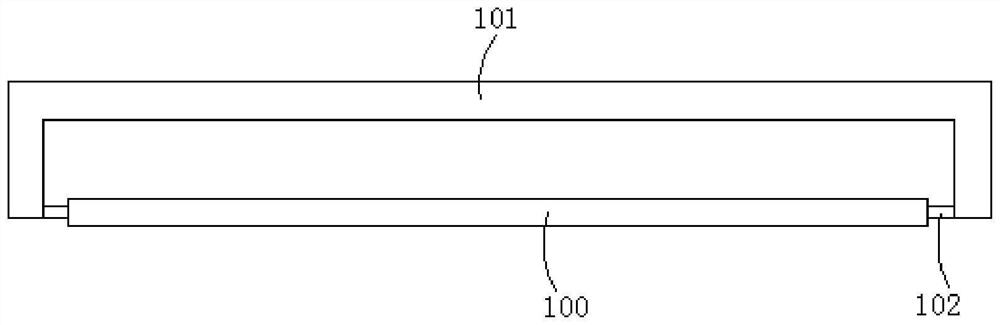

Precision printing machine

PendingCN110682700AAvoid wear and tearPrevent paper jamsOther printing apparatusComputer printingDust control

The invention relates to the field of a printing machine, in particular to a precision printing machine. The precision printing machine comprises a machine shell, an annular card absorbing belt, a paper inlet channel dust-removing roller and a printing head; the dust-removing roller is arranged in front of the annular card absorbing belt and comprises a dust-removing active rotary roller and a dust-removing passive rotary roller; a card dust-removing sensor is arranged in front of the dust-removing roller; the printing head is hinged in front of the card dust-removing sensor; a printing rollerdriven by a printing motor to rotate is arranged below the printing head; transmission gears which are mutually engaged are arranged between a motor shaft of the printing motor and a roller shaft ofthe dust-removing active rotary roller; the control end of the card dust-removing sensor is connected with a card absorbing motor through a cable; a front positioning roller, a back positioning rollerand a positioning sensor are arranged in front of and at back of the printing roller; and the control end of the positioning end is connected with the printing motor through a cable. The precision printing machine provided by the invention is simple in structure, high in printing precision and good in printing effect and can prevent the printing roller or card paper from being worn.

