Steel rail flatness and torsion detection device and method

A detection method and technology of detection equipment, which are applied to measurement devices, instruments, optical devices, etc., can solve problems such as the need to improve detection efficiency, sensor zero offset, and inaccurate measurement on one side, and achieve a wide working temperature range and high altitude. Accurate and improve the effect of detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

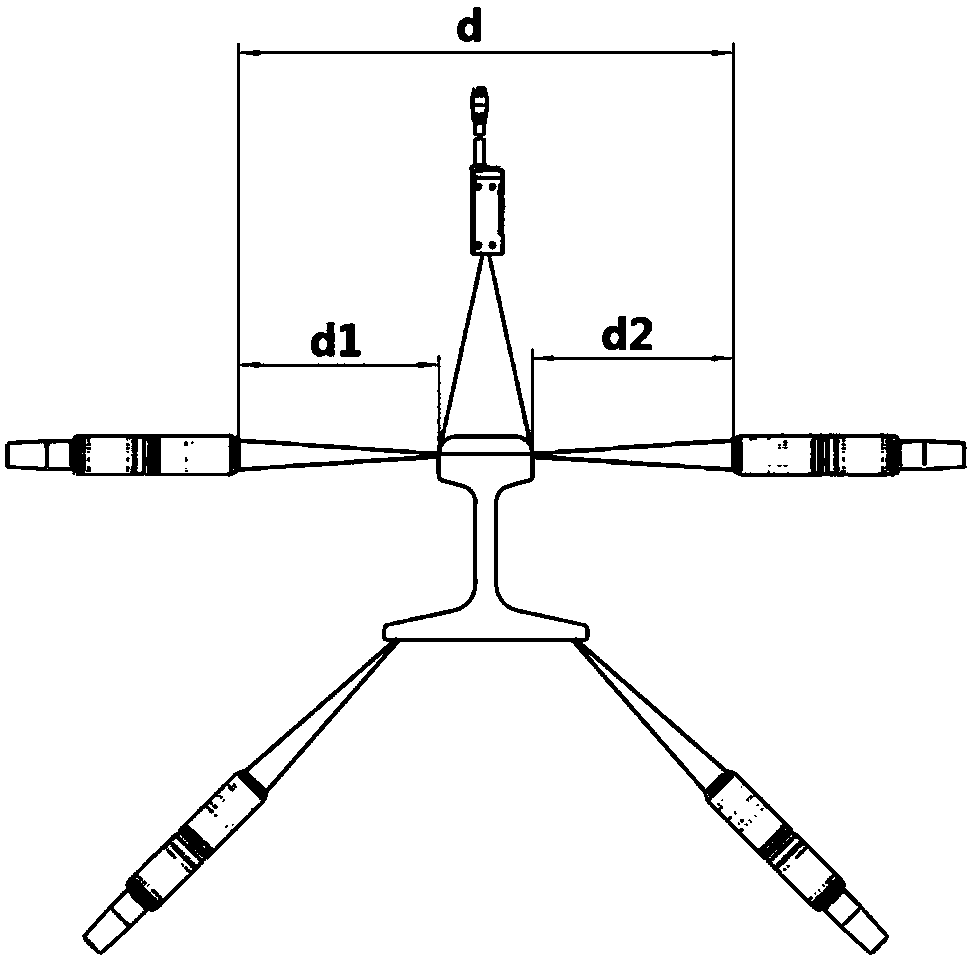

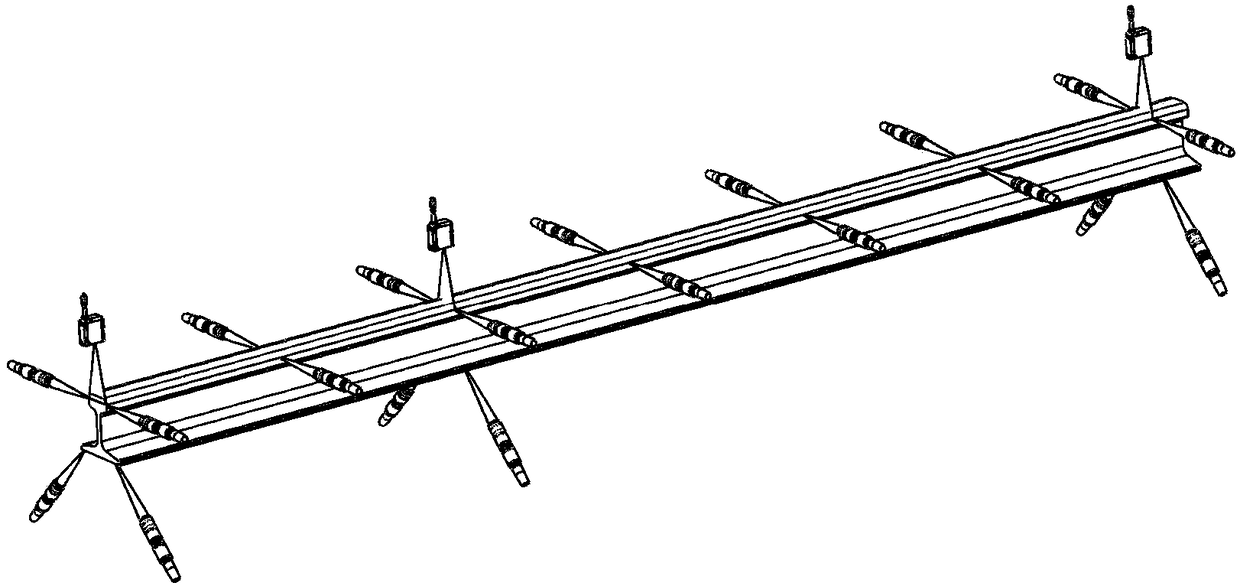

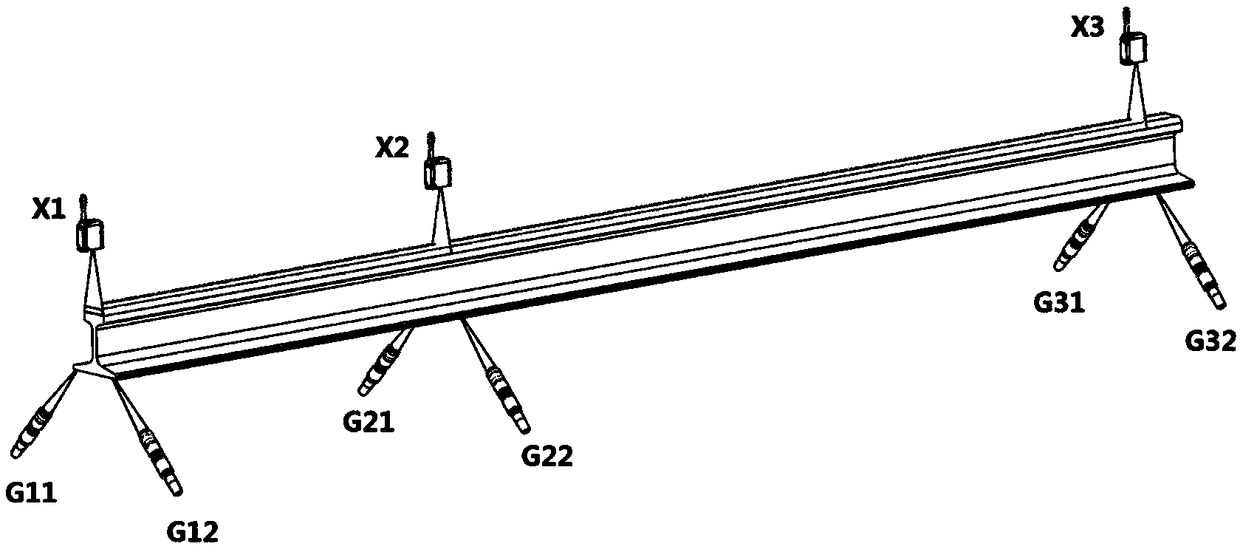

[0030] Such as figure 1 Shown is the rail straightness and torsion detection equipment according to the present invention, which includes a plurality of spectral confocal displacement sensors and a plurality of linear laser profile sensors. Multiple spectral confocal displacement sensors G are placed symmetrically on both sides of the rail head and the bottom of the rail to measure the distance from the measured point to the sensor on the side of the rail head and the bottom of the rail; multiple linear laser profile sensors X are placed on The top of the rail head to capture the rail tread curve. A plurality of spectral confocal displacement sensors and a plurality of linear laser profile sensors are connected with the data acquisition memory, so that the collected data are analyzed and processed to obtain the straightness a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com