Gel polymer electrolyte and preparation method thereof

A technology of gel polymers and electrolytes, which is applied in hybrid capacitor electrolytes, hybrid/electric double layer capacitor manufacturing, circuits, etc., and can solve problems such as high conductivity, reduced stability of electric double layer capacitors, and low melting point

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

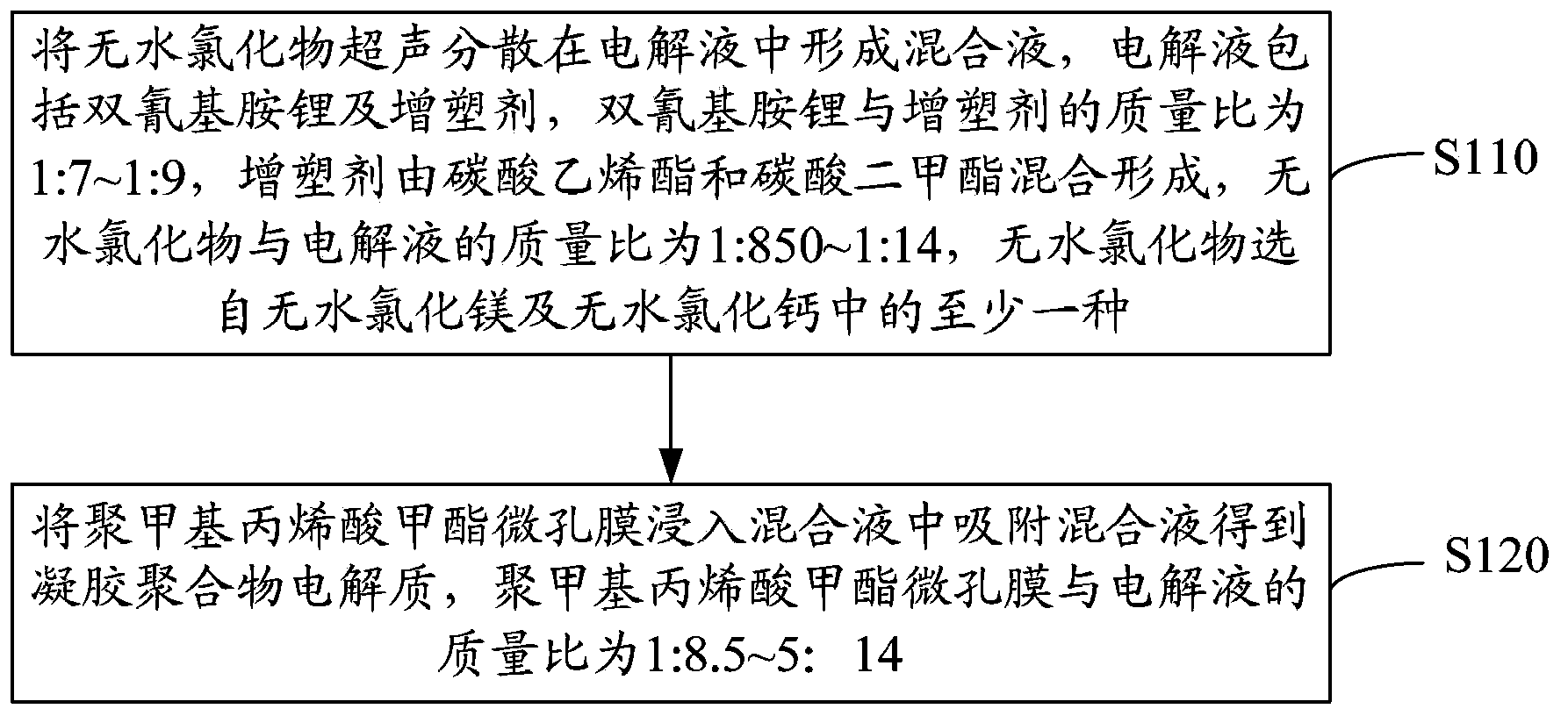

[0023] see figure 1 , the preparation method of above-mentioned gel polymer electrolyte, comprises the following steps:

[0024] Step S110, ultrasonically dispersing the anhydrous chloride in the electrolyte to form a mixed solution, the electrolyte includes lithium dicyanamide and a plasticizer, and the mass ratio of lithium dicyanamide to the plasticizer is 1:7-1: 9. The plasticizer is formed by mixing ethylene carbonate and dimethyl carbonate. The mass ratio of anhydrous chloride to electrolyte is 1:850~1:14. Anhydrous chloride is selected from anhydrous magnesium chloride and anhydrous chloride at least one of calcium.

[0025] Preferably, the mass ratio of the anhydrous chloride to the electrolyte is 2:85-1:14.

[0026] Preferably, the volume ratio of ethylene carbonate to dimethyl carbonate is 1:1.5˜1:3.

