Device for bending pipe with relatively small abrasion

A pipe bending device, smaller technology, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of large phase difference, large surface wear, large product assembly error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

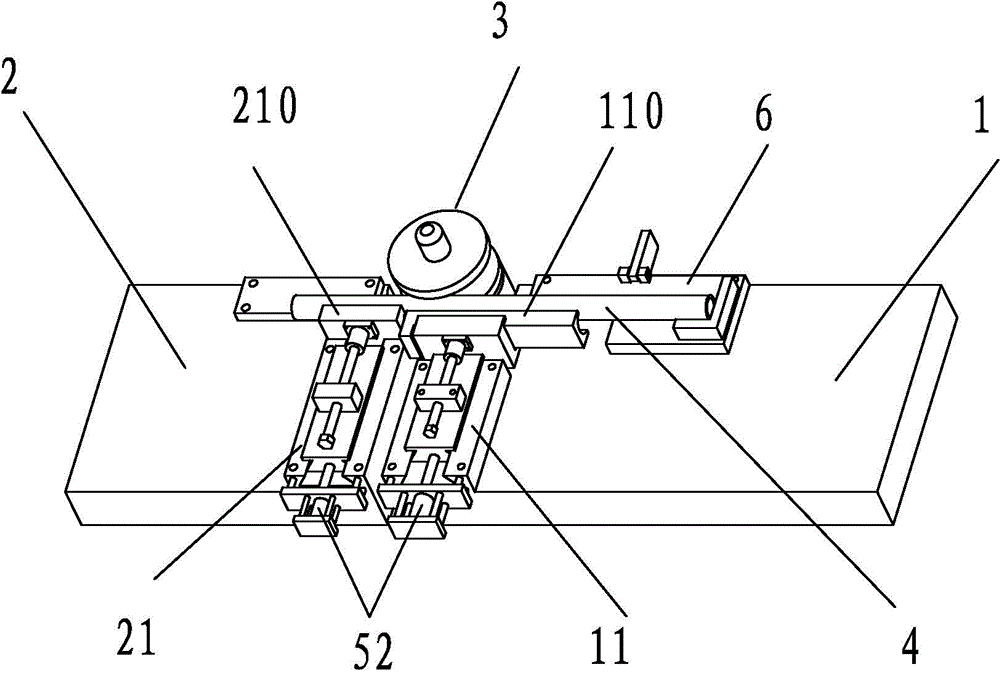

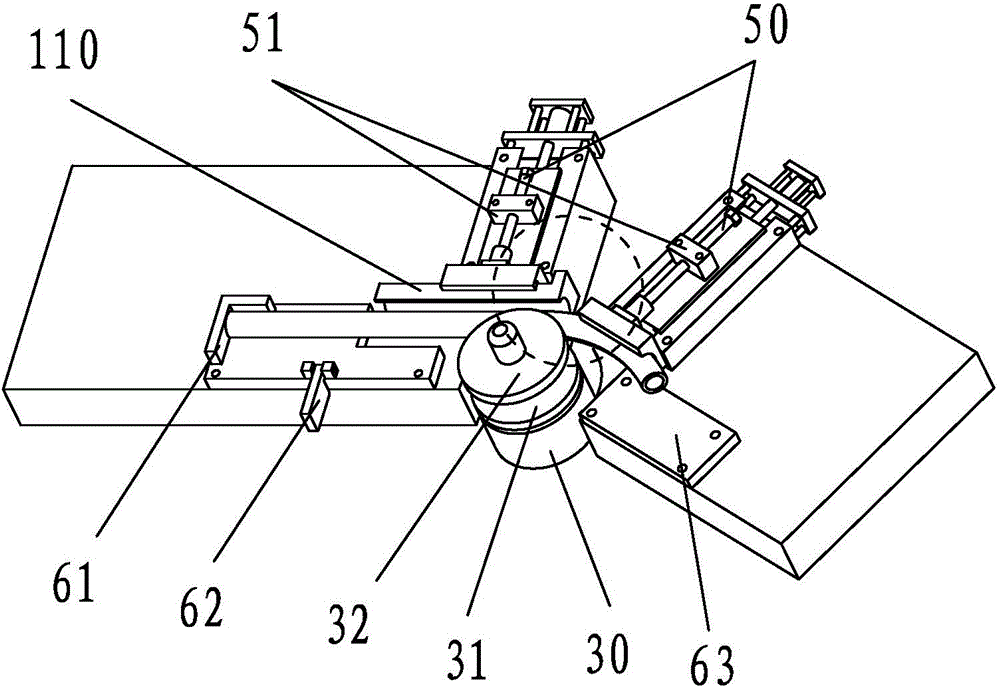

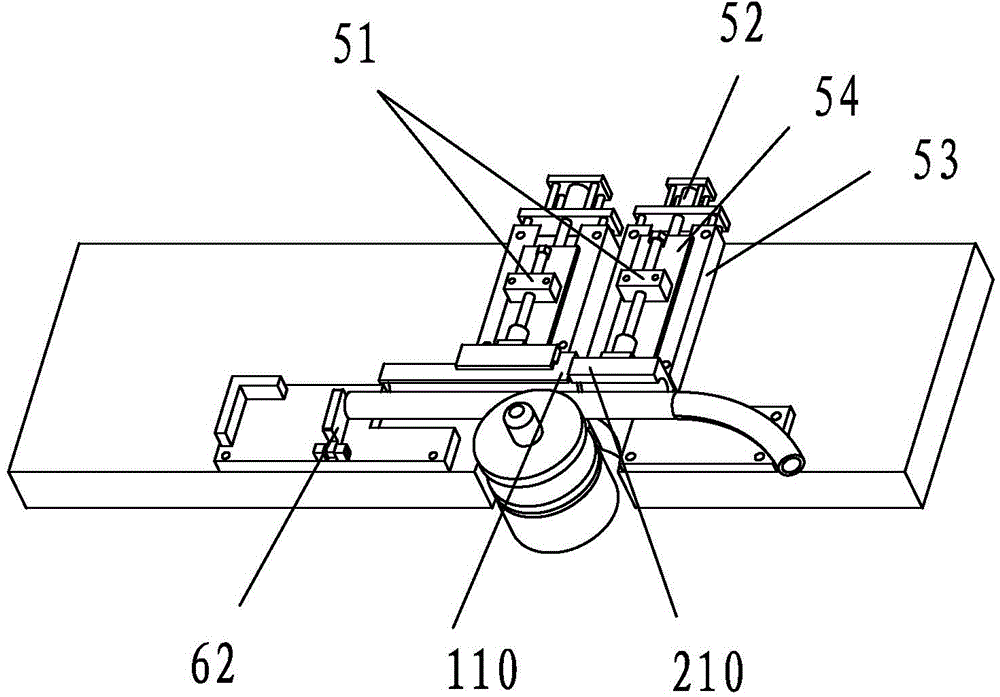

[0016] Such as Figure 1 to Figure 4 As shown, a pipe bending device with less wear and tear comprises a fixed table 1 and a rotatable rotary table 2, and a freely rotating rotary table 3 is arranged between the fixed table and the rotary table. In this embodiment, the rotating The workbench rotates around the rotating round table. One end of the round pipe 4 is positioned on the fixed workbench, and the other end is fixed on the rotating workbench. The side wall of the rotating round table is provided with an arc concave surface 31, and the outer wall of the round pipe is also an arc surface. The circular arc surface is just accommodated in the circular arc concave surface. When the circular tube is actually positioned, the middle part of the circular tube fits in the circular arc concave surface of the side wall of the rotary table, and the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com