Bender speed planning method and device

A technology of speed planning and bending machine, applied in the field of bending machine, can solve the problem of prolonging the processing time of board inspection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

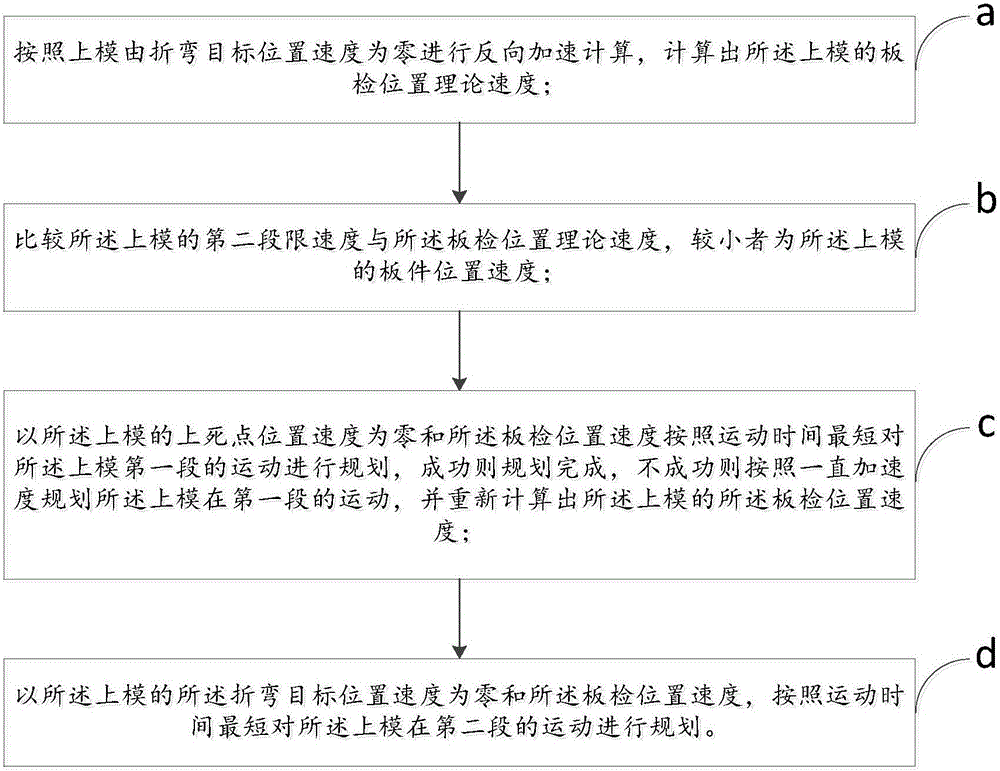

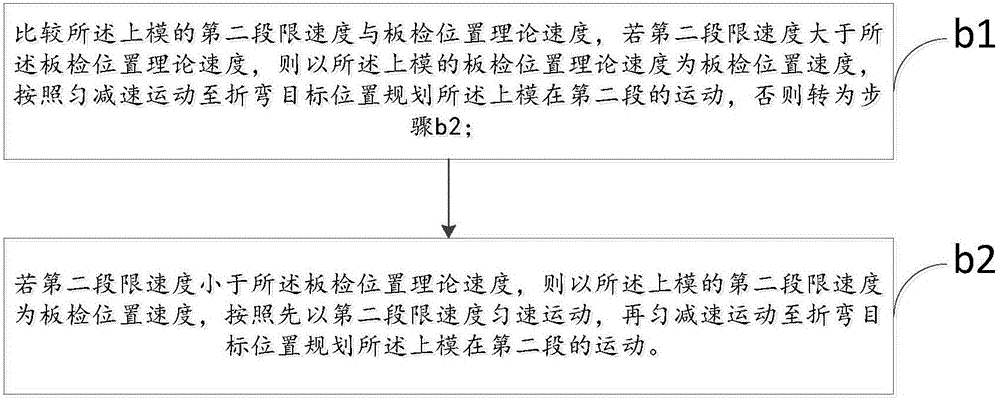

[0070] As mentioned above, the speed planning method of the bending machine, the difference of this embodiment is that, as figure 2 As shown in the flow chart of step b in the bending machine speed planning method of the present invention, said step b includes:

[0071] Step b1, comparing the second speed limit of the upper mold with the theoretical speed of the board inspection position, if the second speed limit is greater than the theoretical speed of the board inspection position, then use the theoretical speed of the board inspection position of the upper die as the board Check the position and speed, and plan the movement of the upper mold in the second section according to the uniform deceleration movement to the bending target position, otherwise go to step b2;

[0072] The calculation formula of uniform motion motion time is:

[0073] t 2 = 2 S ...

