Bending heat exchanger and bending method of heat exchanger

A heat exchanger and heat exchange unit technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve problems such as difficulty in adapting to needs, achieve improved heat exchange performance, increase length, and ensure discount The effect of bending accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

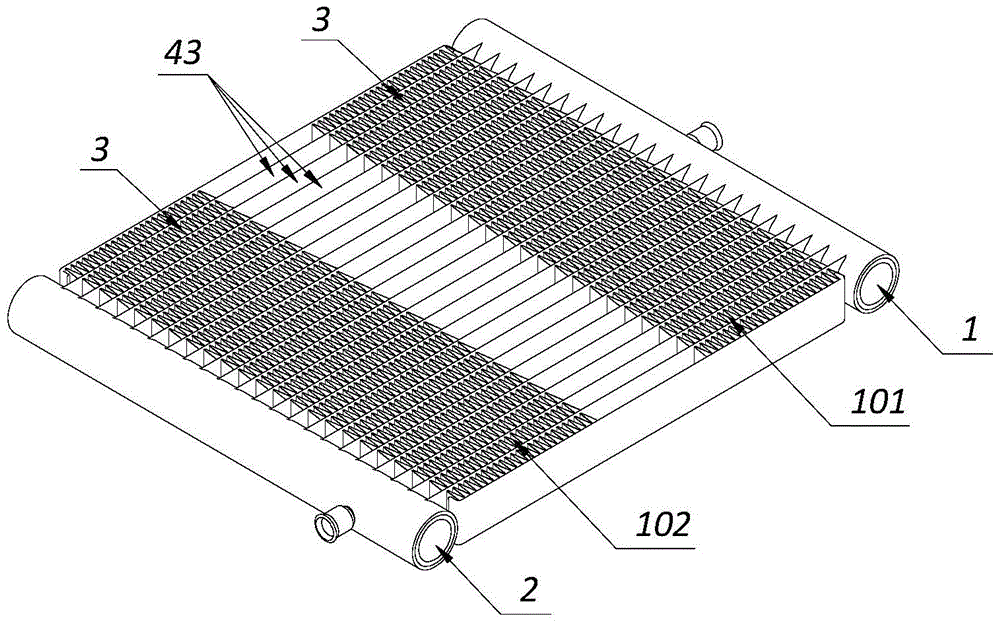

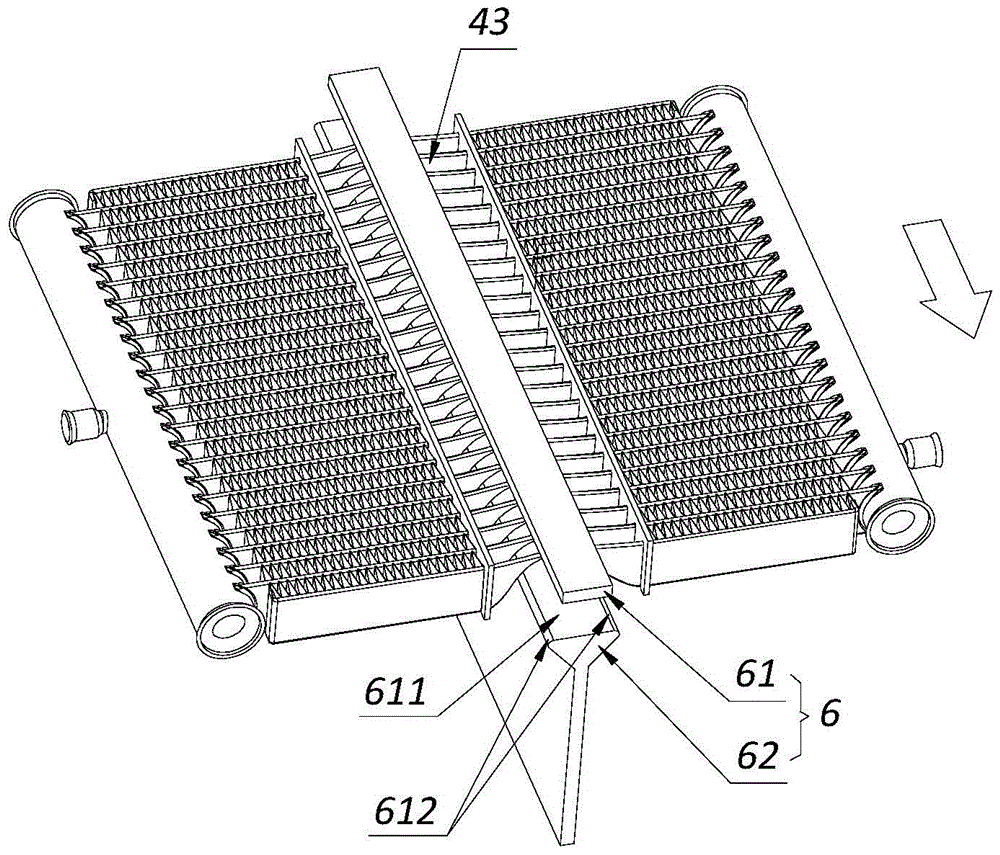

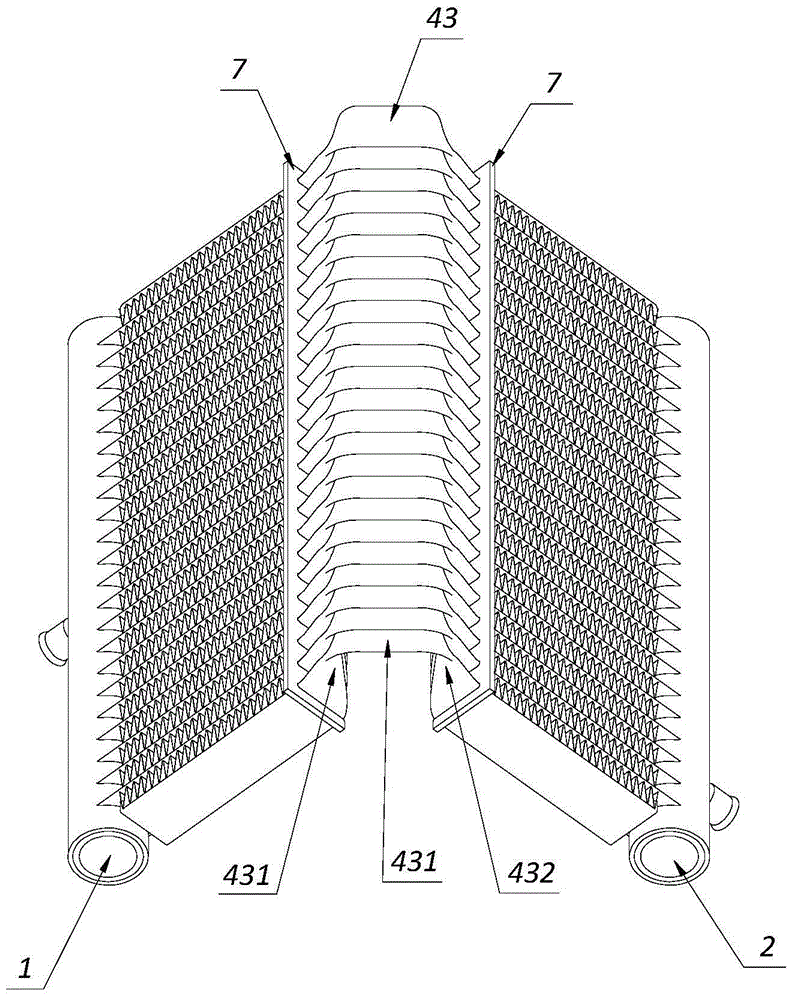

[0040] Please refer to Figure 1 to Figure 6As shown, the present invention discloses a bent heat exchanger 100, which includes a first header 1, a second header 2, several fins 3, connecting the first and second headers 1, Some flat tubes 4 of 2, and some side plates 5. The bent heat exchanger 100 includes a first heat exchange unit 101 and a second heat exchange unit 102 . The flat tube 4 includes a first part 41 located on the first heat exchange unit 101, a second part 42 located on the second heat exchange unit 102, and connecting the first and second parts 41, 42 The middle part (bending part) 43. The first and second headers 1 and 2 are respectively provided with flat tube sockets (not labeled) communicating with the first and second parts 41 and 42 . The first and second parts 41 and 42 are respectively in contact with the fins 3 (in the illustrated embodiment of the present invention, the first and second parts 41 and 42 are brazed with the fins 3 as One). The mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com