Owner:南京莱贝尔特软件科技有限公司

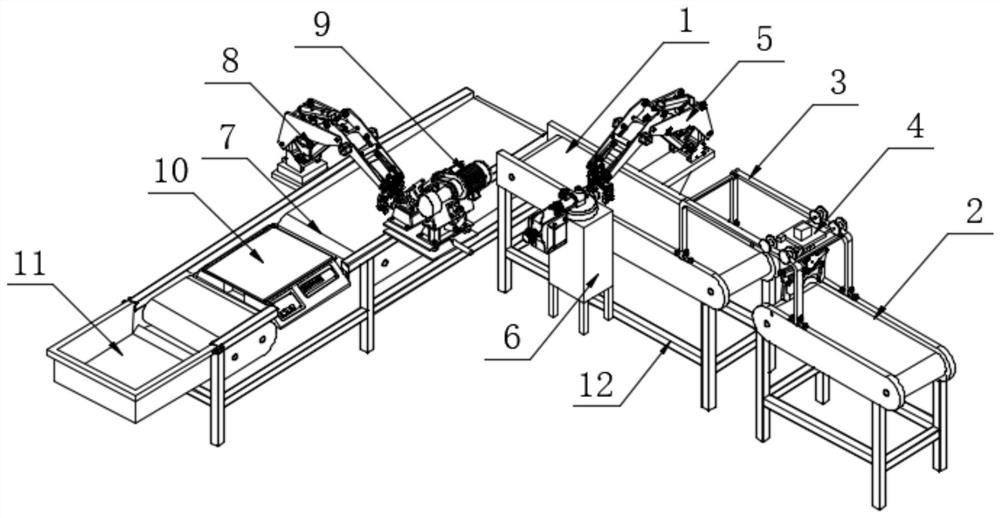

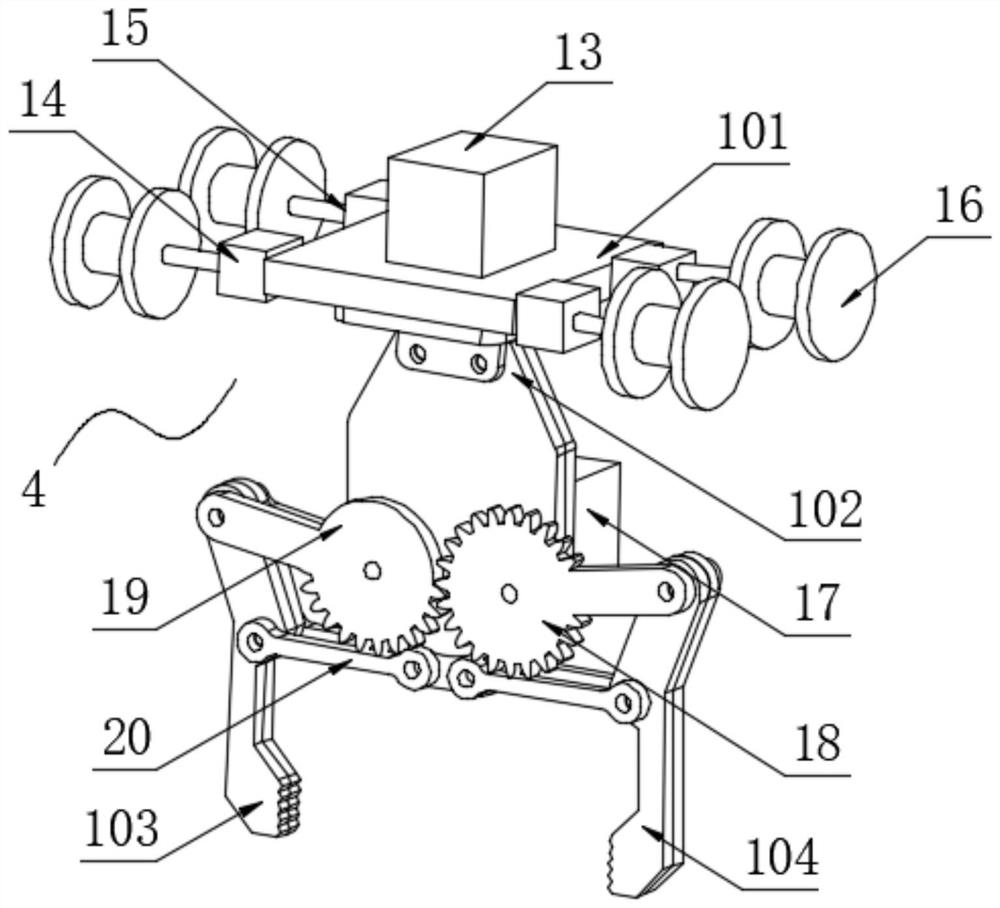

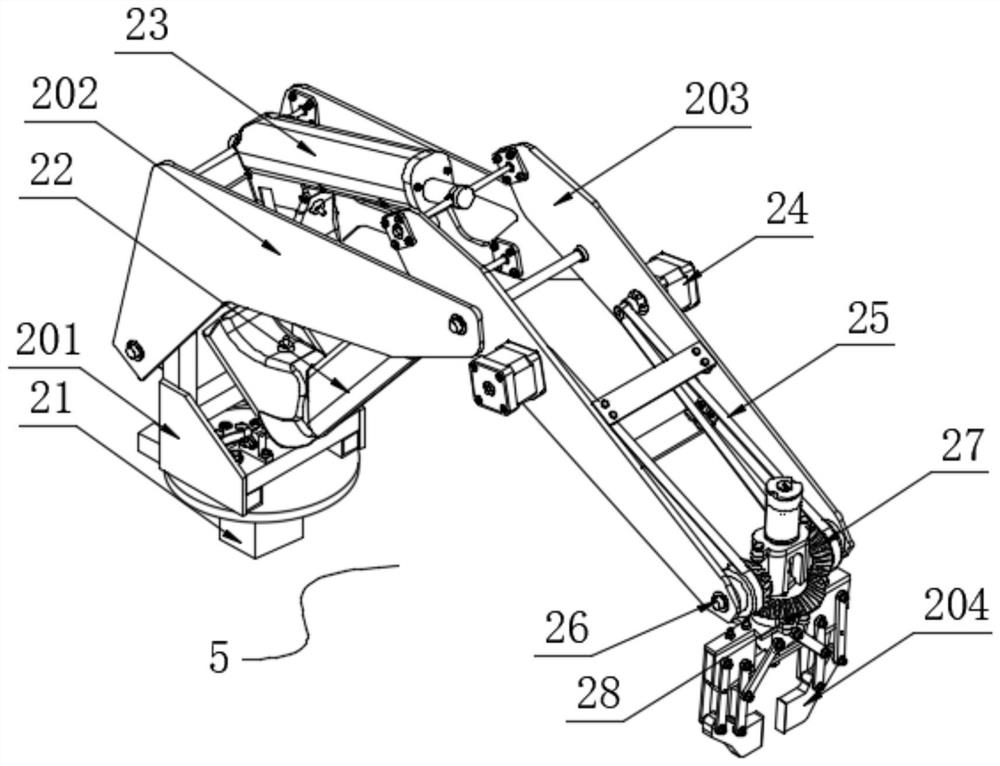

Manipulator for automatic casting production line

InactiveCN113829331AStir wellEasy to useProgramme-controlled manipulatorCasting plantsProduction lineProcess engineering

The invention relates to the technical field of casting equipment, in particular to a manipulator for an automatic casting production line. The manipulator is characterized in that a second conveyor is arranged on one side of the outer end of a first conveyor, a third conveyor is arranged on the other side of the outer end of the first conveyor, a group of connecting frames are fixedly mounted between the first conveyor and the second conveyor, a clamping manipulator is arranged on one side of the bottom end of each connecting frame, a first manipulator mechanism is fixedly mounted on one side of the top end of the first conveyor, and a paint spraying mechanism is fixedly mounted on the side, close to the first manipulator mechanism, of the outer wall of the first conveyor. According to the manipulator for the automatic casting production line, the whole device can achieve simple, convenient and efficient workpiece forging, the working efficiency of a user is effectively improved, and a better use prospect is brought.

Owner:含山县峰园精铸加工厂

Garment edge folding hot press forming device and forming method

ActiveCN112998339ANot easy to shiftFocus on staying straightClothes making applicancesEngineeringMechanical engineering

The invention relates to a garment edge folding hot press forming device and method, and the garment edge folding hot press forming device comprises a hot press forming mechanism and an edge folding positioning mechanism; the edge folding positioning mechanism comprises a positioning long strip, one long edge side of the positioning long strip is connected with a pressing plate, the lower surface of the pressing plate is flush with the lower surface of the positioning long strip, a support is arranged on the machine table, the pressing plate is hinged to the support, and the machine table is further provided with a supporting table used for supporting the pressing plate. The positioning long strip comprises an upper long plate and a lower long plate, and the two sides of the upper long plate and the lower long plate in the width direction are connected; a partition cavity is formed between the upper long plate and the lower long plate, a conveying belt connected end to end is wound around the upper long plate in the length direction, the outer surface of the conveying belt is covered with a fixing belt, the two side edges of the fixing belt in the width direction are fixed to the conveying belt, and long holes extending in the width direction of the fixing belt are evenly formed in the middle of the fixing belt in the length direction. The garment edge folding hot press forming difficulty can be reduced, and the forming precision can be improved.

Owner:福州天泰行运动用品有限公司

Ultra-long large-diameter pile foundation underwater operation platform unit, operation platform and construction method

PendingCN113152300AThe overall layout is reasonableImprove construction efficiency and stabilityArtificial islandsBridge erection/assemblyStructural stabilityCantilever

The invention belongs to the technical field of underwater pile foundation construction. The ultra-long large-diameter pile foundation underwater operation platform unit comprises a supporting barrel and a cantilever positioning guide frame, a guide assembly is arranged on the cantilever positioning guide frame and used for conducting radial limiting supporting on the supporting barrel, a supporting assembly is arranged on the supporting barrel, and the supporting assembly is used for supporting the supporting barrel. The supporting assembly is used for supporting the cantilever positioning guide frame. The invention further discloses a super-long large-diameter pile foundation underwater operation platform and a construction method. The overall arrangement is reasonable, the problems existing in construction of an existing ultra-long large-diameter pile foundation operation platform can be effectively solved, the structural stability and the construction efficiency are improved, modular arrangement can be achieved, and construction and control over the structural stability are more convenient.

