Patents

Literature

31results about How to "Reduce springback" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

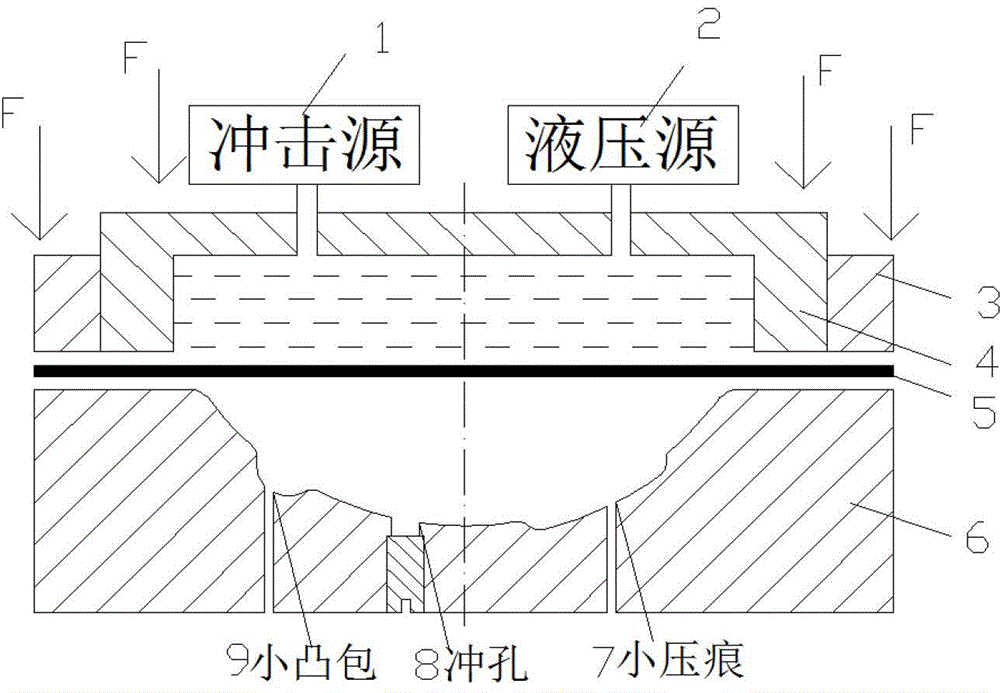

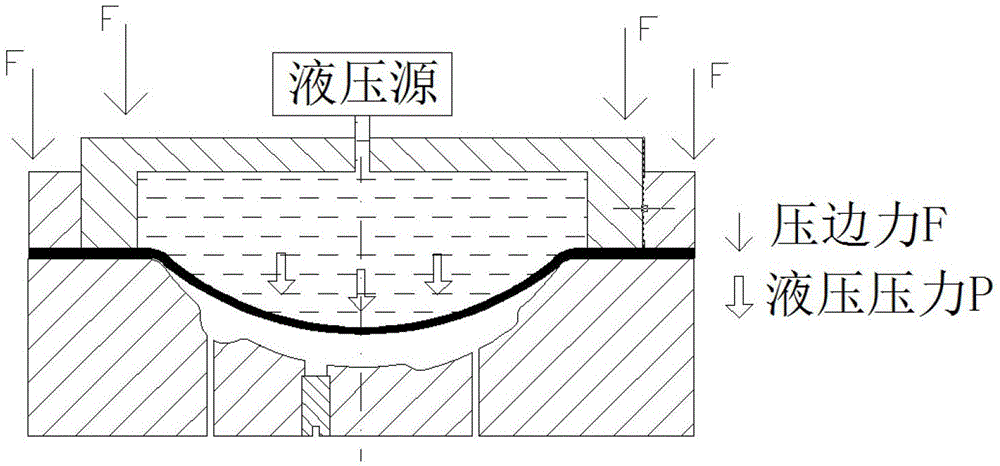

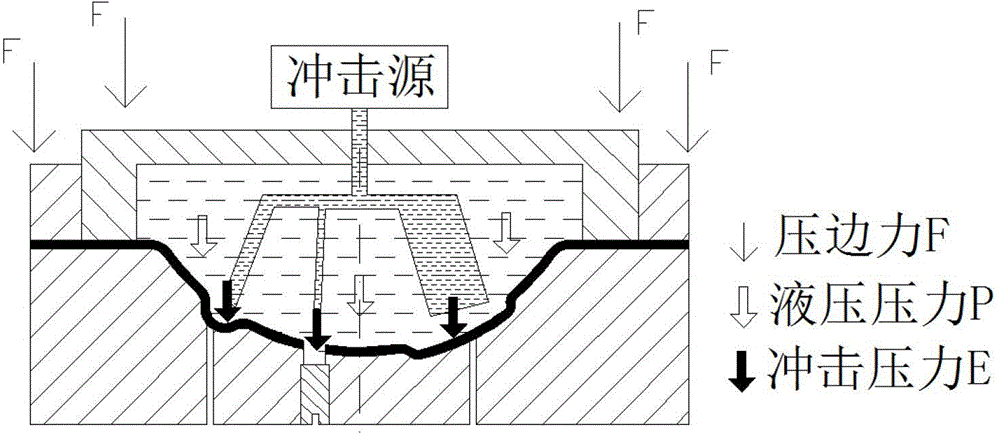

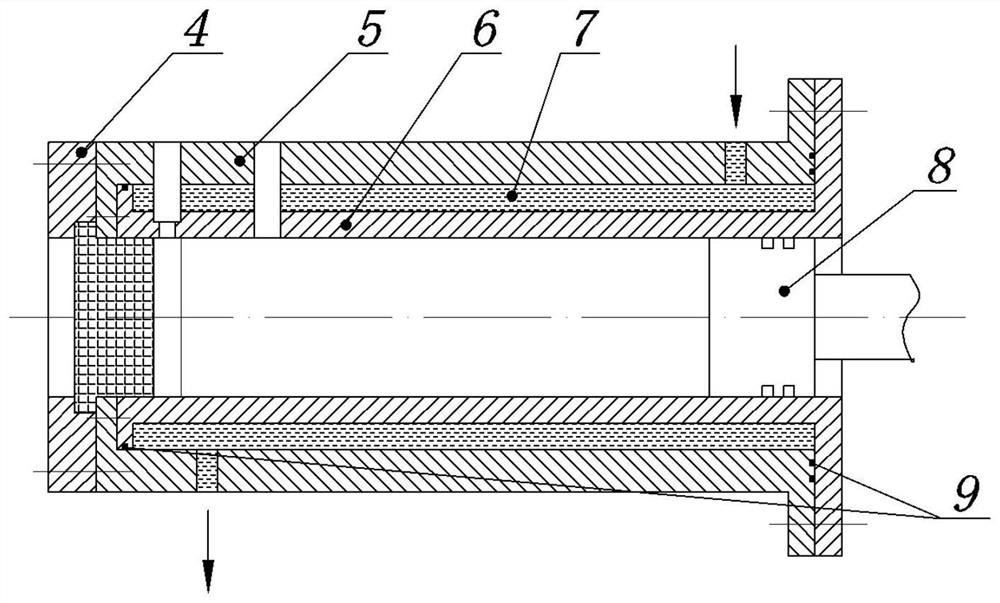

Shock hydraulic composite forming process for small feature part of complex part

InactiveCN102873165AGuarantee the overall forming quality and precisionBroad application prospectsShock waveHigh energy

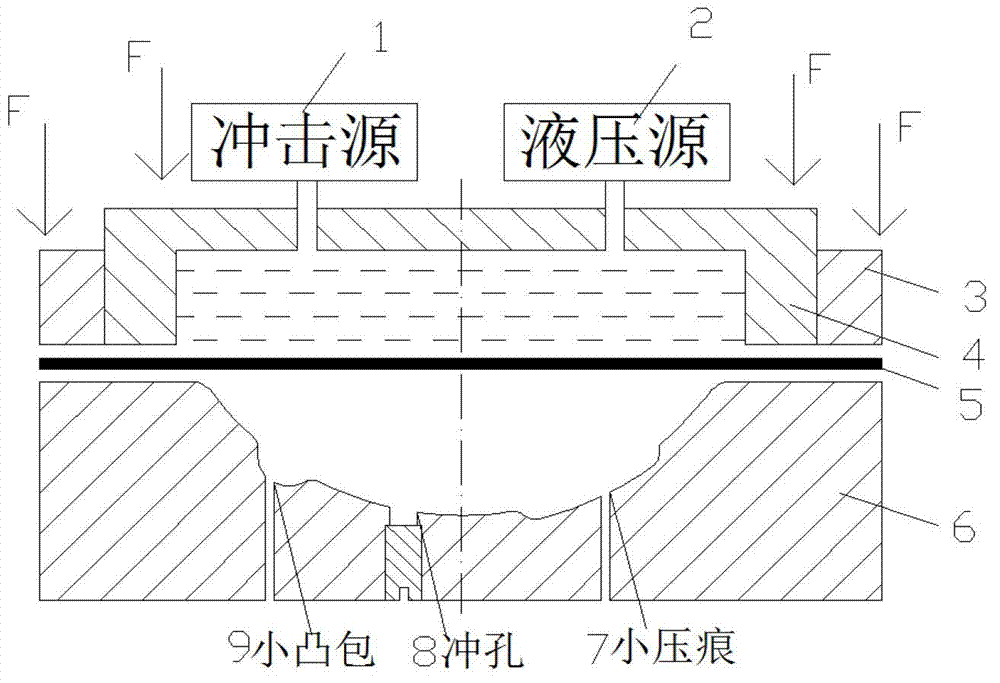

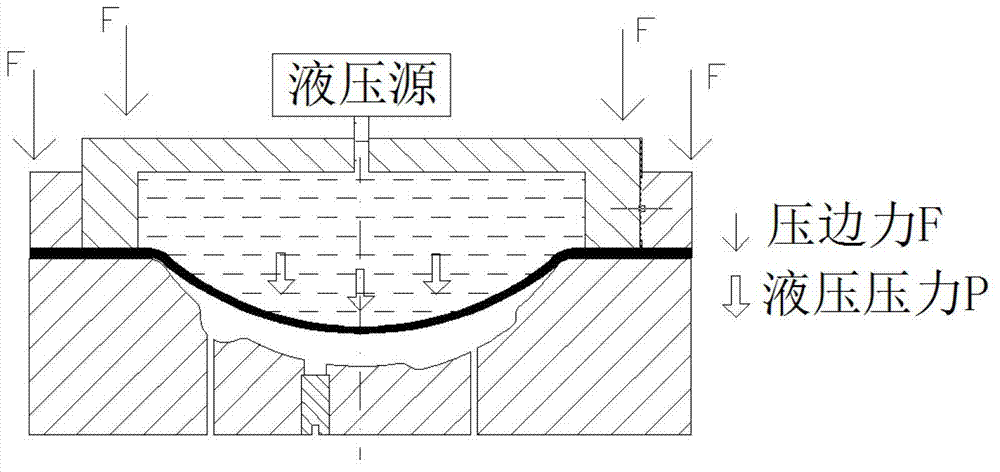

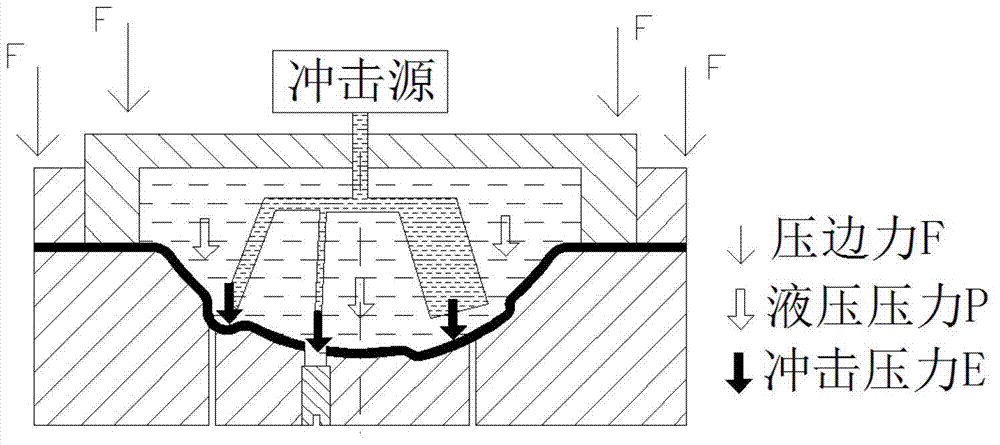

The invention discloses a shock hydraulic composite forming process for a small feature part of a complex part. The shock hydraulic composite forming process is a new forming process which intersects with a shock forming technology and a hydroforming technology and extends and develops from both of the two technologies, having advantages of both of hydro plastic forming and shock energy forming. The shock hydraulic composite forming process is defined as follows: performing the shock forming after the hydroforming is finished, utilizing momentarily released high energy of a shock source to compress high pressure liquid in a forming liquid room to obtain a surged pressure value which is transmitted to formed blanks in form of shock waves, so as to perform the new manufacturing process of elasticoplastic deformation of the part. Due to one-step installation, processing procedure is reduced, which helps to realize monolithic forming of a complex large curved surface part and guarantees positional accuracy of complex parts with various sizes. Meanwhile, the shock time is very short, which reduces requirements in terms of intensity and tightness of the device. The shock hydraulic composite forming process has a wide application prospect in fields such as aeronautics and astronautics, and automobile in aspects of forming, reforming and the like of large complex components with small feature sizes such as small convex hull, small pressing mark, and small holes.

