System for preparing solid-gas flow state dry ice based on CO2 cascade refrigeration twice throttling

A cascading refrigeration and secondary throttling technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of wasting more environment, increasing costs, disadvantages, etc., to ensure stability and reliability, save raw materials, Environmentally friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation process of the present invention will be described in detail below in conjunction with the accompanying drawings, but the present invention is not limited to this embodiment. In order to make the public have a thorough understanding of the present invention, the specific details will be described in detail in conjunction with the system built:

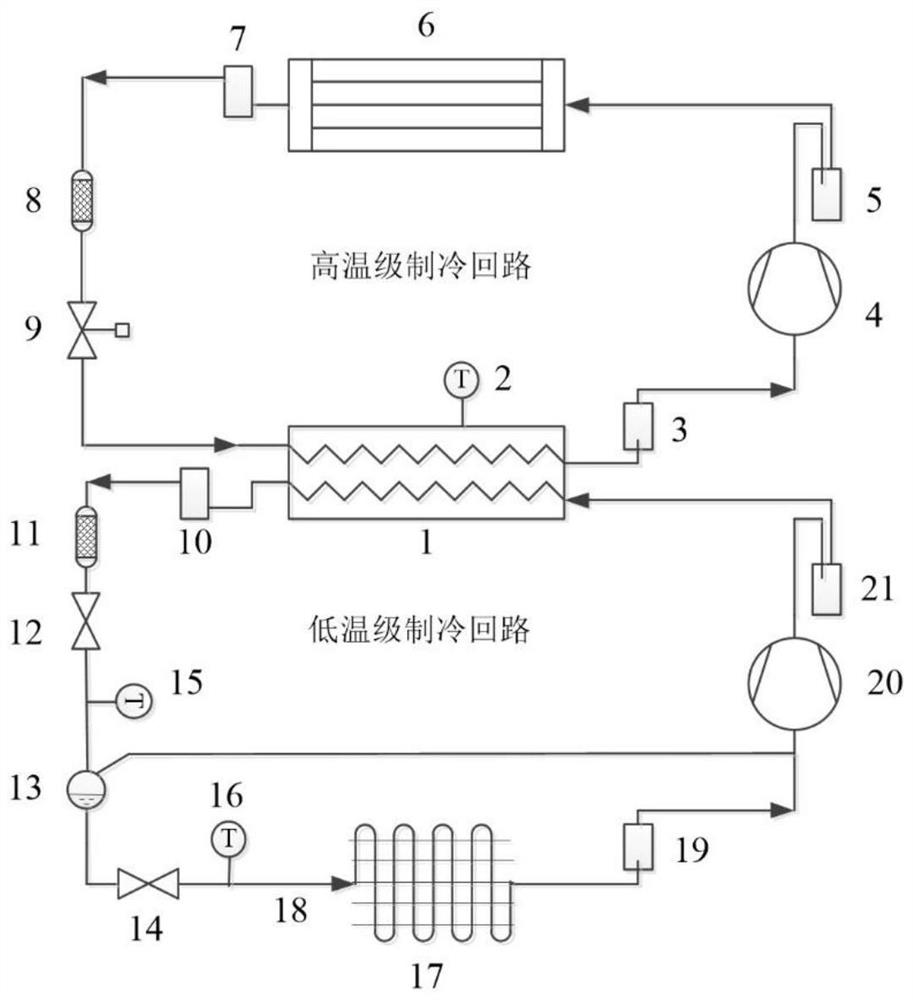

[0027] Such as figure 1 As shown, the present invention proposes a CO-based 2 Cascade refrigeration double-throttling system for continuous preparation of solid-gas dry ice, realizes low-cost, continuous production, high fluidity, and environmentally friendly and emission-reducing preparation technologies for solid-gas dry ice products, including:

[0028] High-temperature stage refrigeration circuit: the outlet of the high-temperature stage of the condensing evaporator 1 is connected with the gas-liquid separator 3, compressor 4, oil separator 5, condenser 6, liquid storage tank 7, dry filter 8, exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com