Owner:HENAN HIGHWAY ENG GROUP +1

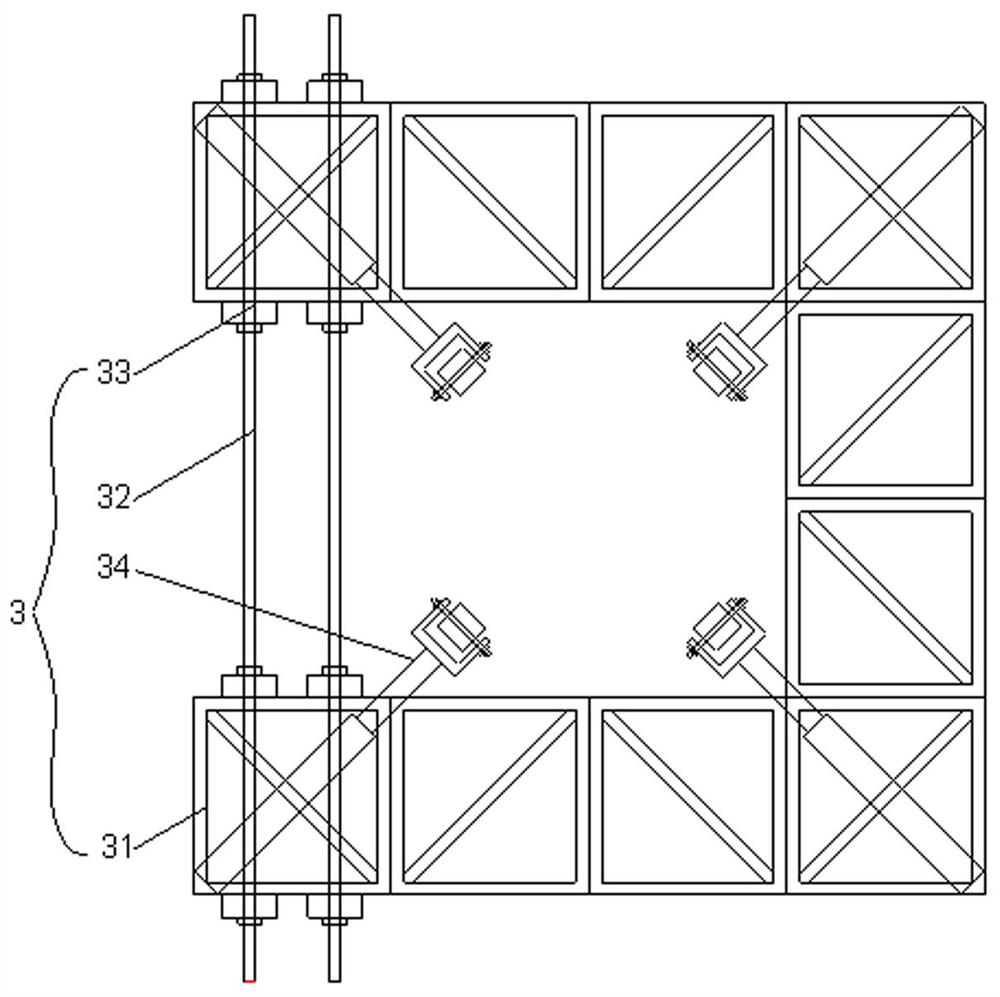

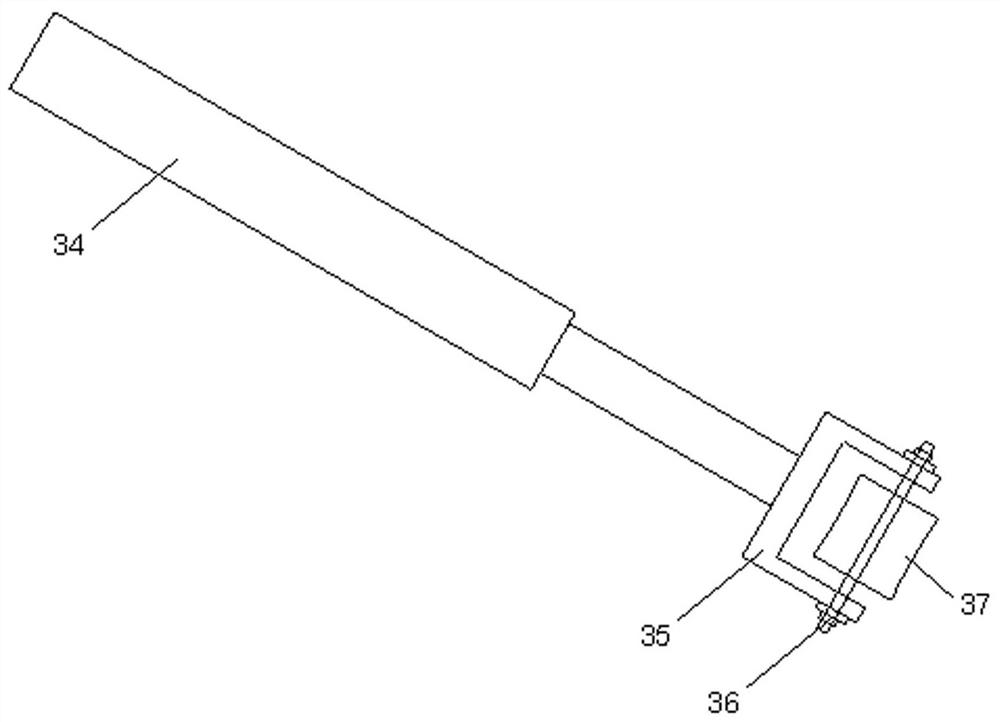

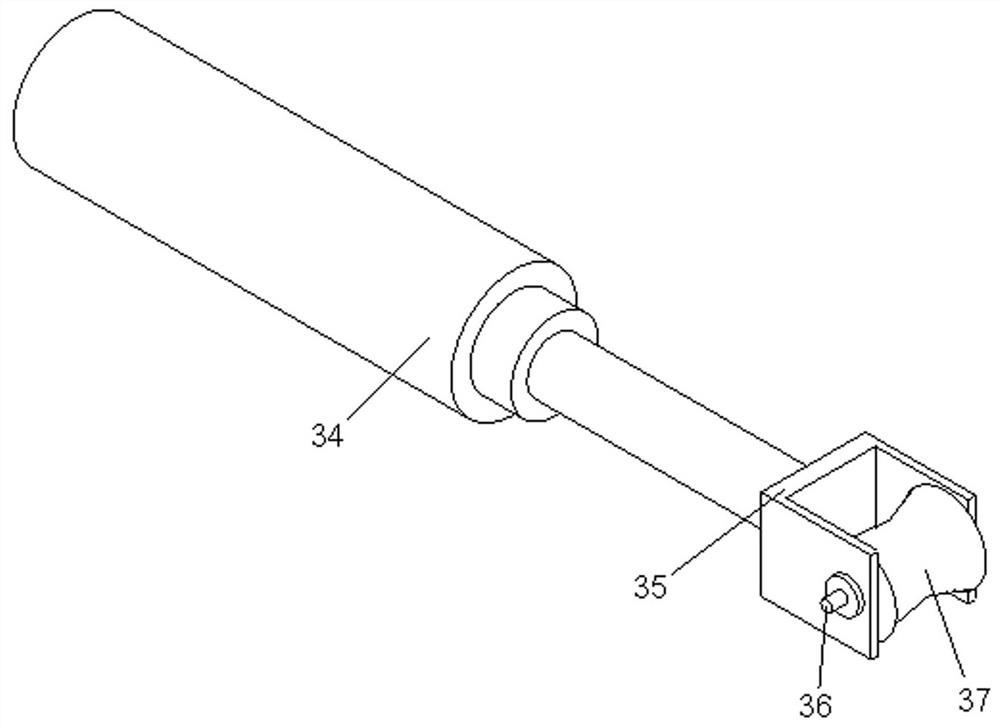

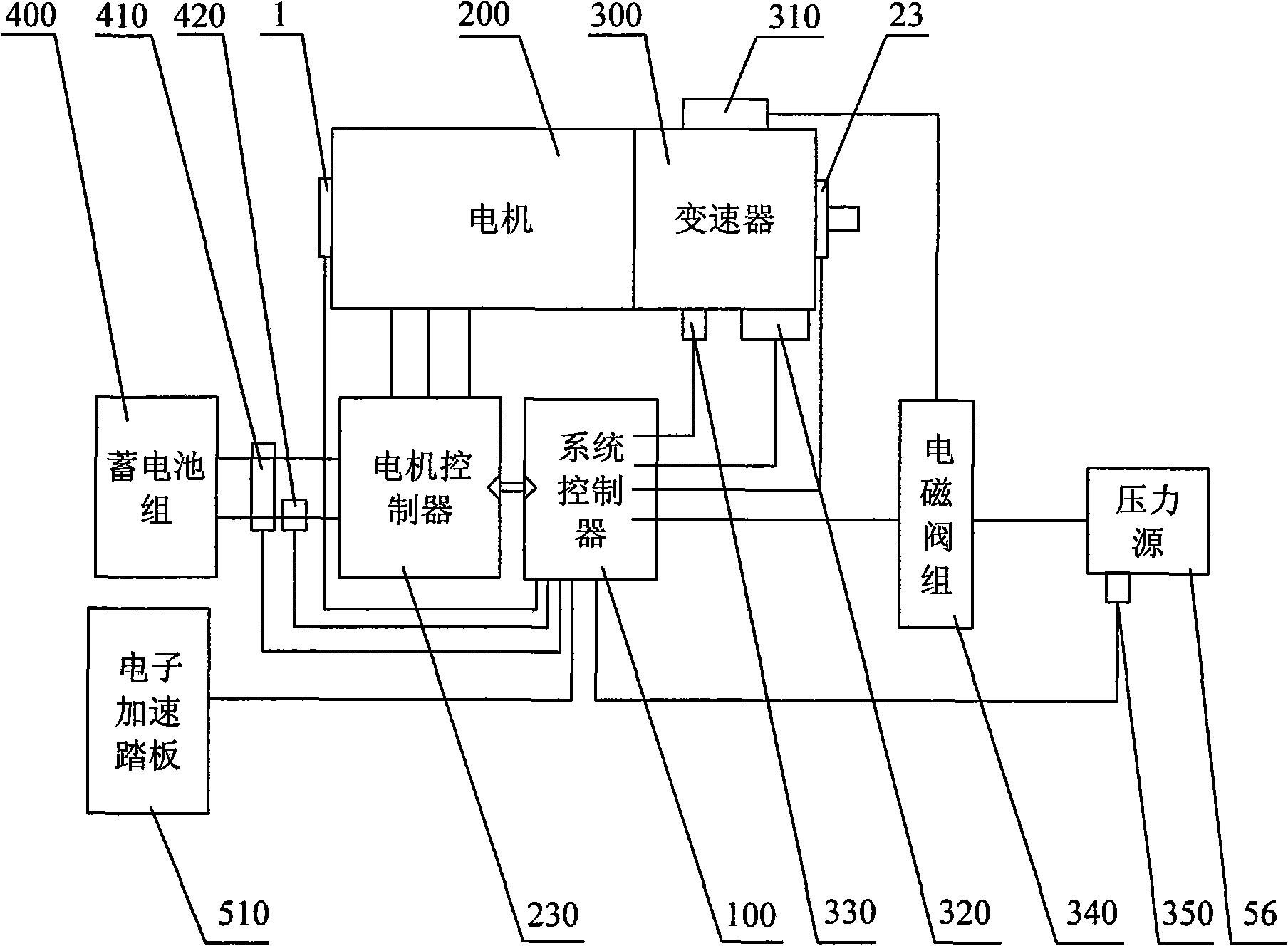

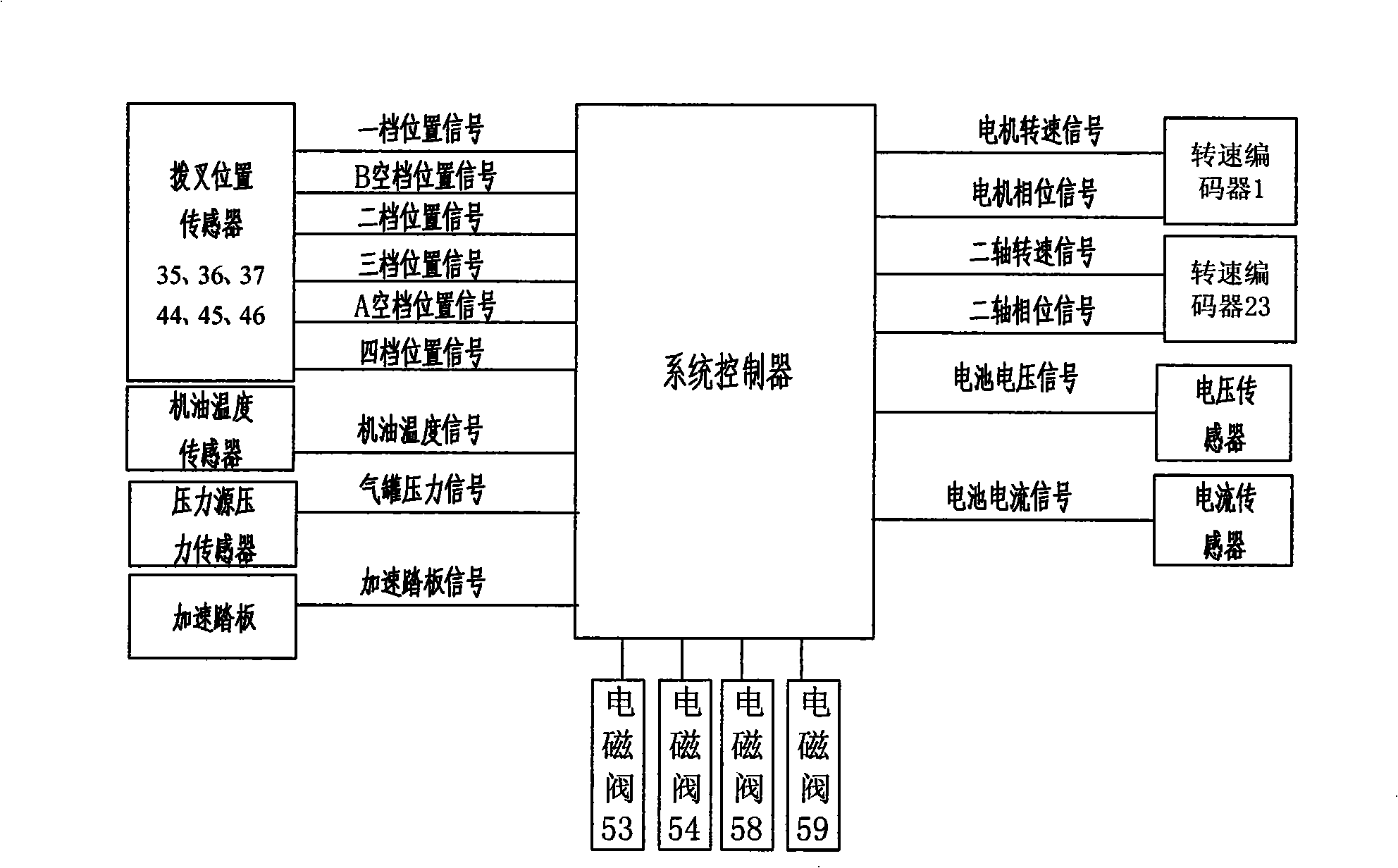

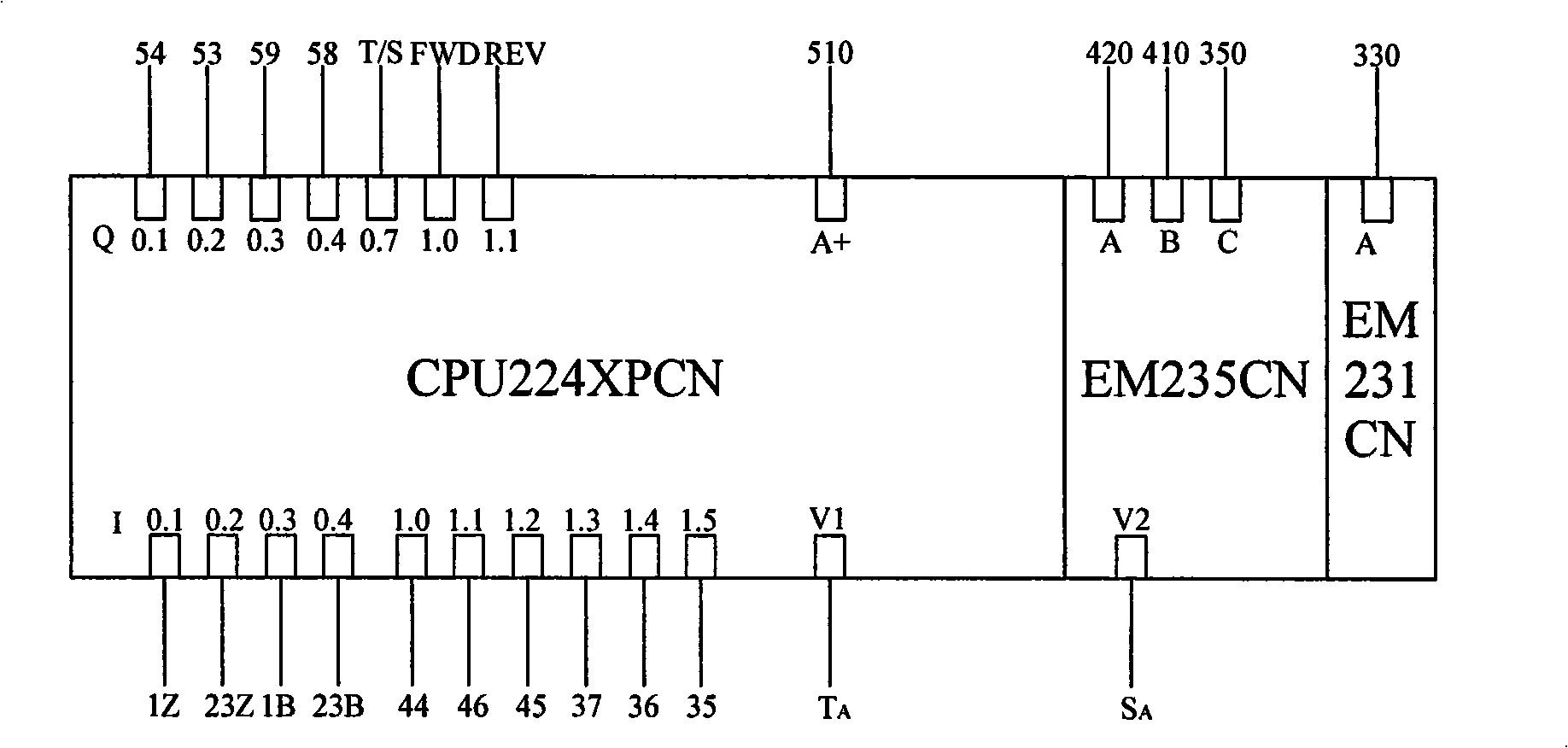

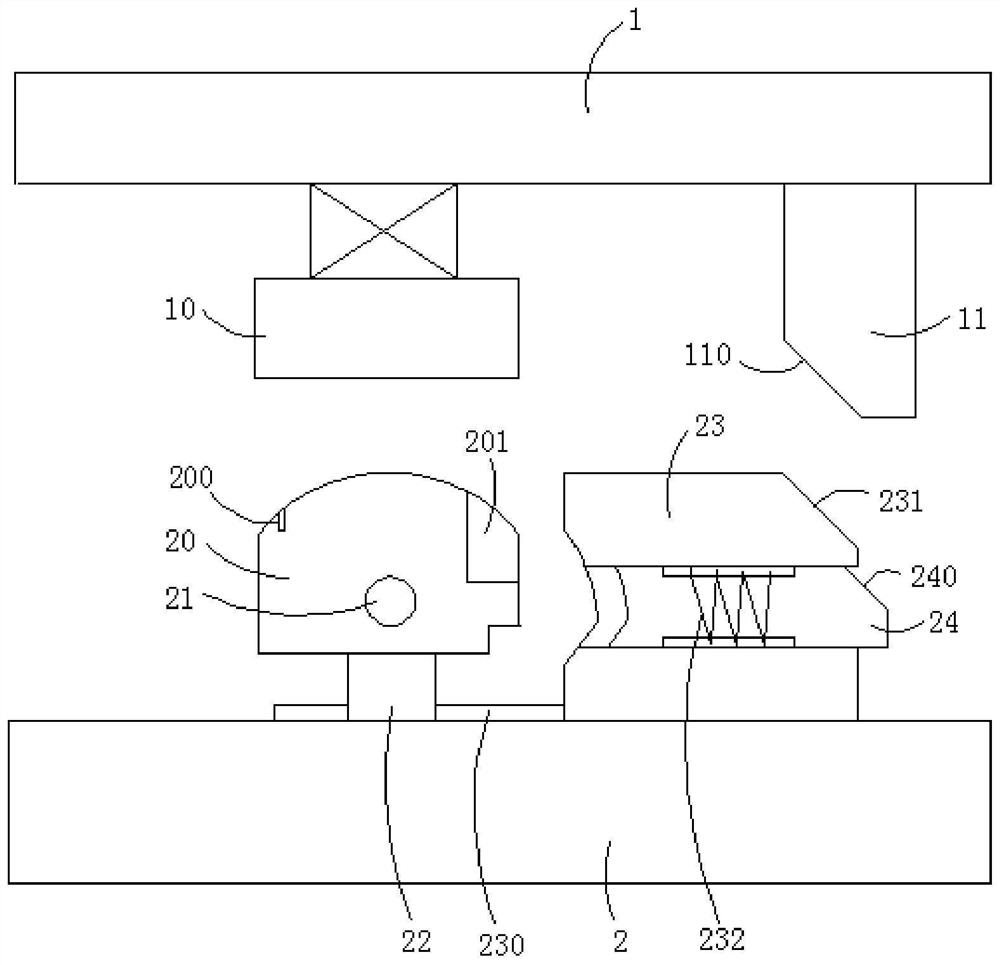

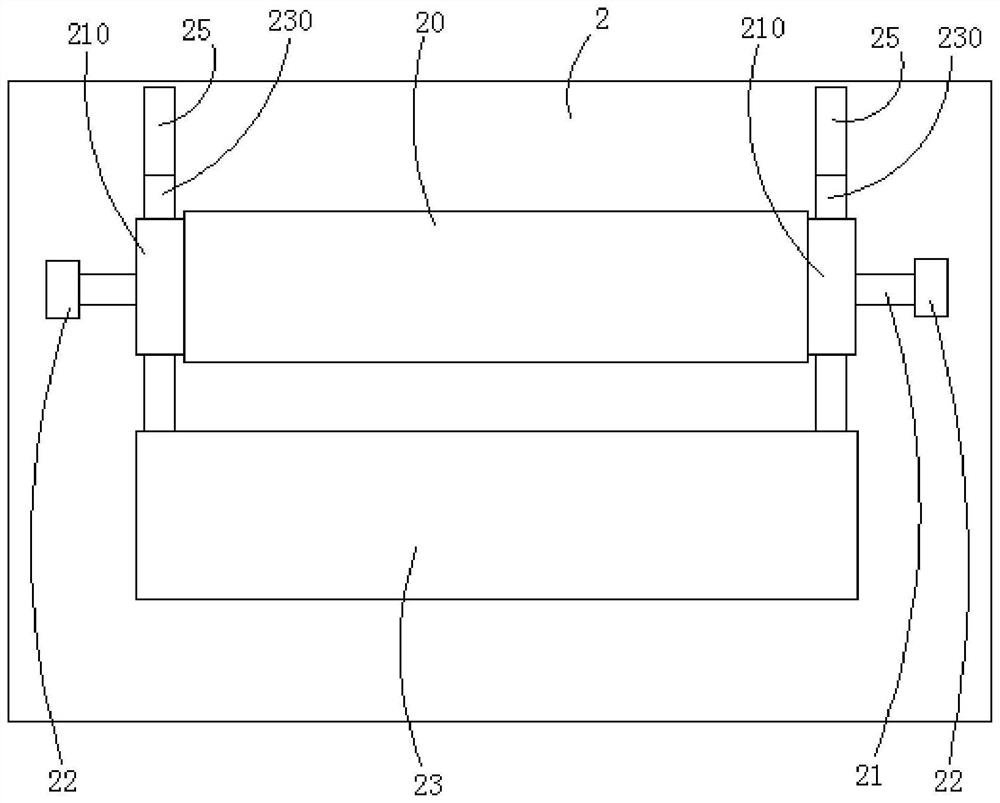

Automatic gear shifting control system of motor in electric automobile

ActiveCN101582676BImprove anti-interference abilityImprove electromagnetic compatibilitySpeed controllerElectronic commutation motor controlElectrical batteryCurrent sensor

The invention relates to an automatic gear shifting control system of a motor in an electric automobile, which is characterized by comprising the following components: a motor controller, a system controller, a battery voltage sensor, a battery current sensor, a first rotating speed coder, a second rotating speed coder, a folk position sensor group, a transmission motor oil temperature sensor, anda pressure source pressure sensor; wherein, the input ends of the motor controller are connected with two output terminals of a storage battery via a first wire; the output end of the motor controller is connected with the input end of the power supply via a second power supply wire. By using the invention, response is rapid, and gear shifting time is less than 1s; speed control is controller atconstant speed with accuracy, and the phase error is less than 1 degree; gear shifting is smooth without any gear shocking.

