Central range hood, terminal part and air valve control method of range hood

A technology for range hoods and terminal components, which is applied in the field of oil fume removal equipment, and can solve problems such as misjudgment of the switch status of range hoods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

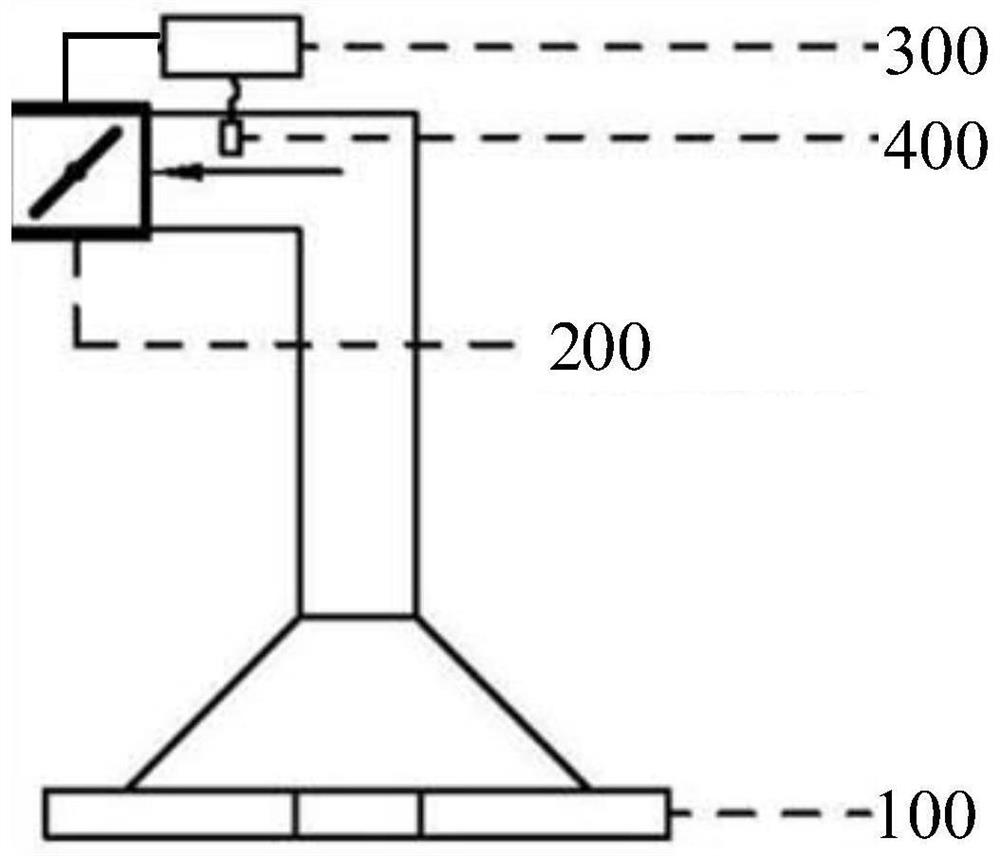

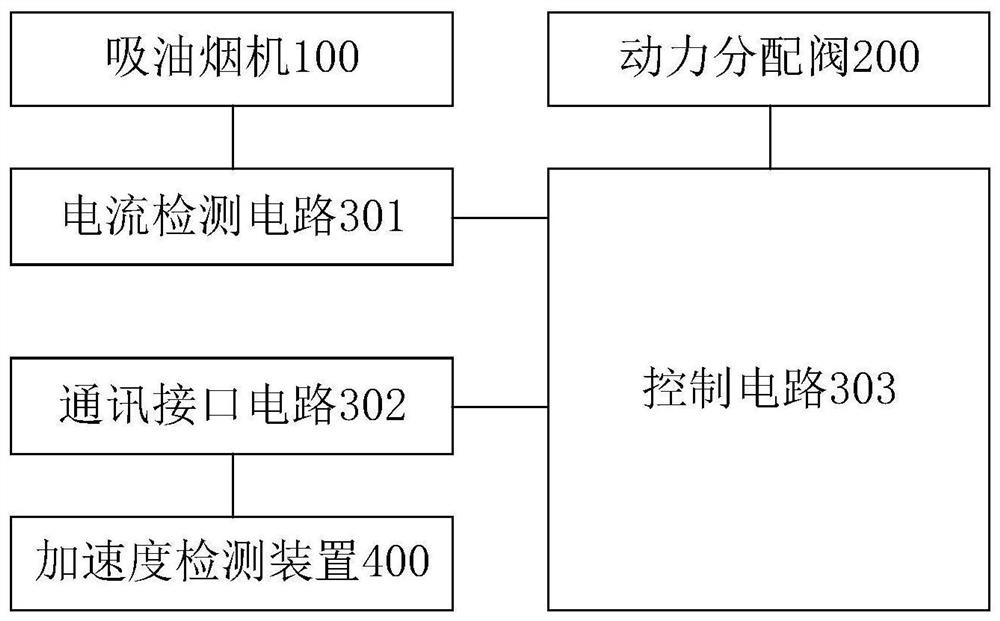

[0029] figure 1 A schematic structural view of a terminal part of a central range hood provided in an embodiment of the present invention, as shown in figure 1 As shown, the terminal components include: a range hood 100 , a power distribution valve 200 , a damper controller 300 and an acceleration detection device 400 .

