Automatic assembling operation device and method for open-type TBM steel arch frame

A technology of working device and steel arch frame, applied in the direction of claw arm, manipulator, chuck, etc., can solve the problems of unstable quality, large manual workload, low degree of automation, etc., and achieve the effect of saving movement time and improving assembly efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

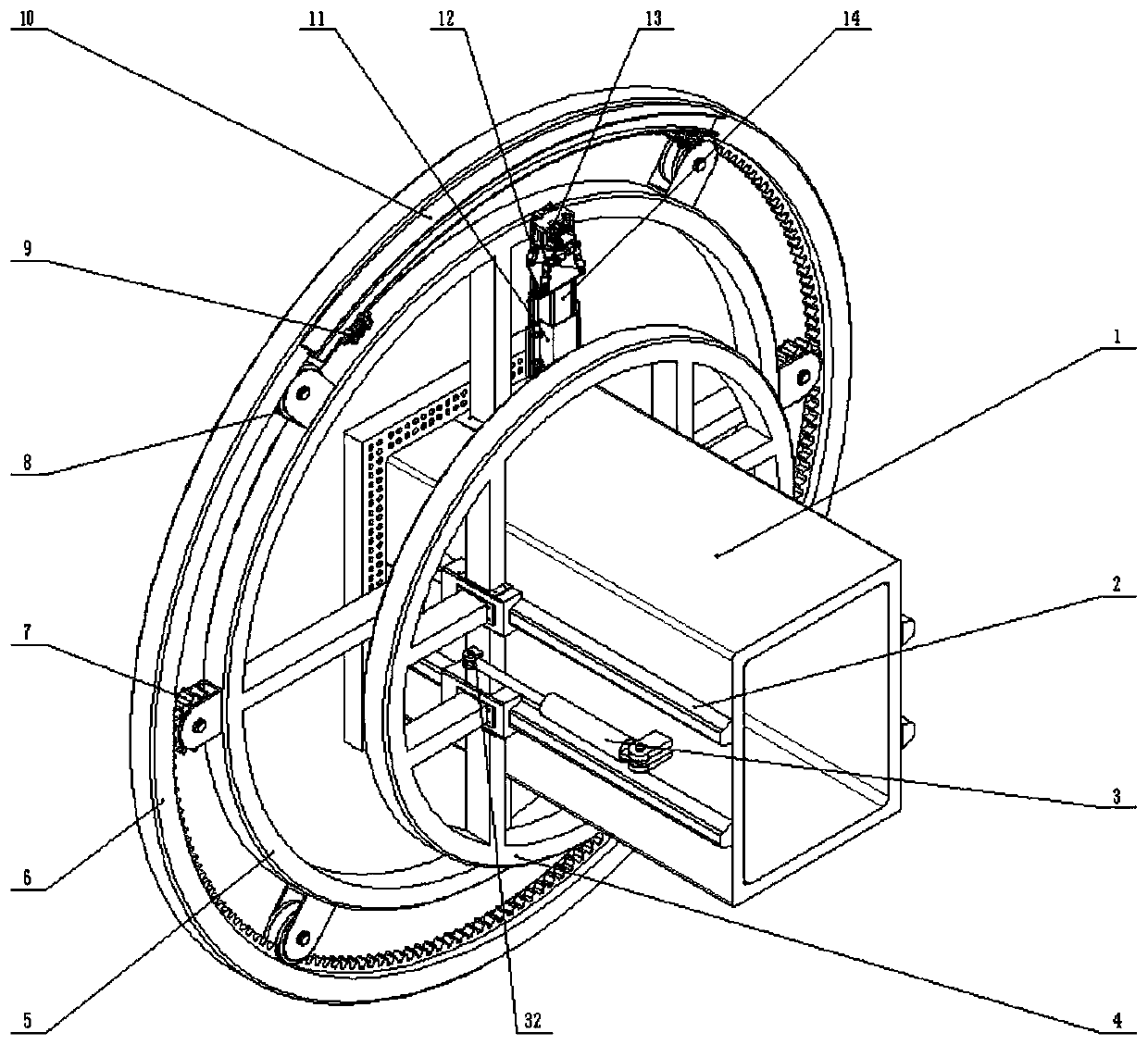

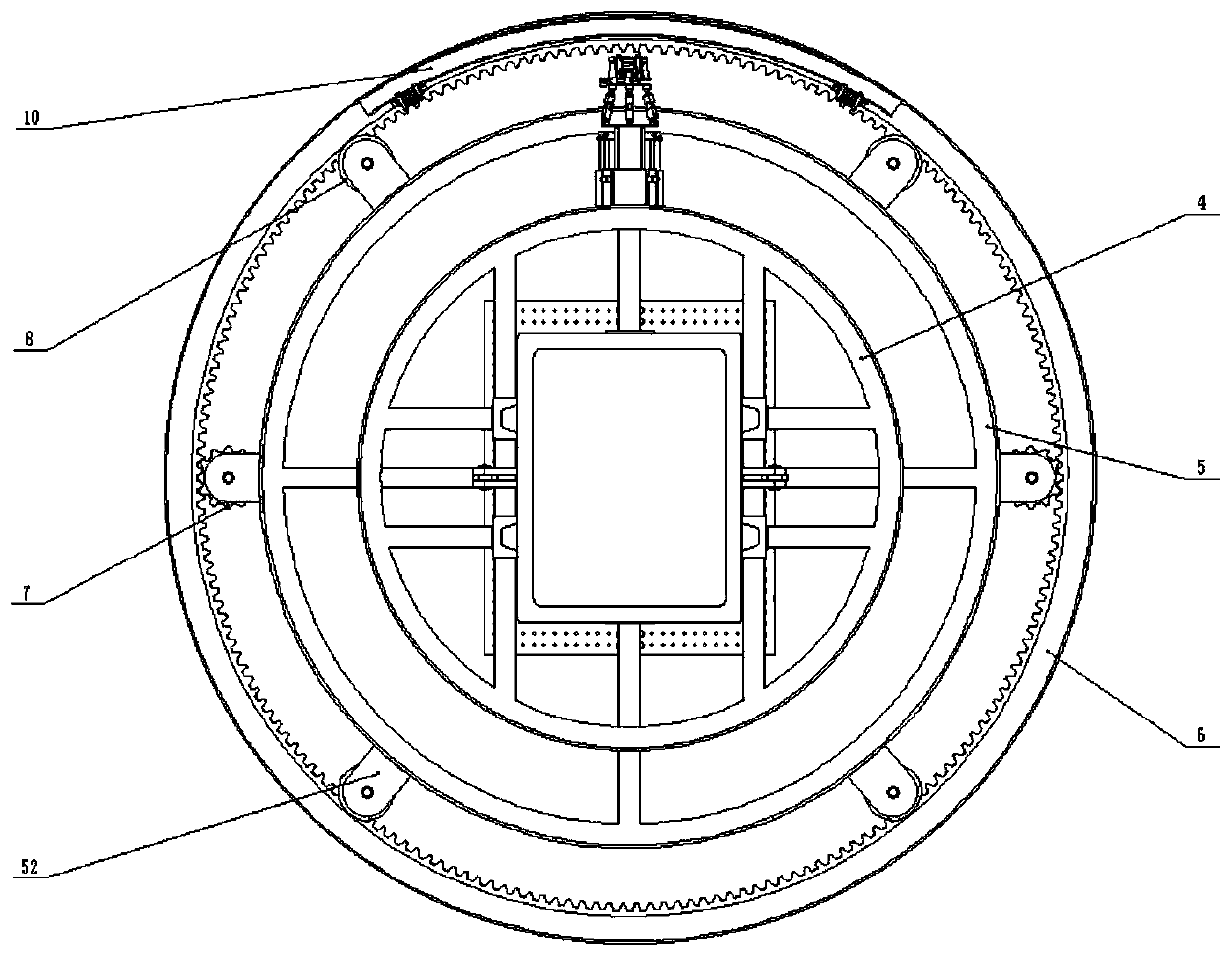