Owner:武汉理工通宇新源动力有限公司

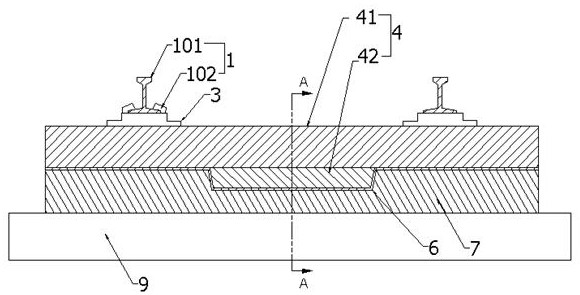

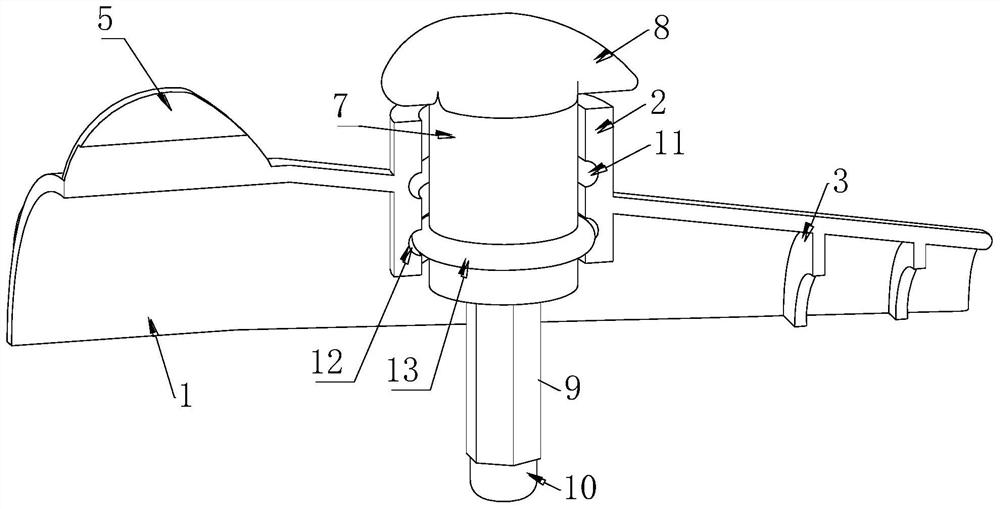

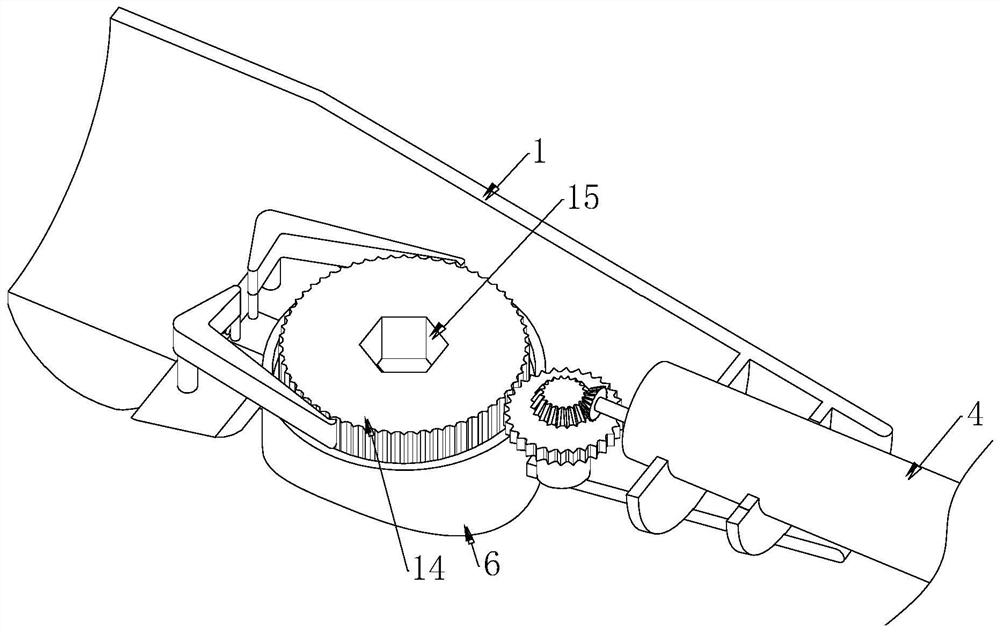

A flipping and shaping method for automobile skeleton parts

ActiveCN112355147BGood precisionCompact and reasonable structureShaping toolsVehicle componentsRotational axisGear wheel

The invention relates to an overturning plastic mold for automobile skeleton parts, comprising an upper mold and a lower mold. One side of the profile positioning block is slidingly provided with a profiling side pressing block and a reset assembly, a driving gear is coaxially fixed on the rotating shaft, and a driving rack is set on the profiling side pressing block; the elastic connection on the upper mold is provided with a flexible holding The upper mold is also equipped with a side knife; the internal activity of the profiling side pressing block is provided with a side shaping block; the profiling side pressing block is provided with a reset piece; the profiling positioning block is provided with a shaping die; the overall structure Reasonable and compact, loading and unloading are carried out in the forward direction, which can ensure the precision control of shaping. In addition, the turning and shaping power provided by the single side knife can simplify the mold structure, and the design of flexible pressing head and magnet can ensure Stability of product deflection process.

Owner:深圳数码模汽车技术有限公司

Medium and low temperature curing electrothermal slurry and preparation method thereof

PendingCN114464337AAvoid deformationSimple curing processNon-conductive material with dispersed conductive materialCable/conductor manufactureCarbide siliconLow temperature curing

The invention relates to the field of electric heating paste, in particular to medium and low temperature curing electric heating paste and a preparation method thereof, and the medium and low temperature curing electric heating paste comprises the following raw materials by weight: 3-15% of graphite powder, 0.5-6% of carbon powder, 0.1-3% of white carbon black, 3-10% of nickel powder, 1-15% of molybdenum powder, 0.5-10% of boron nitride, 1-4% of silicon carbide, 0.1-25% of silver powder, 35-70% of a binder, 0.1-3% of an auxiliary agent, and 0.1-15% of a solvent. A medium-low temperature curing mode is adopted, the curing process is simple, medium-low temperature energy consumption is small, it can be guaranteed that the substrate is not prone to deformation, precision control is more accurate, the resistance value deviation can be small, and the medium-low temperature curing mode can further improve the effect of being used in cooperation with other carrier materials with low melting points.

