High-performance hard alloy material

A cemented carbide, high-performance technology, applied in the field of high-performance cemented carbide materials, can solve the problems of wear resistance and toughness that are difficult to meet the demand at the same time, and achieve the effect of high hardness, low production cost and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

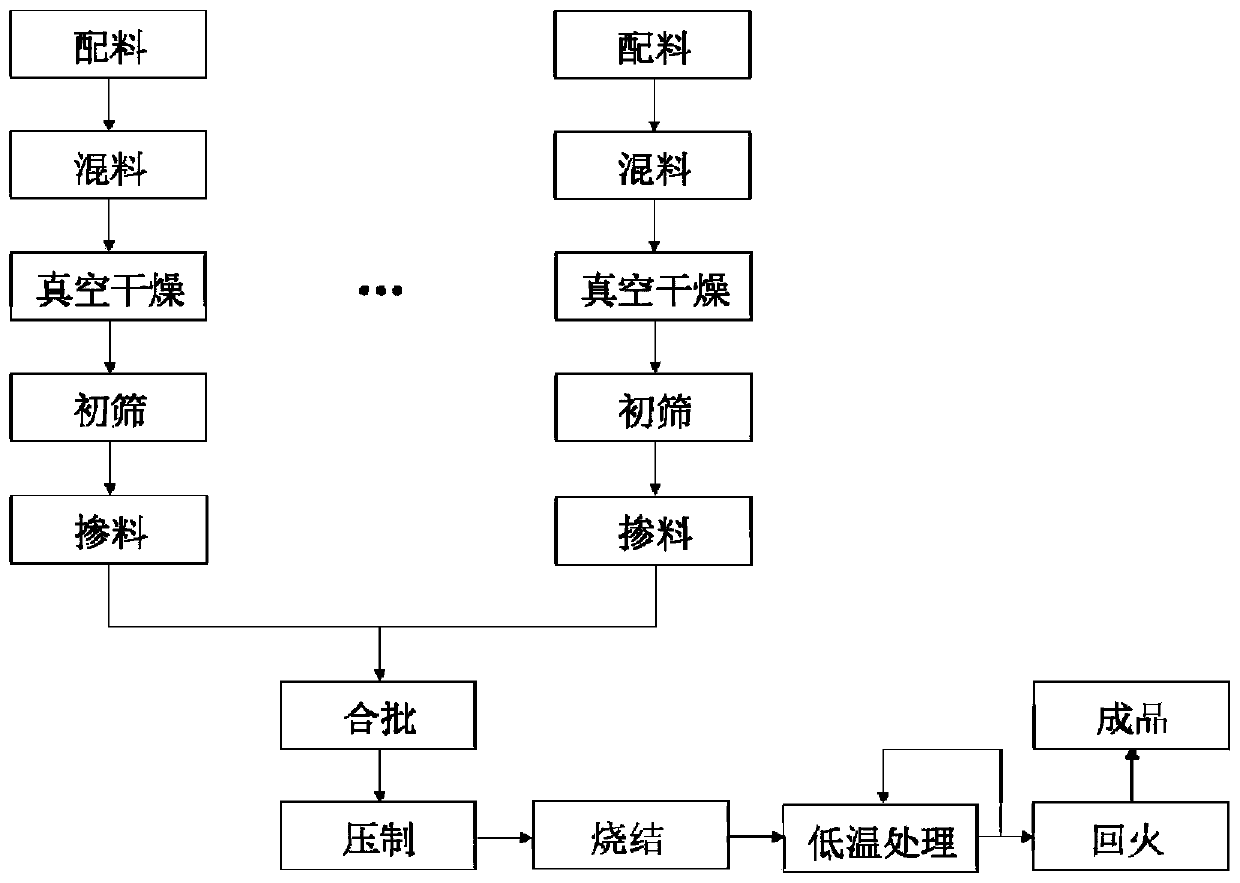

Method used

Image

Examples

Embodiment 1

[0088] The high-performance cemented carbide material of this embodiment is made from the following raw materials by weight: WC: 65 parts; Co: 5 parts; TiC: 10 parts; Ni: 3 parts; TaC: 0.2 parts.

[0089] High-performance cemented carbide materials are prepared by the following processes:

[0090] 1. Ingredients: configure various materials of cemented carbide according to the formula;

[0091] 2. Mixing:

[0092] a. Put the alloy balls and the ingredients prepared in step 1 into the wet mill, and the mass ratio of the alloy balls to the ingredients is 4:2;

[0093] b. Add alcohol with a purity of 98% to the wet mill, and the mass ratio of alcohol to ingredients is 1:2;

[0094] c. Add the paraffin forming agent to the wet mill, and the paraffin addition is 2%;

[0095] d. Start the wet grinding machine, and the wet grinding time is 35 hours to obtain the slurry;

[0096] 3. Drying: vacuum-drying the slurry with a vacuum degree of 800KPa to obtain a dry material;

[0097]...

Embodiment 2

[0108] The high-performance cemented carbide material of this embodiment is made from the following raw materials by weight: WC: 80 parts; Co: 10 parts; TiC: 15 parts; Ni: 8 parts; TaC: 0.7 parts.

[0109] High-performance cemented carbide materials are prepared by the following processes:

[0110] 1. Ingredients: configure various materials of cemented carbide according to the formula;

[0111] 2. Mixing:

[0112] a. Put the alloy balls and the ingredients prepared in step 1 into the wet mill, and the mass ratio of the alloy balls to the ingredients is 4:2;

[0113] b. Add alcohol with a purity of 98% to the wet mill, and the mass ratio of alcohol to ingredients is 1:2;

[0114] c. Add paraffin wax forming agent to the wet mill, and the amount of paraffin wax is 5%;

[0115] d. Start the wet grinding machine, and the wet grinding time is 40 hours to obtain the slurry;

[0116] 3. Drying: vacuum-drying the slurry with a vacuum degree of 800KPa to obtain a dry material;

...

Embodiment 3

[0127] The high-performance cemented carbide material of this embodiment is made from the following raw materials by weight: WC: 70 parts; Co: 7 parts; TiC: 12 parts; Ni: 4 parts; TaC: 0.3 parts.

[0128] High-performance cemented carbide materials are prepared by the following processes:

[0129] 1. Ingredients: configure various materials of cemented carbide according to the formula;

[0130] 2. Mixing:

[0131] a. Put the alloy balls and the ingredients prepared in step 1 into the wet mill, and the mass ratio of the alloy balls to the ingredients is 4:2;

[0132] b. Add alcohol with a purity of ≥98% to the wet mill, and the mass ratio of alcohol to ingredients is 1:2;

[0133] c. Add the paraffin forming agent to the wet mill, and the paraffin addition amount is 3%;

[0134] d. Start the wet grinding machine, and the wet grinding time is 37 hours to obtain the slurry;

[0135] 3. Drying: vacuum-drying the slurry, the vacuum degree is 650KPa, to obtain a dry material;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com