Owner:BEIHANG UNIV

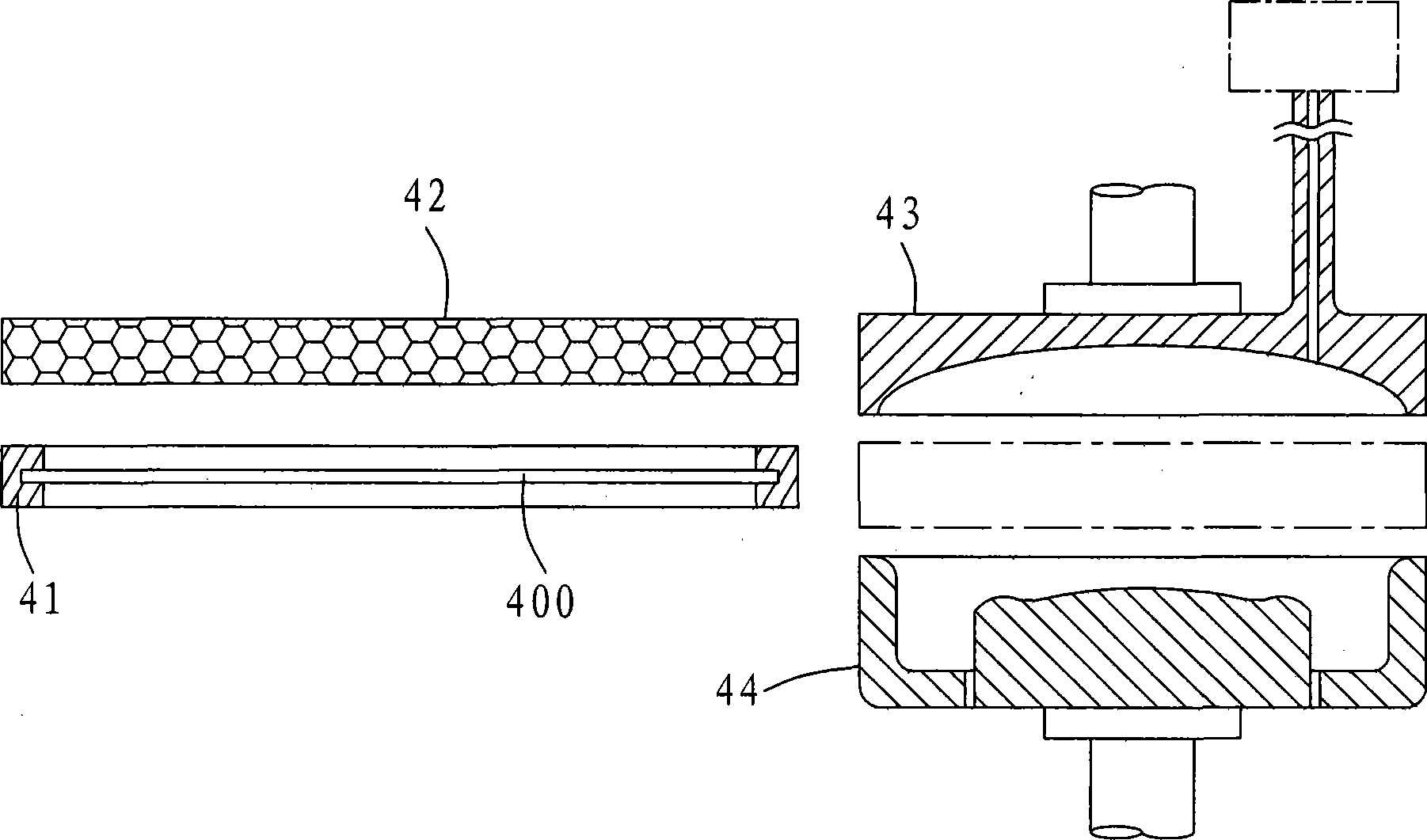

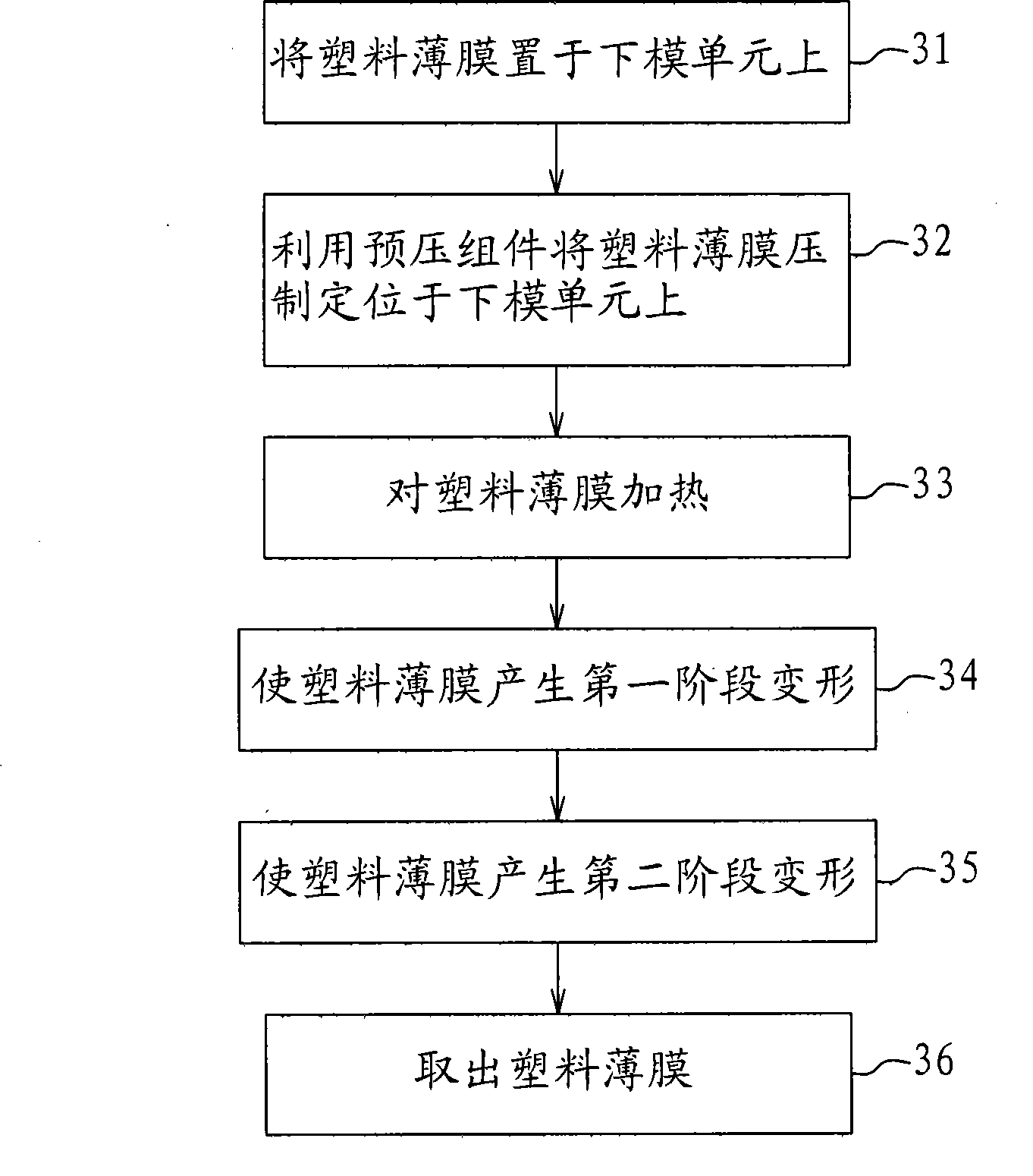

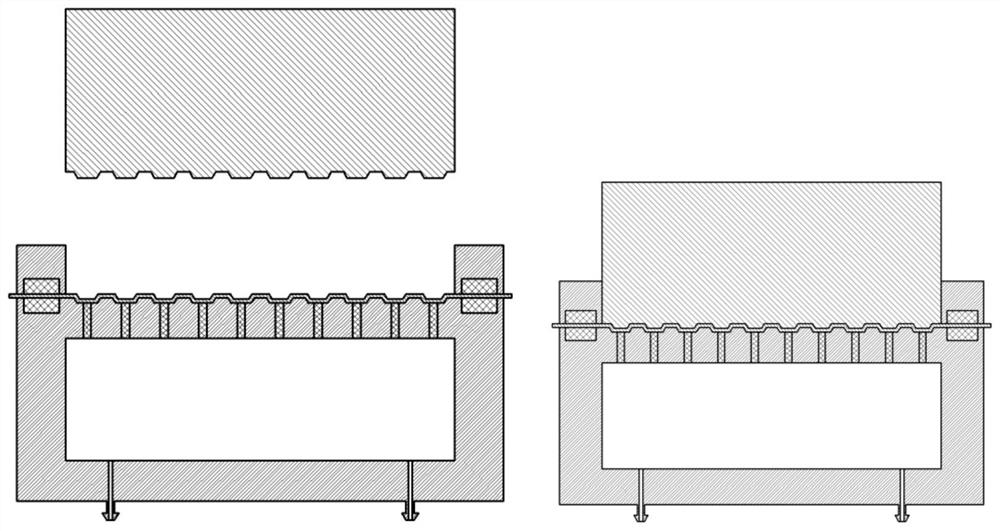

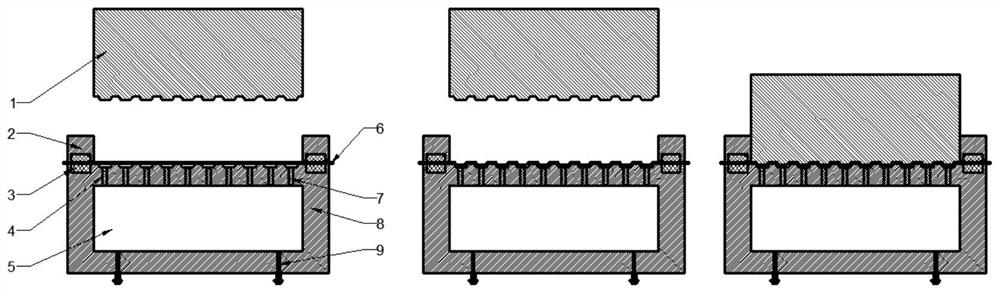

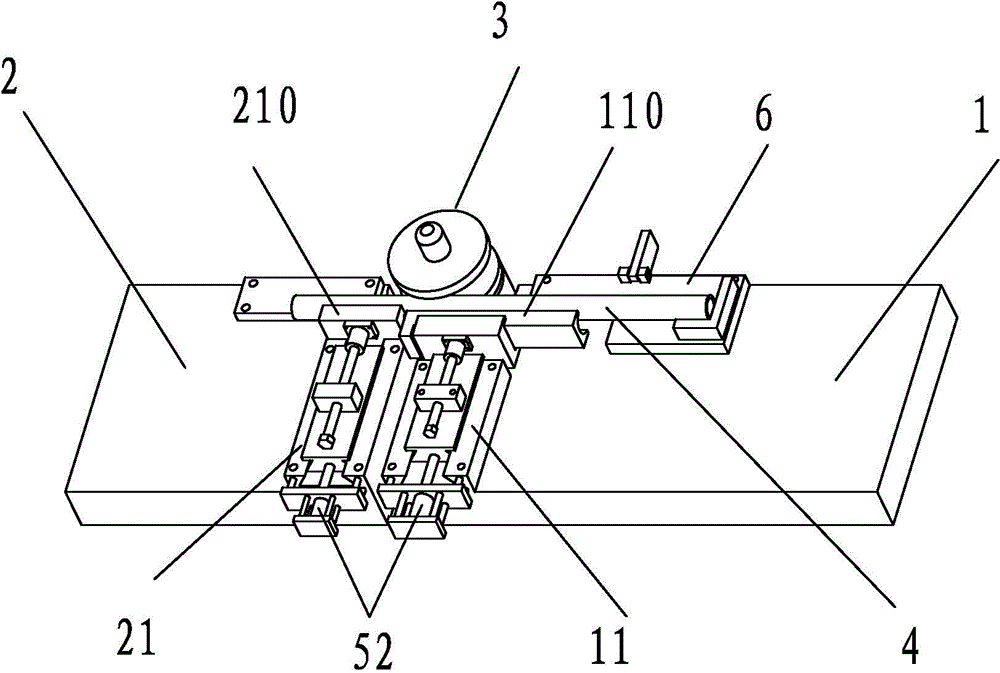

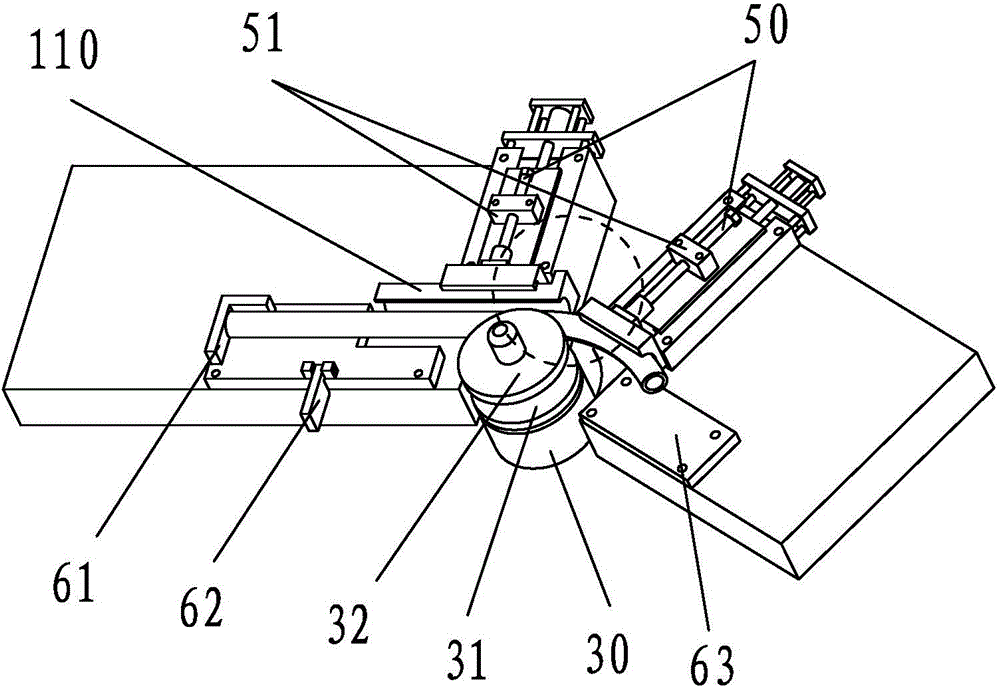

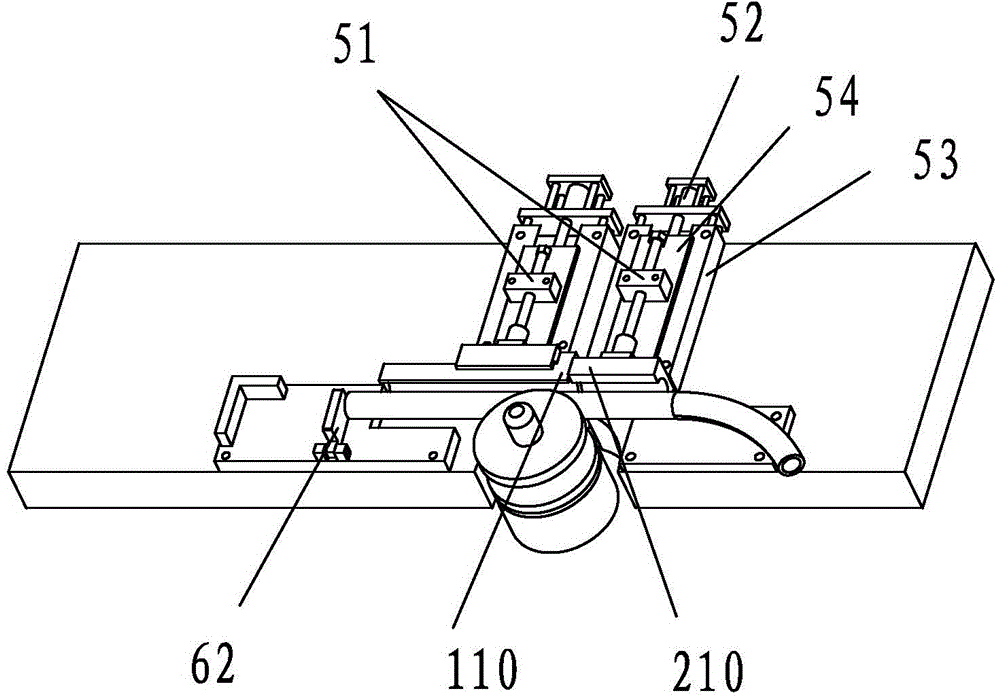

Film forming equipment and method

The invention relates to film molding equipment and a film molding method thereof. The film molding equipment comprises a machine table, an upper film unit and a lower film unit which are arranged on the machine table, a heating unit and a prepressing device. The lower film unit is arranged below the upper film unit and can drive the neighboring upper film unit and a film can be placed on the lower film unit. The prepressing device comprises a prepressing element which is arranged between the upper film unit and the lower film unit and the prepressing unit can be driven to lean against the lower film unit downwards to clamp the film between the prepressing element and the lower film unit; so that the film can not warp and deform in the process of being heated by the heating unit. With the method which has two phases of molding steps, the rebound phenomenon caused by the recovery stress in the process of molding film can be reduced and a comparatively real external structure can be obtained.

Owner:KAOTAI TECH

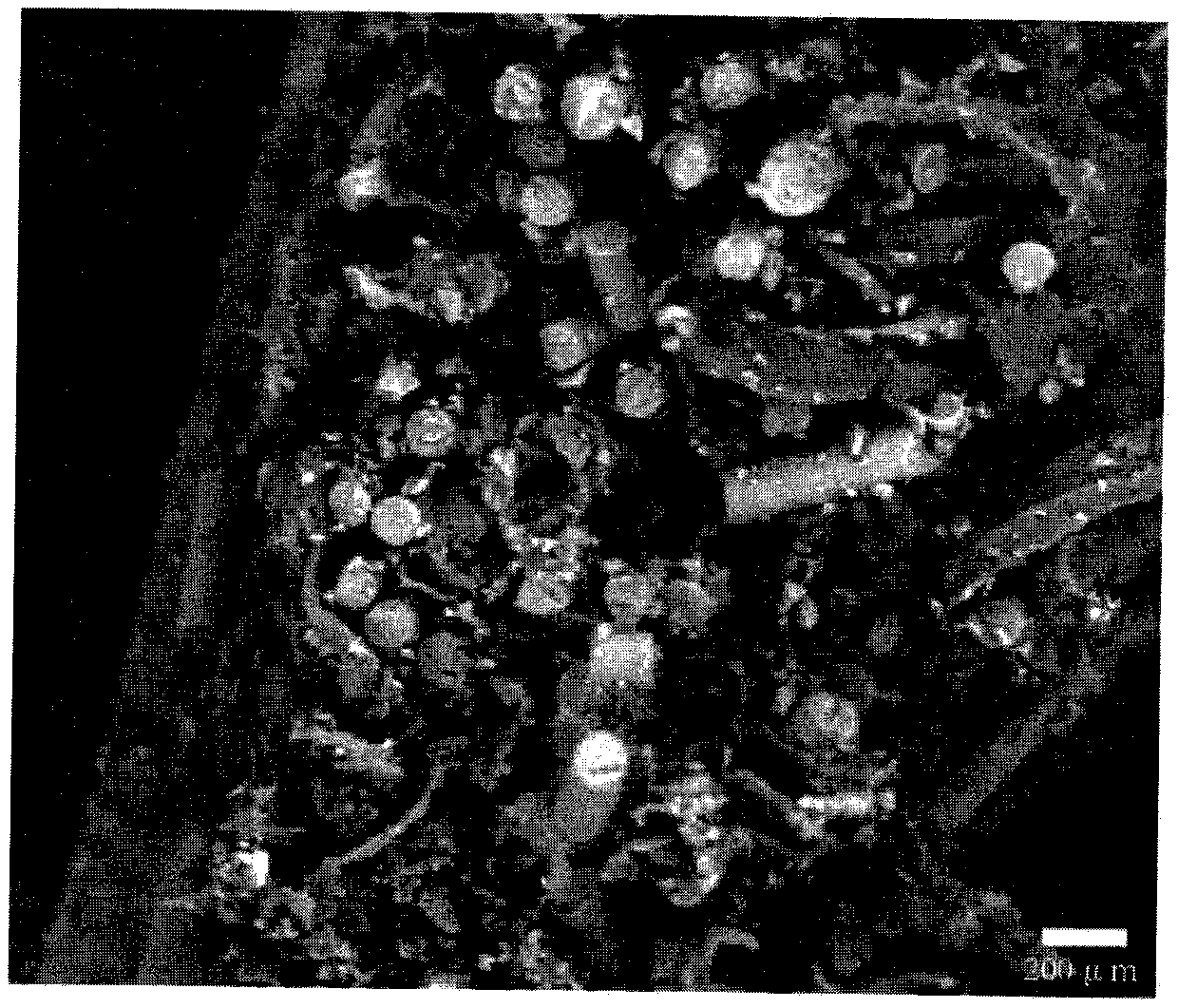

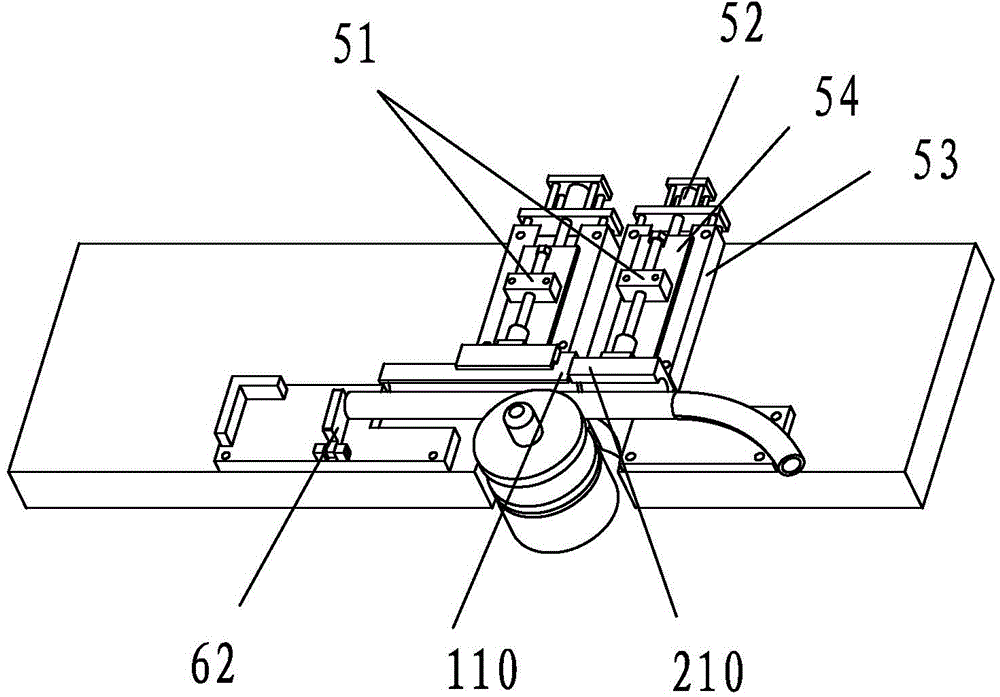

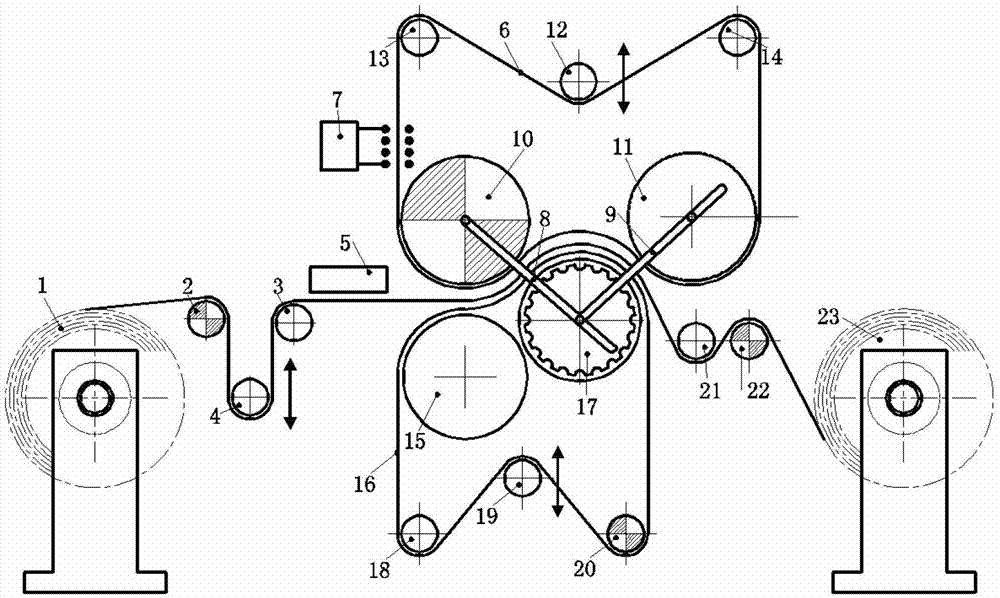

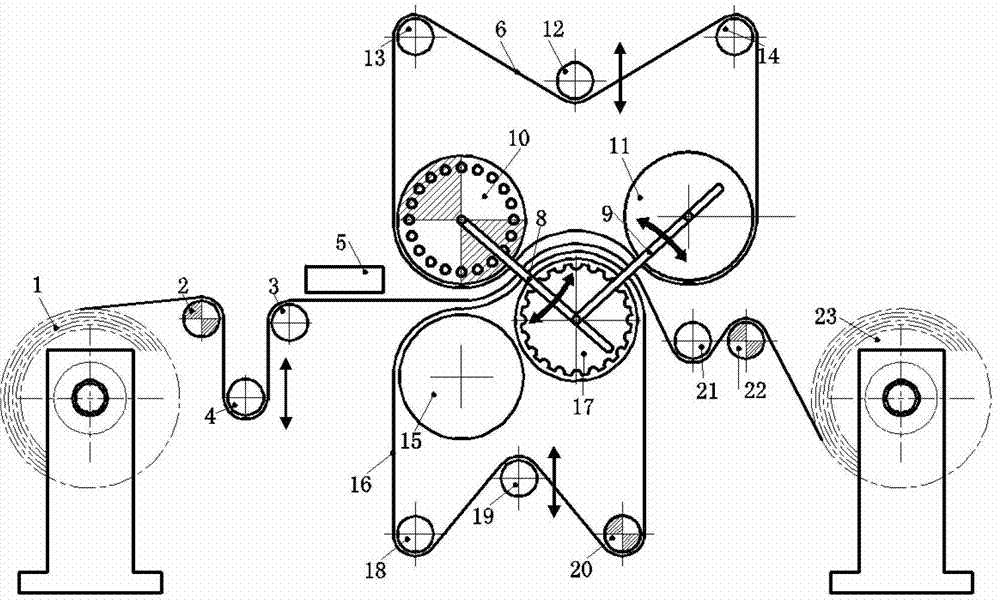

Preparing method capable of weaving continuous fiber enhanced thermoplasticity prepreg tape and product

The invention discloses a preparing method capable of weaving continuous fiber thermoplasticity prepreg tape and a product, and belongs to the technical field of resin-based composite materials. A dipping front area and a dipping rear area are included. The dipping front area is provided with a yarn reversing frame, a yarn dividing frame and a screw extruder machine head part. The dipping rear area is provided with a drawing roller, a meshing drum, a heating casing pipe, a temperature control box, a tractor and a winding machine. According to the purpose, a secondary fusion dipping method is adopted, a fiber bundle is scattered and spread in the dipping front area, inner-layer fiber is incompletely dipped, the surface of fiber is coated with a layer of resin, and under the action of the traction roller and the meshing drum, secondary dipping is achieved, gas in the fiber is extruded out, the resin and the fiber are further scattered, and the soft and woven prepreg tape with the rough surface is manufactured.

