Small quick compressor based on electromagnetic control

A technology of electromagnetic control and electromagnetic control circuit, which is applied in the direction of pump control, mechanical equipment, combustion engine, etc., can solve the problems of slow warm-up, uneven heating, etc., and achieve the effect of enhancing persuasion, uniform temperature gradient, and reducing time cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the following embodiments in no way limit the present invention.

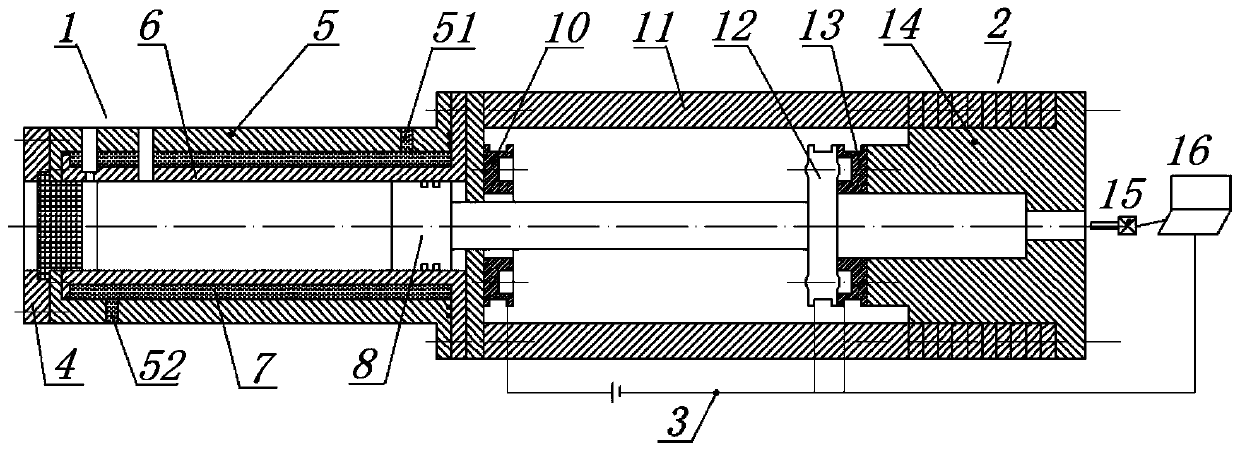

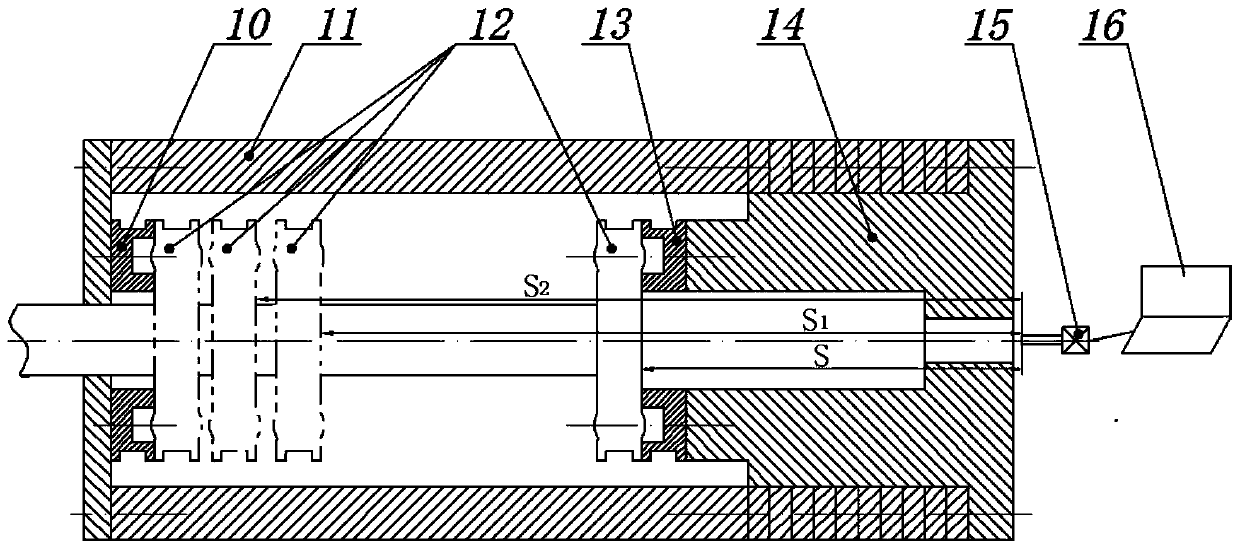

[0033] Such as figure 1 As shown, a small fast compressor based on electromagnetic control proposed by the present invention includes a main combustion chamber system 1 , a power system 2 and an electromagnetic control circuit 3 .