Owner:谢金龙

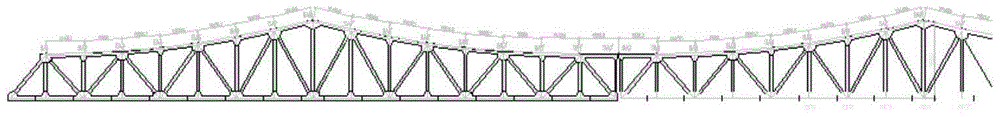

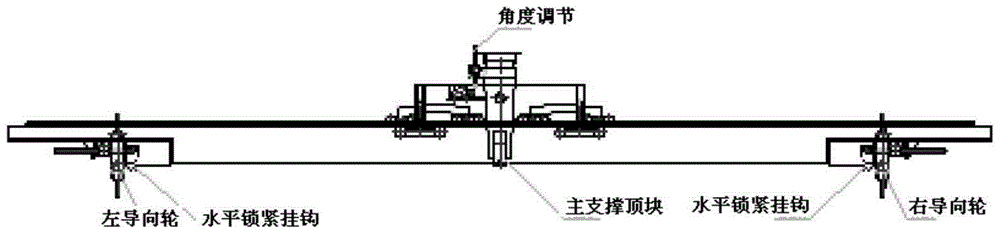

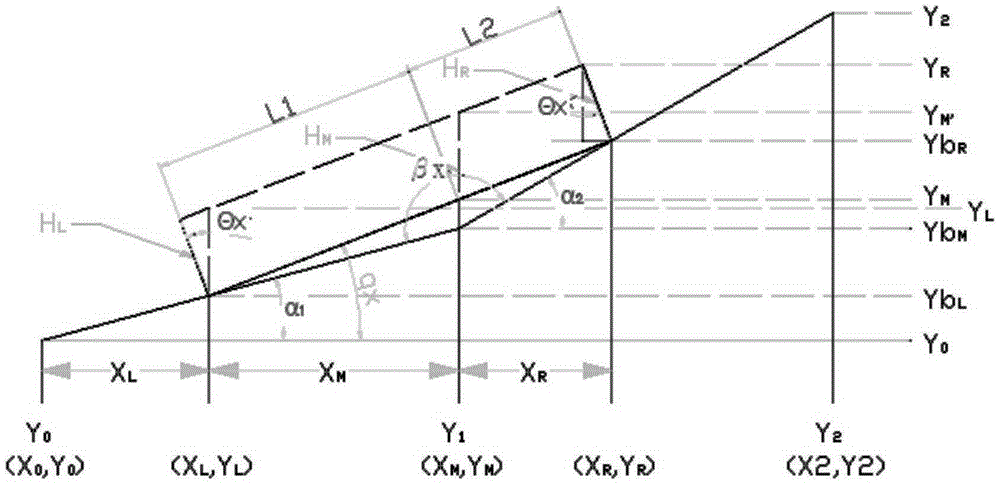

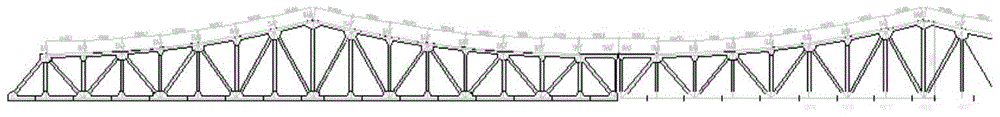

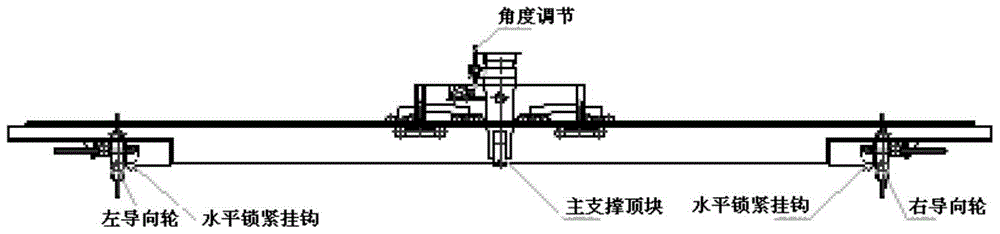

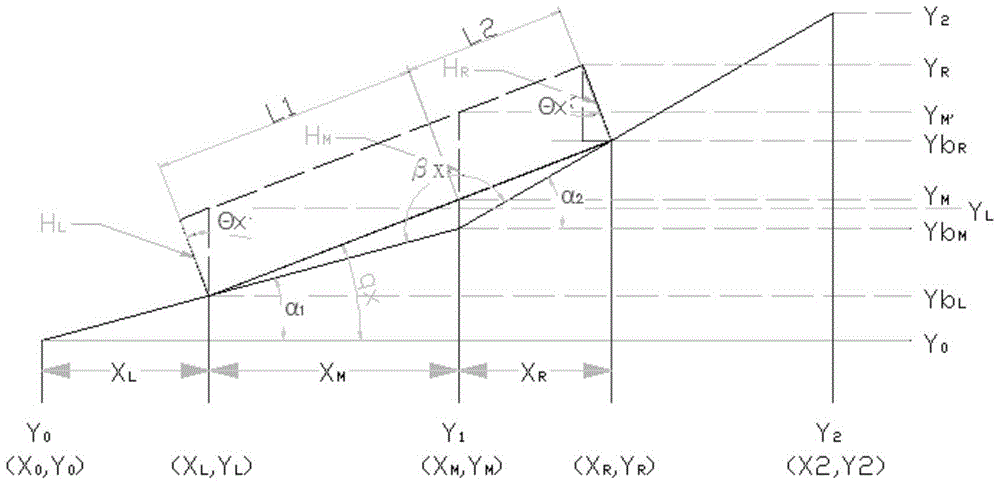

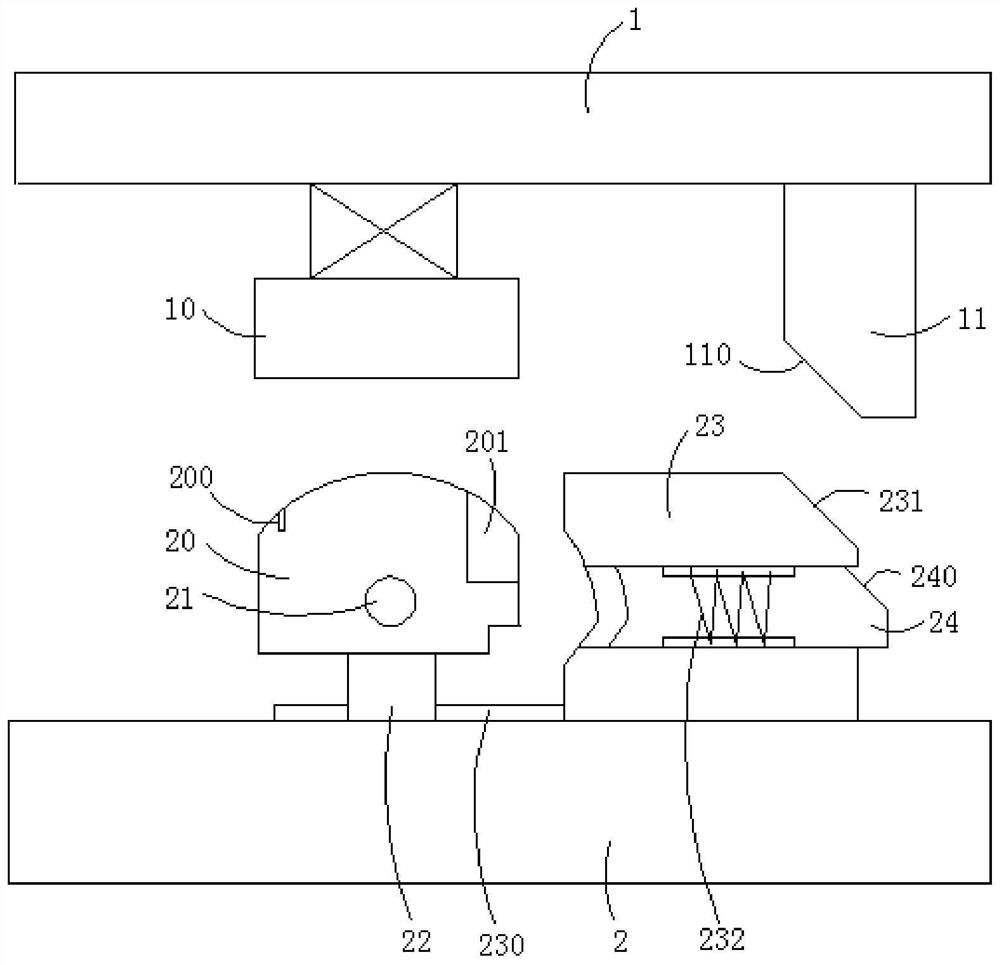

Self-adaption positioning control system of bridge detection vehicle

ActiveCN105239505AGuaranteed precision controlGeneral referenceBridge structural detailsEngineeringChange control

The invention discloses a self-adaption positioning control system of a bridge detection vehicle. The bridge detection vehicle comprises walking boots and a walking trolley, wherein the walking boots are devices which are used for detecting close contact and fixation between the detection trolley and a bridge; the walking boots comprise a trolley rail, telescopic guide wheels and telescopic fastening hooks; the walking trolley is a driving device of the detection vehicle, and is used for driving the walking boots and the detection vehicle to walk on the upper chord of the bridge; the walking trolley comprises a telescopic main support and walking wheels. The system comprises a walking-boot section changing control module and a walking trolley control module, wherein the walking-boot section changing control module is used for controlling the walking boots to change sections; the walking trolley control module is used for controlling the walking trolley to walk within a target section after the walking boots stop walking and are positioned by the horizontal fastening hooks. Through the adoption of the control system disclosed by the invention, the control with needed accuracy can be guaranteed. The control system has very important and general reference value and very important and general popularizing value for similar engineering machinery and bridge machinery.