Owner:TIANJIN POLYTECHNIC UNIV

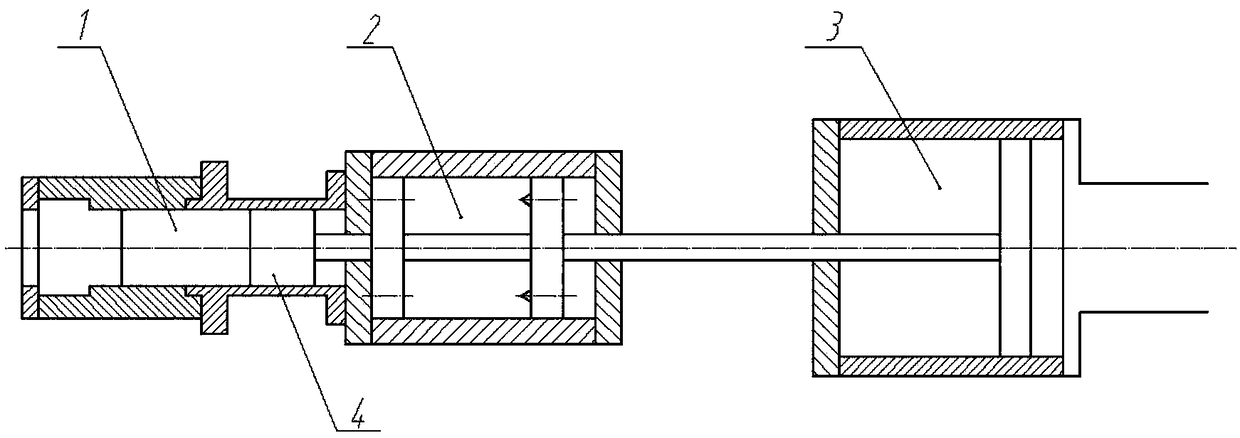

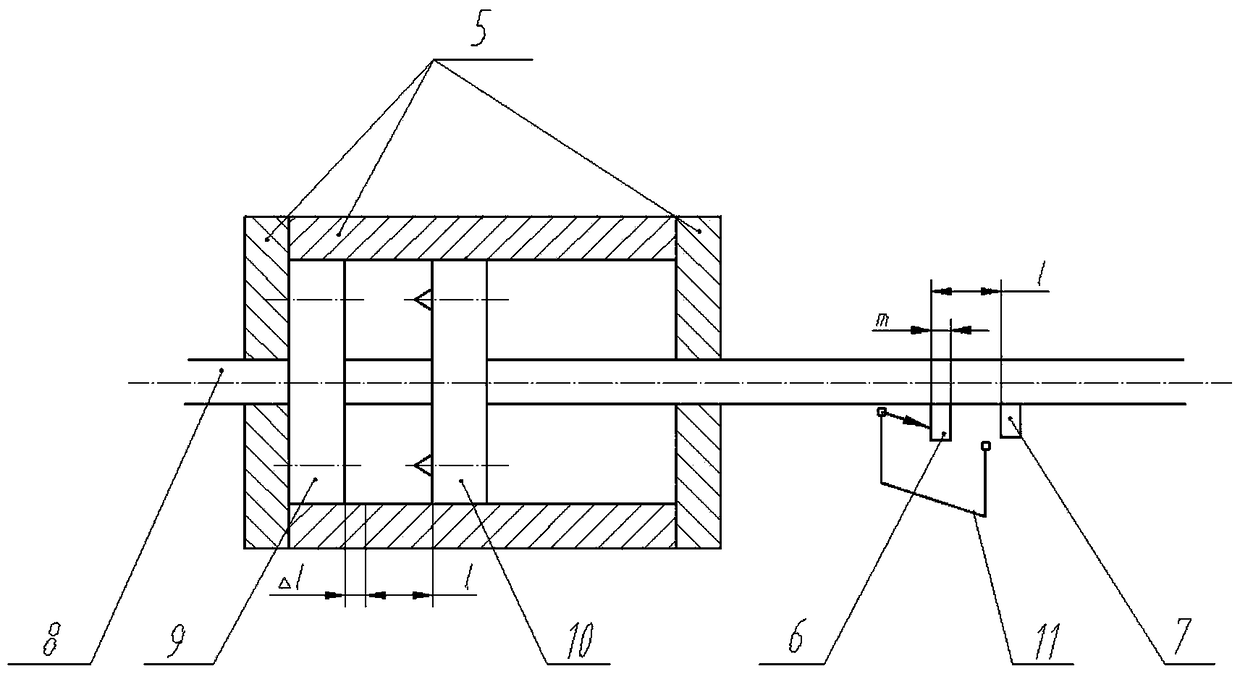

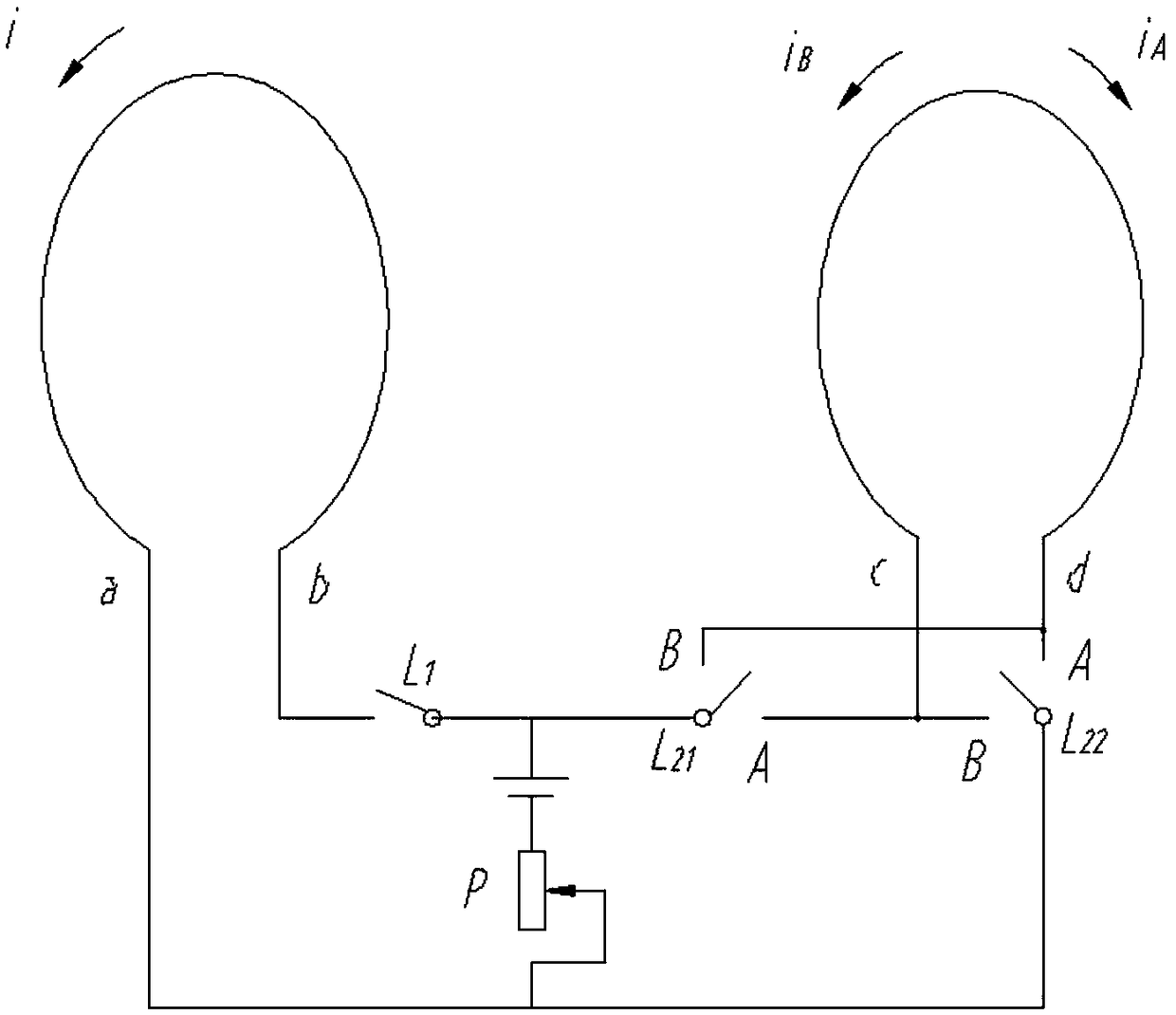

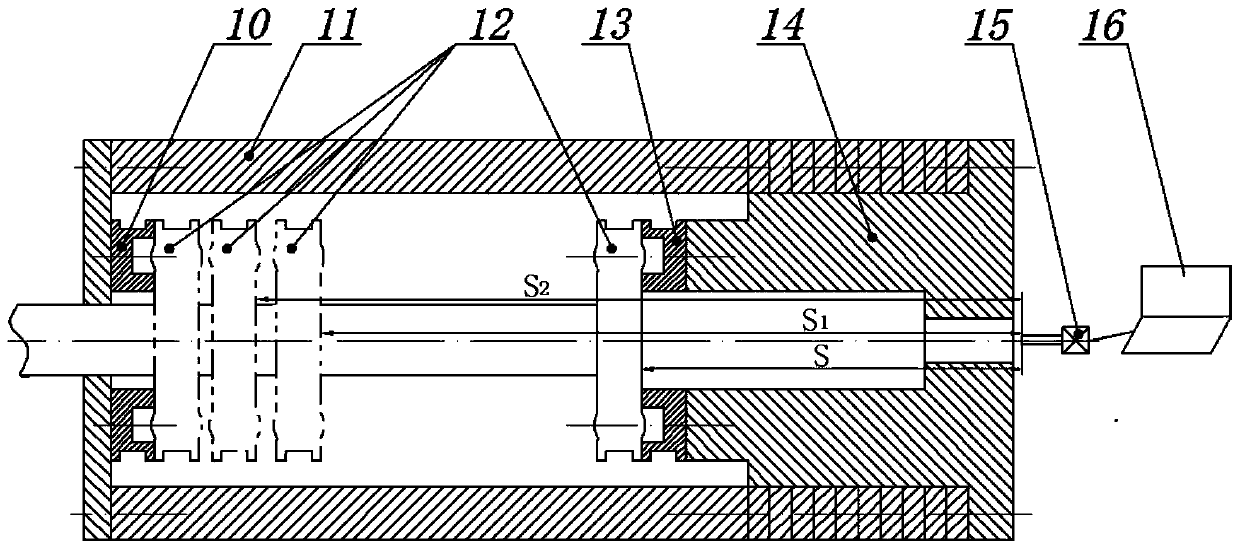

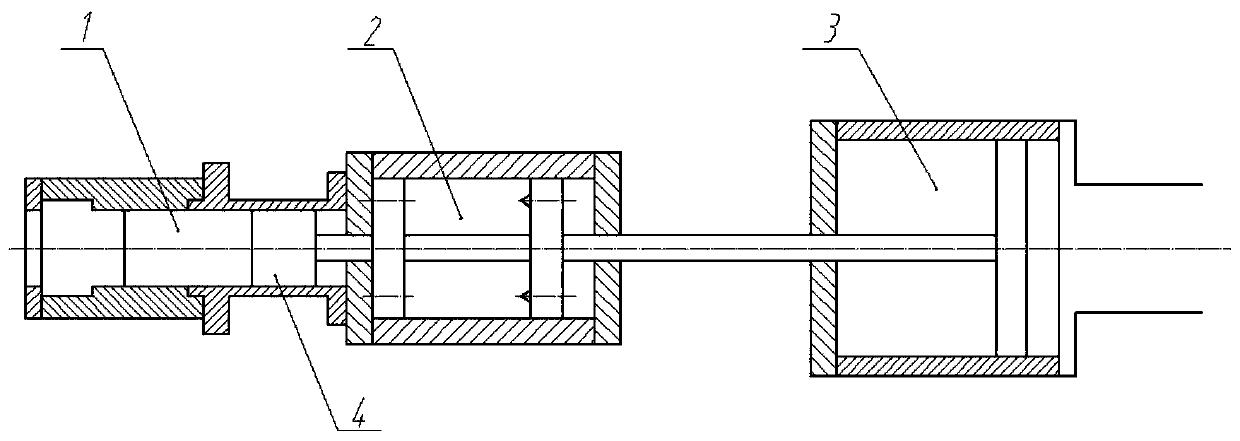

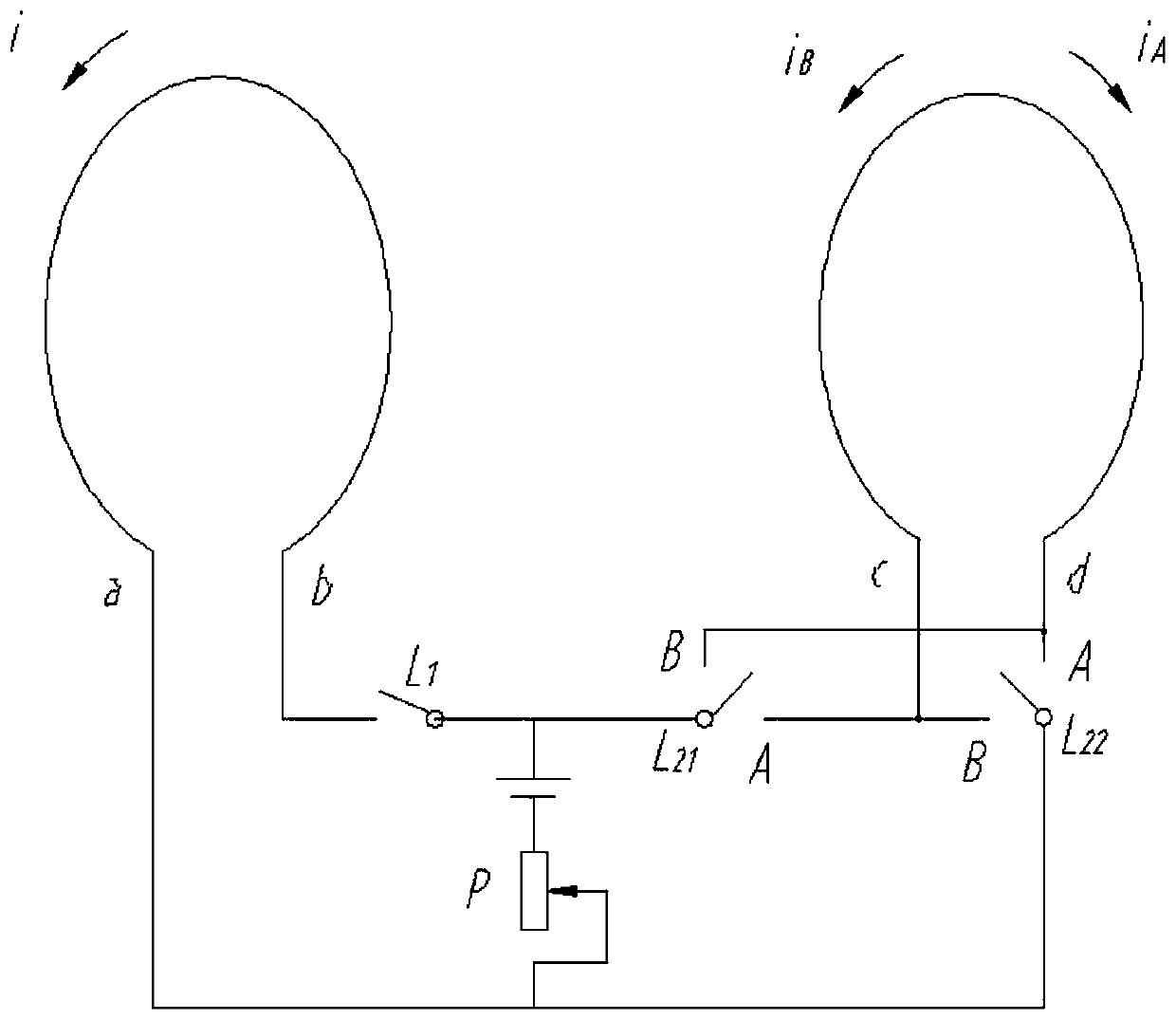

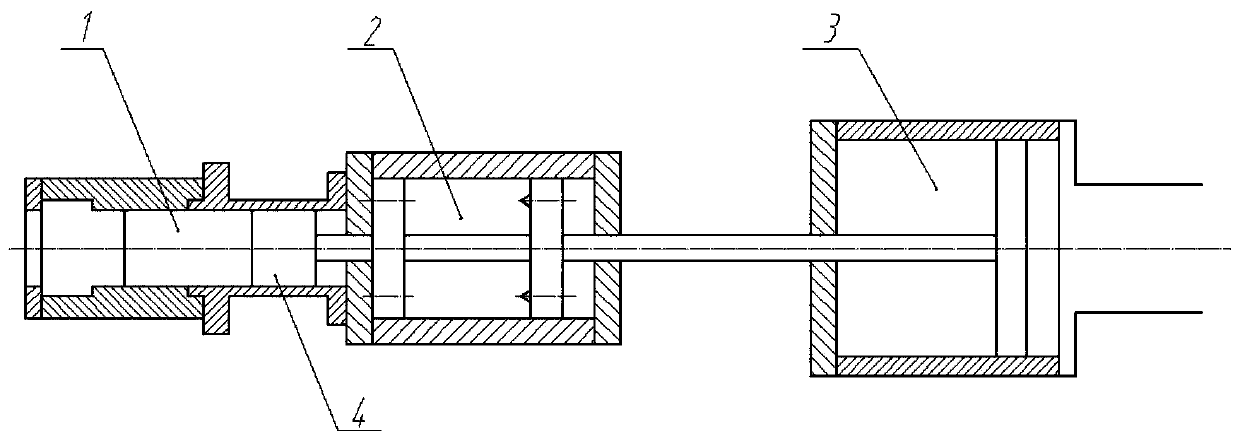

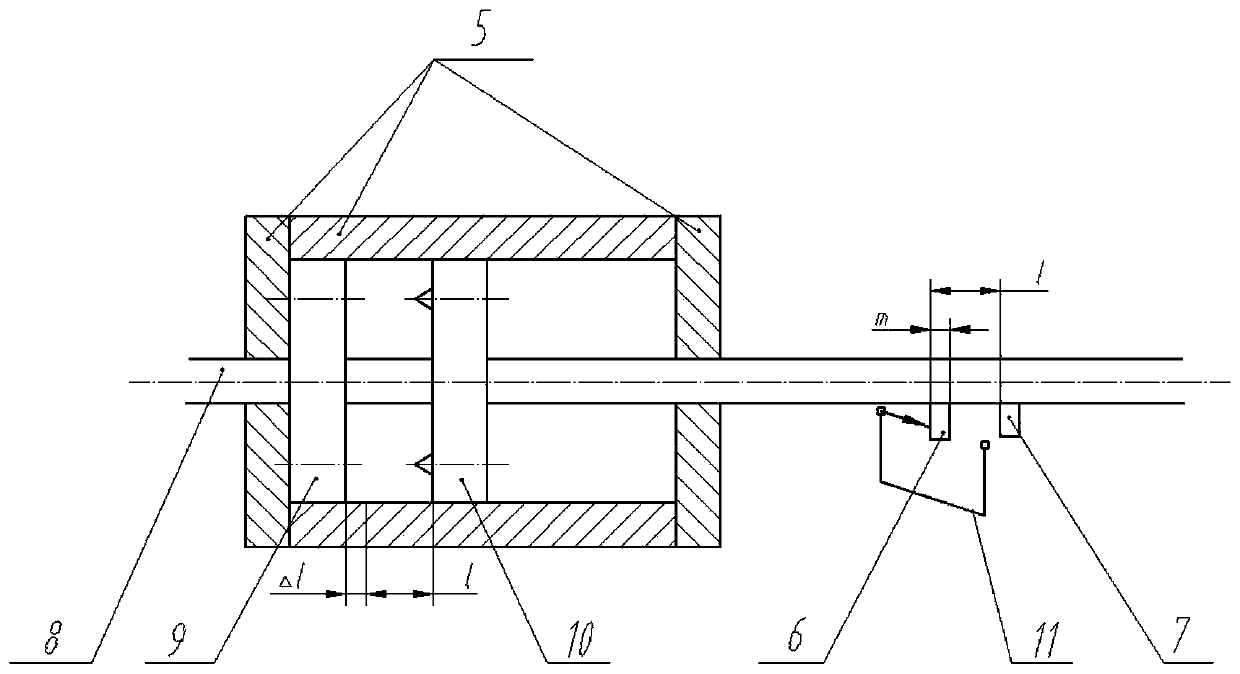

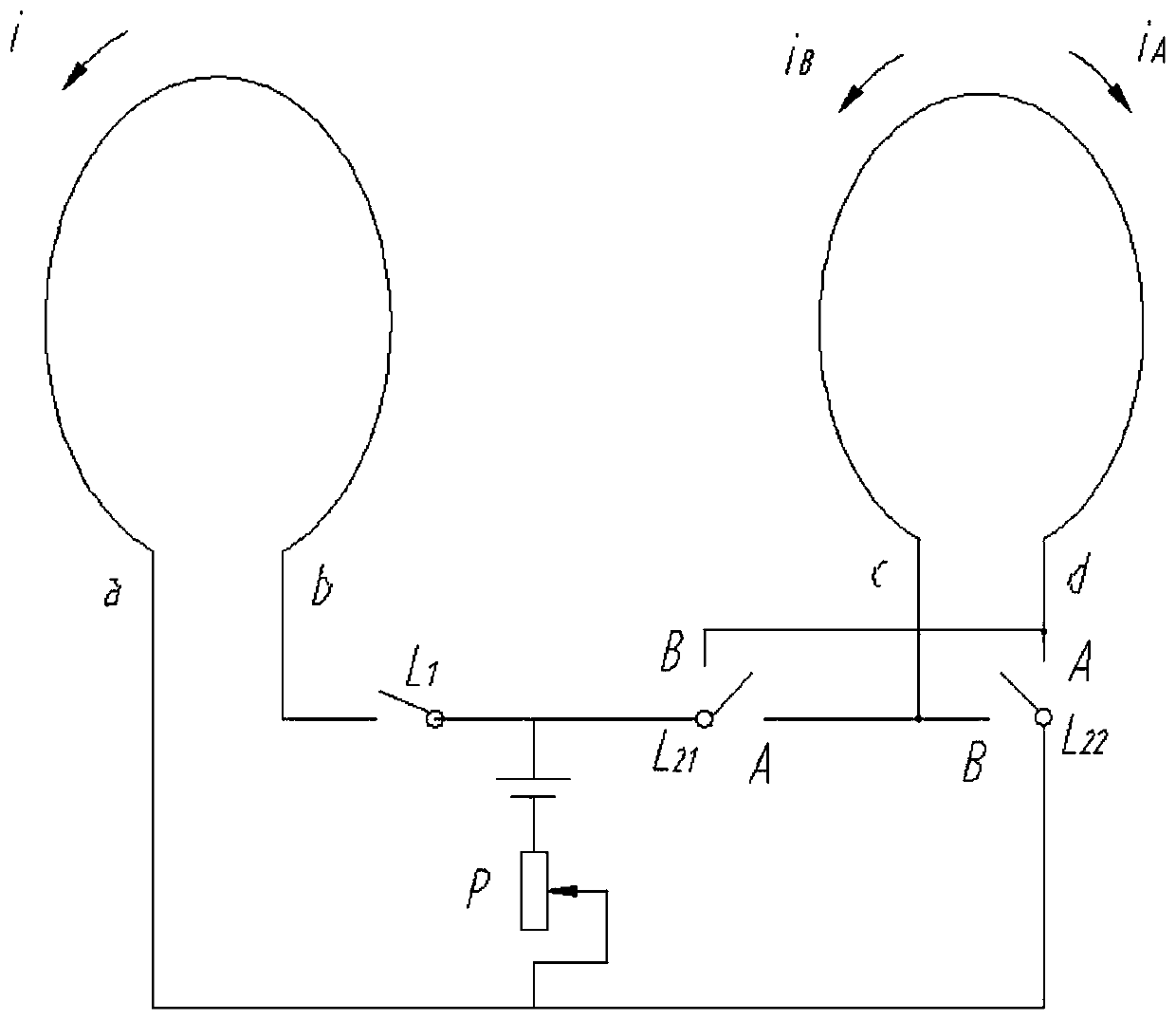

Control method based on electromagnetic braking system of fast compressor

The invention relates to a control method based on an electromagnetic braking system of a fast compressor. The applicative electromagnetic braking system of the fast compressor comprises a central control unit, a braking cylinder made of a magnetic separation material, a pushing rod penetrating through the braking cylinder, an electromagnetic braking circular ring fixed to the braking cylinder, anelectromagnetic braking piston fixed to the pushing rod, a first light shading plate, a second shading plate, a photoelectric sensor and an electromagnetic braking control circuit, wherein the firstlight shading plate and the second shading plate are fixed to the pushing rod, and the photoelectric sensor is fixed nearby the pushing rod. The control method comprises the following steps that the braking distance l is estimated preliminarily according to the magnitude of a current capable of being provided, electromagnetic force between two electromagnetic coils and the initial velocity v of apushing rod combination during braking, a small part of restore distance delta l is still formed between the piston and an upper stop point after braking is completed, the electromagnetic braking piston and the electromagnetic braking circular ring are further fastened, the two second shading plates and the photoelectric sensor are mounted, and when braking is started, the distance between the twoelectromagnetic coils meets the formula of L=l+delta l.

Owner:TIANJIN UNIV

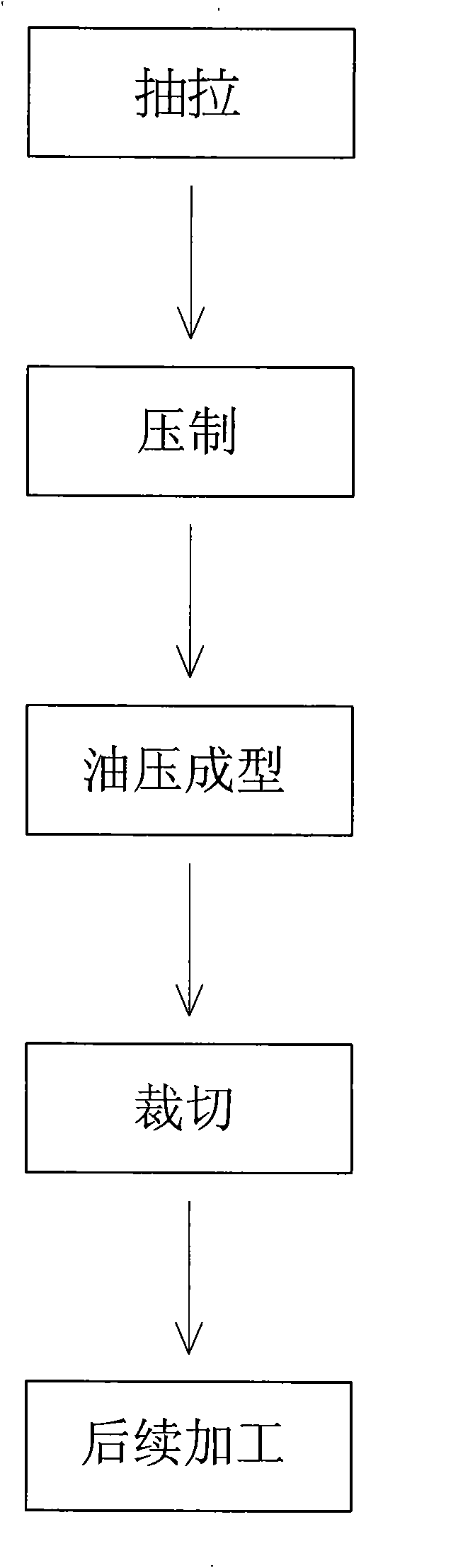

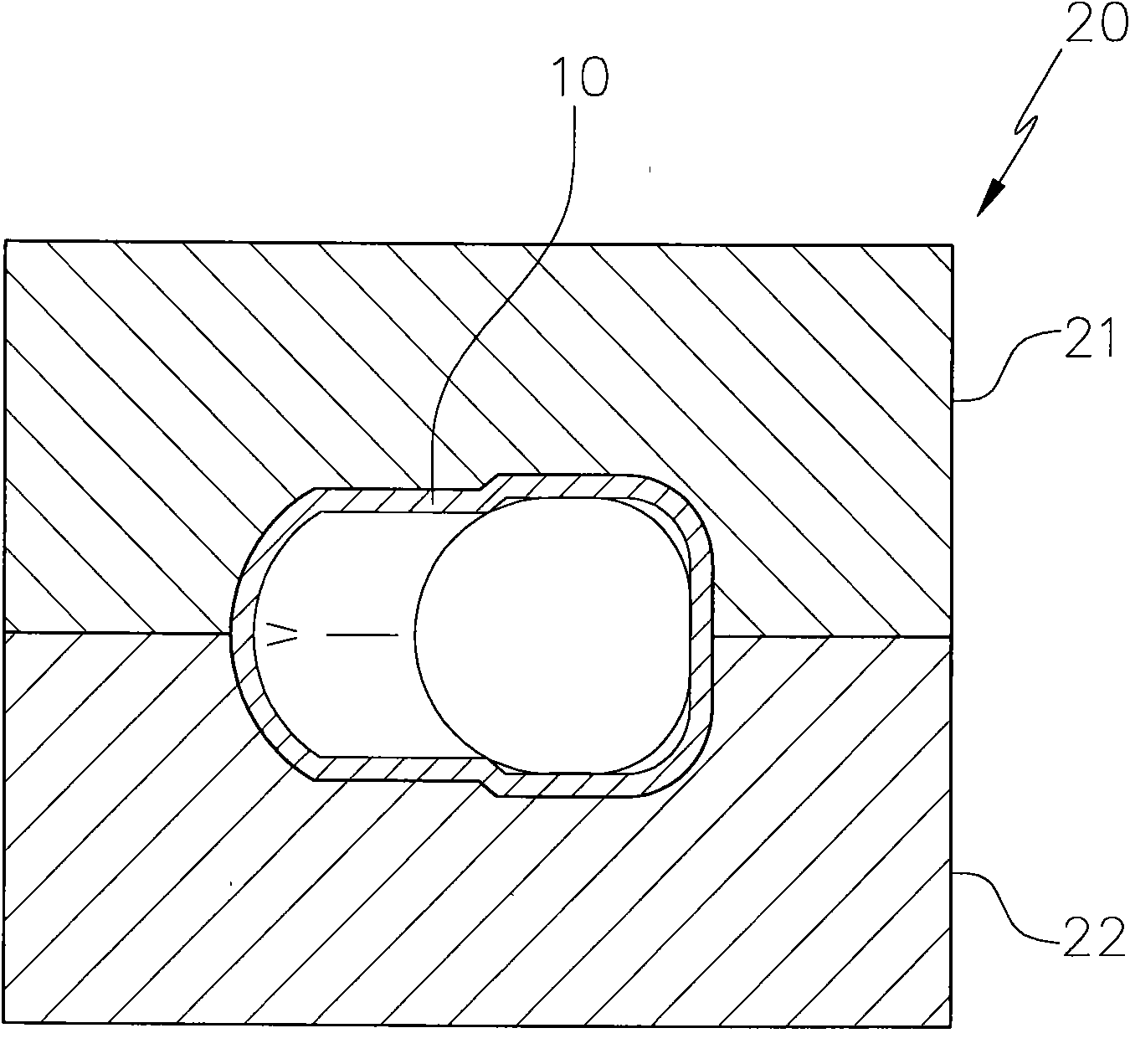

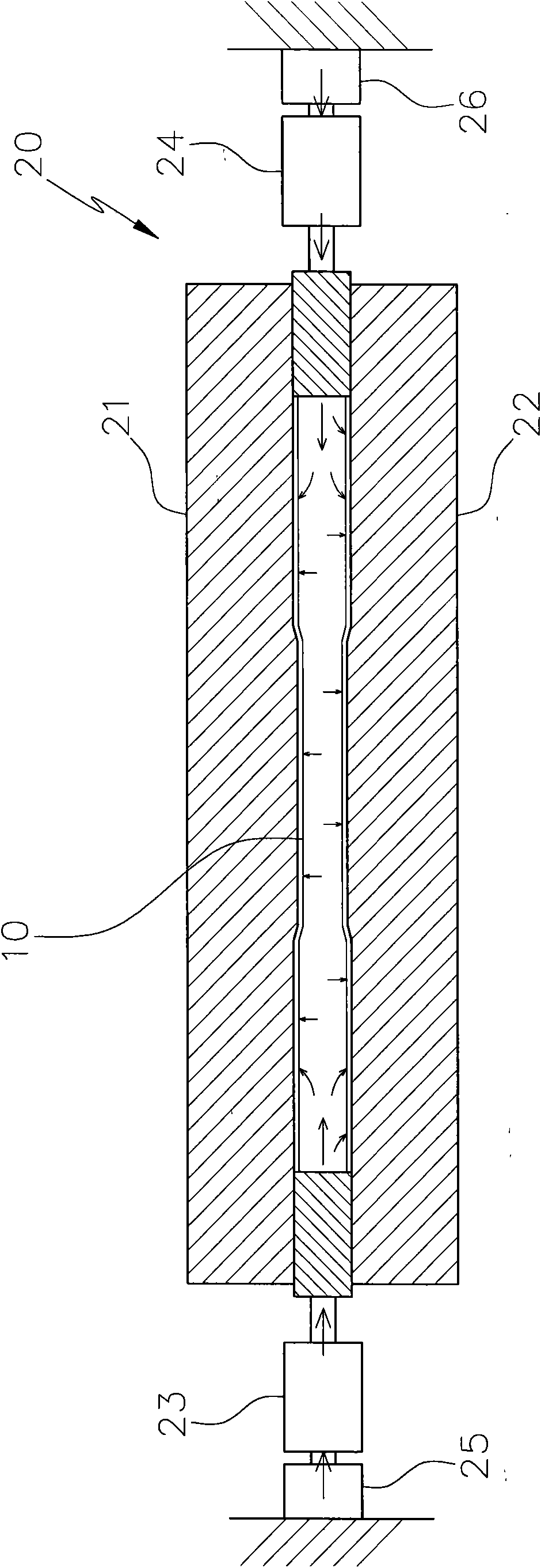

Method for molding and manufacturing metal pipe

InactiveCN102069102AEasy to shapeMeet the appearance design requirementsHigh pressureHigh pressure gas

The invention relates to a method for molding and manufacturing a metal pipe, wherein the pipe is preformed into a crude pipe blank so as to implement a hot gas molding method. The hot gas molding method comprises the following steps of: firstly, preheating the crude pipe blank to reach a proper molding temperature; secondly, placing the crude pipe blank into a molding mould which is heated to reach the set temperature; thirdly, sealing both ends of the crude pipe blank, injecting high-pressure gas into the crude pipe blank, and propelling the both ends of the crude pipe blank as pushing compensation when the pressure of the high-pressure gas reaches the set pressure, so as to mold an outline of the crude pipe blank; and fourthly, taking out the crude pipe blank for post-processing to mold and manufacture a finished pipe product. Therefore, in the production process, not only the outline of the pipe can be easily molded to meet the design requirements of various outlines, but also the rebound phenomenon can be reduced so as to guarantee the size accuracy. Moreover, the pressure of the working gas can be greatly reduced. Consequently, the advantages of easiness of molding and manufacturing and saving of equipment cost can be achieved.

Owner:METAL INDS RES & DEV CENT

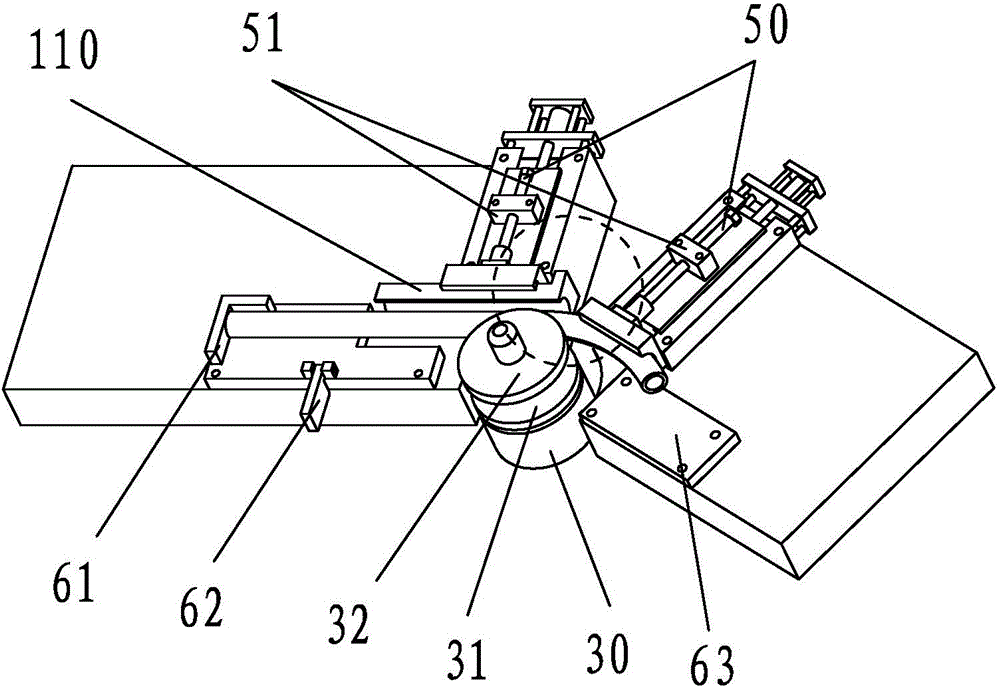

Device for bending pipe with relatively small abrasion

InactiveCN104874651AAvoid damageFlexible bending methodMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The present invention discloses a device for bending a pipe with relatively small abrasion. The device comprises a stationary work table and a rotary work table capable of rotating; a freely rotating rotary circular bench is disposed between the stationary work table and the rotary work table; a circular pipe is bended by the rotary work table in a rotation direction by using a side wall of the rotary circular bench as a bending point; the stationary work table is provided with a first chuck for clamping the front portion of the circular pipe; the rotary work table is provided with a second chuck for clamping the rear portion of the circular pipe; the first chuck can freely slide in a length direction of the circular pipe; the side wall of the rotary circular bench is provided with an arc-shaped recessed surface; and the central section of the circular pipe is attached to the arc-shaped recessed surface of the side wall of the rotary circular bench. The device is simple in structure and good in bending precision, and abrasion of the circular pipe is small.