Embodiment 2

[0082] As mentioned above, the speed planning method of the bending machine, the difference of this embodiment is that in the step b, the calculation formula of the board inspection position speed is:

[0083] v 1 = ( 1 + v L 2 - v 11 | v 11 - v L 2 | ) v 11 2 + ( 1 + ...

Embodiment 3

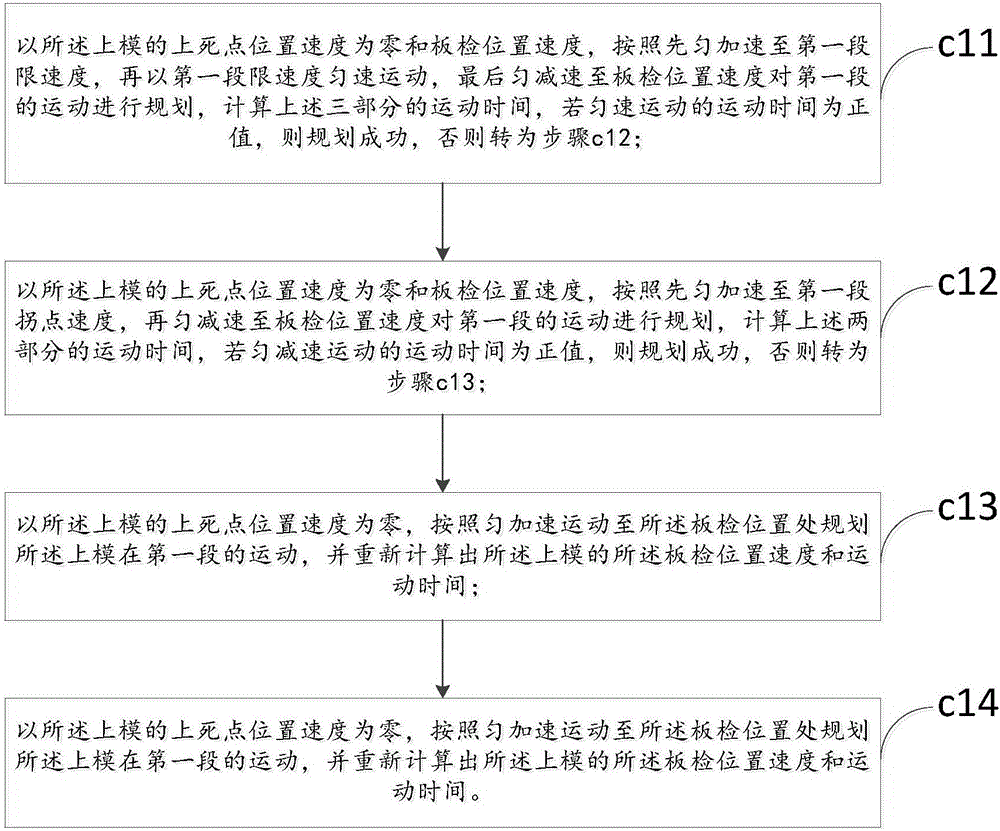

[0088] As mentioned above, the speed planning method of the bending machine, the difference of this embodiment is that, as image 3 The process flow of step c in the bending machine speed planning method of the present invention Figure 1 As shown, the step c includes:

[0089] Step c11, with the speed at the upper dead center position of the upper die being zero and the speed at the board inspection position, first uniformly accelerate to the first speed limit, then move at a uniform speed at the first speed limit, and finally decelerate uniformly to the board inspection position Speed plans the movement of the first segment, and calculates the movement time of the above three parts. If the movement time of the uniform movement is positive, the planning is successful, otherwise go to step c12;

[0090] The calculation formula of the uniform motion time is:

[0091] t 12 = 2 a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com