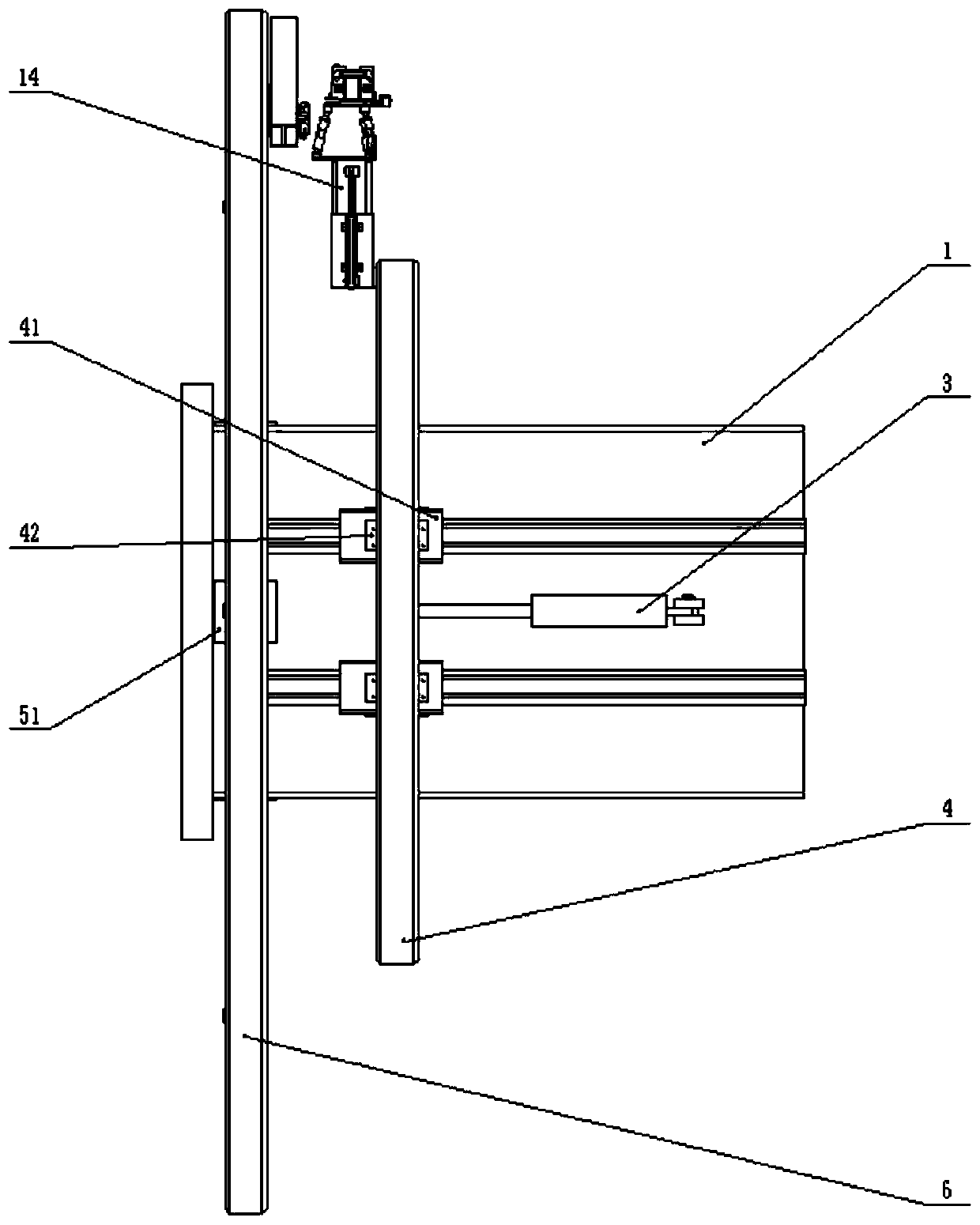

[0023] Such as figure 1 As shown, the present invention includes a main beam 1, a horizontal sliding guide rail 2, a walking cylinder 3, a walking ring 4, a rotating ring bracket 5, a rotating ring 6, a driving wheel 7, a supporting guide wheel 8, a steel arch clamp 9, and a telescopic arm 11 , attitude adjustment device 12, steel arch assembly manipulator end 13; wherein, the walking ring 4 cooperates with the horizontal sliding guide rail 2 on the side of the main beam 1 through the slider 41, and the two ends of the walking cylinder 3 are respectively hinged to the main beam hinged joint 31 and the walking The ring hinged joint 32, the rotating ring bracket 5 is fixed on the main beam 1 through the rotating ring flange 51, the driving wheel 7 and the rotating ring base 52 supporting the guide wheel 8 are uniformly welded on the rotating ring bracke...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com