Owner:ZHEJIANG LIFAN FURNITURE

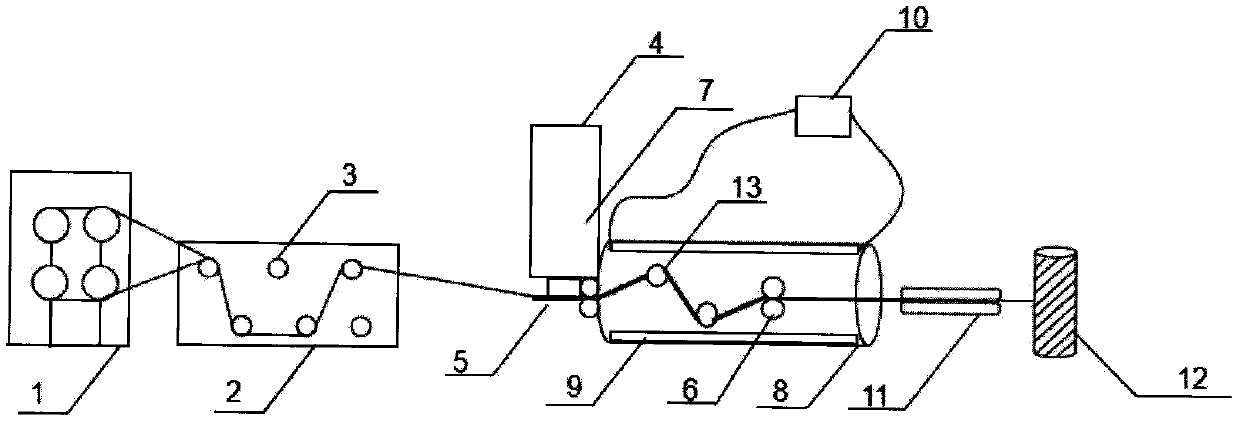

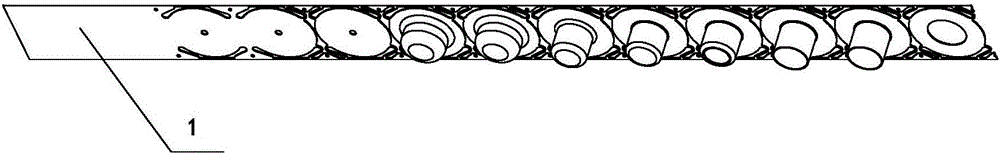

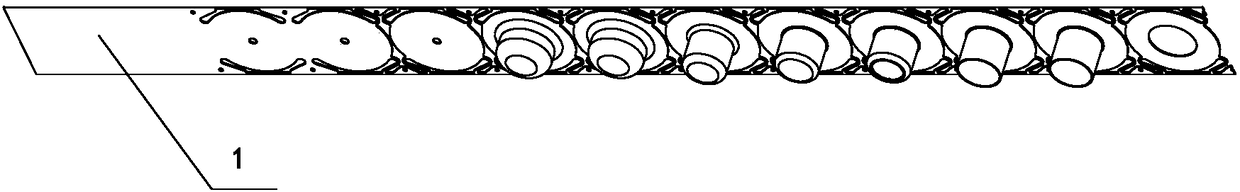

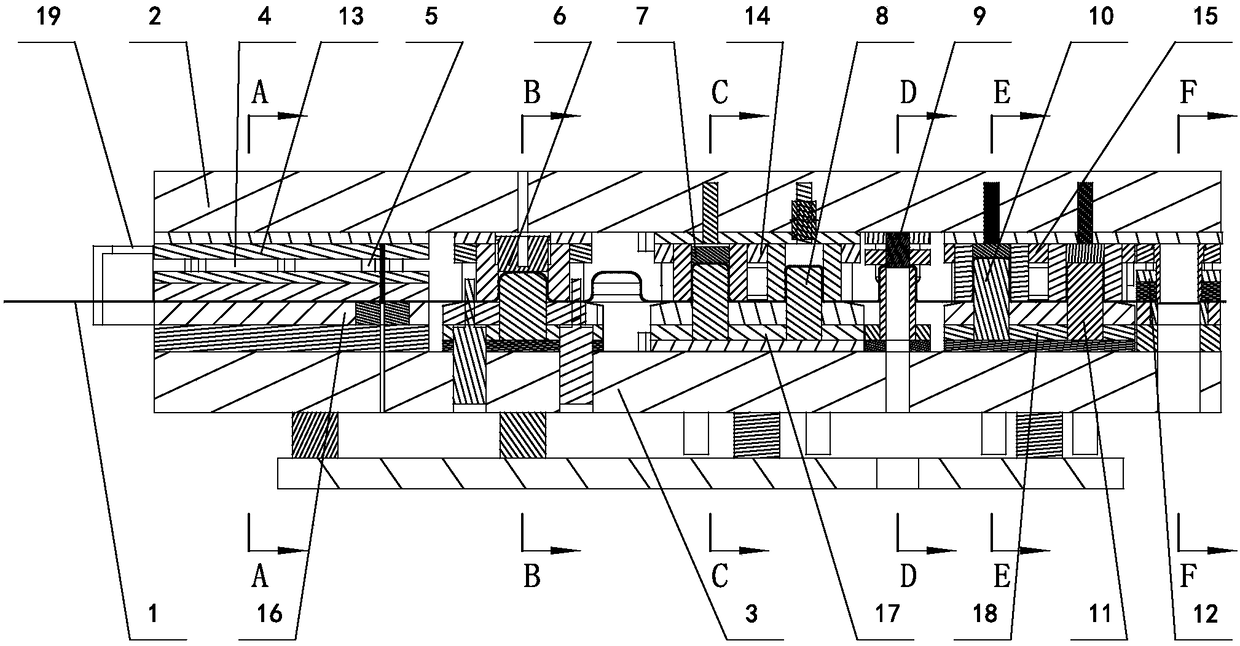

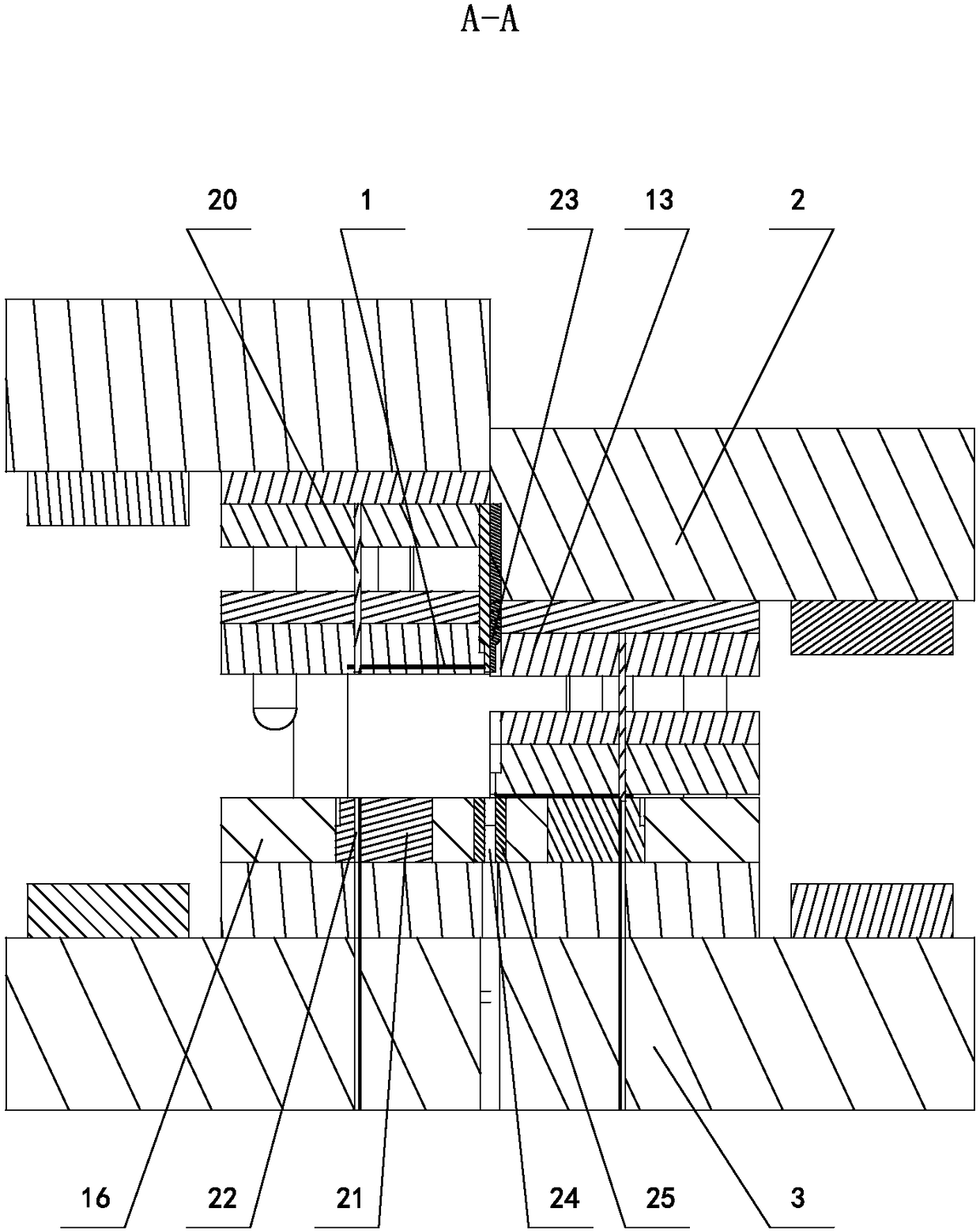

Reel-to-reel hot rolling forming device for fine structures of polymer thin film products

The invention relates to a reel-to-reel hot rolling forming device for fine structures of polymer thin film products. The device is characterized by comprising a frame, an unwinding module, a preheating module, a forming / shape-preserving module, a tensioning force adjusting module and a winding module, wherein the frame is mechanically connected with the preheating module, the forming / shape-preserving module and the tensioning force adjusting module; the tensioning force adjusting module is connected with the forming / shape-preserving module; being unwound by the unwinding module, a to-be-processed thin film substrate is heated by the preheating module, then enters into the forming / shape-preserving module for hot pressing and cooling formation, is imprinted, and is finally wound around the winding module. Compared with the prior art, the reel-to-reel hot rolling forming device has the advantages that the joint degree between the substrate and a mould during shape preserving and cooling processes is enhanced; the microstructure resilience on the surface of a thin film is reduced; the forming precision is improved; and suitability for mass production of large-area thin film devices is achieved.

Owner:SHANGHAI JIAOTONG UNIV

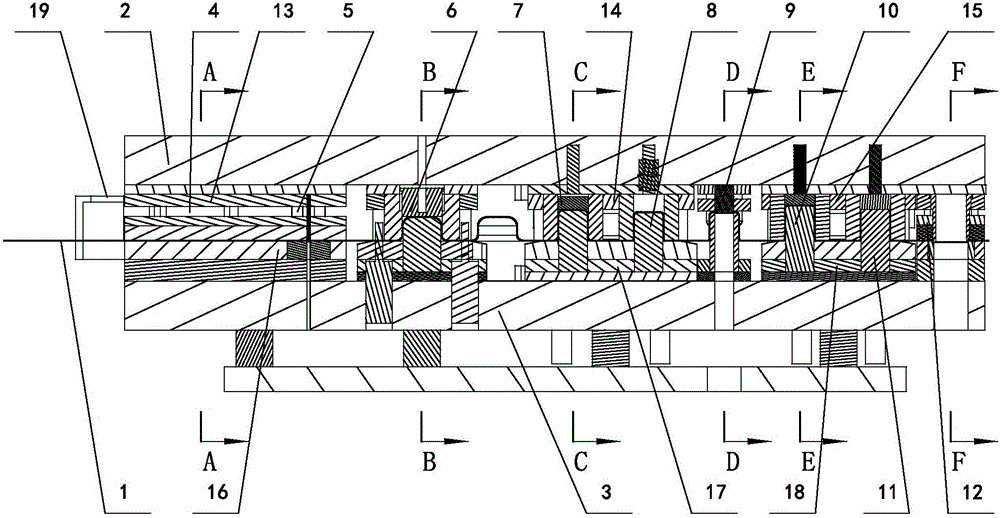

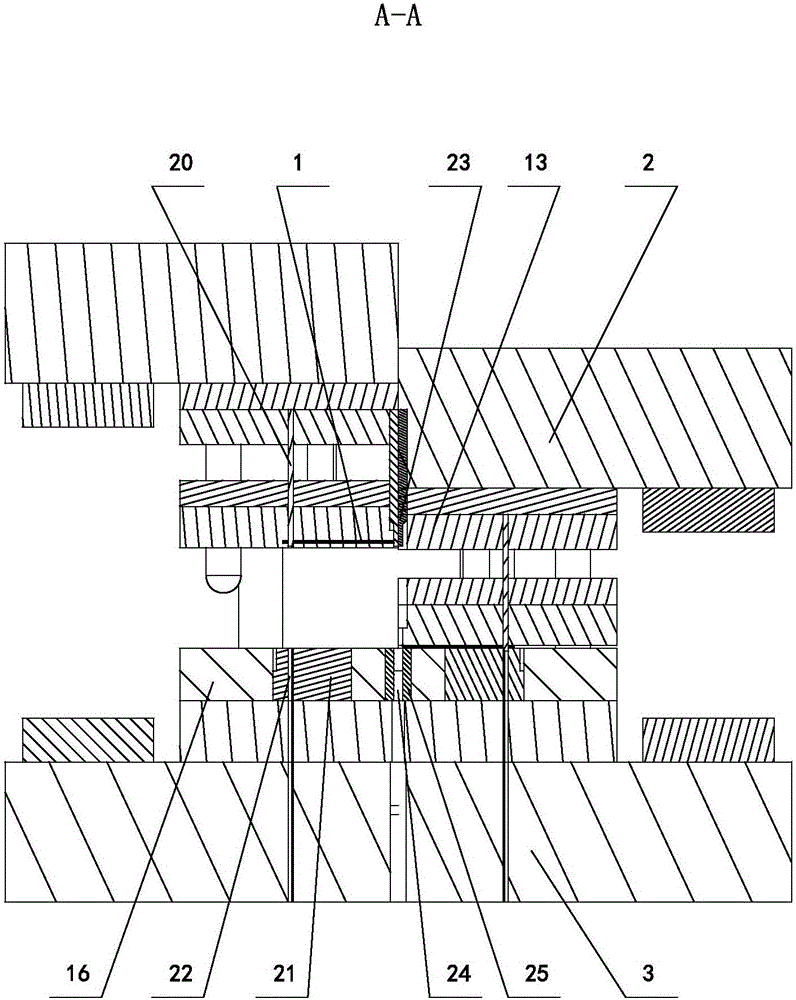

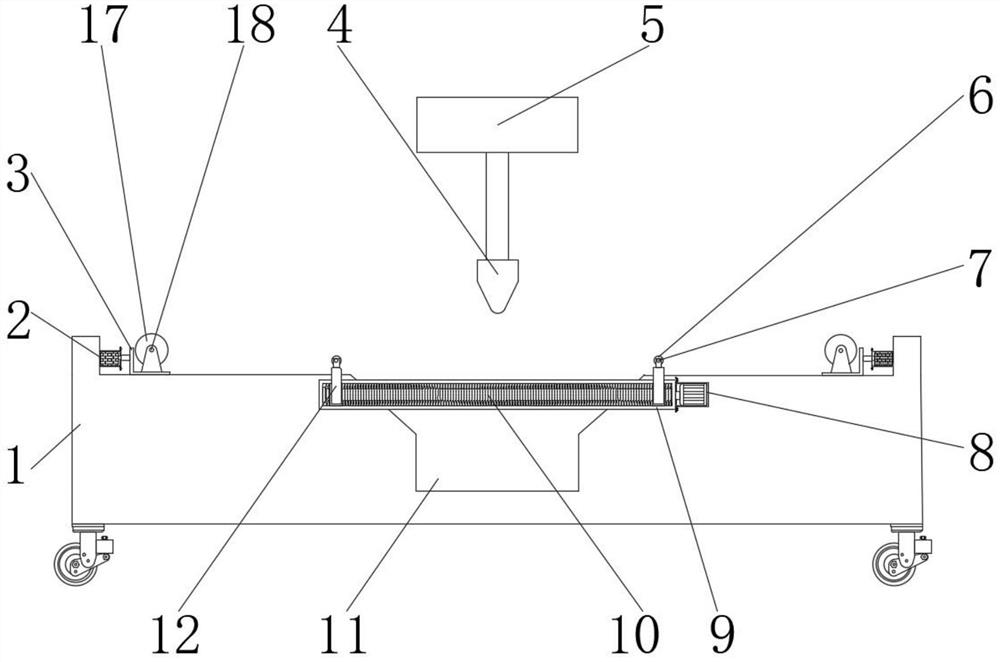

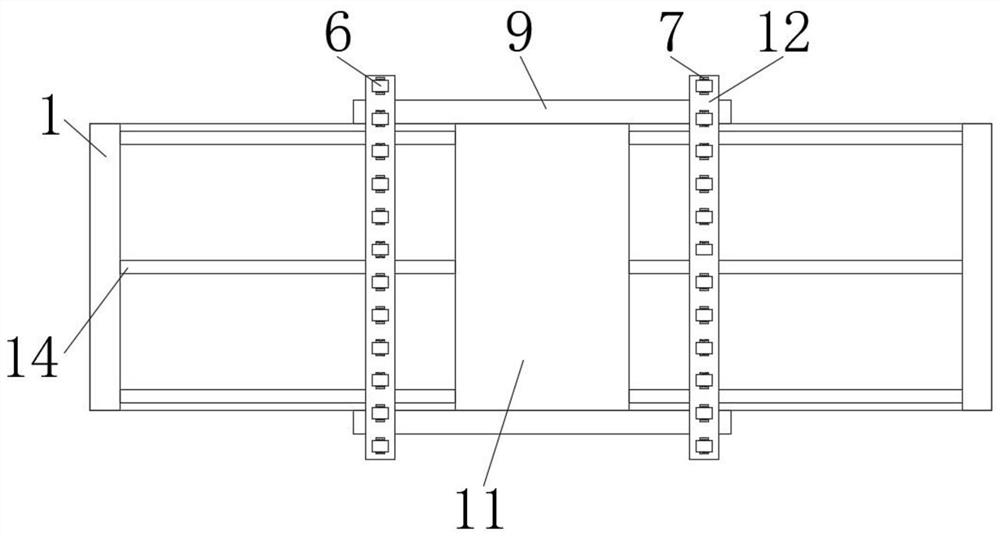

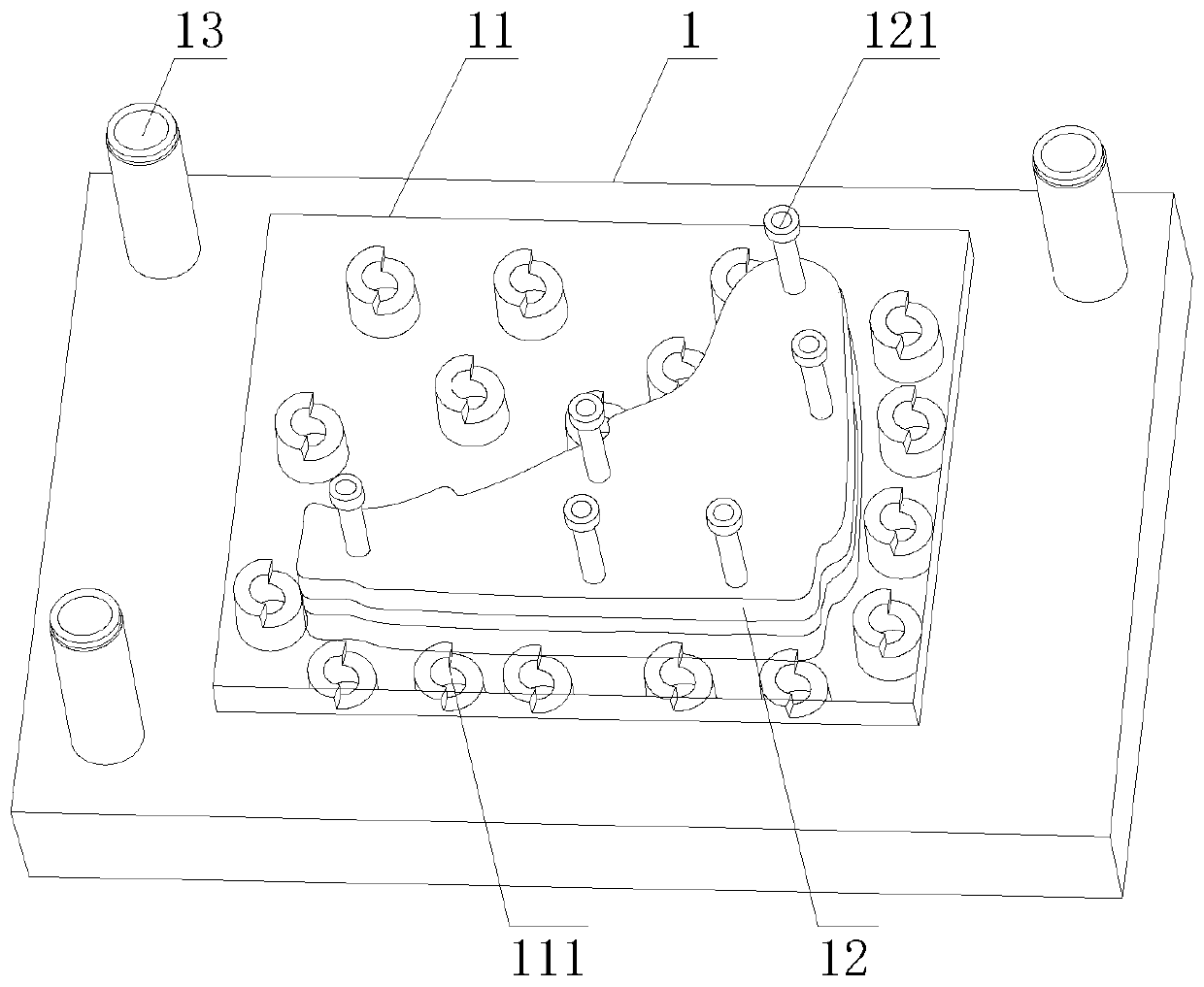

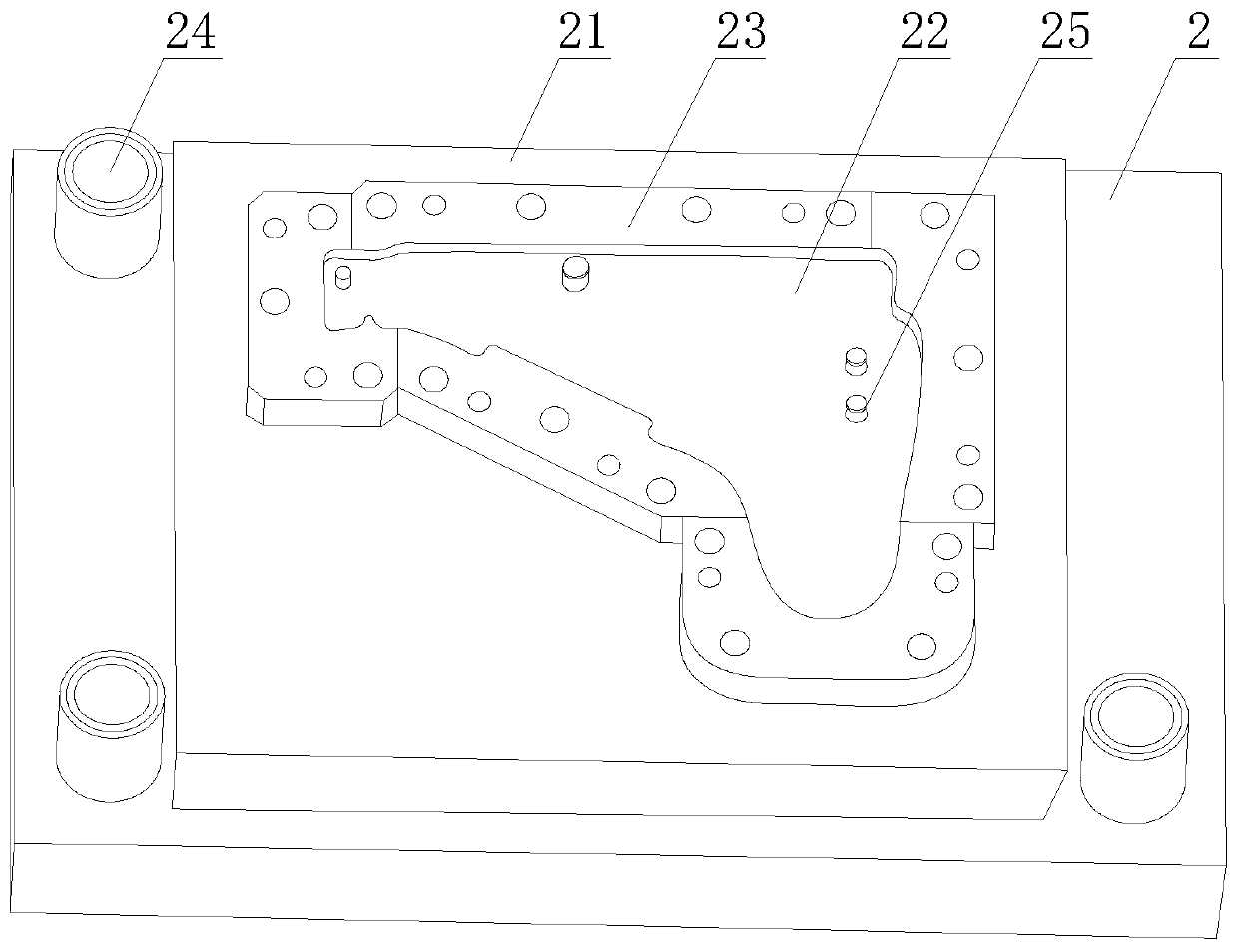

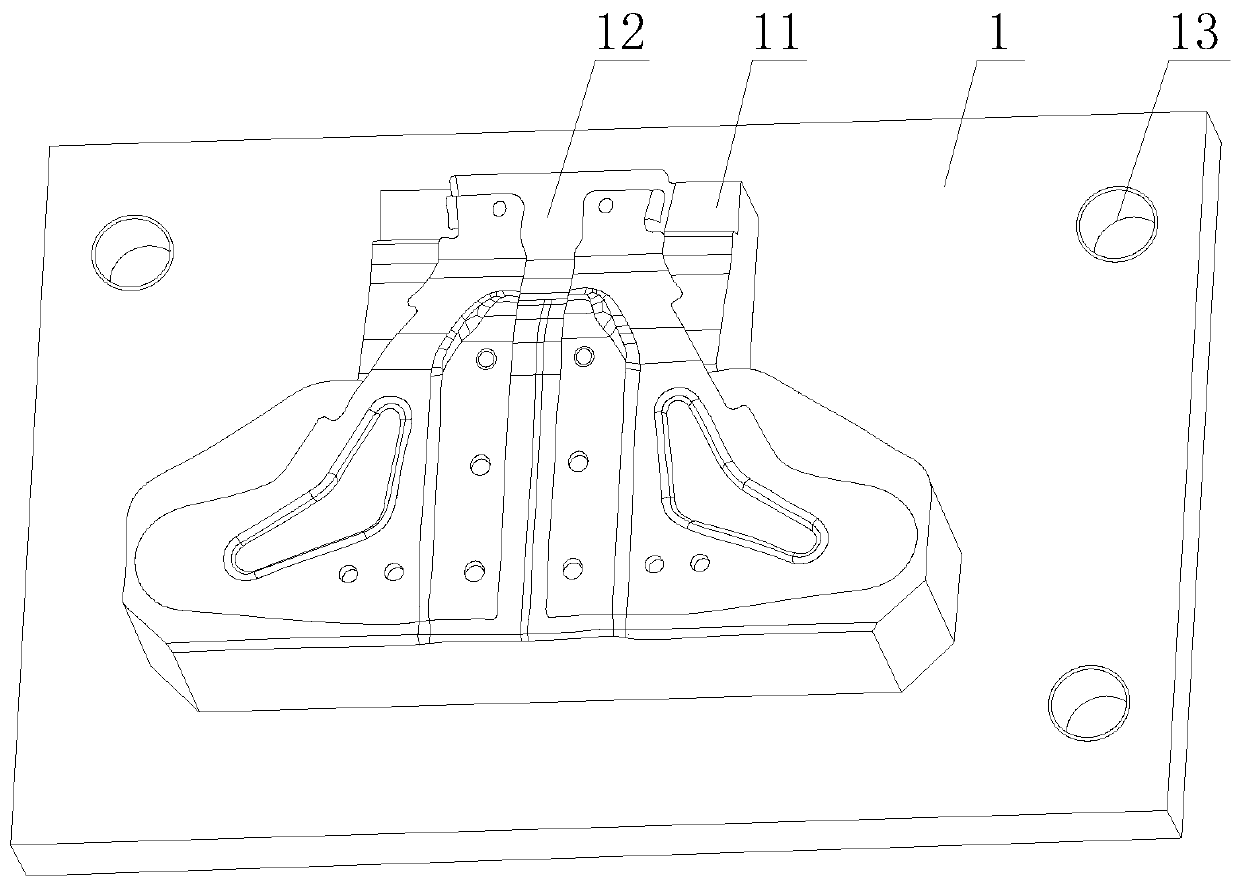

Forming mold of vehicle tubular punching welding part

ActiveCN106734586AIncrease productivityReduce the number of operatorsShaping toolsPerforating toolsEngineeringPunching

