Tunnel arch ring and cable groove side wall integrated secondary lining telescoping steel form

A technology of cable trench and formwork trolley, which is applied in the direction of tunnel lining, tunnel, shaft lining, etc., to achieve the effects of reducing construction costs, advanced technology, and good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

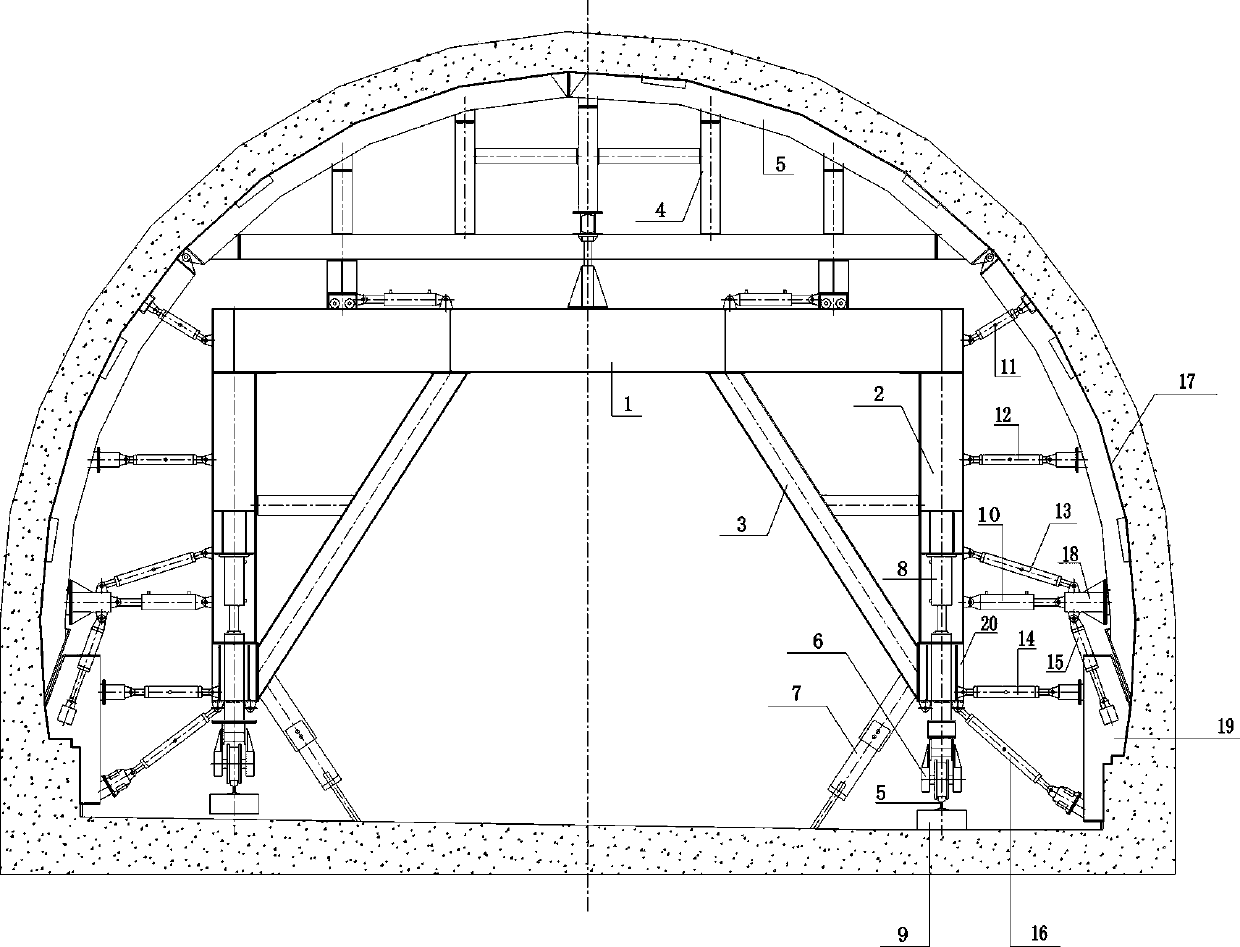

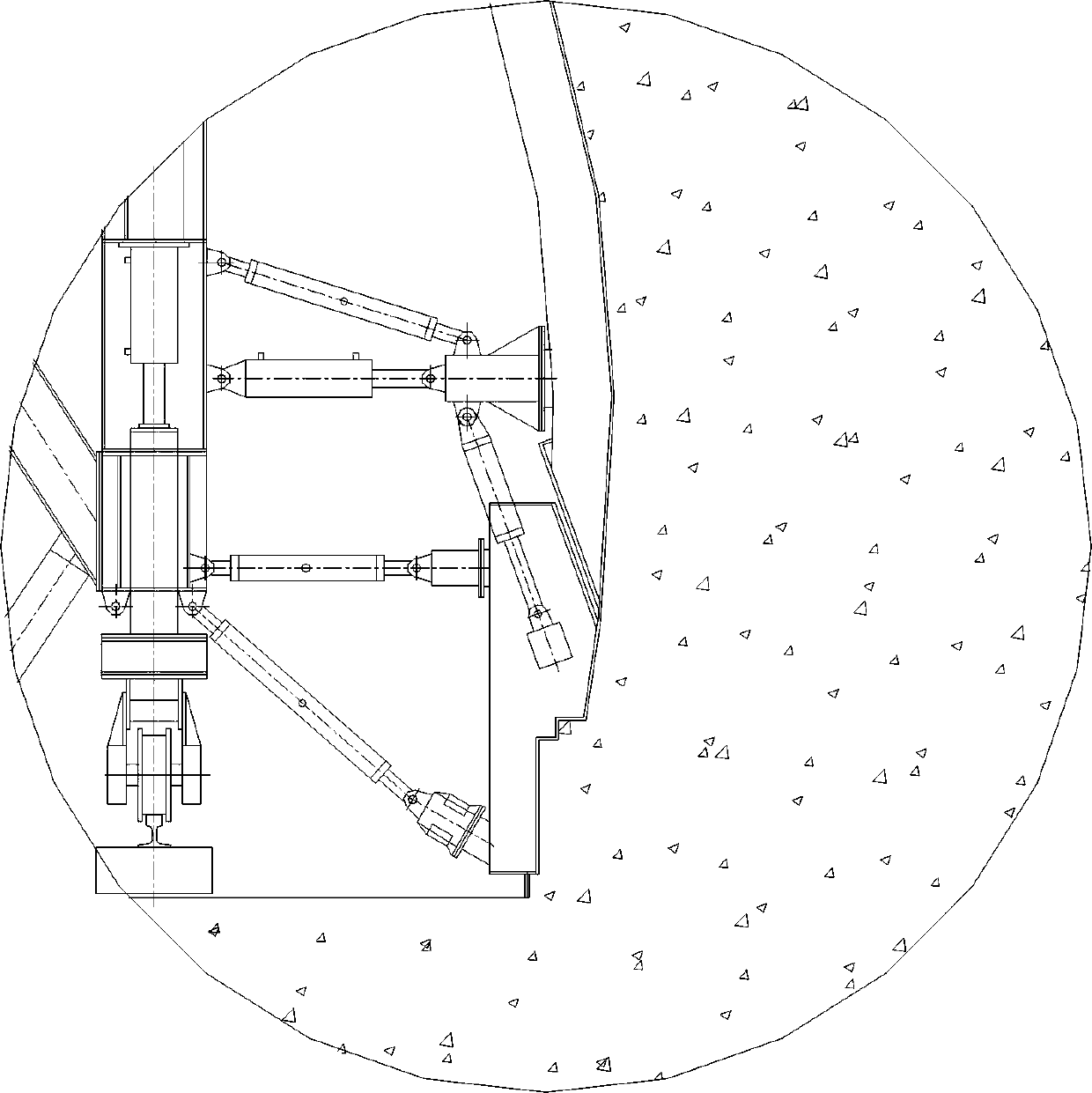

[0028] Such as figure 1 , figure 2 as shown in figure 1 As shown, the two-lined steel formwork trolley integrated with the tunnel arch ring and the side wall of the cable trench includes a door frame system, a connection system, and a panel system. The gantry system is composed of beams 1, legs 2, diagonal braces 3 and columns 4, and the connection system is composed of spandrel connection screw 11, cross brace screw 12, horizontal oil cylinder 10, arch foot screw 14, diagonal brace wire Rod 13, lifting screw mandrel 15 and outer support screw mandrel 16 form, and panel system is made up of curved panel 17 and cable ditch side wall panel 19.

[0029] The beams 1, legs 2, braces 3, and columns 4 are made of steel plates, and bolts are used to connect each component to form a portal frame system. The overall structure size of the portal frame is determined according to the tunnel structure size, and the portal frame space meets the requirements of the tunnel. Safe driving ne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com