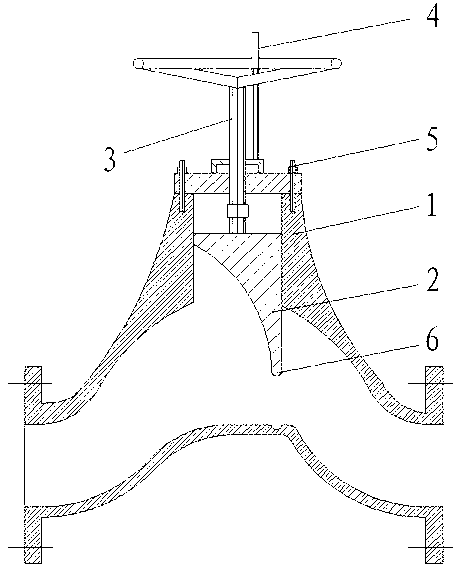

Low-resistance valve capable of precisely controlling flow rate

A technology for precise control and control of valves, applied in valve details, valve devices, sliding valves, etc., can solve the problems of valve wear, valve disc easily worn, and valve body pressure drop, etc., to reduce fluid loss and eliminate flow. Dead zone, effect of wide fluid passage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, the present invention will be further described.

[0026] In the valve body of the present invention, the fluid flows along the C-shaped flow channel, the flow channel is more smooth, and the fluid is distributed in a streamlined manner; the upper part of the valve disc is rectangular, and the lower part is arc-shaped, which can effectively reduce the impact of the fluid on the baffle; the valve disc and the valve body The seal adopts a hemispherical sealing groove; after the valve body is cast, the inner surface of the valve body 1 is finely processed, and the maximum roughness of the processing is 3.2 μm; , first adjust the spiral micrometer structure upwards, when the valve disc is adjusted to the approximate position, adjust the spiral micrometer structure downward, stop rotating after making a sound, and can accurately display and control the valve opening; adjust the valve disc to reduce the flow rate , first adjust ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com