Hydraulically powered gas injection valve

A gas injection and hydraulic technology, applied in the direction of lift valve, valve device, valve details, etc., can solve the problem of inability to accurately control the opening of the valve core, and achieve the effect of ensuring the relative position, improving the measurement accuracy and improving the reliability of use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

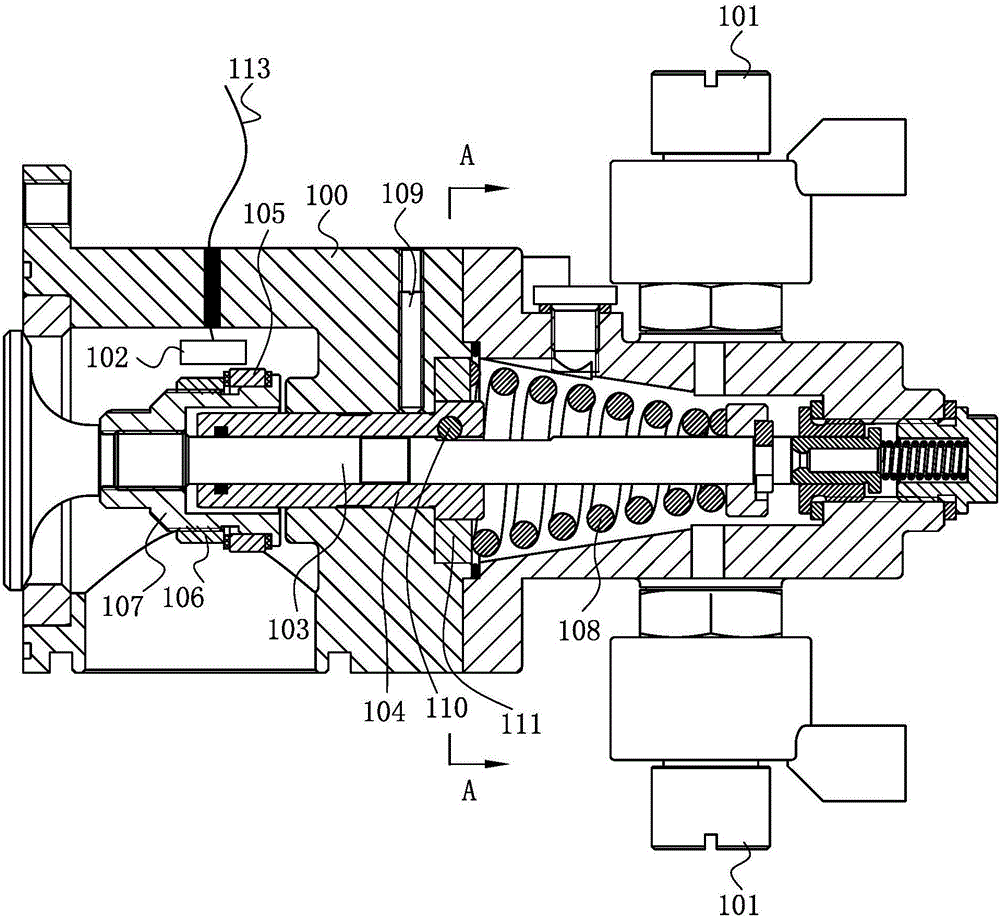

[0021] Such as figure 1 As shown, a hydraulically driven gas injection valve, a solenoid valve 101 is installed outside the valve body 100, through the on-off control of the solenoid valve 101 hydraulic oil enters and exits the valve body cavity, so that the valve core 103 moves, and then opens or closes the injection valve.

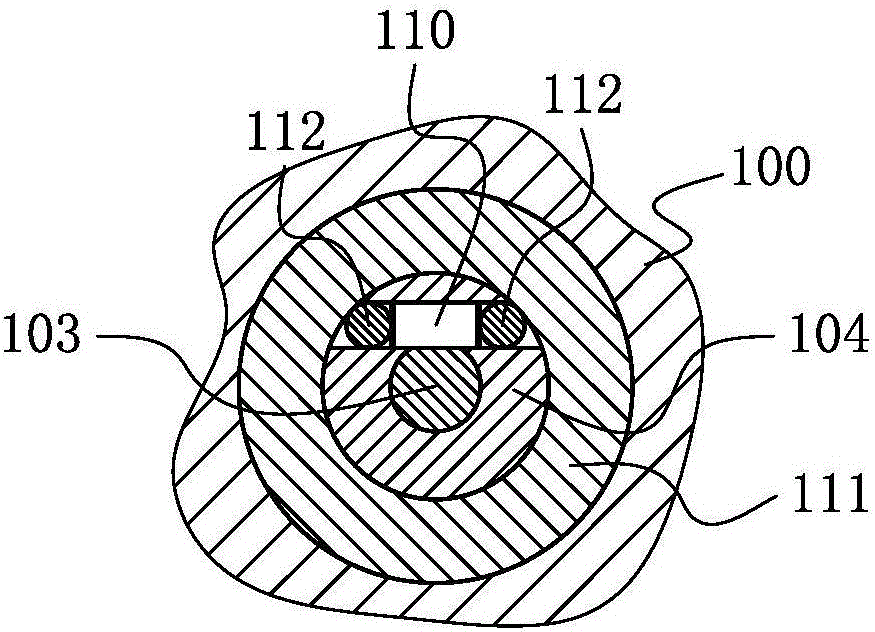

[0022] A valve sleeve 104 is disposed inside the valve body 100 , and a set screw 109 is disposed on the valve body 100 to prevent the valve sleeve from rotating.

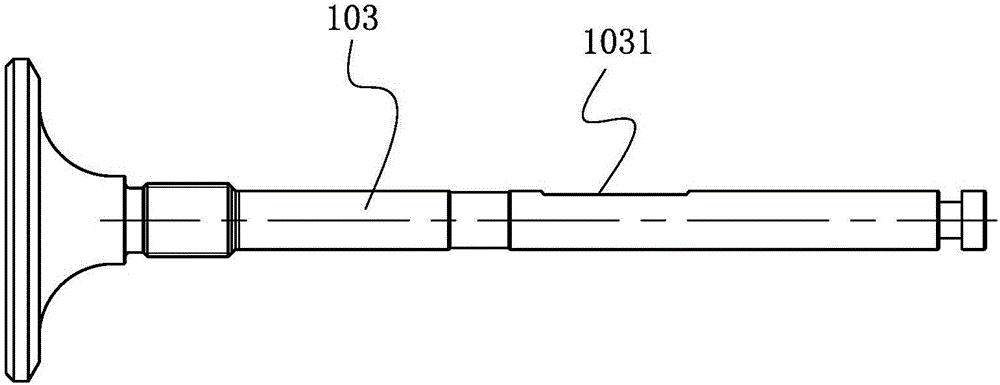

[0023] The valve rod of the valve core 103 is slidingly fitted with the valve sleeve 104 , and the valve rod has a first protruding portion and a second protruding portion protruding from both ends of the valve sleeve 104 respectively. The first protruding part of the valve stem is fixedly connected with a magnet 105 through a magnet seat, and a magnetic field sensor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com