Mechanism for controlling position of variable valve

A valve position, variable technology, applied in the valve device, valve operation/release device, valve details, etc., can solve the problem that the valve opening cannot be intelligently controlled, the range of the opening is arbitrary, etc., to achieve high precision, high opening Accurate range and strong stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

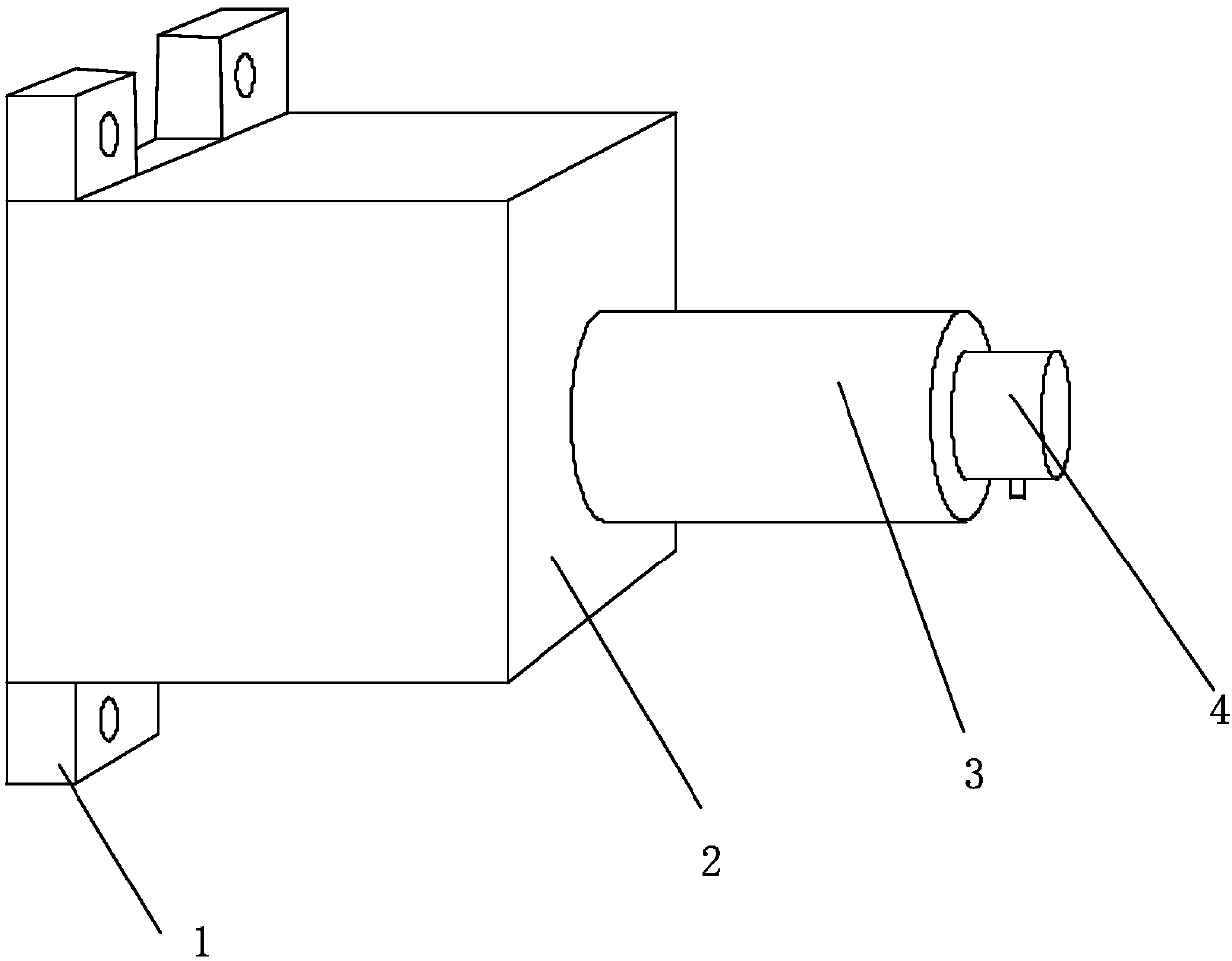

