Garment edge folding hot press forming device and forming method

A technology for thermoforming and clothing, applied in the field of clothing processing, can solve the problems of easy deviation of the crease position and difficult operation, and achieve the effects of not easy to shift, easy to control the accuracy, and accurate crease position.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

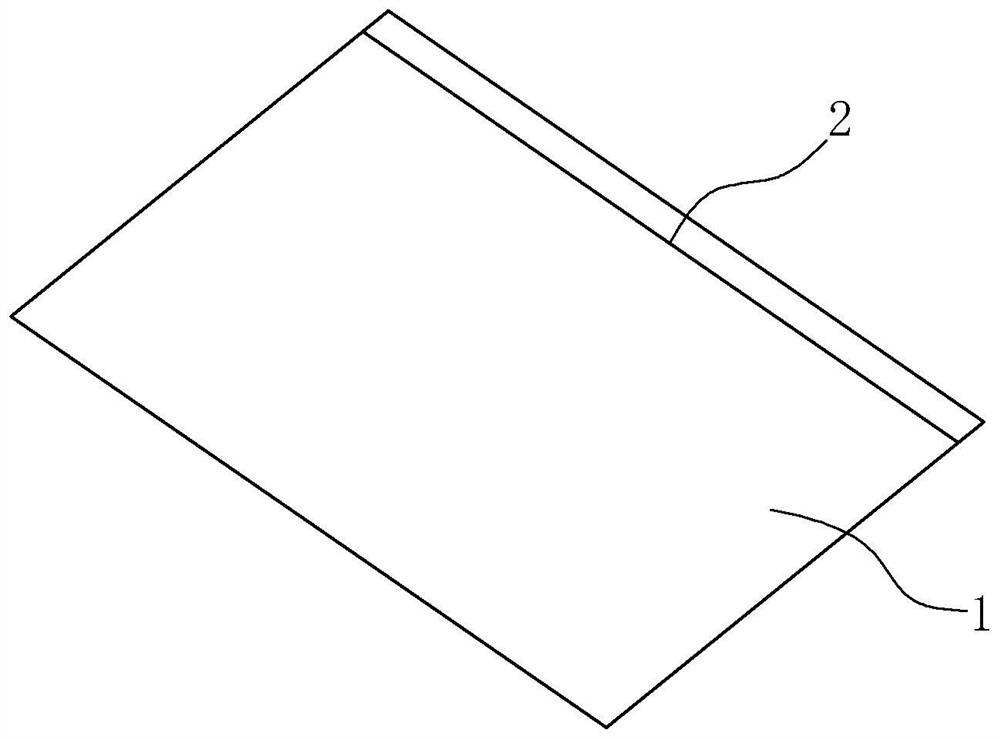

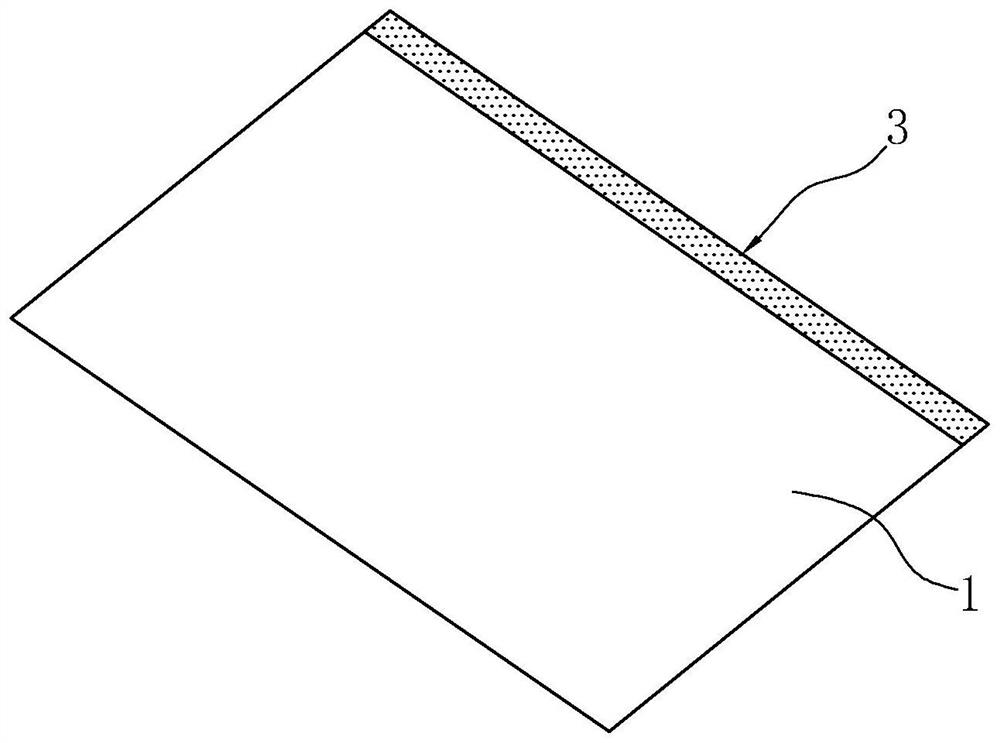

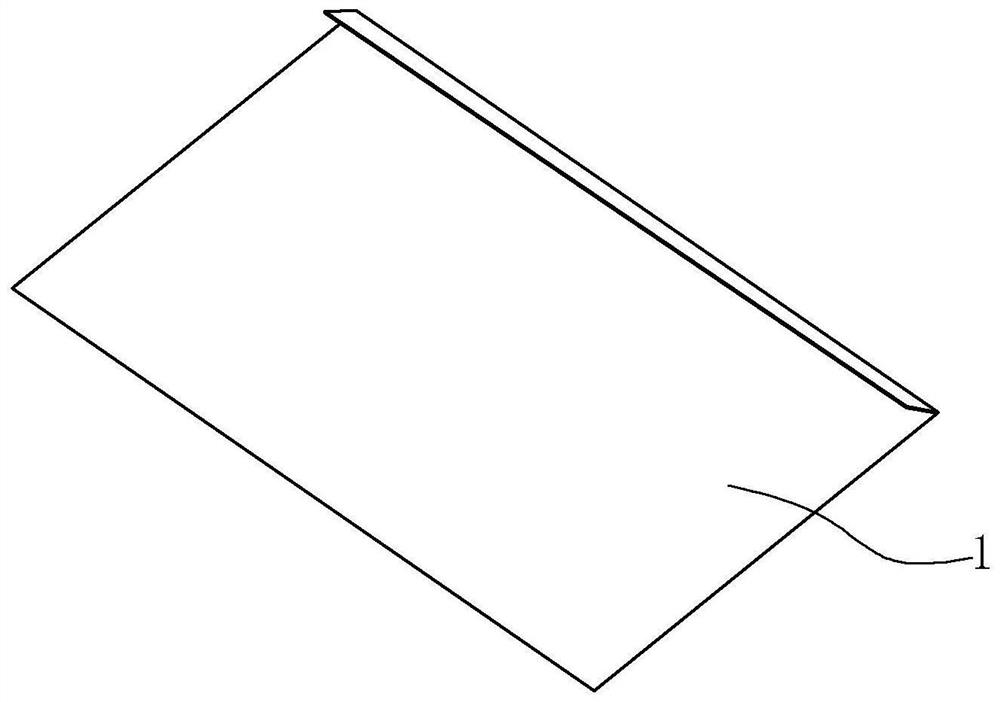

[0045] Contraction below Figure 5-10 Further detailed description of the present application.

[0046] The present application example discloses a clothing folding hot press molding device, such as Figure 5 As shown, a thermocompression molding mechanism 7 is provided on a machine 6, and a hot pressing mechanism 7 is provided on the inlet side of the hot press forming mechanism 7.

[0047] The hot press forming mechanism 7 includes a lower mount 9, a lower mounting frame 9, and a lower mounting frame 9 is fixed to the machine 6, and the lower frame is mounted, and the drive motor 12 is mounted, and the drive motor 12 is used to drive the conveyor belt. 11 performs drive. The mounting frame 10 is mounted above the lower mounting frame 9, and the upper conveyor belt 13 is mounted in the mounting frame 10. The machine 6 is also provided with a gantry 14, and a cylinder 15 is fixed to the gantry 14, and the piston rod of the cylinder 15 is mounted down. And the lower end of the piston...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com