Special curing agent of 3-element EPR

A technology of EPDM rubber and vulcanizing agent, which is applied in the field of rubber vulcanizing agent to achieve the effects of reducing labor intensity, avoiding weighing errors, and avoiding environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] a. Take sulfur, peroxide, thiazole, thiuram, dithiocarbamate, amine and aldehyde-amine condensate, ethanolamine according to the total weight percentage of 5-60%, 1-50%, 1-70% , 3-50%, 1-50%, 1-25%, 1-25% weighing.

[0032] Sulfur can be used as elemental sulfur or insoluble sulfur.

[0033] Peroxides can be dicumyl peroxide, 1.3-bis(tert-butylperoxydiisopropyl)benzene, 2.5-dimethyl 2.5-(di-tert-butylperoxy)hexane, 4.4'-bis (tert-butylperoxy) n-butyl valerate, 1.4-bis(tert-butylperoxydiisopropyl)benzene.

[0034] Thiazole can be used as 2-mercaptobenzothiazole, dibenzothiazole disulfide, 2-mercaptobenzothiazole cyclohexyl ammonium salt, 1-(N,N-diethylaminomethyl)-2-benzo Thiazolylthiones.

[0035] Thiuram can be used tetramethylthiuram monosulfide, tetramethylthiuram disulfide, tetraethylthiuram disulfide, tetrabutylthiuram disulfide, tetramethylthiuram tetrasulfide, four Sulphide bispentaethylene thiuram, disulfide bispentaethylene thiuram, hexasulfide bispentaethy...

Embodiment 2

[0043] 18 kilograms of 400-mesh high-purity sulfur powder produced in Taiyuan, Shanxi, 23 kilograms of dicumyl peroxide (commodity code DCP) produced in Taicang, Jiangsu, and 1-(N,N-diethylaminomethyl)-2 produced in Russia, 27 kilograms - Benzothiazolylthione (commodity code BTMA), 14 kilograms of tetramethylthiuram tetrasulfide (commodity code Nocceler TRS) newly produced in Ouchi, Japan, 10 kilograms of German Rhein production dibutyl ammonium dithiophosphate (commodity Code name Rhenocure AT), 6 kg of n-butyraldehyde aniline condensate produced by Du Pont of the United States (product code name Accelerator 808), 2 kg of triethanolamine produced by Beijing Chemical Industry No. 15 minutes, and then discharged into a common dry granulator for granulation.

Embodiment 3

[0045] 38 grams of 400-mesh high-purity sulfur powder produced in Taiyuan, Shanxi, 10 grams of dicumyl peroxide (commodity code DCP) produced in Taicang, Jiangsu, and 8 grams of 1-(N,N-diethylaminomethyl)-2 produced in Russia - Benzothiazolyl thione (commodity code BTMA), 9 grams of tetramethylthiuram tetrasulfide (commodity code Nocceler TRS) produced in Ouchi, Japan, 25 grams of German Rhein production dibutyl ammonium dithiophosphate (commodity code name RhenocureAT), 3 grams of n-butyraldehyde aniline condensate produced by Du Pont of the United States (product code name Accelerator 808), and 7 grams of triethanolamine produced by Beijing Chemical Industry No. Minutes, and then discharged into the usual dry granulator for granulation.

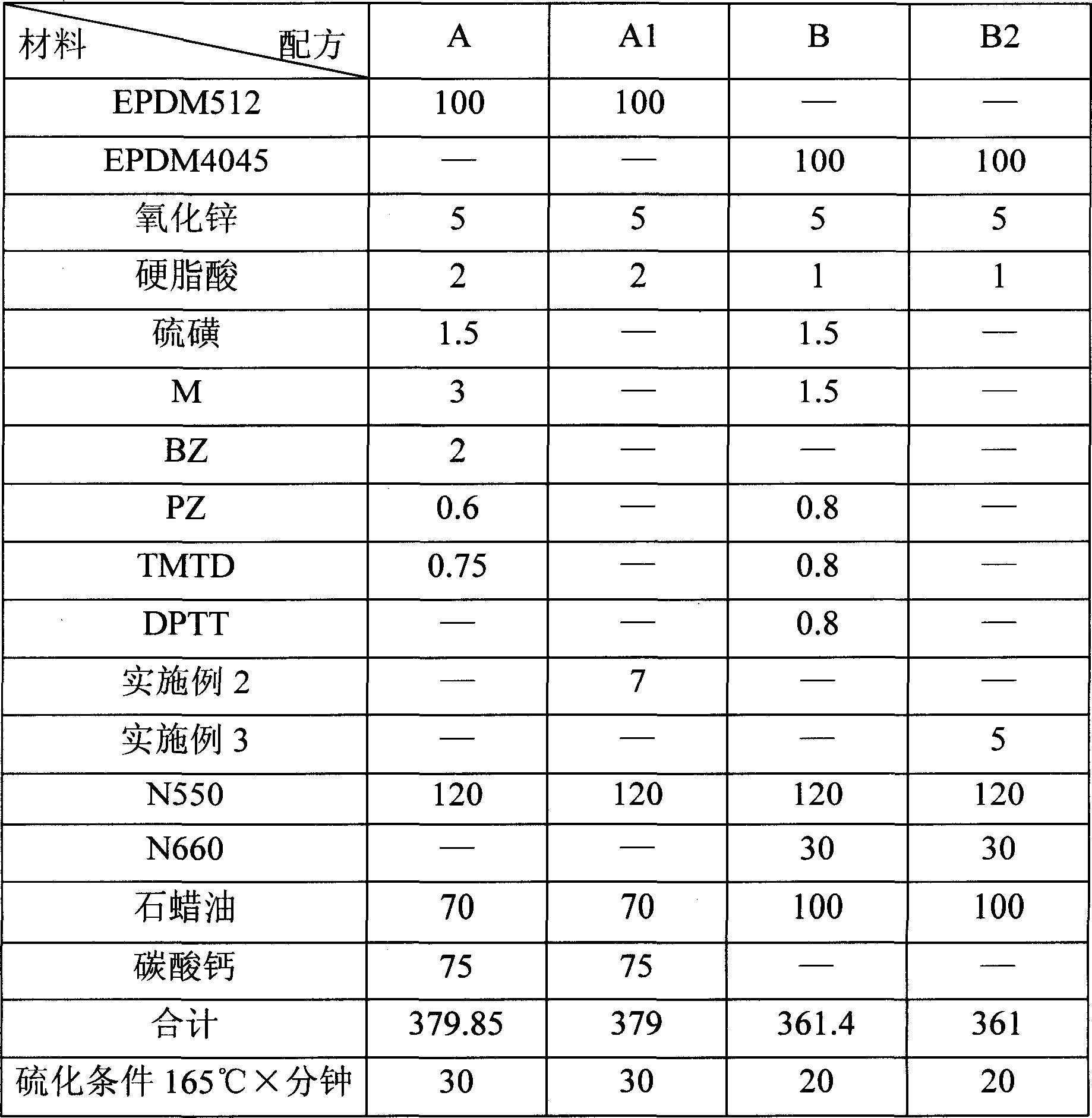

[0046] The application effect comparison is as follows:

[0047] 1. Materials

[0048] EPDM512: ENB content 4.3%, DSM Chemicals, Netherlands

[0049] EPDM4045: ENB content 8%, China Jilin Chemical Company

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com