A combined track slab, prefabricated slab track system and its installation and construction method

A construction method and track slab technology, applied in the direction of track, road, ballast layer, etc., can solve the problems of many process steps, slow construction progress, lower track structure, etc., and achieve the goal of reducing process steps, saving construction period and reducing filling layer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

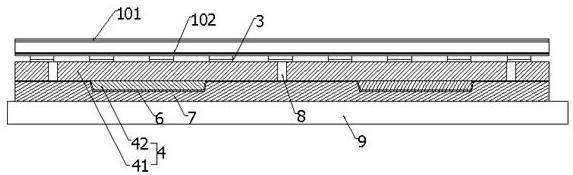

[0071] This embodiment provides a combined track plate 4, such as Figure 5 and Figure 6 As shown, it includes a track plate 41 for installing the rail row structure, the bottom of the track plate 41 is connected with a limiting boss 42, and both the track plate 41 and the limiting boss 42 are prefabricated structures.

[0072] Since the limited boss 42 is connected to the track plate 41 of this program, the combined track plate 4 can be directly installed in the base, so that the structure is completed between the limit boss 42 and the base and the mutual spacing is not required. During the construction of the track system, the base is poured first, and then the filling layer is poured, thereby reducing the pouring process of the filling layer and improving the on-site installation and construction efficiency of the ballastless track system.

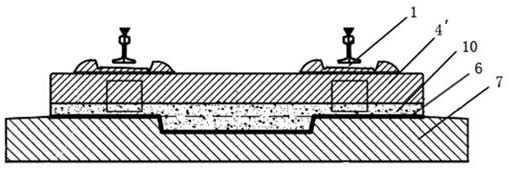

[0073] In the existing technology, such as figure 1 As shown, the track slab 41 is a slab structure, and a filling layer 10 is arra...

Embodiment 2

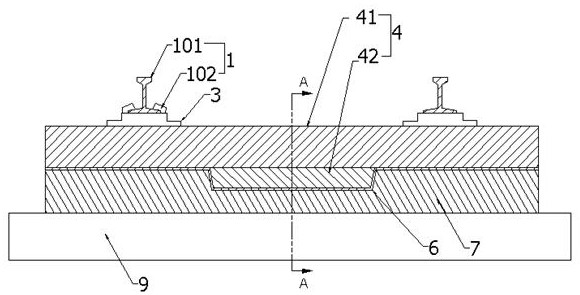

[0080] This embodiment provides a prefabricated slab track system, such as Figure 2-4 As shown, the prefabricated slab track system includes a rail row structure 1, a combined track slab 4, an isolation layer 6 and a base 7 from top to bottom, wherein the rail row structure 1 includes a steel rail 101, and is used to fix the The fastener 102 of the rail 101, the combined track plate 4 includes a track plate 41 for installing the rail row structure 1, the bottom of the track plate 41 is connected with a limiting boss 42, and the track plate 41 and the limiting The bosses 42 are all prefabricated structures, the isolation layer 6 is arranged on the bottom of the track plate 41 and the limit boss 42, and the base 7 is a cast-in-place base for fixing and supporting the combined track plate 4.

[0081] In the existing technology, such as figure 1 As shown, the track slab 4' is a slab structure, and a filling layer 10 is arranged below the track slab 4'. The filling layer 10 is p...

Embodiment 3

[0092] This embodiment provides a method for installation and construction of a prefabricated slab track system, such as Figure 2-4 shown, including the following steps:

[0093] a, prefabricated combined track plate 4, comprising track plate 41 and spacer boss 42, and isolating layer 6 is arranged on the bottom of described track plate 41 and spacer boss 42, forms the overall structure of track plate, and its Transported to the site, the connection methods of the track plate 41, the limit boss 42 and the isolation layer 6 can adopt the various methods in Embodiment 1;

[0094] b. Construction base reinforcement cage and laying formwork, make, place and fix the base reinforcement cage according to the design requirements, and erect the formwork of the cast-in-place base 7 according to the design size and position, the reinforcement cage of the base 7 adopts the structure and structure in the prior art size;

[0095] b. The overall structure of the track slab prefabricated i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com