[0027] Preferably, the time for ultrasonic dispersion is 5 minutes to 30 minutes.

[0028] Step S120, immersing the polymethyl methacrylate microporous membrane in...

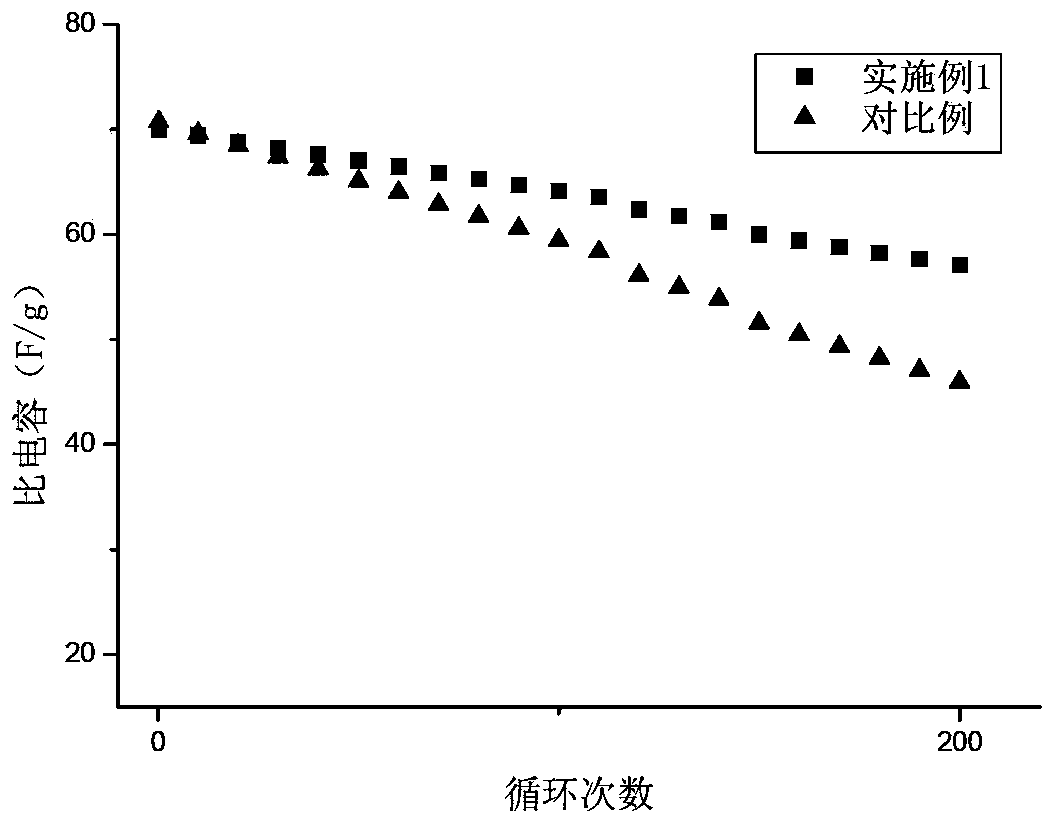

Embodiment 1

[0034] In the glove box, 0.5g of anhydrous magnesium chloride was ultrasonically dispersed (ultrasound for 30min) in 8.5g of lithium salt solution to form a mixed solution, wherein the lithium salt solution included LiN(CN) 2 And plasticizer, the mass ratio of LiN(CN)2 to plasticizer is 1:8, the plasticizer is formed by mixing EC and DMC with a volume ratio of 1:2, and then 1g of dried PMMA microporous membrane is immersed in In the above mixed solution, the PMMA microporous membrane completely adsorbed the mixed solution after 180 minutes to obtain a PMMA-based gel polymer electrolyte added with anhydrous magnesium chloride. In the obtained gel polymer electrolyte, the mass percentage of PMMA matrix is 10%, the mass percentage of lithium salt and plasticizer is 85%, and the mass percentage of anhydrous magnesium chloride is 5%.

Embodiment 2

[0036] In the glove box, ultrasonically disperse 0.4g of anhydrous calcium chloride (ultrasound for 25min) in 8.4g of lithium salt solution to form a mixed solution, wherein the lithium salt solution includes LiN(CN)2 and plasticizer, LiN(CN)2 The mass ratio with the plasticizer is 1:8, and the plasticizer is formed by mixing EC and DMC with a volume ratio of 1:2, and then immersing 1.2g of dried PMMA microporous membrane in the above mixed solution, and after 150min, it is Take it out to obtain a PMMA-based gel polymer electrolyte added with anhydrous calcium chloride. In the obtained gel polymer electrolyte, the mass percentage of PMMA matrix is 12%, the mass percentage of lithium salt and plasticizer is 84%, and the mass percentage of anhydrous calcium chloride is 4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com