Passive spring roller hemming component

A passive, hemming technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of rigid system impact and wear, adverse effects of hemming quality, complex airbag buffer system, etc., to achieve accurate movement position and speed, energy saving Good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

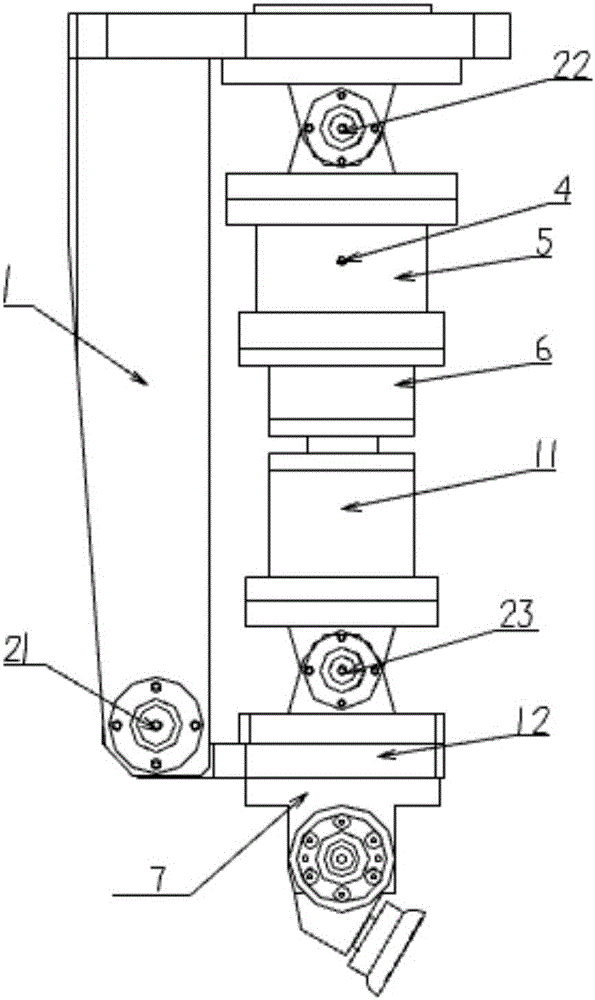

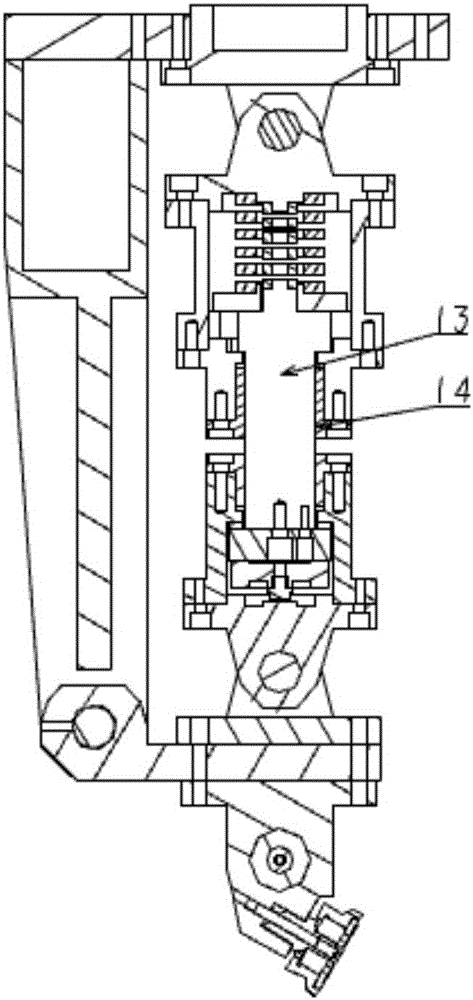

[0041] Such as Figure 1-3 As shown, a passive spring hemming assembly is in contact with the body of the car to be hemmed, including:

[0042] Support 1, its top is provided with the flange top cover 3 that links to each other with mechanical arm, and the bottom is hinged with base plate 12 by first hinge 21, and described flange top cover 3 and described bottom plate 12 are parallel and oppositely arranged;

[0043] A spring buffer 5, which is arranged between the flange top cover 3 and the bottom plate 12, and the upper part of the spring buffer 5 is hinged with the flange top cover 3 through a second hinge 22;

[0044] Cylinder 6, which is arranged between the spring buffer 5 and the bottom plate 12, the upper part of the cylinder 6 is connected with the lower part of the spring buffer 5, and the cylinder 6 has a seat for accommodating the guide rod 13 In the inner space, the upper end of the guide rod 13 is in conflict with the spring buffer 5, and the lower end of the c...

Embodiment 2

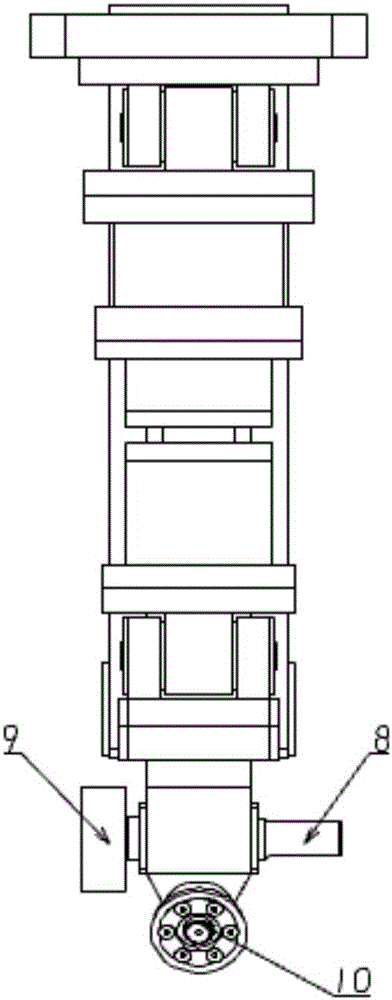

[0053] Such as Figure 4-6 As shown, a passive spring hemming assembly is in contact with the body of the car to be hemmed, including:

[0054] Support 1, the upper part of which is provided with a flange top cover 3 connected to the mechanical arm, which is perpendicular to the plane where the support 1 is located;

[0055] A spring buffer 5, which is arranged below the flange top cover 3, and the upper part of the spring buffer 5 is hinged with the flange top cover 3 through a fourth hinge 24;

[0056] Cylinder 6, which is arranged below the spring buffer 5, the upper part of the cylinder 6 is connected with the lower part of the spring buffer 5, the cylinder 6 has an inner space for accommodating the guide rod 61, the guide The upper end of the rod 61 interferes with the spring buffer 5; and

[0057] The second piping body 7, which is arranged below the cylindrical body, the upper part of the second piping body 7 and the bottom of the cylindrical body 6 are hinged by the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com