The invention discloses a forming mold of a vehicle tubular punching welding part. The forming mold comprises a lower mold module and an upper mold module; an edge punching mechanism (4), an interval punching mechanism (5), a punching forming mechanism and a shearing forming mechanism (12) are straightly arranged between the upper mold module and the lower mold module in sequence; a product blank plate (1) passes through the edge punching mechanism (4), the interval punching mechanism (5), the punching forming mechanism and the shearing forming mechanism (12) in sequence for blanking formation; upper molds of all mechanisms are all connected to the same one upper mold plate as a large upper mold plate (2), and lower molds of all mechanisms are all connected to the same one lower mold plate as a large lower mold plate (3); the large lower mold plate (3) is fixedly connected to a worktable; and the large upper mold plate (2) is fixedly connected to an output end of a driving part slidingly connected with an equipment frame. After the structure is adopted, the production efficiency is greatly improved, and meanwhile, the number of operators is largely reduced, so that the production cost is reduced.

Owner:宁波世纪东港机械有限公司

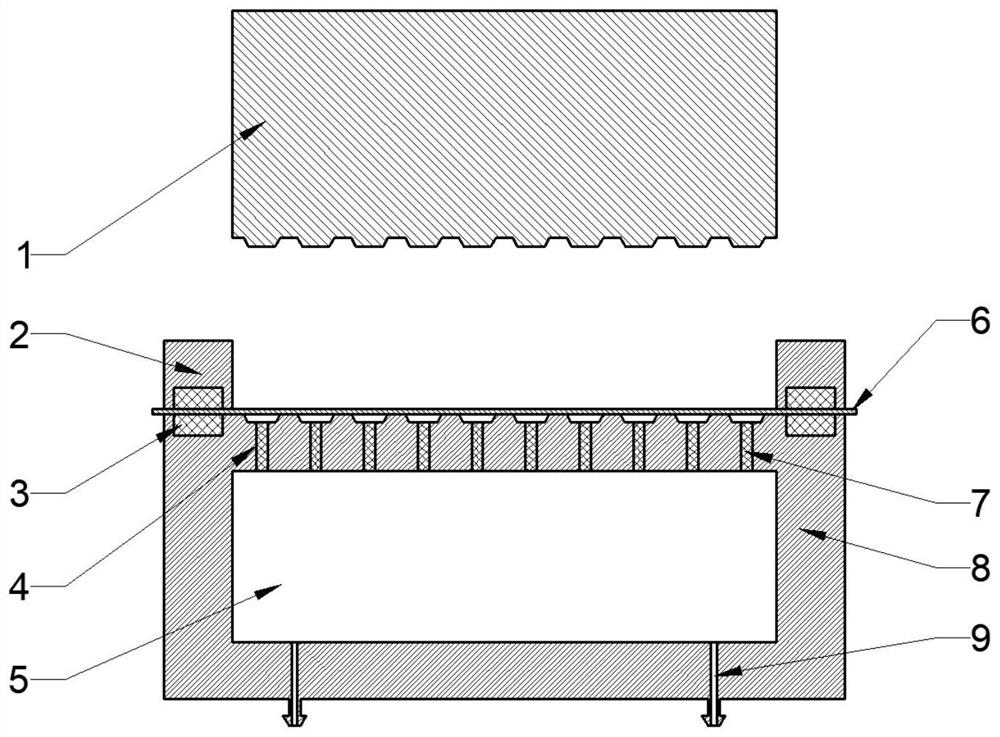

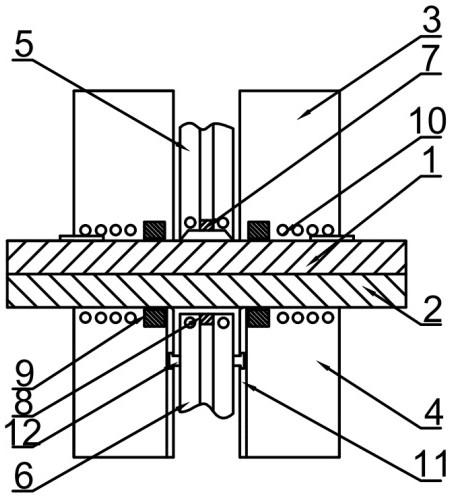

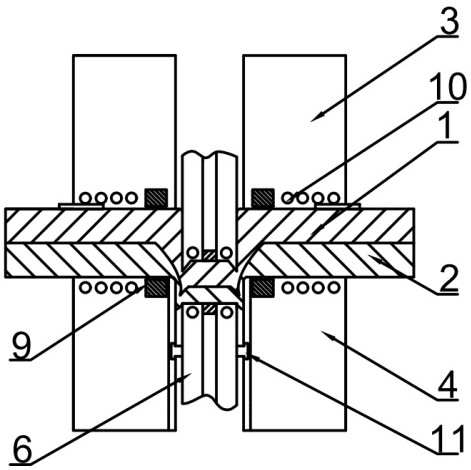

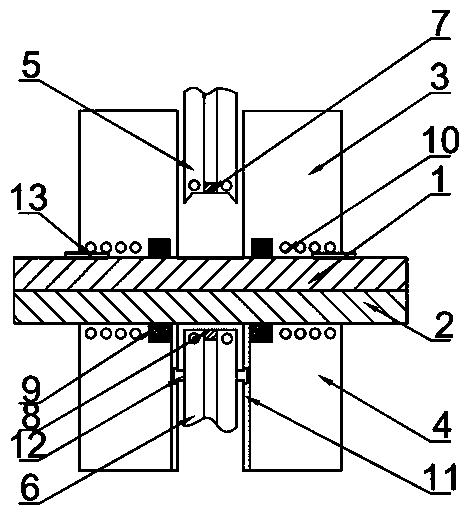

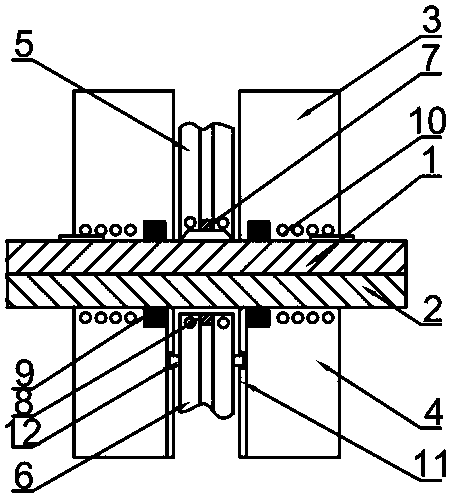

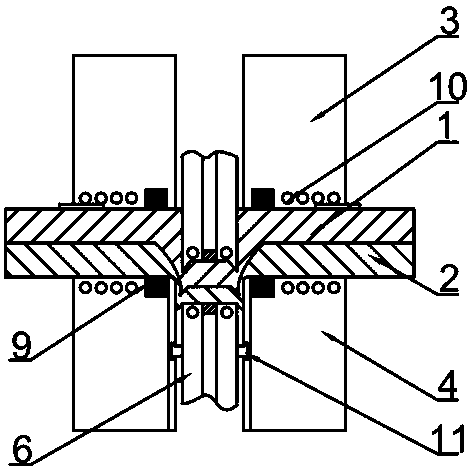

Bipolar plate manufacturing device and method based on positive and negative pressure auxiliary forming

ActiveCN112474964AReduce springbackHelp drive progressShaping toolsMetal-working feeding devicesFuel cellsStamping

The invention discloses a bipolar plate manufacturing device and method based on positive and negative pressure auxiliary forming. The device comprises an upper die and a lower die which are both connected with a machine tool, wherein a bipolar plate is fixed to the upper surface of the lower die through a bolt by means of a blank holder for stamping; the lower surface of the upper die and the upper surface of the lower die are provided with grooves corresponding to the stamped bipolar plate; the lower die internally comprises an air cavity used for storing air and keeping air pressure; the air cavity is connected with an external air source through an air inlet and outlet hole of the lower die; the upper portion of the wall of the air cavity is provided with an air hole; and the upper dieand the lower die achieve stamping of the bipolar plate under the control of the air pressure of the air cavity and the machine tool. According to the bipolar plate manufacturing device and method, the plate springback phenomenon in the bipolar plate machining process is reduced, the forming precision is high, the machining process is simple, popularization is easy, and automation is achieved. Meanwhile, the machining process is not limited by the size of the bipolar plate, and progress and popularization of fuel cells are promoted while the production period is shortened and the production cost is reduced.

Owner:NANJING INST OF TECH

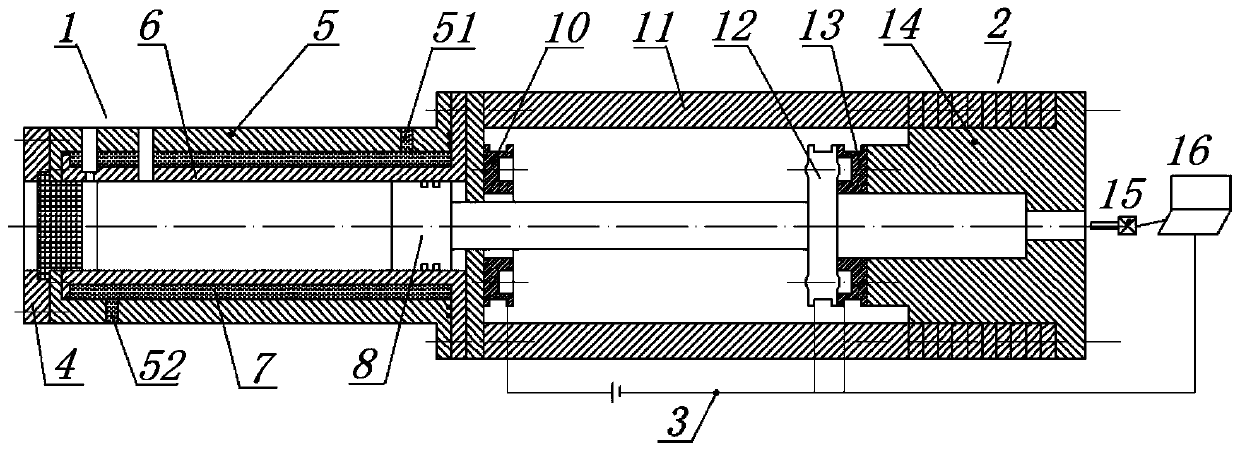

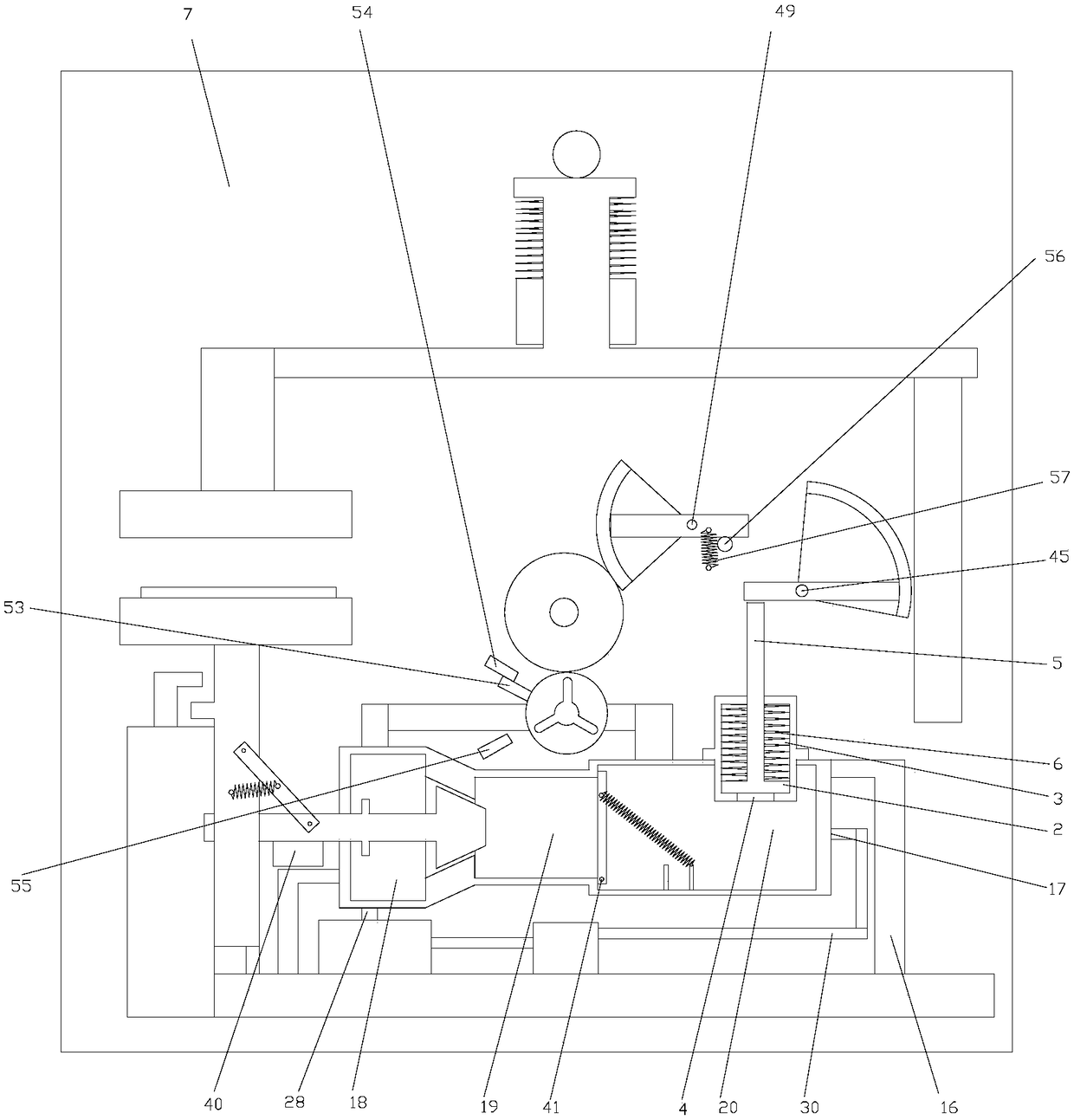

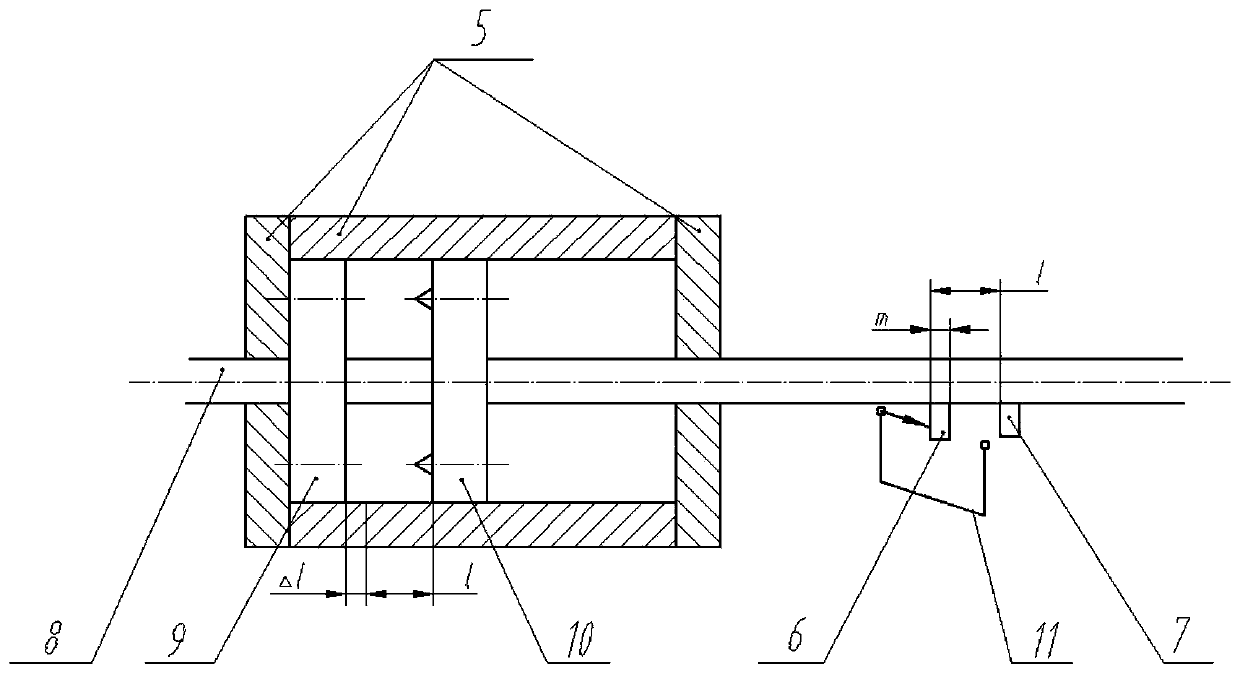

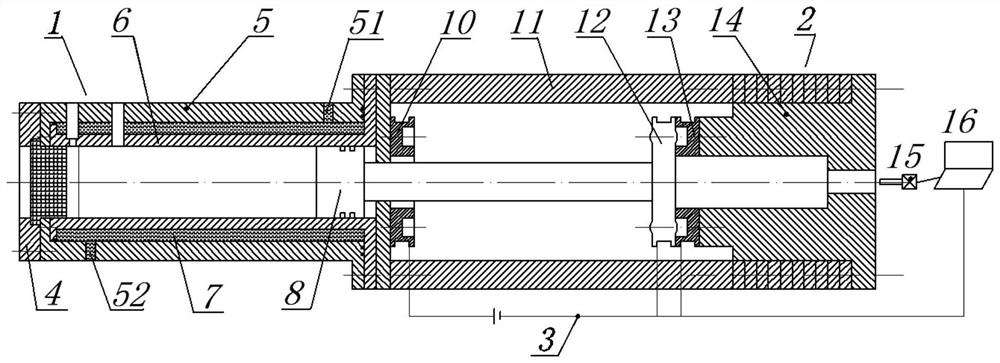

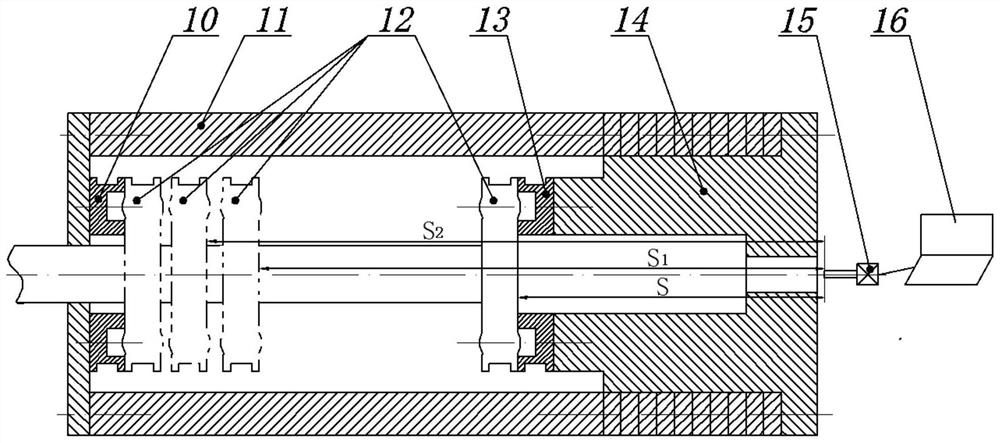

Small quick compressor based on electromagnetic control

ActiveCN110905764ASimple and fast operationSave time and costInternal combustion piston enginesPump controlLaser rangingCombustion chamber

The invention discloses a small quick compressor based on electromagnetic control. The small quick compressor is mainly composed of a main combustion chamber system, a power system and an electromagnetic control circuit. The main combustion chamber system is composed of a gland and two layers of sleeves. Heat conduction oil flows through a gap between the two sleeves to heat a combustion chamber.The power system comprises a cylinder body, a power cylinder gland, a braking circular ring, a power piston, a driving circular ring and a laser distance measuring sensor. The laser distance measuringsensor measures the distance through a center hole of the power cylinder gland, and therefore, control of the compression process is achieved. The electromagnetic control circuit comprises a direct-current power supply, a slide rheostat and five switches, wherein the direct-current power supply supplies current; the slide rheostat is used for adjusting the circuit current so as to change the electromagnetic force between the coils; three switches are used as on-off switches of a circuit, and the other two switches are jointly used as change-over switches and are responsible for changing the current flow direction in the coil, so that the direction of electromagnetic force is changed. The quick compressor is simpler and more compact in structure, and the working process is more efficient.