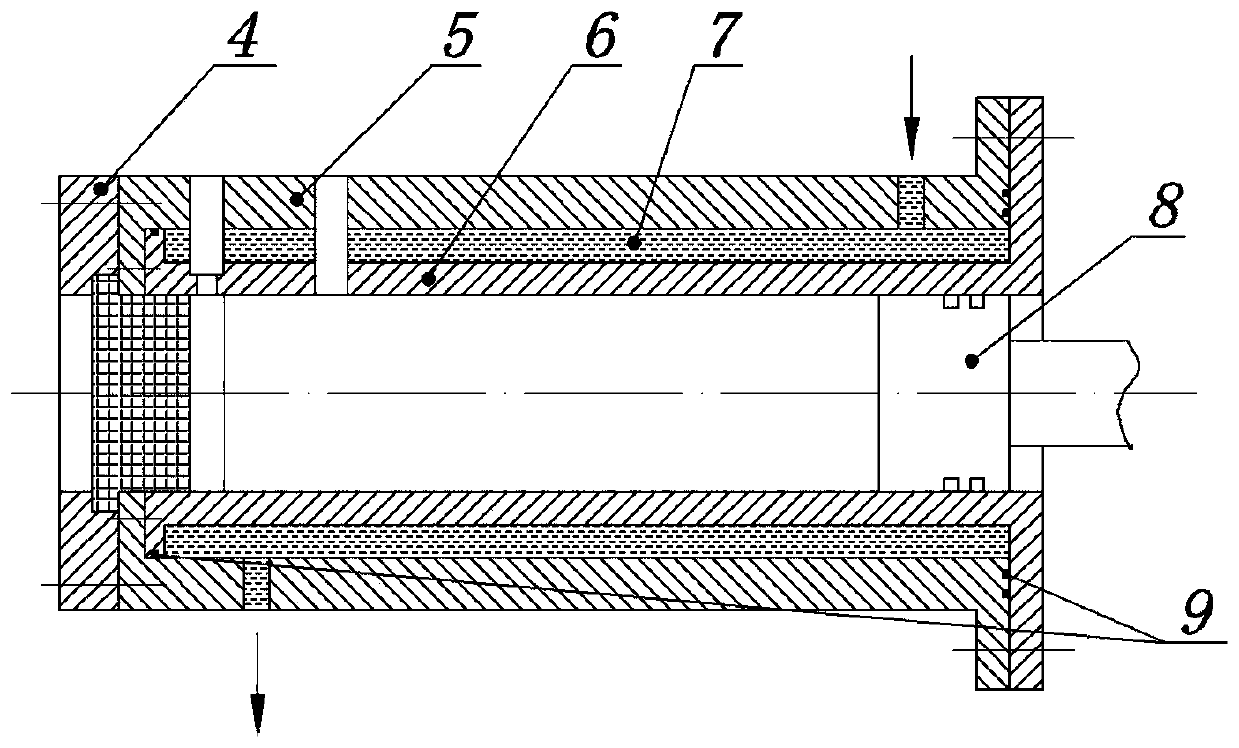

[0034] Such as figure 1 and figure 2 As shown, the main combustion chamber system 1 includes a combustion chamber gland 4, a cylinder and a compression piston 8, and the cylinder block 11 of the cylinder is composed of an outer sleeve 5 and an inner sleeve 6 nested in each other. There is a radial gap between the sleeve 5 and the inner sleeve 6, and the gap is 5±0.5mm, thereby forming an annular space; one end of the outer sleeve 5 is provided with an oil inlet hole 51, The other end of the outer sleeve is provided with an oil outlet hole 52, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com