Anti-electrowetting effect-based self-cleaning device and method for oil stain surface

A self-cleaning and electrowetting technology, applied in the direction of cleaning methods and appliances, chemical instruments and methods, etc., can solve problems such as difficult to clean oil stains, easy to damage the film layer, easy to change the properties of the film surface, etc. The effects of electrical effect failure, wide operating range, good stability and sustainability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

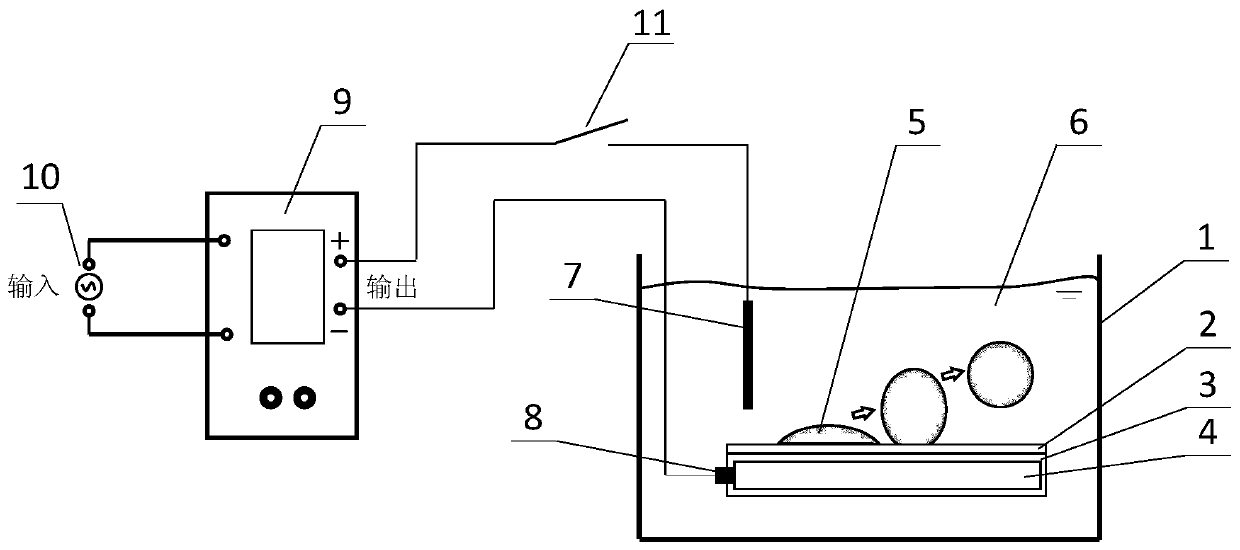

[0039] like figure 1 , in this embodiment, the self-cleaning device for oily surfaces based on the reverse electrowetting effect includes: a self-cleaning environment device connected by wires and an adjustable power supply 9 . Among them, the self-cleaning environment device includes: a fluid chamber 1 , an oily film surface 2 , a dielectric material layer 3 , a base metal 4 and a low-conductivity fluid 6 .

[0040] Preferably, the low-conductivity fluid 6 is contained in the fluid cavity 1, as the working environment fluid in the self-cleaning process of the oil film surface 2; the dielectric material layer 3 is sprayed on the outer surface of the base metal 4, and the base metal 4 is completely wrapped; The film surface 2 is closely attached to the outer surface of the dielectric material layer 3 .

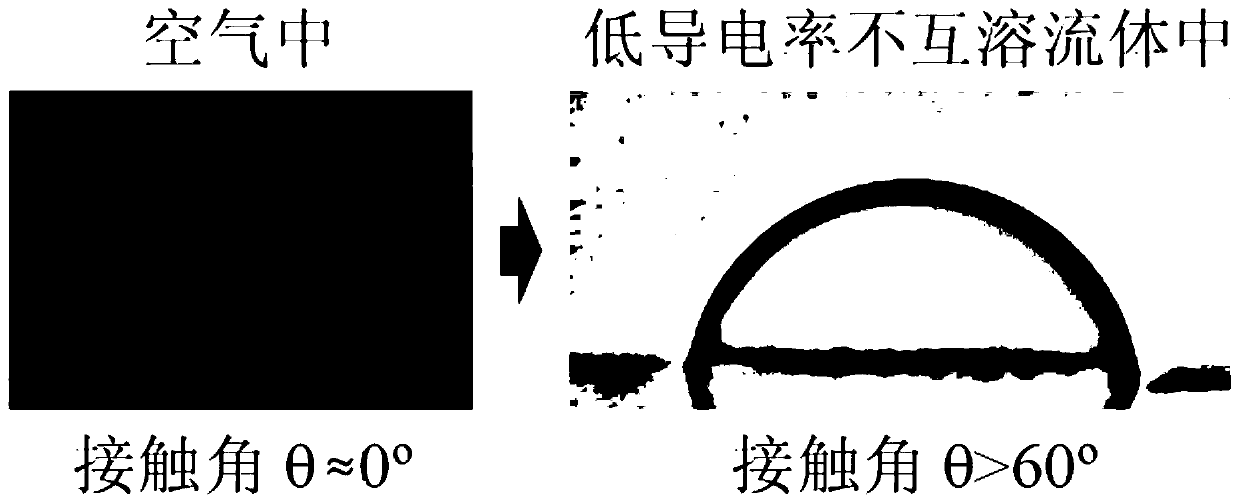

[0041] It can be seen that the present invention is based on the dielectric wetting effect, and the surface of the oily film that needs to be treated is placed in a low-conduc...

Embodiment 2

[0043] like figure 1 , the self-cleaning device for oily surfaces based on the reverse electrowetting effect further includes: a positive terminal 7 and a negative terminal 8. Among them, the positive terminal 7 is suspended in the low-conductivity fluid 6, and is connected to the output positive terminal of the regulating power supply 9 through a wire; output negative terminal connection.

[0044] Preferably, the negative terminal 8 and the wires placed in the low-conductivity fluid 6 are all insulated and coated, which prevents the occurrence of electrolysis and oxidation on the surface of the positive and negative electrodes and the metal substrate, so that the reverse electrowetting process has Very good stability and sustainability.

[0045] Preferably, a circuit breaker 11 is also provided on the wire used to connect the positive terminal 7 and the output positive end of the regulating power supply 9, which can control the on-off of the self-cleaning device on the enti...

Embodiment 3

[0056] On the basis of the above embodiments, the present invention also discloses a self-cleaning method for oily surfaces based on the reverse electrowetting effect, including: building a self-cleaning environment device; connecting the self-cleaning environment device to an adjustable power supply 9 through wires. Among them, the self-cleaning environment device is built through the following steps: the low-conductivity fluid 6 is contained in the fluid chamber 1 as the operating environment for the self-cleaning process of the oily film surface 2; a dielectric material layer 3 is sprayed on the outer surface of the base metal 4, The base metal 4 is completely wrapped; the surface of the oily film 2 and the outer surface of the dielectric material layer 3 are closely attached, and they are placed in the low-conductivity fluid 6 together.

[0057] In this embodiment, the self-cleaning scheme of the greasy surface based on the reverse electrowetting effect realizes the specifi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com