Owner:TIANJIN UNIV

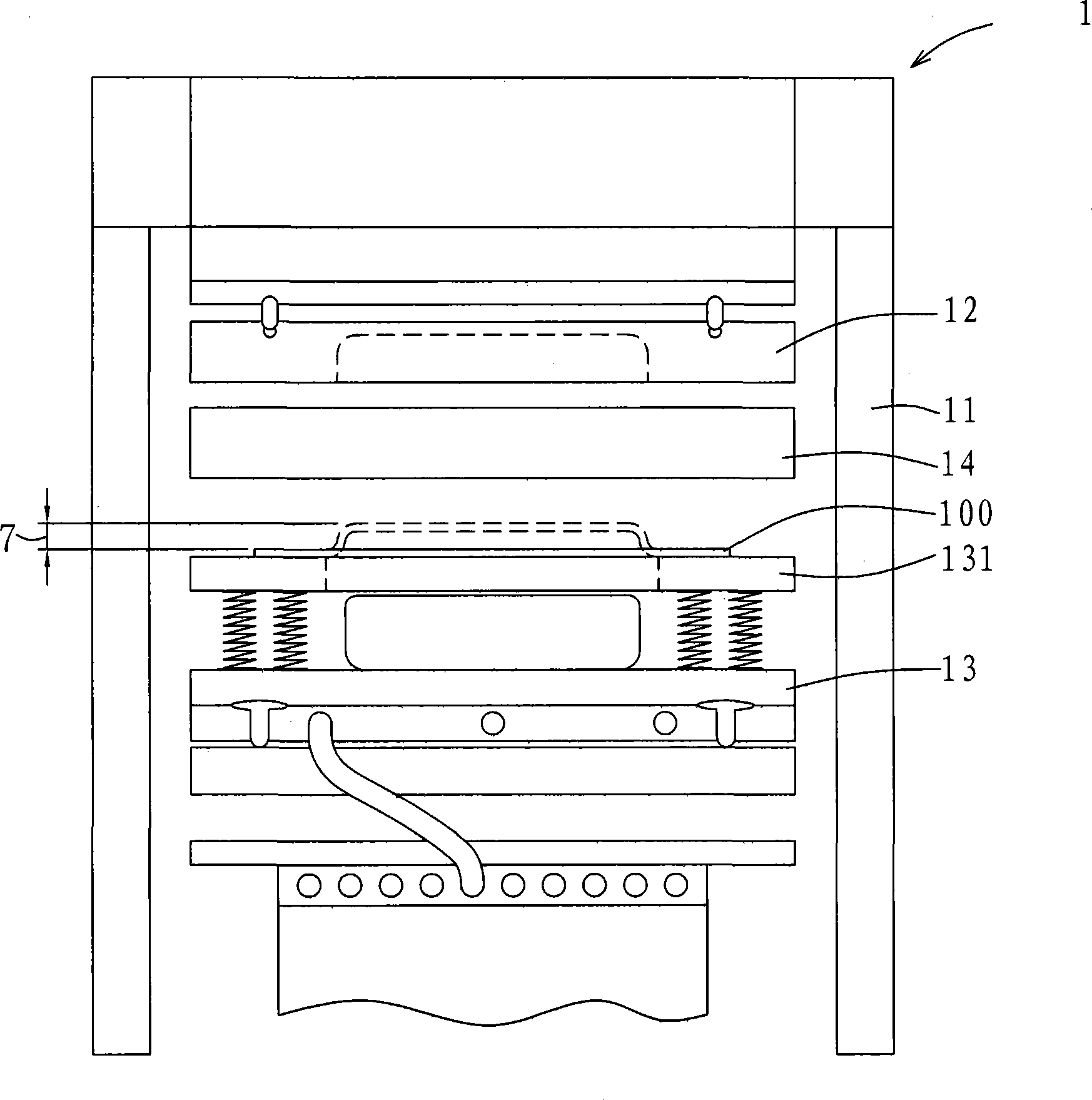

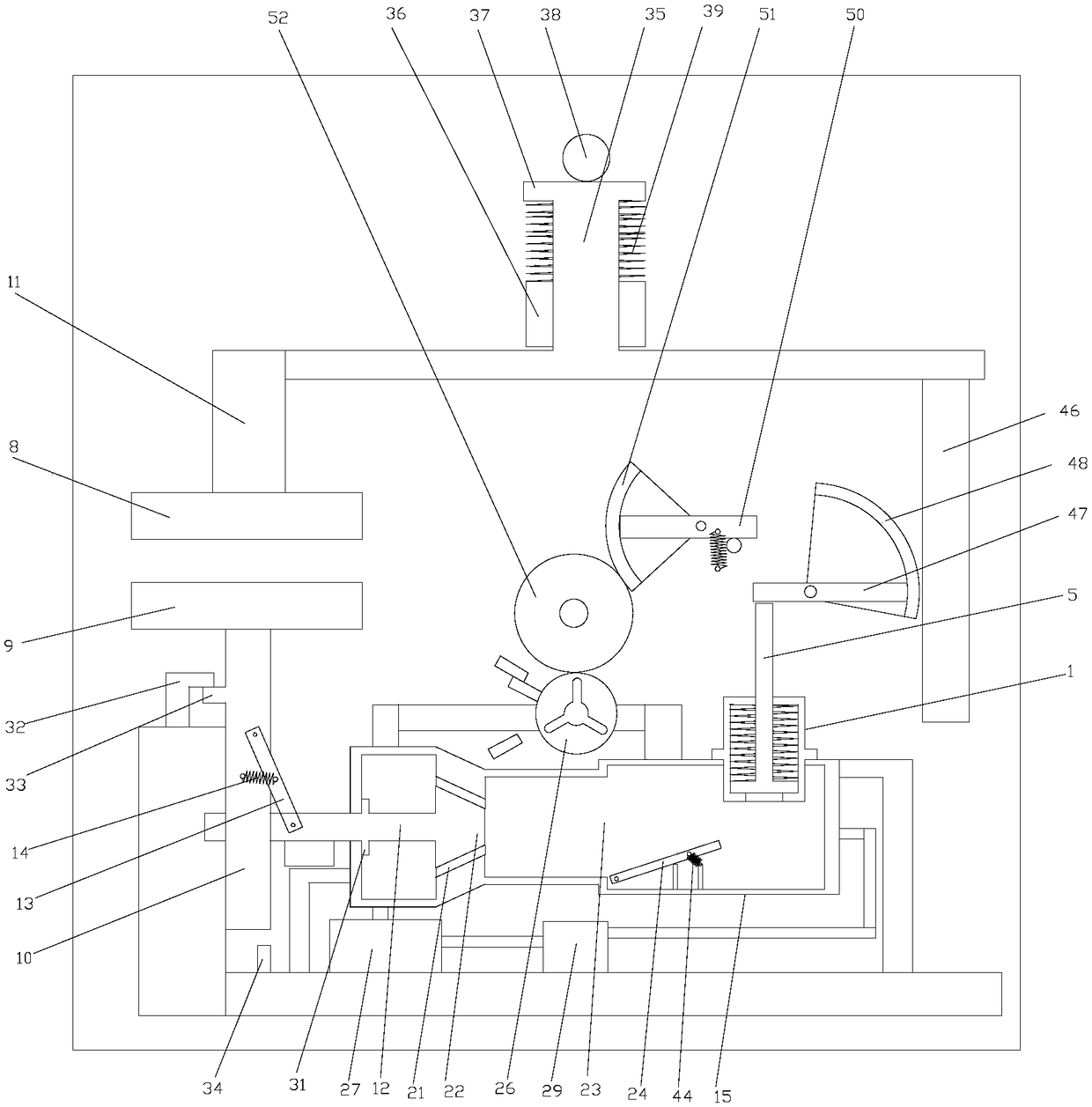

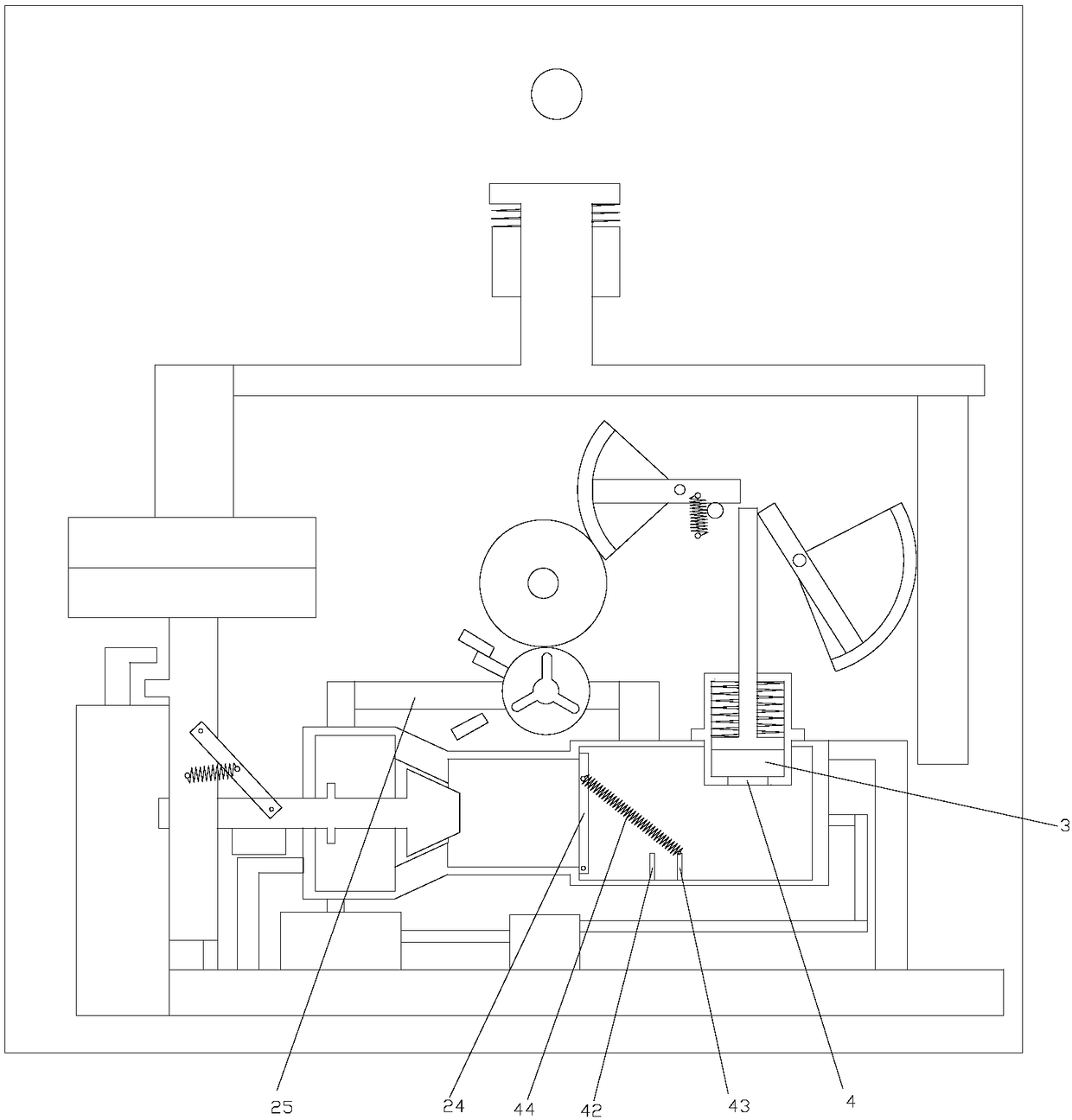

Full-automatic stamping forming die

The invention discloses a full-automatic stamping forming die. The full-automatic stamping forming die comprises a base 7. An upper die base 8 and a lower die base 9 are slidably connected to the base7. A male die is arranged on the upper die base 8. A female die matched with the male die is arranged on the lower die base 9. The lower die base 9 and the upper die base 8 are provided with a supporting rod 10 and a sliding frame 11 correspondingly. The supporting rod 10 and the sliding frame 11 are slidably connected to the base 7 through a first sliding assembly and a second sliding assembly in the vertical direction correspondingly. A plug stick 12 is slidably connected to the base 7 and is connected with the supporting rod 10 through a driving rod 13. The driving rod 13 is obliquely arranged between the plug stick 12 and the supporting rod 10. The two ends of the driving rod 13 are rotatably connected with the plug stick 12 and the supporting rod 10 correspondingly. A first tension spring 14 is arranged between the driving rod 13 and the supporting rod 10. The full-automatic stamping forming die provided by the invention is higher in automation level and higher in machining precision.

Owner:安祖桂

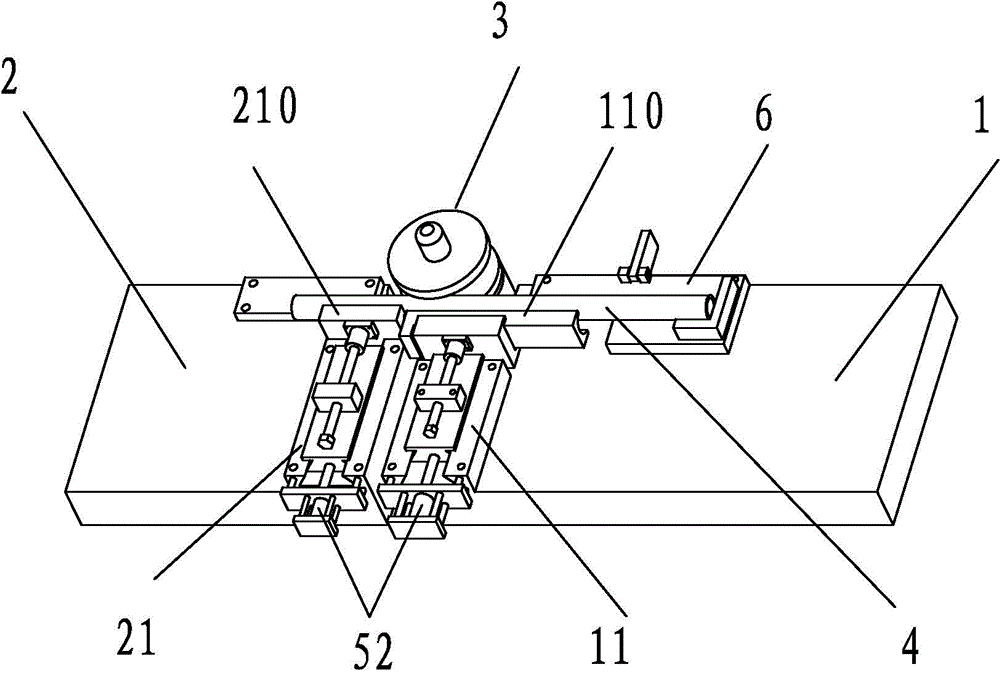

Positioning mechanism of circular pipe bending device

InactiveCN104874653AAvoid damagePrecise positioningMetal-working feeding devicesPositioning devicesEngineeringMechanical engineering

The present invention discloses a positioning mechanism of a circular pipe bending device. The positioning mechanism comprises a stationary work table and a rotary work table capable of rotating; a freely rotating rotary circular bench is disposed between the stationary work table and the rotary work table; the circular pipe is positioned on the stationary work table; the circular pipe is bended in a rotation direction when the rotary work table rotates along a plane; the stationary work table is provided with a first clamping device for clamping the front portion of the circular pipe; the first clamping device comprises a first chuck and a driving device for driving the first chuck; the rotary work table is provided with a second clamping device for clamping the rear portion of the circular pipe; the second clamping device comprises a second chuck and another driving device for driving the second chuck; a positioning bench for positioning the circular pipe is disposed on the stationary work table; and the head bend of the positioning bench is provided with an L-shaped positioning strip. The positioning mechanism is accurate in positioning and good in clamping effect, and is not easy to loosen.

Owner:ZHEJIANG LIFAN FURNITURE

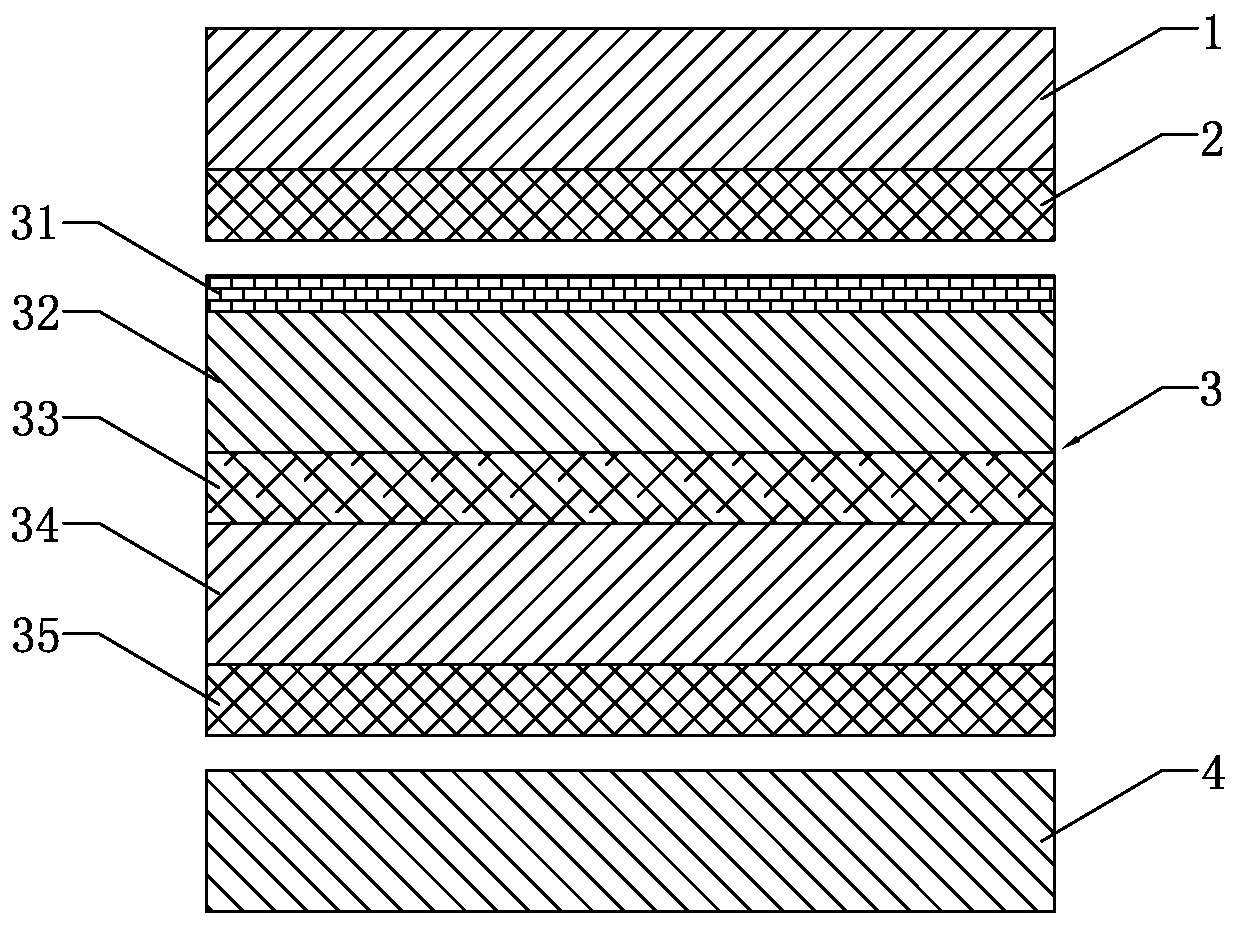

A kind of protective film that does not rebound under hot pressing and preparation method thereof

ActiveCN105969233BImprove thermoforming performanceImprove curing effectSynthetic resin layered productsFilm/foil adhesive release linersTectorial membraneEngineering