Owner:HUBEI LONGYUAN POWER SCI & TECH CO LTD

Adaptive Positioning Control System of Bridge Inspection Vehicle

The invention discloses a self-adaption positioning control system of a bridge detection vehicle. The bridge detection vehicle comprises walking boots and a walking trolley, wherein the walking boots are devices which are used for detecting close contact and fixation between the detection trolley and a bridge; the walking boots comprise a trolley rail, telescopic guide wheels and telescopic fastening hooks; the walking trolley is a driving device of the detection vehicle, and is used for driving the walking boots and the detection vehicle to walk on the upper chord of the bridge; the walking trolley comprises a telescopic main support and walking wheels. The system comprises a walking-boot section changing control module and a walking trolley control module, wherein the walking-boot section changing control module is used for controlling the walking boots to change sections; the walking trolley control module is used for controlling the walking trolley to walk within a target section after the walking boots stop walking and are positioned by the horizontal fastening hooks. Through the adoption of the control system disclosed by the invention, the control with needed accuracy can be guaranteed. The control system has very important and general reference value and very important and general popularizing value for similar engineering machinery and bridge machinery.

Owner:HUBEI LONGYUAN POWER SCI & TECH CO LTD

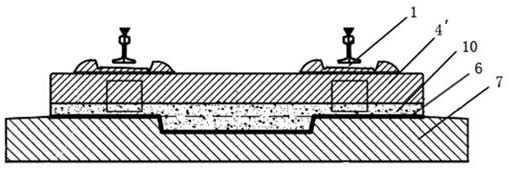

Overturning shaping die and method for automobile framework part

ActiveCN112355147AGood precisionCompact and reasonable structureShaping toolsVehicle componentsRotational axisGear wheel

The invention relates to an overturning shaping die for an automobile framework part. The overturning shaping die comprises an upper die and a lower die; a profiling positioning block, a rotating shaft and two bearing seats are arranged on the lower die, and a magnet is arranged on the profiling positioning block; a profiling side pressing block and a reset assembly are arranged on the side, located on the profiling positioning block, of the lower die in a sliding mode, a driving gear is coaxially fixed to the rotating shaft, and a driving rack is arranged on the profiling side pressing block;a flexible pressing head is connected to the upper die in an elastic manner; a side cutter is also arranged on the upper die; a side shaping block is movably arranged in the profiling side pressing block in a penetrating mode; a reset piece is arranged on the profiling side pressing block; and a shaping female die is arranged on the profiling positioning block. According to the overturning shaping die for the automobile framework part, the overall structure is reasonable and compact, feeding and discharging are conducted in the forward direction, shaping precision control can be guaranteed, in addition, turning and shaping power is provided through the single-side cutter, the die structure can be simplified, and the stability of the product in the deflection process can be guaranteed through the design of the flexible pressing head and the magnet.

Owner:深圳数码模汽车技术有限公司

A combined track slab, prefabricated slab track system and its installation and construction method

ActiveCN112941975BReduce pouring processImprove installation efficiencyBallastwayTrackwayArchitectural engineering

The invention relates to the technical field of railway track engineering, in particular to a combined track slab, a prefabricated slab track system and an installation and construction method thereof. The prefabricated slab track system of the present invention includes a rail row structure, a combined track slab, an isolation layer and a base, The rail row structure is installed on the combined track slab, the combined track slab includes a prefabricated track slab and a limiting boss, the limiting boss is connected to the bottom of the track slab, and the isolation layer is arranged at the bottom of the combined track slab , the base is a cast-in-place base, which is used to fix and support the combined track slab. Since the combined track slab is directly fixed in the cast-in-place base, there is no need to pour the filling layer, so the process of on-site concrete pouring is reduced. It greatly improves the construction efficiency of the ballastless track, reduces the construction cost and saves the construction period.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

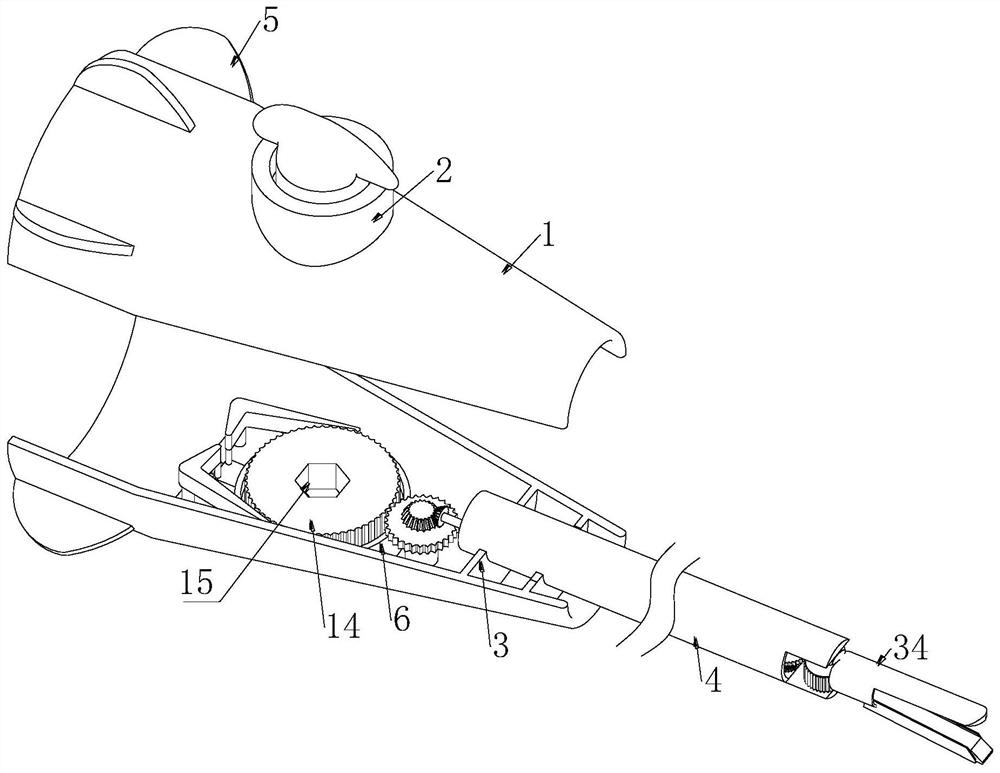

Knife holder rotating support for linear cutting stapler

ActiveCN112617929BGuaranteed precision controlEasy to use and flexibleSurgical staplesFree rotationStructural engineering

The invention discloses a knife holder rotating bracket for a linear cutting stapler, which belongs to the field of staplers, and comprises a rotating handle, the top of which is fixedly connected with a knob tube, and the bottom end of the knob tube extends to the inside of the rotating handle , the inner wall of the rotating handle is fixedly connected with a fixed plate near the right side, the inner wall of the fixed plate is fixedly connected with a tube, the outer wall of the rotating handle is fixedly connected with an evenly distributed anti-skid plate near the left side, the rotating The inner wall of the bottom side of the handle and the position corresponding to the knob barrel are fixedly connected with a placement barrel, the inside of the knob barrel is movably inserted with a rotary shaft, the top of the rotary shaft is fixedly connected with a knob, and the bottom end of the rotary shaft is fixedly connected with a The polygonal button column can realize the free rotation angle within the rotatable range of the staple cartridge by twisting and screwing, which increases its application range and makes the use of the stapler more flexible and convenient.

Owner:SUZHOU FRANKENMAN MEDICAL EQUIP

High-strength steel assembled ship moon pool assembly technology

InactiveCN109773412AAvoid deformationGuaranteed precision controlVessel partsMarine engineeringInternal stress

A high-strength steel assembled ship moon pool assembly technology is characterized by comprising the following steps that a concave moon pool is machined and completed on a concave bed-jig, a convexmoon pool is machined and completed on a convex bed-jig, the concave moon pool and the convex moon pool are folded to form the moon pool, the whole moon pool is hoisted and arranged on a ship, the concave bed-jig and the convex bed-jig adopt integrally formed groove faces, any two adjacent faces of a concave groove of the concave bed-jig and a convex groove of the convex bed-jig are perpendicularto each other, and the moon pool adopts high-strength steel. The high-strength steel assembled ship moon pool assembly technology has the advantages that a separated manufacturing manner is adopted, the moon pool is manufactured away from a platform, deformation, caused by internal stress of a large steel structure of the platform, of the moon pool is avoided, and meanwhile the whole precision control of the moon pool is guaranteed through segmented control over the moon pool components.

Owner:周莹

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com