Feeding mechanism for metallized film processing

A technology of metallized film and feeding mechanism, which is applied in metal material coating process, ion implantation plating, coating, etc., can solve the problem of the convenience and timeliness of feeding, which cannot meet the requirements of industrial mass production, The limited amount of winding insulating film can achieve the effect of high degree of automation, convenient feeding, and avoiding unstable tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to further describe the present invention, it is further described below in conjunction with embodiment.

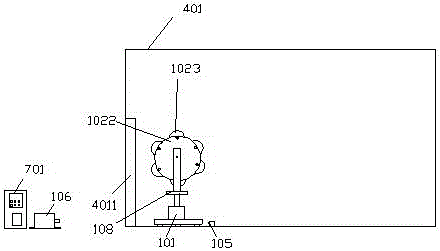

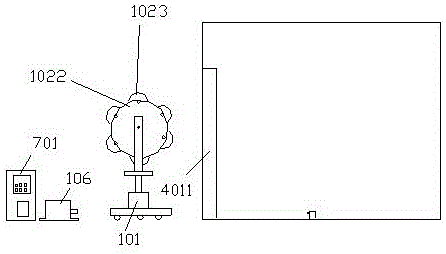

[0026] Such as figure 1 As shown, the present invention discloses a feeding mechanism for metallized film processing, including a first lifting mechanism 101 and a feeding device. The telescopic end of the first lifting mechanism 101 cooperates with the feeding device to drive the feeding device to move up and down.

[0027] Such as figure 1 As shown, the vacuum chamber 401 includes an entry door 4011 at the entry end.

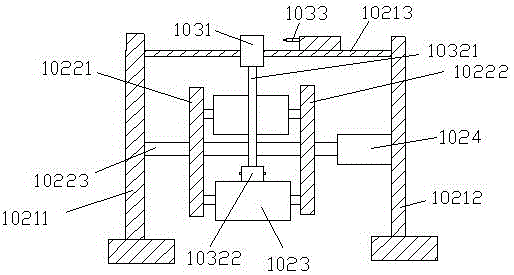

[0028] Such as figure 1 As shown, the feeding device includes a first support frame, a first rotating cylinder 1022 , and a feeding roller 1023 . The first rotating cylinder 1022 is rotatably matched with the first supporting frame, and the first rotating cylinder 1022 can rotate around its central axis. Several feeding rollers 1023 are distributed on the first rotating cylinder 1022 around the central axis of the first rotating cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com