Owner:NALI OPTICAL MATERIAL DONGGUAN

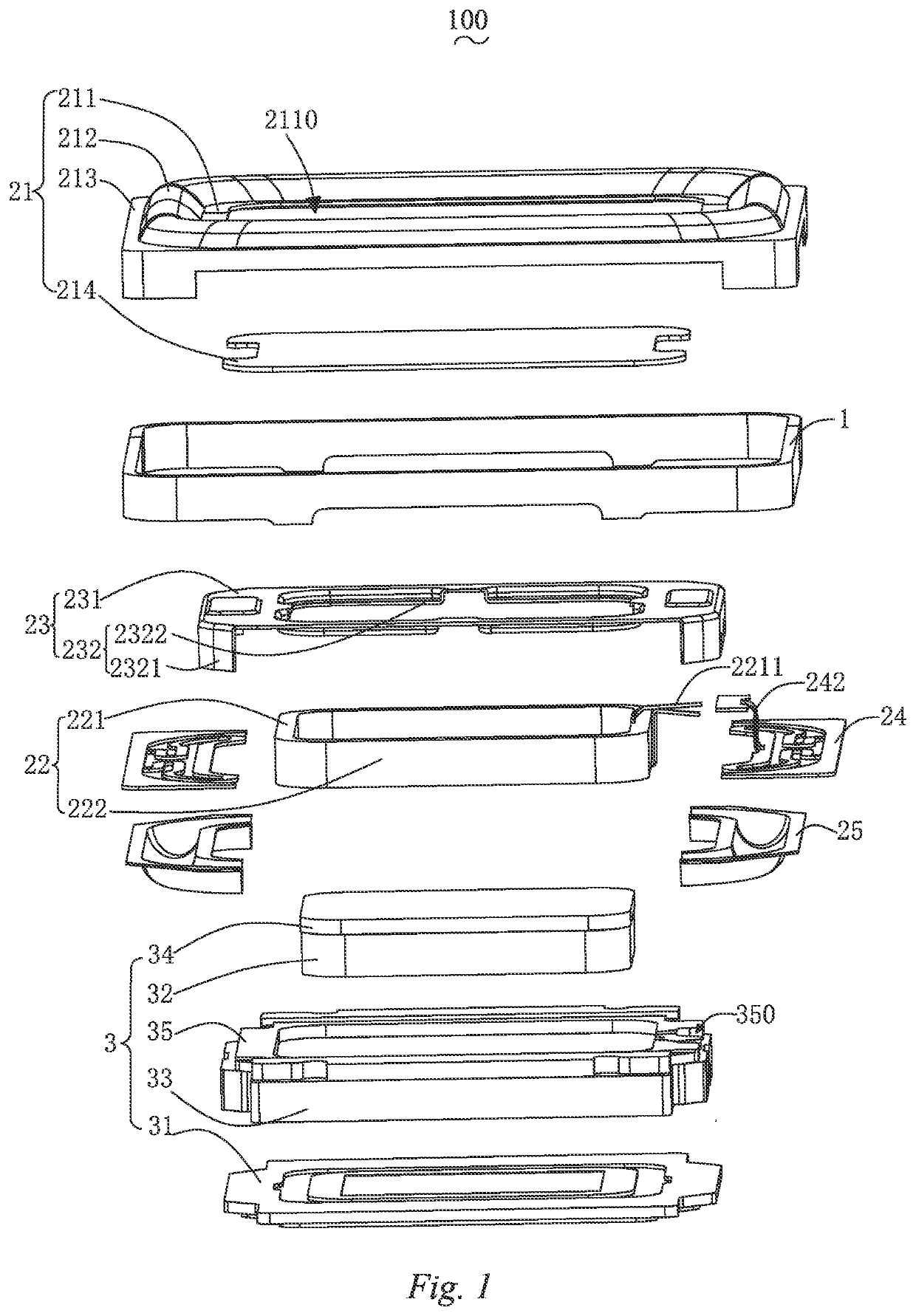

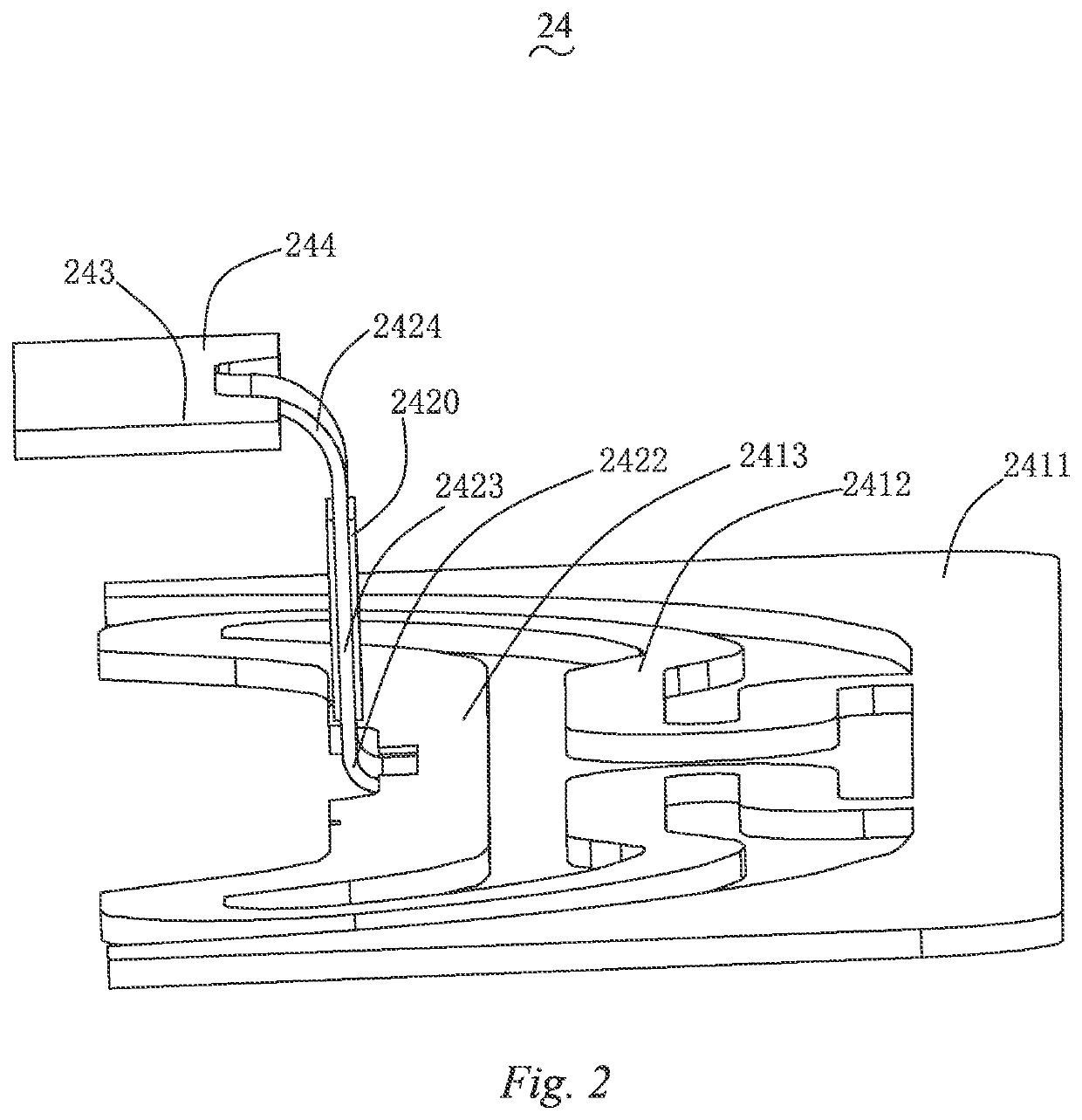

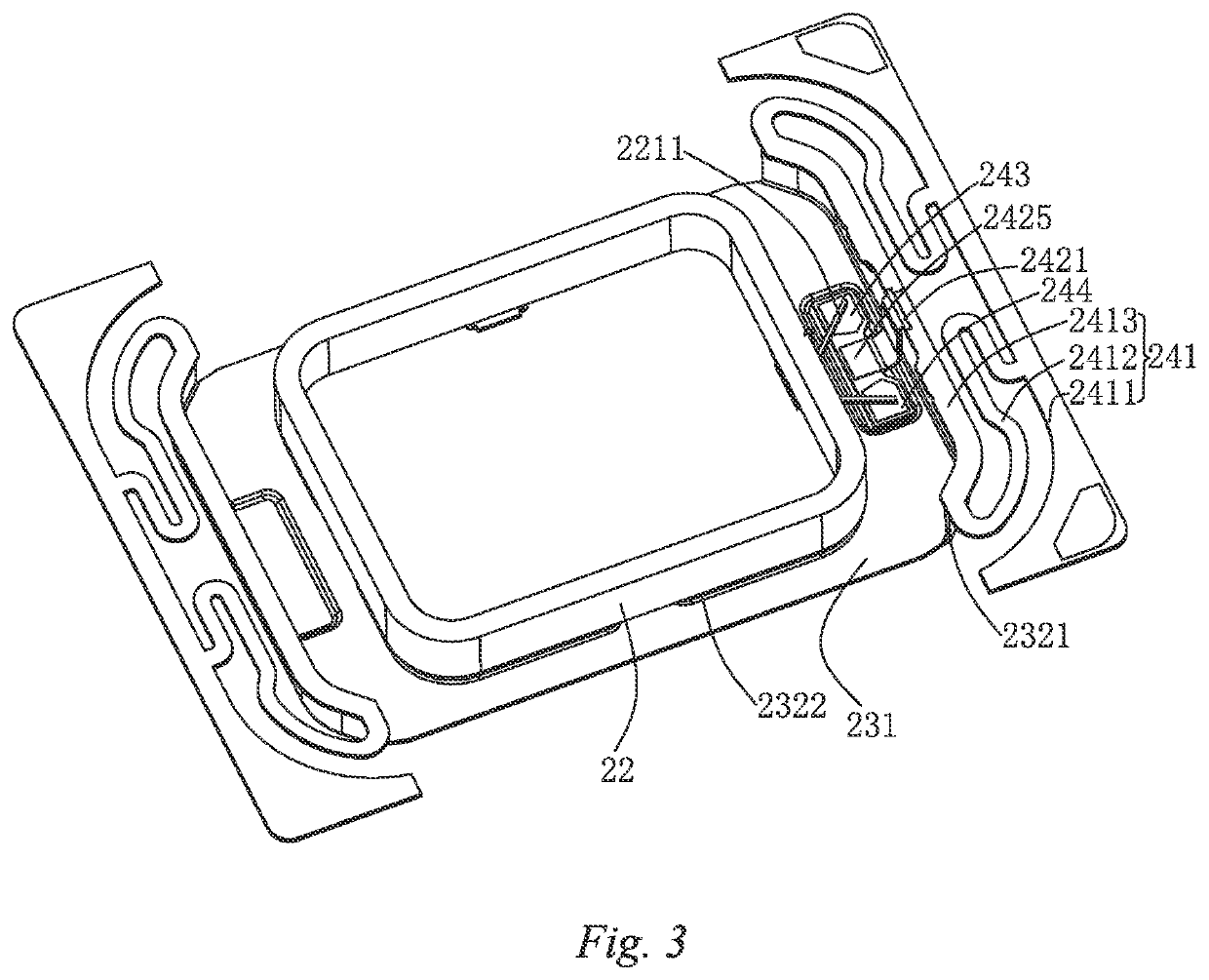

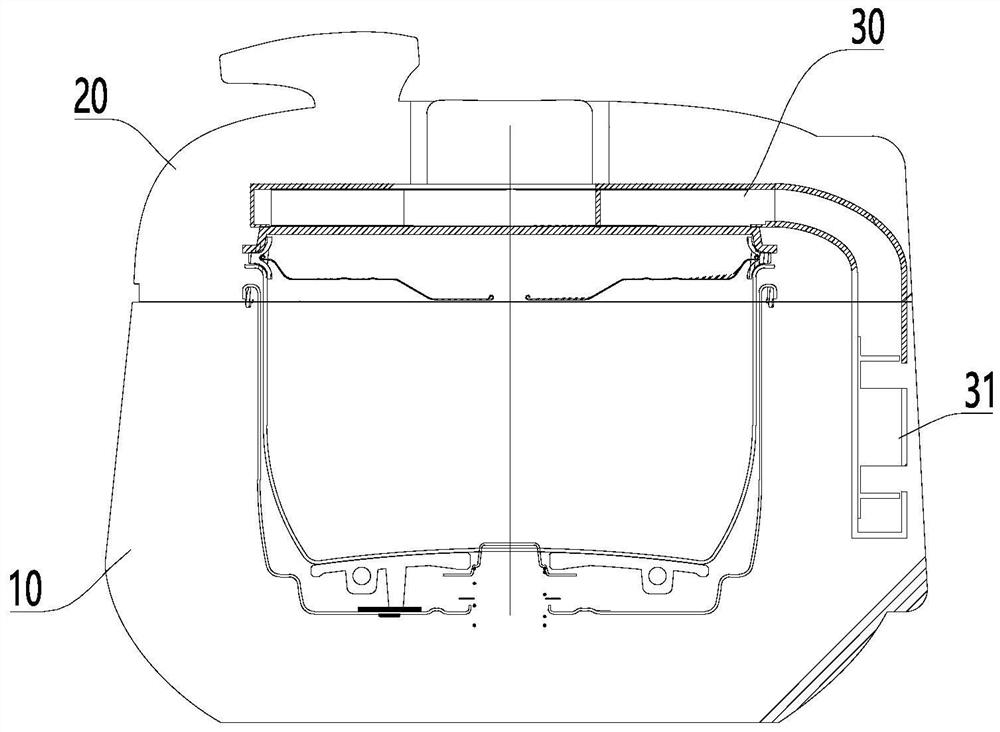

Sounding device

PendingUS20220174417A1Reduce stressReduce springbackLoudspeakersDiaphragm mounting/tensioningPhysicsEngineering

Disclosed is a sounding device, including a frame, a vibration system, and a magnetic circuit system. The vibration system includes a diaphragm, a framework, a voice coil, and an elastic conductor. The elastic conductor includes an elastic conductor body, a connection arm, and a pad portion. The connection arm includes a first connection portion, a first bending portion, a second connection portion, a second bending portion, and a third connection portion. A covering film is attached to inner and outer surfaces of the connection arm, and the covering film is moved from inside and / or outside surfaces of the first bending portion and the second bending portion. Removal of the covering film reduces the stress on inner and outer surfaces of bent areas, stabilizes bending angles, reduces springback, and makes pad positions precise.

Owner:AAC MICROTECH CHANGZHOU

A device and method of riveting non -rivet rivet

ActiveCN111266469BWon't breakAdapt to mass productionShaping toolsMetal working apparatusEngineeringLaser heating

The invention belongs to the technical field of rivetless riveting, and in particular relates to a device and method for riveting martensitic steel plates without rivets. The device includes: an upper mold, a lower mold, a punch, a holder, an upper laser heater, a lower laser heater, a thermistor and a cooling water channel. The centers of the upper mold and the lower mold are provided with through holes. The upper mold and the lower mold are symmetrically arranged on the upper and lower sides. Both the head and the support head can move freely in their respective through holes. The upper laser heater is set on the bottom surface of the punch, the lower laser heater is set on the top surface of the holder, the upper mold and the lower mold are equipped with thermistors and cooling channels, and the punch is close to the upper laser heater. A cooling water channel is also provided at the position of the support head and the position close to the lower laser heater. The rivet formed by the above-mentioned device and the underlying material are interlocked to ensure high connection strength.

Owner:SHANDONG JIANZHU UNIV

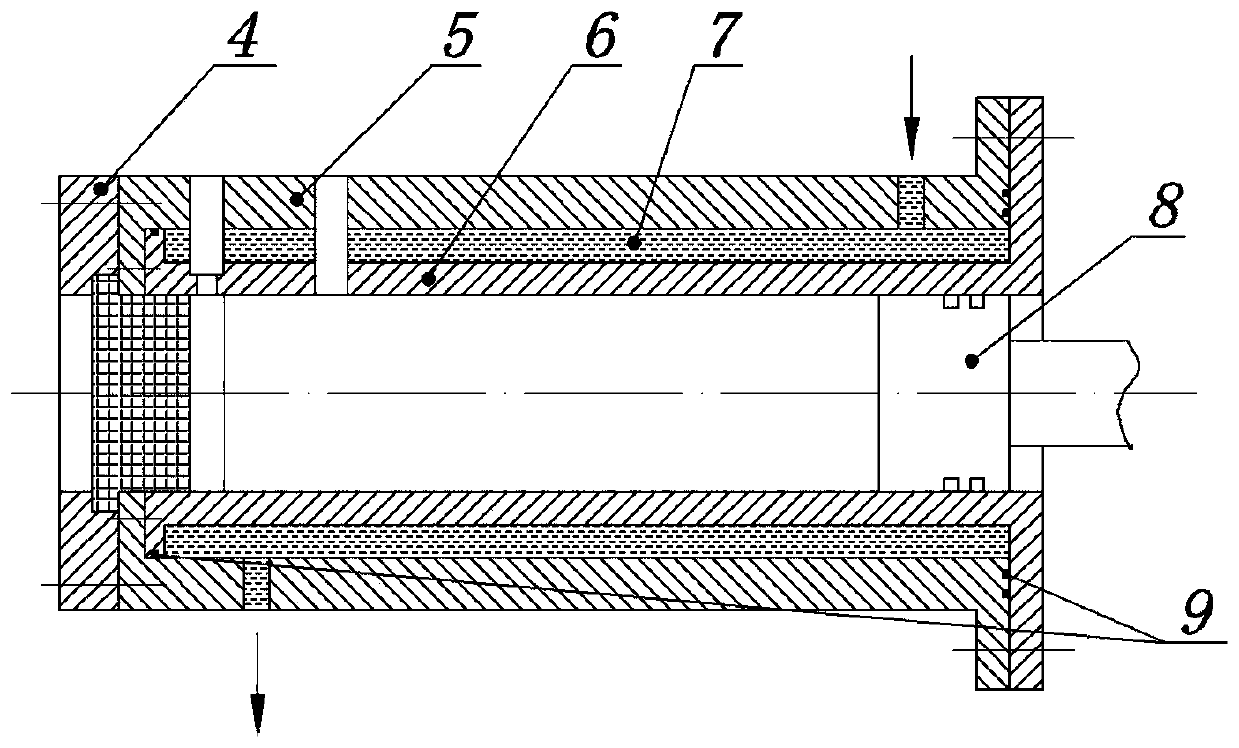

An Electromagnetic Brake System for Fast Compressors

The invention relates to an electromagnetic braking system for a rapid compressor. The electromagnetic braking system comprises a central control unit, a braking cylinder made of a magnetic separationmaterial, a pushing rod penetrating through the braking cylinder, an electromagnetic braking circular ring fixed to the braking cylinder, an electromagnetic braking piston fixed to the pushing rod, afirst light shading plate, a second shading plate, a photoelectric sensor and an electromagnetic braking control circuit, wherein the first light shading plate and the second shading plate are fixedto the pushing rod, and the photoelectric sensor is fixed nearby the pushing rod. Circumferentially-wound electromagnetic coils are embedded on the electromagnetic braking circular ring and the electromagnetic braking piston correspondingly; the two light shading plates are fixed to the corresponding positions on the pushing rod when baking needs to be started and needs to be completed, the distance between the two light shading plates is equal to the braking distance l, and the photoelectric sensor is arranged at the first light shading plate when braking is started; and the photoelectric sensor sends detection signals on the two light shading plates into the central control unit.

Owner:TIANJIN UNIV

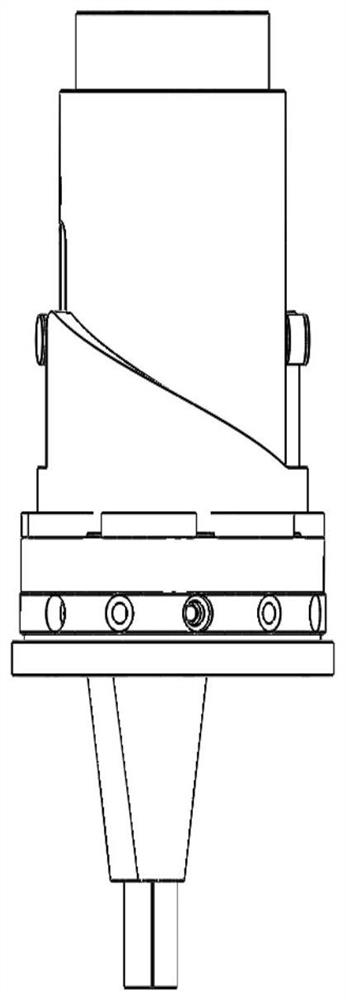

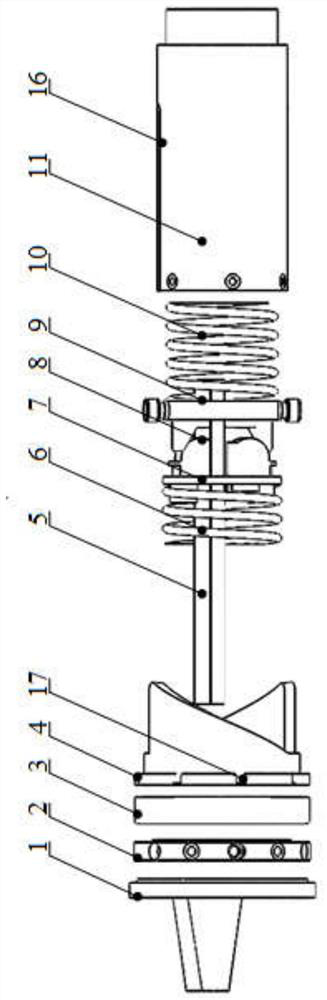

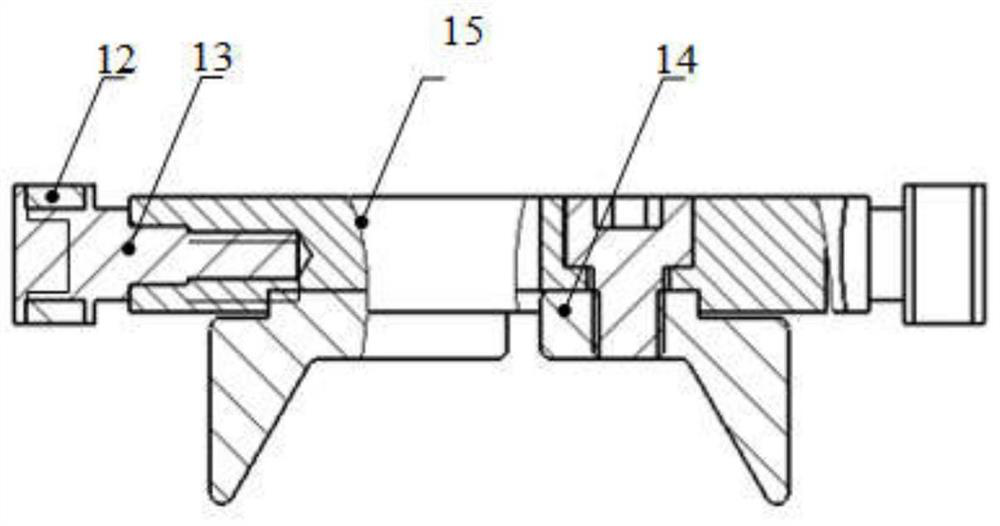

Two-side clamping type impact actuating device

ActiveCN113267367AReduce reboundContinuous Axial FrictionWithdrawing sample devicesPhysicsImpact hammer

The invention provides a two-side clamping type impact actuating device which comprises a center cylinder, a guide section, an inner and outer connecting ring, a space cam and an impacted piece; the tail end of the center cylinder is connected with the guide section through the inner and outer connecting ring, and the space cam is arranged on the lower portion of the center cylinder in a sleeving mode and connected with the guide section through a bearing; an energy storage spring, an impact hammer, clamping sliding blocks, a sliding table and a reset spring are sequentially arranged in the center cylinder from top to bottom; the two clamping sliding blocks are arranged, a gap is formed between the two clamping sliding blocks, and the two clamping sliding blocks are both arranged in a sliding groove of the sliding table in a sliding mode; the impact hammer comprises an impact hammer body and an impact clamping block; and one end of an impacted piece is vertically inserted into the center cylinder from the upper end face of the center cylinder, sequentially penetrates through the energy storage spring, the impact hammer, the gap between the two clamping sliding blocks, the sliding table and the reset spring, and then extends out of the guide section. According to the invention, the impact actuation of the impacted piece of any configuration under the magnitude of the section size of 1*1 mm<2> is realized, and the springback phenomenon caused by impacting a hard object can be effectively reduced.

Owner:HARBIN INST OF TECH

Device and method for clinching martensitic steel plate

ActiveCN111266469AWon't breakAdapt to mass productionShaping toolsMetal working apparatusMetallurgyLaser heating

The invention belongs to the technical field of clinching, and particularly relates to a device and a method for clinching a martensitic steel plate. The device comprises an upper die, a lower die, apunch, a holding head, an upper laser heater, a lower laser heater, thermistors, and cooling water channels, wherein through holes are formed in the centers of the upper die and the lower die; the upper die and the lower die are symmetrically arranged up and down; the punch is located in the through hole of the upper die; the holding head is located in the through hole of the lower die; both the punch and the holding head can move freely in the respective through holes; the upper laser heater is arranged in the bottom surface of the punch; the lower laser heater is arranged in the top surfaceof the holding head; and the upper die and the lower die is provided with thermistors and cooling water channels; and cooling water channels are arranged at a position, close to the upper laser heater, in the punch and a position, close to the lower laser heater, in the holding head. Rivets formed by the device are interlocked with a bottom material to ensure high connection strength.

Owner:SHANDONG JIANZHU UNIV

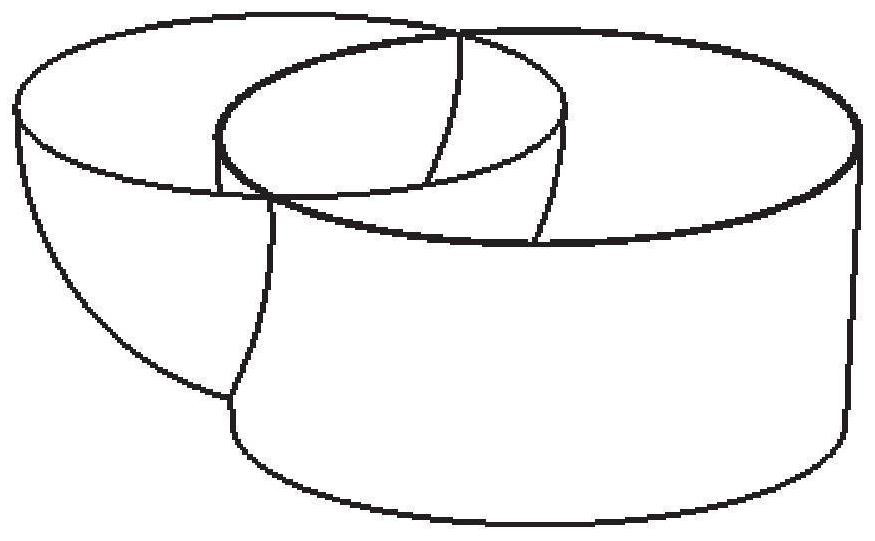

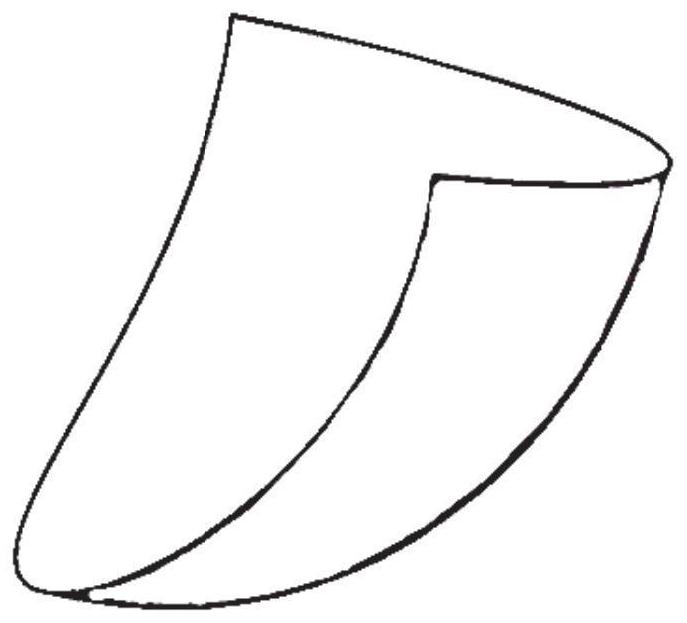

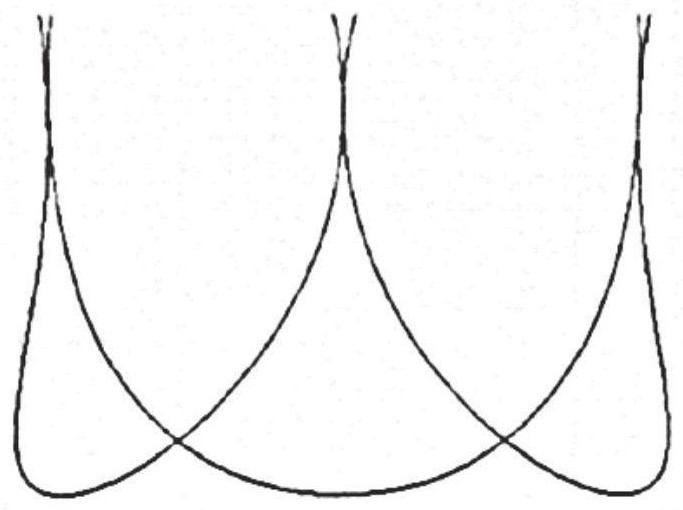

A kind of manufacturing method of artificial heart valve stent

ActiveCN113101014BConform to the shapeAchieve preparationHeart valvesComputer printingBiomedical engineering

The invention discloses a method for manufacturing an artificial heart valve stent, which solves the problem of manufacturing errors in the mechanical manufacturing of the valve stent in the prior art, and has the beneficial effects of convenient processing and accurate manufacturing of the valve stent. The specific solutions are as follows: 1. A method for manufacturing an artificial heart valve stent, comprising selecting a valve prototype reference plane, and modeling based on the selected valve prototype reference plane; creating a model according to the valve prototype reference plane according to the valve leaflet distribution of the artificial heart valve stent, and using half of the valve prototype reference plane to create a model. The space intersection line of the inverted conical surface and the rotating surface whose apex angle is the set angle is the reference valve stent curve, and the single leaflet shape is obtained by combining the height of the leaflet, the free edge of the leaflet and the plane angle of the joint; Copy, make each valve leaflet evenly distributed at a set angle, complete the modeling of the artificial heart valve stent, convert the built model into the file required by the printer, and input the file into the printer; print through the printer.

