An Eccentric Hob Translating Cutter for Rectangular Cutting Section of Hard Rock

A technology of rectangular cutting and eccentric rolling, which is applied in mining equipment, earthwork drilling, tunneling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

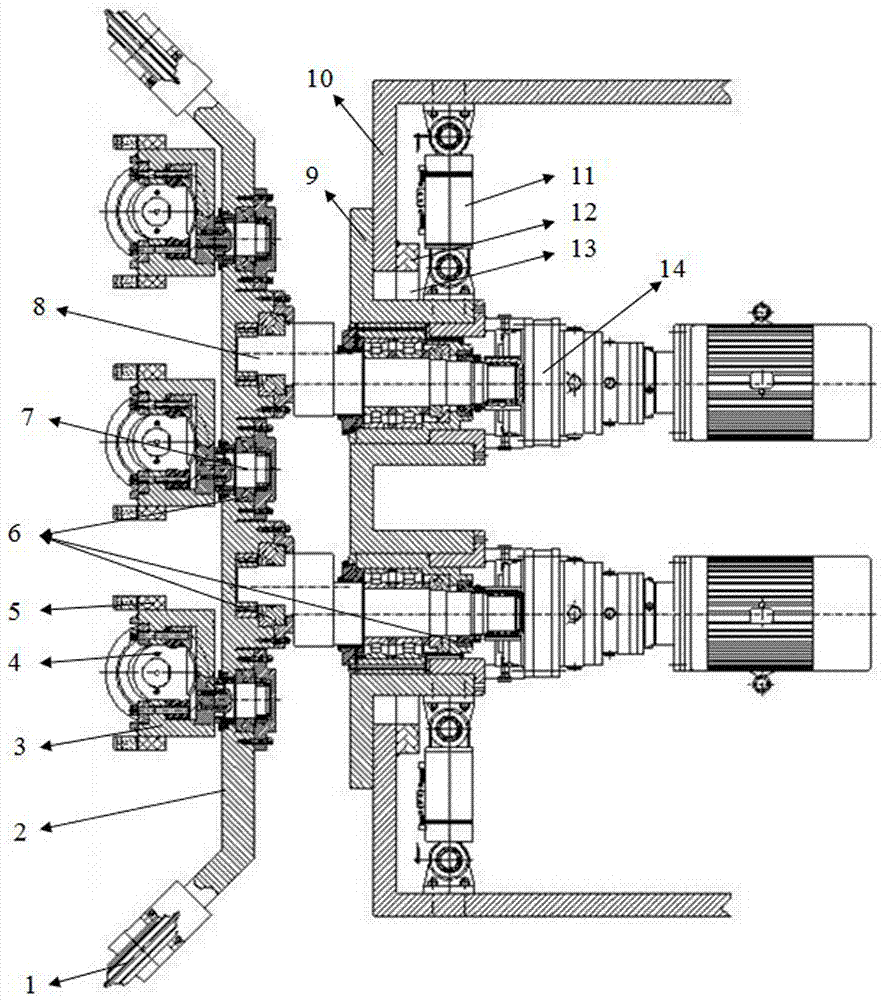

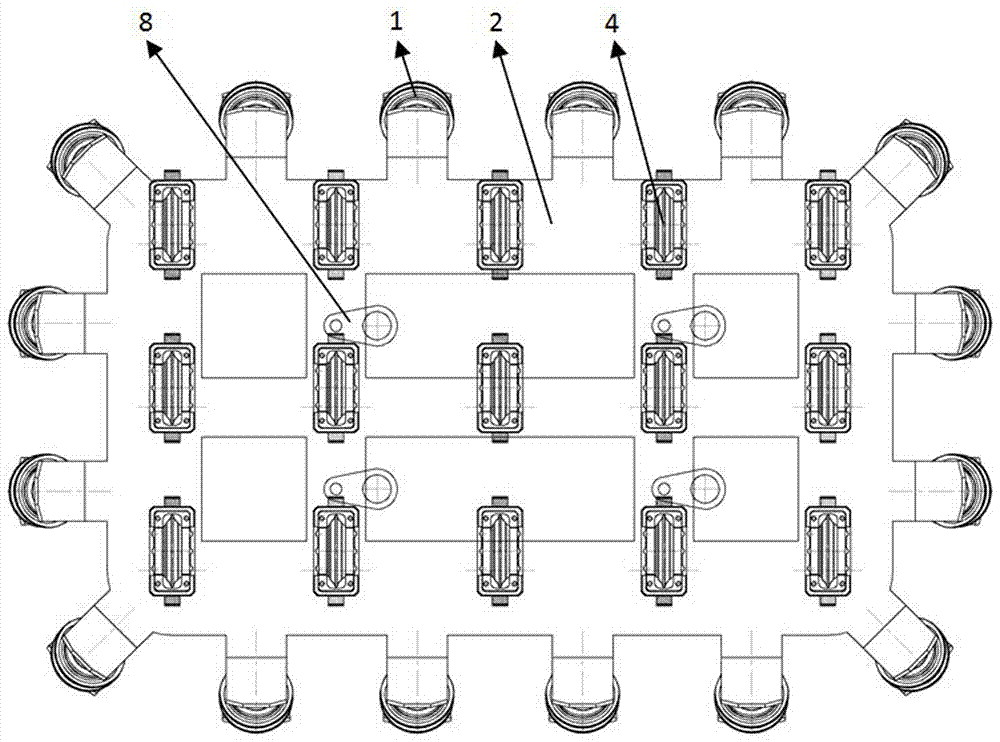

[0023] Such as Figure 1~3 As shown, the present invention provides a kind of eccentric hob translational cutterhead for hard rock rectangular cutting section, including cutterhead body 2, cutter, drive system, cutterhead body 2 is driven by drive system, and described cutterhead body 2 is a spoke-type rectangular cutter body; the tool includes a positive hob 4, wherein the positive hob 4 is installed on the positive hob tool seat 3, and the positive hob tool seat 3 and the rotary shaft 7 of the tool seat are fastened and connected as a whole by bolts , the tool seat rotating shaft 7 is connected to the cutter head body 2 through a bearing, and the center of the positive hob tool seat 3 is eccentric with the center of the tool seat rotating shaft 7.

