Ink jet head and ink jet printer

A technology of inkjet head and ink, which is applied in printing and other directions, and can solve problems such as ink electrolysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

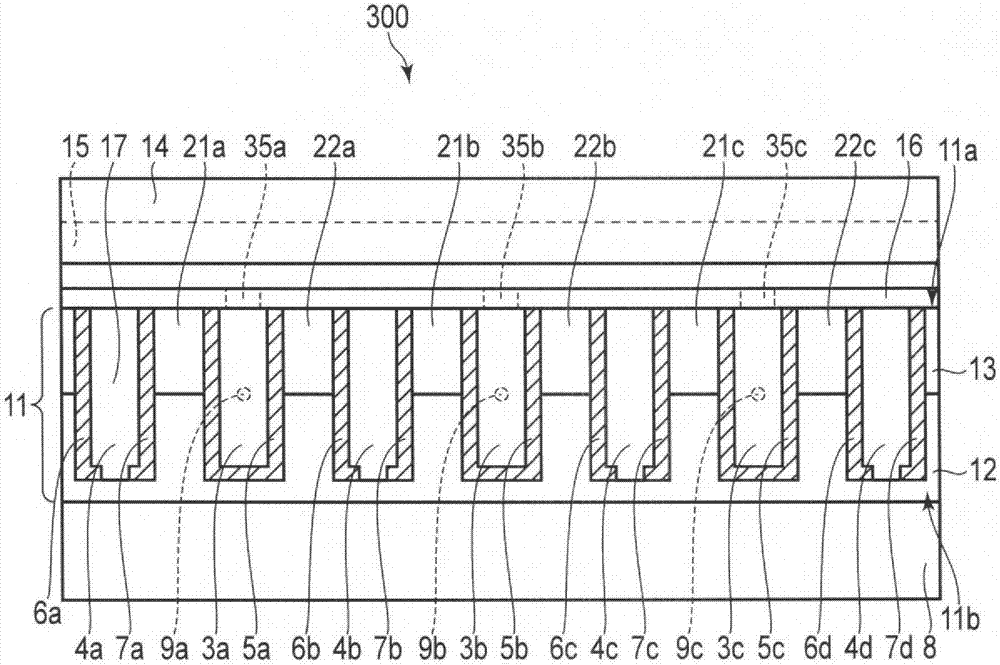

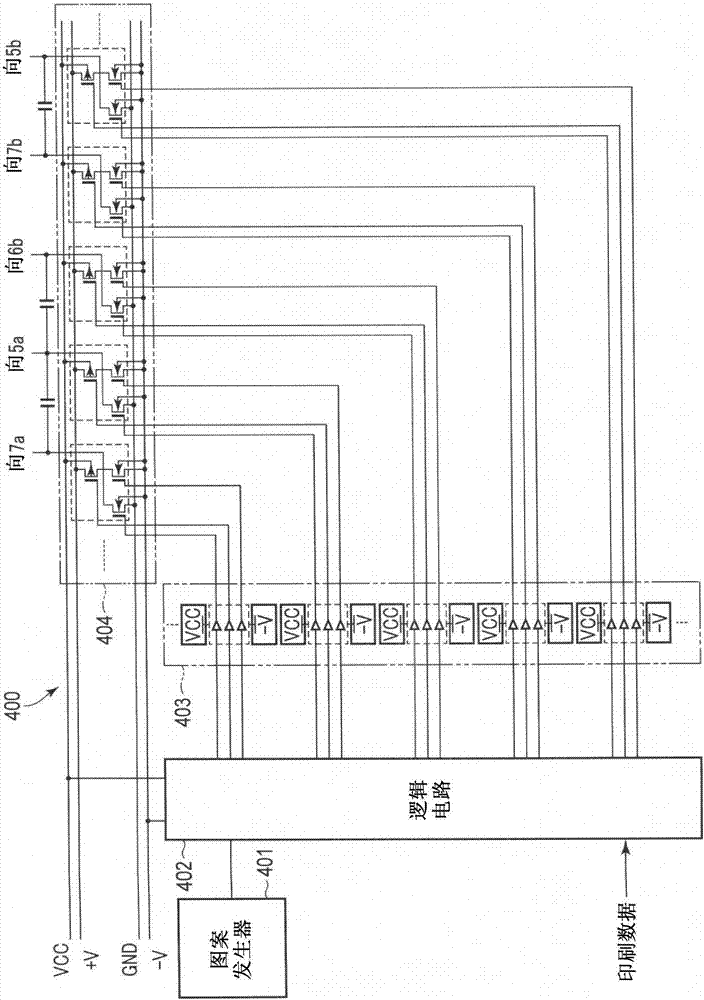

[0017] Embodiments will be described below with reference to the drawings.

[0018] The inkjet printer of the embodiment ejects ink stored in an ink cartridge to a printing medium (for example, paper) to form an image on the printing medium. An inkjet printer applies a voltage to a piezoelectric element forming a pressure chamber inside an inkjet head, and ejects ink from the pressure chamber.

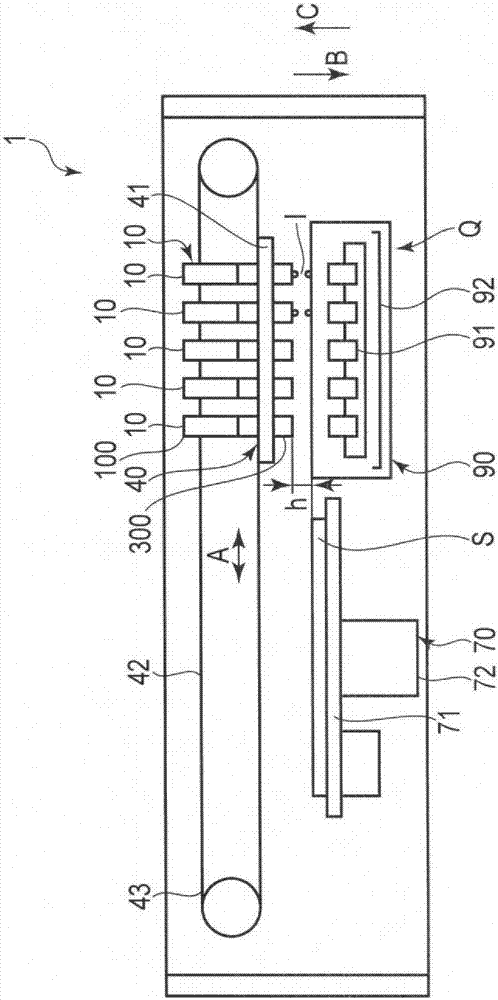

[0019] figure 1 It is a diagram showing a configuration example of the inkjet printer 1 .

[0020] The inkjet printer 1 includes a plurality of inkjet head units 10 and ink cartridges respectively corresponding to the plurality of inkjet head units 10 . In addition, the inkjet printer 1 includes a head supporting portion 40 that movably supports a plurality of inkjet head units 10 , a printing medium moving portion 70 that movably supports a printing medium S, and a maintenance unit 90 .

[0021] The inkjet head unit 10 includes an inkjet head 300 as a liquid ejection unit and an in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com