Owner:SHANDONG UNIV

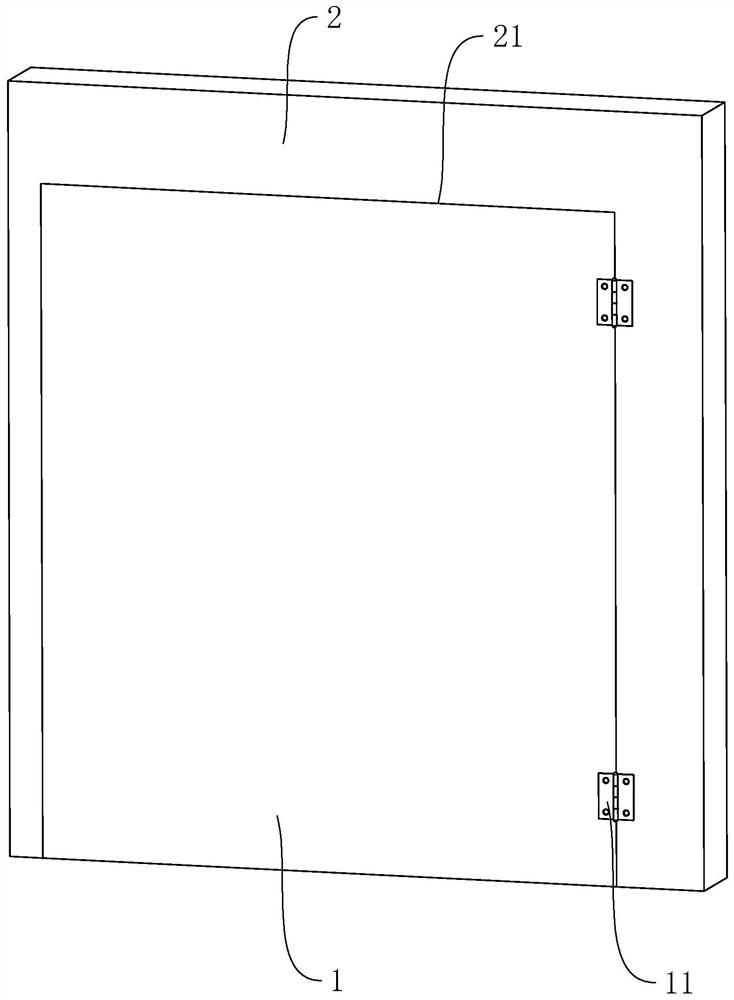

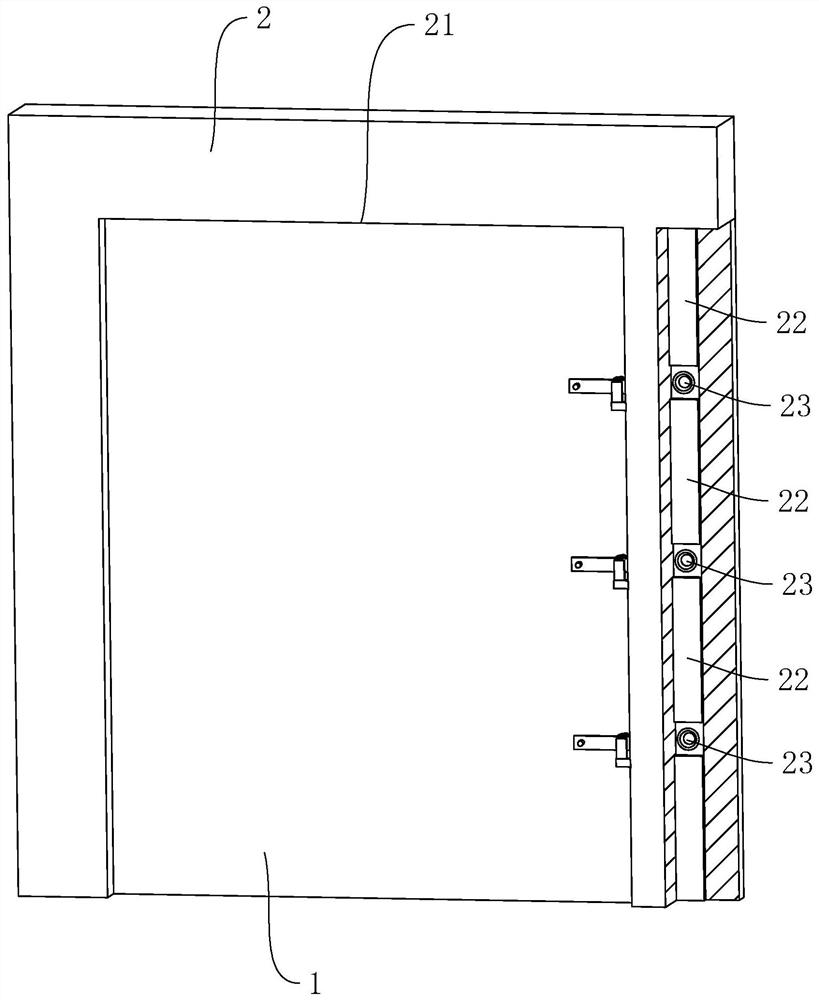

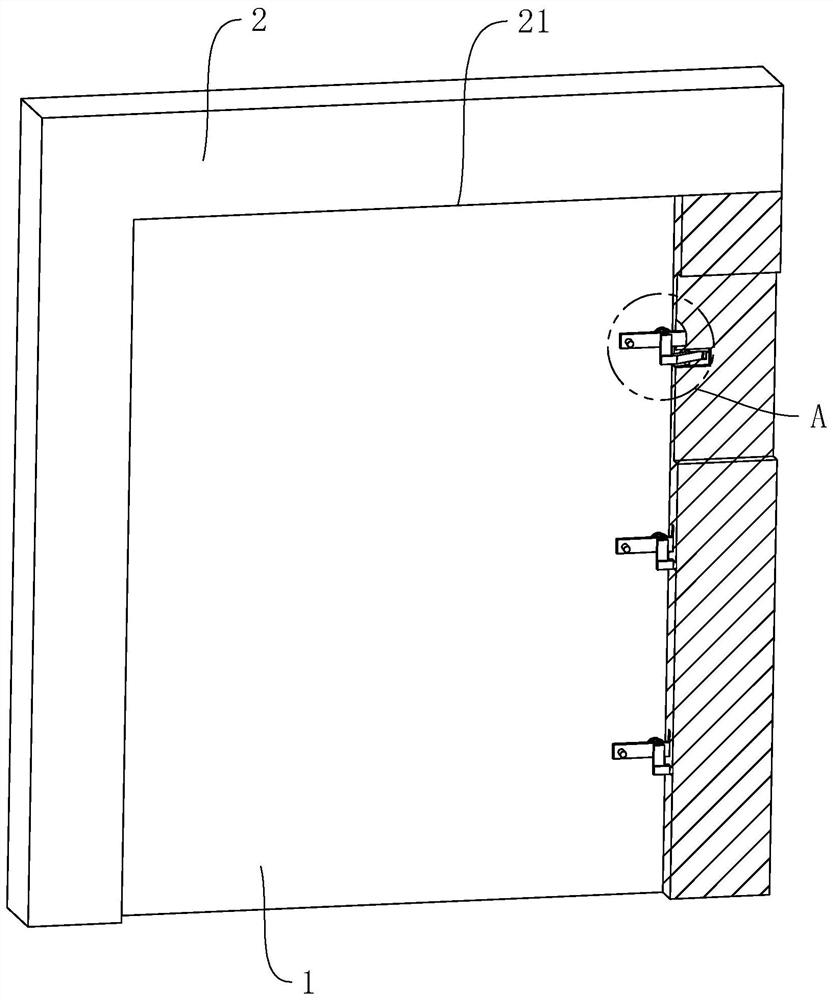

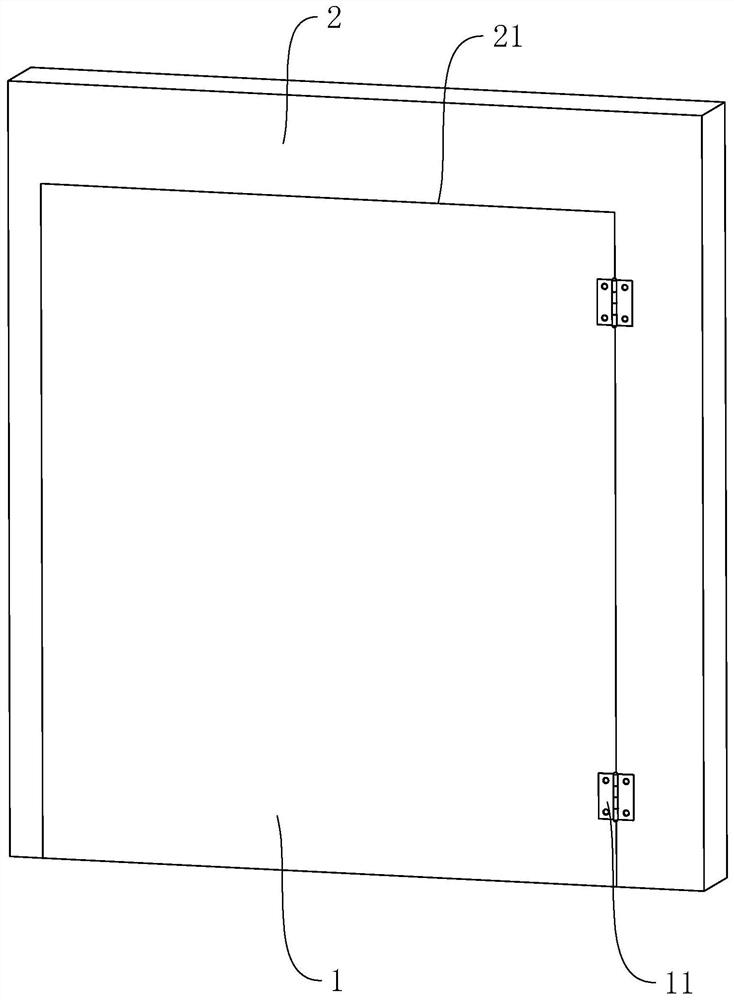

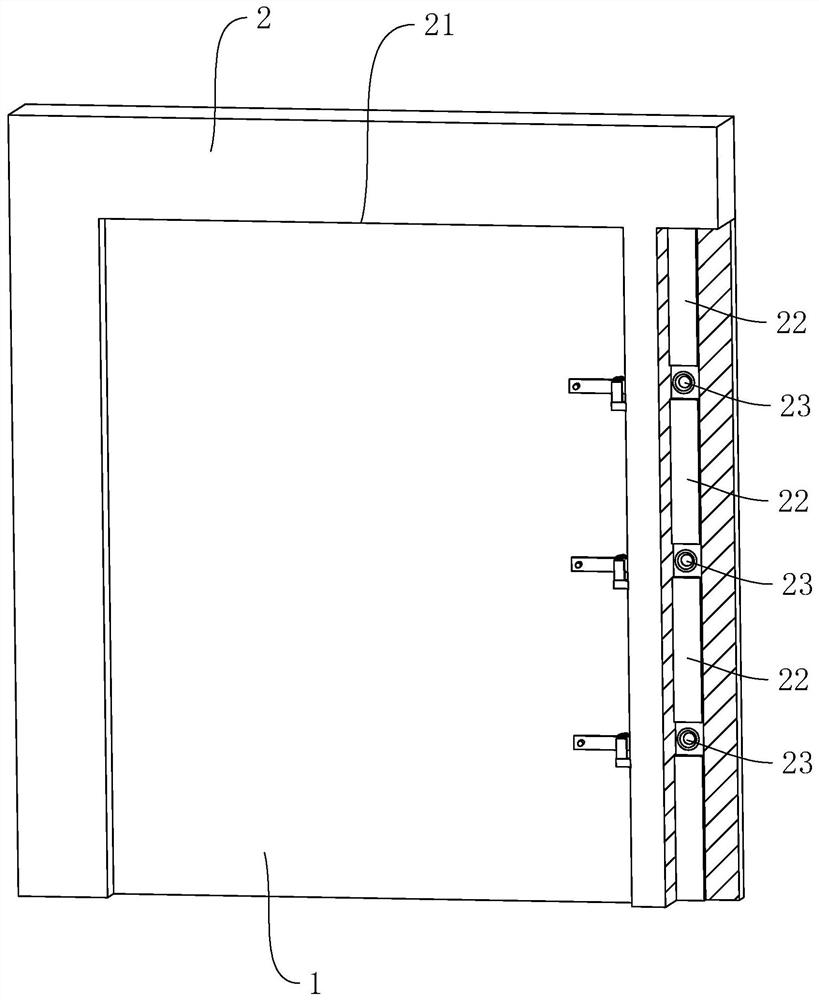

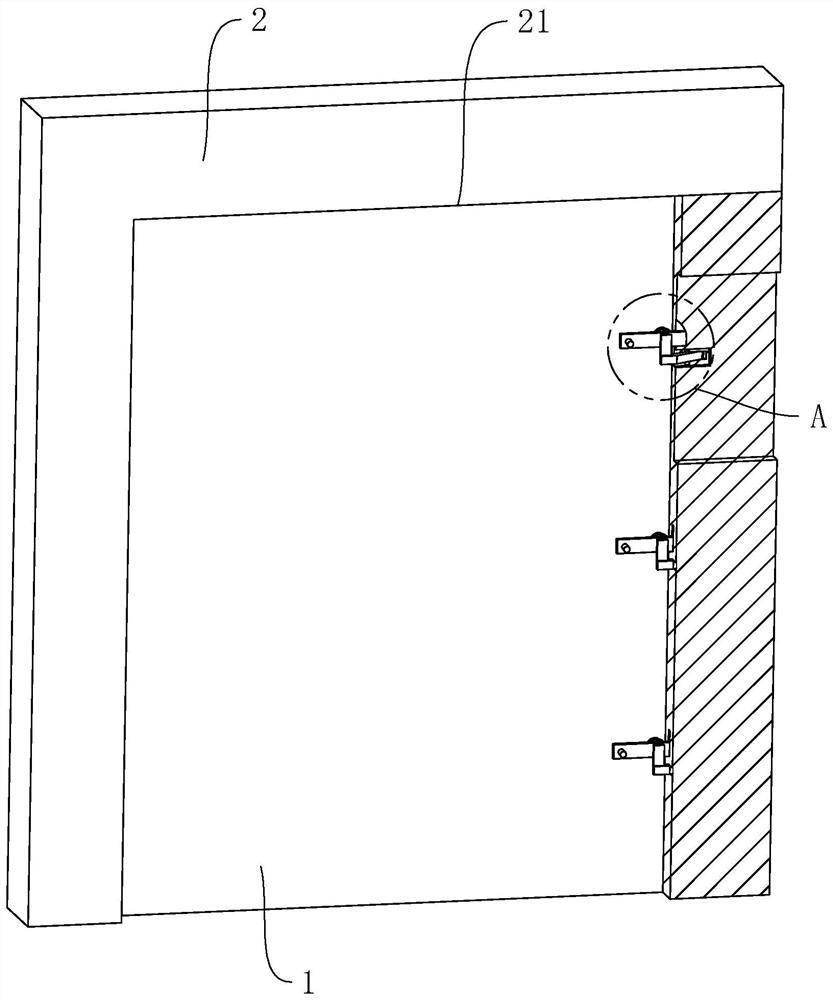

Electric door opening and closing auxiliary device

ActiveCN112761426BReduce springbackEasy to lock actionBuilding braking devicesBuilding locksElectric controlControl theory

The application relates to an auxiliary device for opening and closing an electronically controlled door, which includes a door body and a frame body. A through hole matching the door body is opened on the side of the frame body. The hinge covers the through hole, the side of the frame body away from the hinge is provided with a trigger component, the side of the frame body away from the hinge is provided with a slot, and the door body is provided with a linkage component and a locking component. The component is connected with the locking component. When the door is closed, the door body moves and abuts against the trigger component, the trigger component moves and abuts against the linkage component, and the linkage component moves synchronously and drives the locking component to screw into the slot. The application has the effect of being convenient for the electric control door to lock the door.

Owner:广州市巨安人防工程有限公司

Shock hydraulic composite forming process for small feature part of complex part

The invention discloses a shock hydraulic composite forming process for a small feature part of a complex part. The shock hydraulic composite forming process is a new forming process which intersects with a shock forming technology and a hydroforming technology and extends and develops from both of the two technologies, having advantages of both of hydro plastic forming and shock energy forming. The shock hydraulic composite forming process is defined as follows: performing the shock forming after the hydroforming is finished, utilizing momentarily released high energy of a shock source to compress high pressure liquid in a forming liquid room to obtain a surged pressure value which is transmitted to formed blanks in form of shock waves, so as to perform the new manufacturing process of elasticoplastic deformation of the part. Due to one-step installation, processing procedure is reduced, which helps to realize monolithic forming of a complex large curved surface part and guarantees positional accuracy of complex parts with various sizes. Meanwhile, the shock time is very short, which reduces requirements in terms of intensity and tightness of the device. The shock hydraulic composite forming process has a wide application prospect in fields such as aeronautics and astronautics, and automobile in aspects of forming, reforming and the like of large complex components with small feature sizes such as small convex hull, small pressing mark, and small holes.

Owner:BEIHANG UNIV

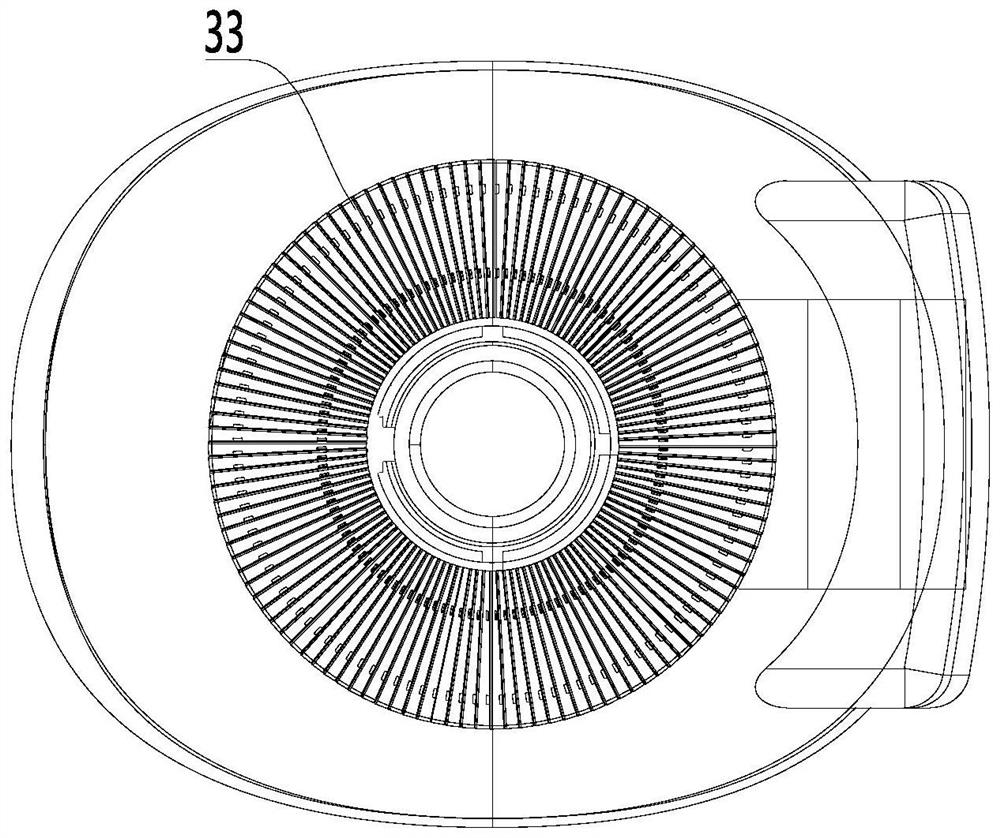

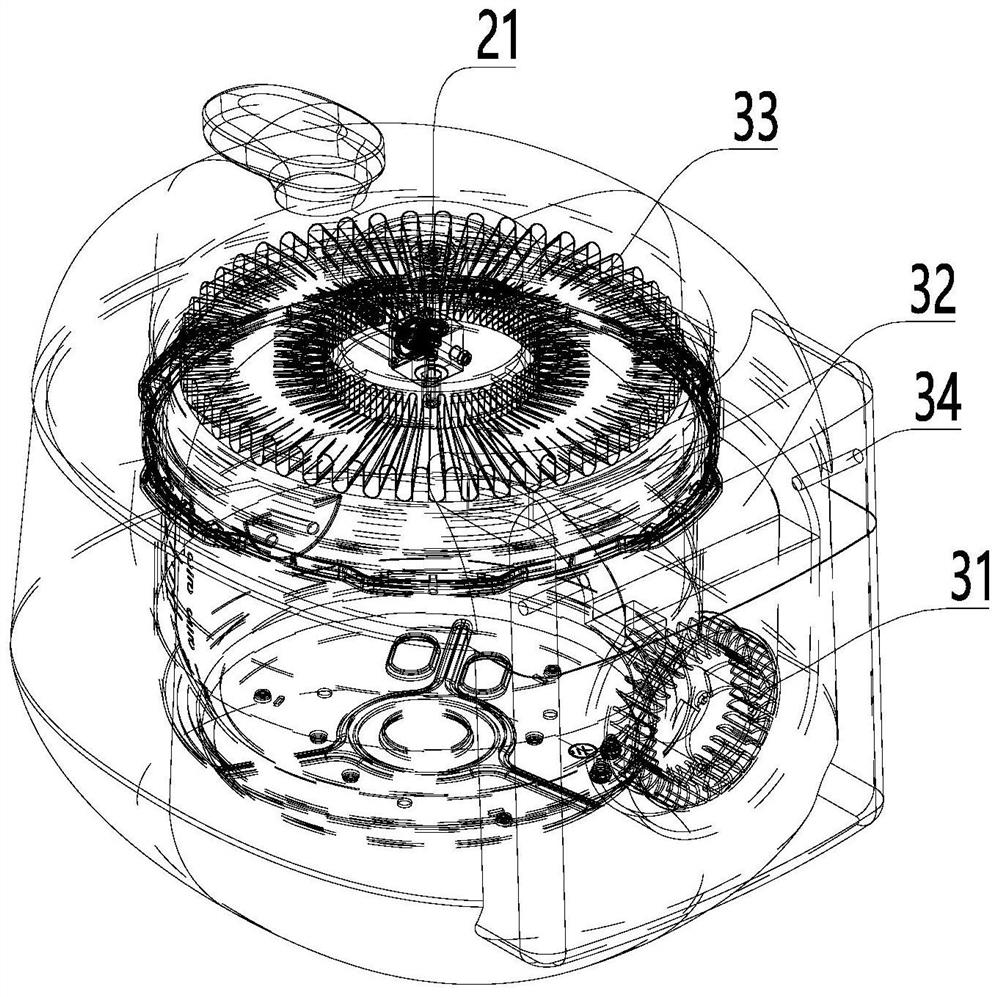

Cooling fin and air cooling structure

PendingCN112822915APromote formationReduce processing difficultyCooling/ventilation/heating modificationsEngineeringForced-air

The invention relates to the technical field of cooling devices, in particular to a cooling fin and an air cooling structure. The cooling fin includes: a base plate; supporting ribs formed by extending from the surface of the bottom plate to the direction far away from the bottom plate; and a first assembly part or a second assembly part which is suitable for being connected with the second assembly part or the first assembly part on another adjacent cooling fin in a clamping mode. According to the cooling fin, the heat dissipation area can be increased, forced air cooling resistance can be reduced, the heat dissipation amount is further increased, the cooling fin can be combined and assembled in an end-to-end connection mode, an air cooling heat dissipation channel can be conveniently formed, and the machining difficulty of an integral radiator is reduced.

Owner:GREE ELECTRIC APPLIANCES INC

Machining method for closed-end thin-wall component

The invention relates to the technical field of deep drawing of a hydraulic machine, in particular to a machining method of a closed-end thin-wall component. The machining method comprises the steps that a male mould moves downwards idly, and starts to decelerate when the male mould is about to be in contact with a plate material, so that the male mould starts to draw the plate material with a constant speed of a number of millimeters per minute; the male mould is in contact with the plate material at a constant speed and stops till the male mould reaches a deepest point; the male mould maintains static for 10-30 minutes at the deepest point; the male mould moves upwards to an initial position; the drawn thin-wall component is rotated horizontally for 90 degrees; the male mould moves downwards idly, and stops till reaching the deepest point; the male mould maintains static for 5-10 minutes at the deepest point; and the male mould move upwards to the initial position, so that plate material pressing is finished. When the male mould moves downwards to the lowest position, two times of pressure maintaining are performed, so that the phenomenon of plate material rebounding is reduced to the greatest extent; and two drawing processes are performed at different angles, so that deformity uniformity of the plate material is ensured.

Owner:YANGZHOU NIER ENG PLASTICS

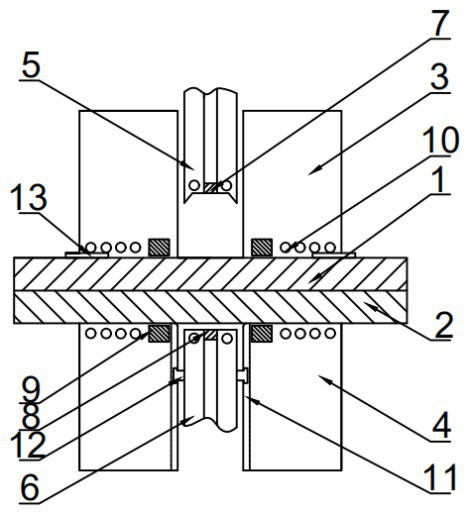

Forming dies for stamping and welding parts of pipes for vehicles

ActiveCN106734586BIncrease productivityReduce manufacturing costShaping toolsPerforating toolsPunchingEngineering

The invention discloses a forming mold of a vehicle tubular punching welding part. The forming mold comprises a lower mold module and an upper mold module; an edge punching mechanism (4), an interval punching mechanism (5), a punching forming mechanism and a shearing forming mechanism (12) are straightly arranged between the upper mold module and the lower mold module in sequence; a product blank plate (1) passes through the edge punching mechanism (4), the interval punching mechanism (5), the punching forming mechanism and the shearing forming mechanism (12) in sequence for blanking formation; upper molds of all mechanisms are all connected to the same one upper mold plate as a large upper mold plate (2), and lower molds of all mechanisms are all connected to the same one lower mold plate as a large lower mold plate (3); the large lower mold plate (3) is fixedly connected to a worktable; and the large upper mold plate (2) is fixedly connected to an output end of a driving part slidingly connected with an equipment frame. After the structure is adopted, the production efficiency is greatly improved, and meanwhile, the number of operators is largely reduced, so that the production cost is reduced.

Owner:宁波世纪东港机械有限公司

Steel plate bending device for lap joint of steel structure parts

PendingCN112676389AControllableReduce springbackMetal-working feeding devicesPositioning devicesBrakeLap joint

The invention provides a steel plate bending device for steel structure part lap joint, and belongs to the technical field of steel component machining equipment. The steel plate bending device for lap joint of the steel structure parts comprises a bending workbench, two brake air cylinders, a punch driving air cylinder, a bending punch and a servo motor; a steel plate bending groove is formed in the bending workbench, and fixed mounting boxes are fixedly connected to the front side wall and the rear side wall of the bending workbench correspondingly; and adjusting threaded rods are arranged in the two fixed mounting boxes. Two adjustable supports which are arranged on the outer surfaces of two sections of threads of the adjusting threaded rods in a threaded sleeving manner can do movement in opposite directions, the movement is synchronous, the controllability of the movement distance is high due to lead screw transmission, the distance between the two adjustable supports can be accurately and synchronously controlled, in other words, when the bending angle needs to be adjusted, the distance between the two adjusting supports can be adjusted and controlled, and compared with a traditional adjusting manner, controllability is better achieved.

Owner:马鞍山力森金属结构有限公司

Electric control door opening and closing auxiliary device

ActiveCN112761426AReduce springbackEasy to lock actionBuilding braking devicesBuilding locksStructural engineeringElectric control

The invention relates to an electric control door opening and closing auxiliary device. The device comprises a door body and a frame body, a through hole matched with the door body is formed in the side face of the frame body, the door body covers the through hole through a hinge arranged between the door body and the frame body, a trigger assembly is arranged on the side, away from the hinge, of the frame body, an inserting groove is formed in the side, away from the hinge, of the frame body, the door body is provided with a linkage assembly and a locking assembly, the linkage assembly is connected with the locking assembly, and when a door is closed, the door body moves and is abutted against the trigger assembly, the trigger assembly moves and is abutted against the linkage assembly, and the linkage assembly synchronously moves and drives the locking assembly to be screwed into the inserting groove. The electric control door opening and closing auxiliary device has the effect of conveniently locking an electric control door.

Owner:广州市巨安人防工程有限公司

A kind of preparation method of bamboo slice homogenization bamboo tableware

ActiveCN114407160BAddressing differences in carrying capacitySolve crackingWood compressionWood treatment detailsVascular bundleComposite material

Owner:ZHEJIANG FORESTRY ACAD

Stamping die for front suspension left-right upper bracket inner side plate

PendingCN111014461AStable jobImprove accuracy and efficiencyShaping toolsStructural engineeringManufacturing engineering

The invention discloses a stamping die for a front suspension left-right upper bracket inner side plate, which comprises an upper die holder and a lower die holder, wherein an upper base plate is arranged on the upper die holder, an upper die plate is arranged on the upper base plate, a stamping column is arranged on an upper side edge of the upper die holder, a guide column is arranged at an upper end of the upper base plate, and a stamping rod is arranged on the upper die plate; a lower base plate is arranged on the lower die holder, a lower die plate is arranged on the lower base plate, anda butt-joint plate, arranged on the lower base plate, is covered on the outer side of the lower die plate. The stamping die for the front suspension left-right upper bracket inner side plate is stable in work in stamping, the product forming precision and efficiency can be effectively improved, and the product resilience phenomenon can be reduced; the rejection rate is low, the production can bereduced, and the enterprise economic benefit can be improved; a symmetric structure can reduce the pressure of the stamping and reduce the abrasion of the die; and different die structures meet different structure requirements, the use diversity is improved, the structure is compact, the design is reasonable, and the stamping space is increased.

Owner:十堰帝尔科技有限公司

A Small Fast Compressor Based on Electromagnetic Control

ActiveCN110905764BSimple and fast operationSave time and costInternal combustion piston enginesPump controlCombustion chamberEngineering

The invention discloses a small fast compressor based on electromagnetic control, which is mainly composed of a main combustion chamber system, a power system and an electromagnetic control circuit. The main combustion chamber system consists of a gland and a two-layer sleeve, and heat transfer oil flows through the gap between the two sleeves to heat the combustion chamber. The power system includes a cylinder block, a power cylinder gland, a brake ring, a power piston, a drive ring and a laser distance sensor. The laser ranging sensor measures the distance through the center hole of the power cylinder gland, and thereby realizes the control of the compression process. The electromagnetic control circuit includes a DC power supply, a sliding rheostat and five switches. The DC power supply provides current; the sliding rheostat is used to adjust the circuit current, thereby changing the magnitude of the electromagnetic force between the coils; the three switches are used as on-off switches for the circuit, and the other two Together as a switch, they are responsible for changing the direction of the current flow in the coil, thereby changing the direction of the electromagnetic force. The fast compressor of the present invention has a simpler and more compact structure and a more efficient working process.

Owner:TIANJIN UNIV

Control Method Based on Fast Compressor Electromagnetic Braking System

Owner:TIANJIN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com