[0024] The positive hob holder 3 is equipped with scrapers 5 at both ends of the tool rolling direction; side hobs 1 are distributed around the cutter head body 2, and the side hobs 1 extend obliquely outward at an angle of 45° t...

Embodiment 2

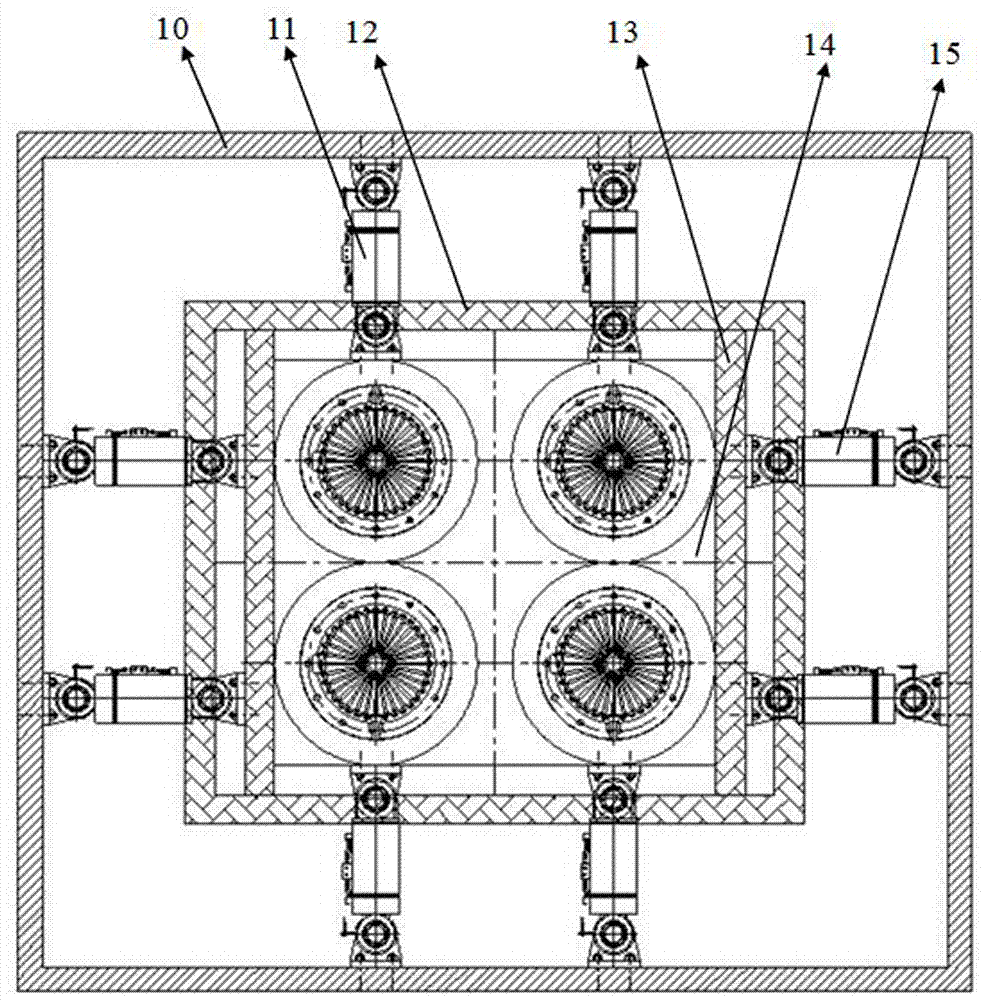

[0032] Such as Figure 4 , 5 As shown, it is the application of the new cutter head on the rectangular jacking pipe. Four sets of the new cutter head are arranged at the upper left, lower left, upper right, and lower right positions of the front end of the shield body, and the maximum offset distance of the offset mechanism is used as the cutter head. Disc spacing, while ensuring that the four groups of cutter heads are in the same vertical plane. Each group of new cutterheads is driven by four sets of eccentric drive shafts, and the new cutterheads work under the push of the main jack cylinder to realize the excavation of hard rock tunnels with special-shaped cross-sections.

[0033] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com