[0030] The range hood 100 is respectively connected with the power distribution valve 200 and the damper controller 300, and the acceleration detection device 400 is suspended inside the pipeline between the range hood 100 and the power distribution valve 200; the damper controller 300 is respectively connected with the power distribution valve 200 is connected to the acceleration detection device 400.

[0031] The acceleration detection device 400 is used to detect its own suspension acceleration, and send the suspension acceleration to the damper controller 300 .

[0032] The air valve controller 300 is used to detect the working current of the range hood...

Embodiment 2

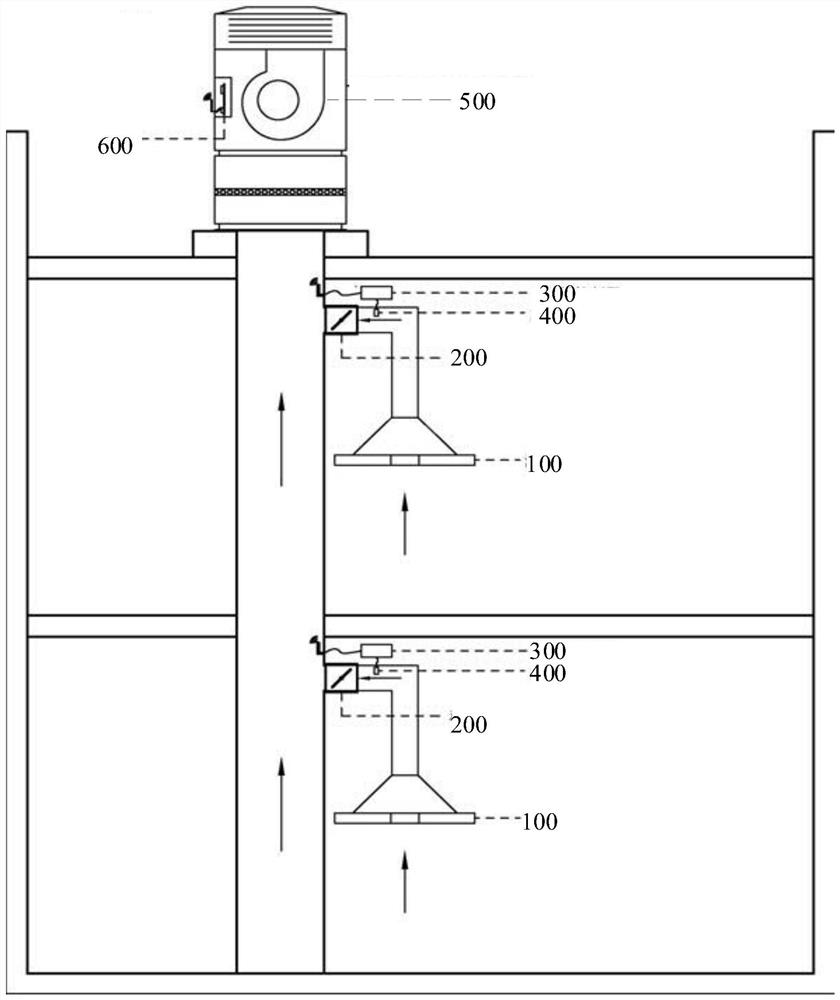

[0059] image 3 A schematic structural diagram of a central range hood provided in an embodiment of the present invention, as shown in image 3 As shown, the central range hood includes: a fan 500, a main controller 600, and terminal components of any one of the central range hoods in the first embodiment above located on each floor.

[0060] The main controller 600 is respectively connected with the fan 500 and the damper controller 300 in each terminal component.

[0061] The damper controller 300 is used to send the working status of the range hood 100 to the main controller 600 .

[0062] The main controller 600 is used for sending the operation frequency information to the fans 500 according to the working states of the range hoods 100 on all floors.

[0063] The fan 500 is used for exhausting air according to the operating frequency information.

[0064] Specifically, the terminal components on each floor in the central range hood are communicatively connected to the ...

Embodiment 3

[0070] Figure 4 A flow chart of a damper control method for a range hood provided in an embodiment of the present invention, the method is applied to the damper controller in any terminal part of the central range hood in the first embodiment above, such as Figure 4 As shown, the method specifically includes the following steps:

[0071] Step S102, detecting the operating current of the range hood, and receiving the suspension acceleration of the acceleration detection device.

[0072] Specifically, when the damper controller controls the opening of the power distribution valve (referred to as the damper), it first needs to determine the working state of the range hood. In the embodiment of the present invention, the damper controller first needs to detect the range hood working current, and at the same time will receive the suspension acceleration sent by the acceleration detection device connected to it in communication.

[0073] Step S104, when the working current is gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com