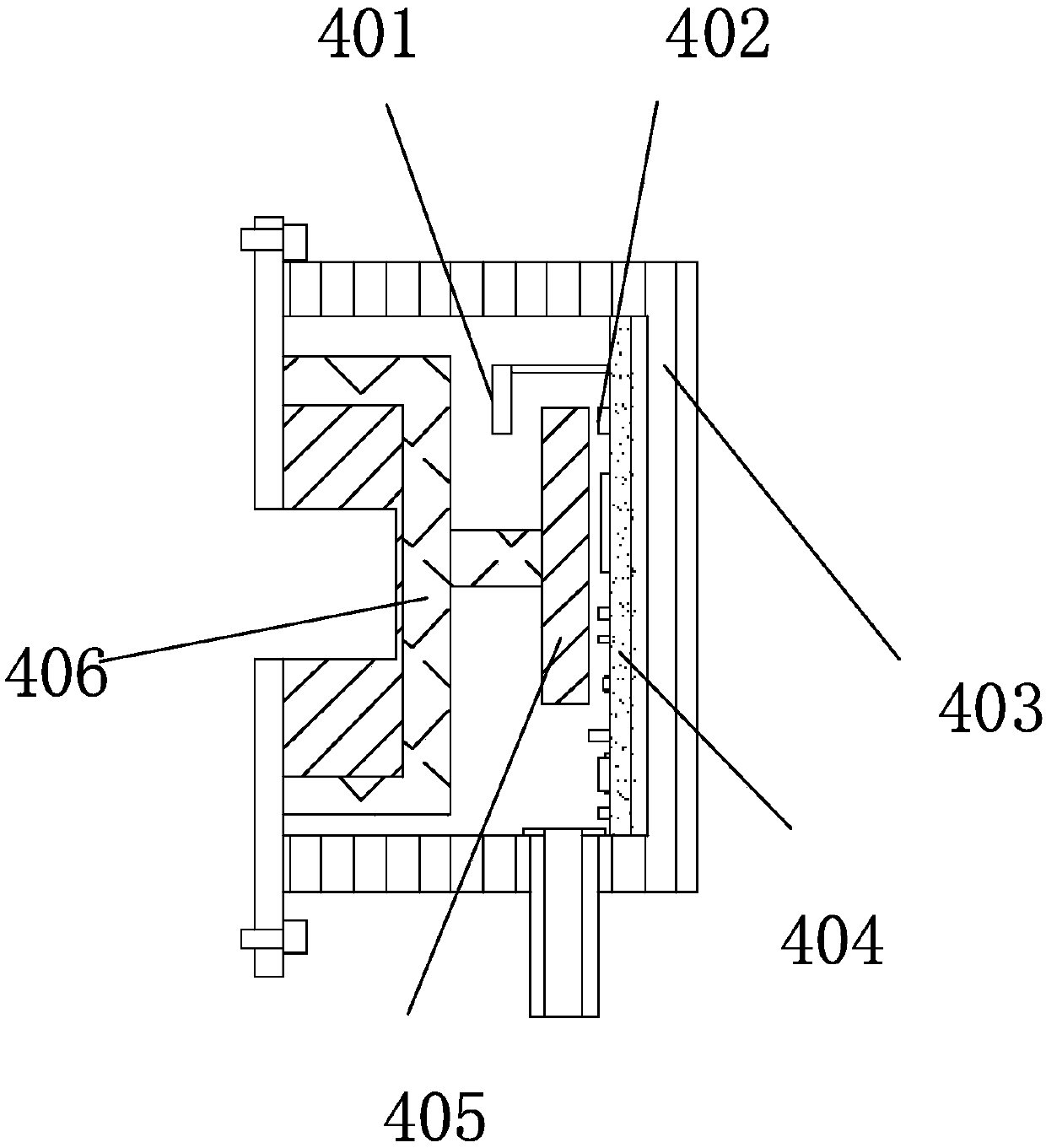

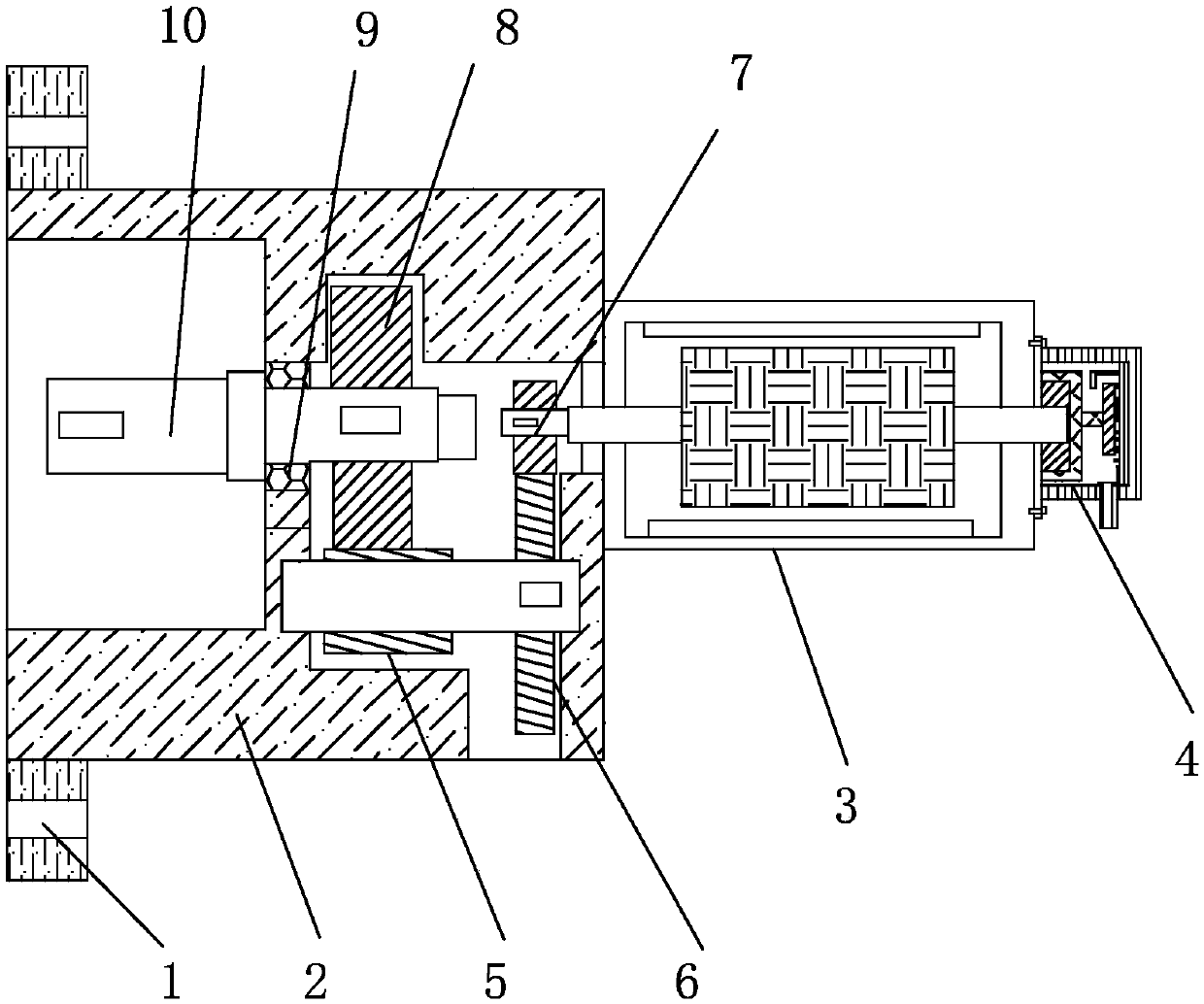

[0015] see Figure 1-Figure 3 , the present invention provides a mechanism for controlling the position of a variable valve: its structure includes: a fixed ear 1, a machine base 2, a servo motor 3, an encoder 4, a secondary gear shaft 5, a primary gear 6, a Stage pinion 7, stage two large gear 8, bearing 9, output shaft 10, the base 2 is fixed on the left side of the servo motor 3 and connected by bolts, the right side of the servo motor 3 is equipped with an encoder 4 and is connected by screws connection, the output shaft 10 is fixed inside the machine base 2 and adopts clearance fit, and the four fixed ears 1 are installed on the upper and lower sides of the machine base 2 and fixed by welding. The first-stage pinion 7 is installed on the serv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com