Manufacturing method of ink-jet printing digital micro-fluidic chip

A technology of inkjet printing and digital microflow, which is applied to chemical instruments and methods, printing, and laboratory containers, etc. It can solve the problems of easy damage, weak physical strength of PI film, and difficult processing technology, and achieve low cost, Improve sensitivity and overcome the effect of easy breakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

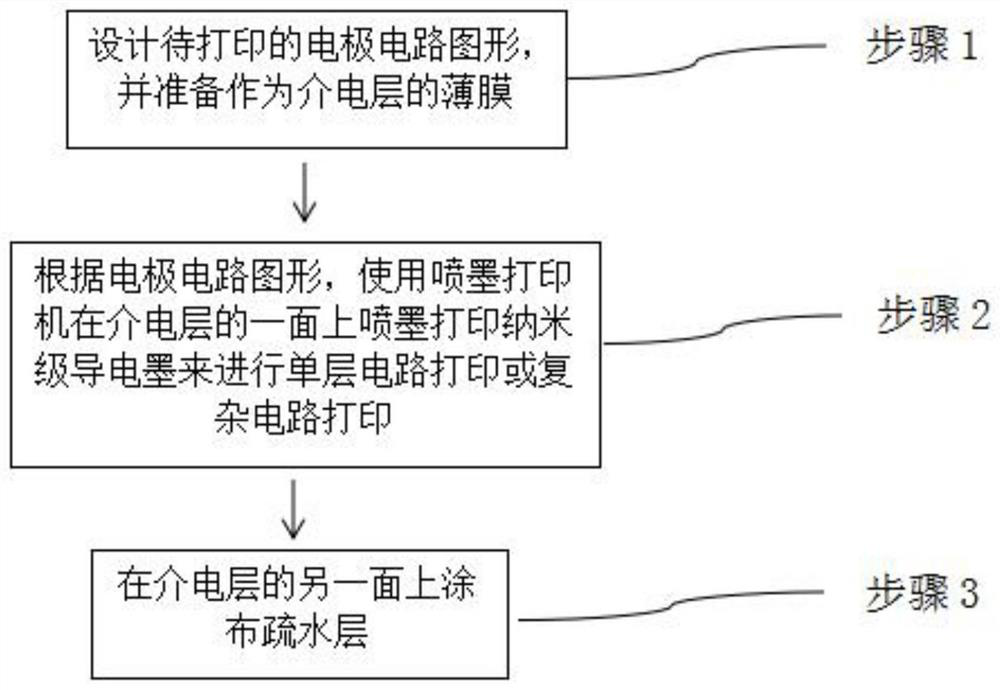

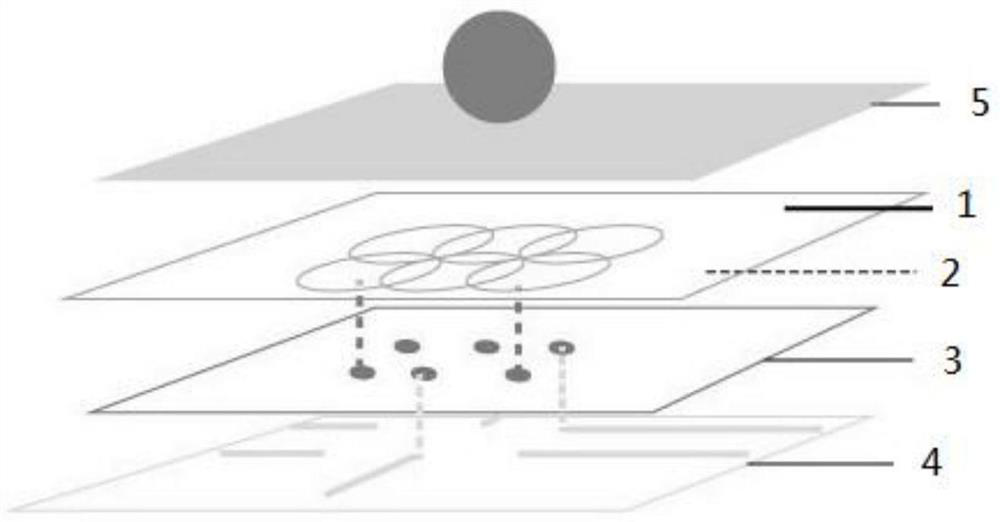

[0024] In order to make the technical means and effects realized by the present invention easy to understand, the present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

[0025]

[0026] In this embodiment, the basic function of the digital microfluidic chip is to control a small amount of liquid droplets. The amount of liquid droplets needs to be controlled precisely, and there are various limitations. In order to increase the flexibility and control functions of the chip, it is necessary to control the liquid The control accuracy and breadth of the drop volume (droplet types of different sizes) are improved. Since the size of the driving droplet is determined by the size of the driving electrode and the gap between the plates, this embodiment forms an inkjet micro-precision circuit on the dielectric layer, avoiding the concave-convex wave scale of the dielectric layer / hydrophobic layer on the electrode layer with d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com