Shock hydraulic composite forming process for small feature part of complex part

A technology of complex parts and composite forming, applied in the field of metal plastic forming, can solve the problems of waste of resources, affecting the overall performance of parts, scrapping large parts, etc., achieving broad application prospects and ensuring the effect of forming quality and accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

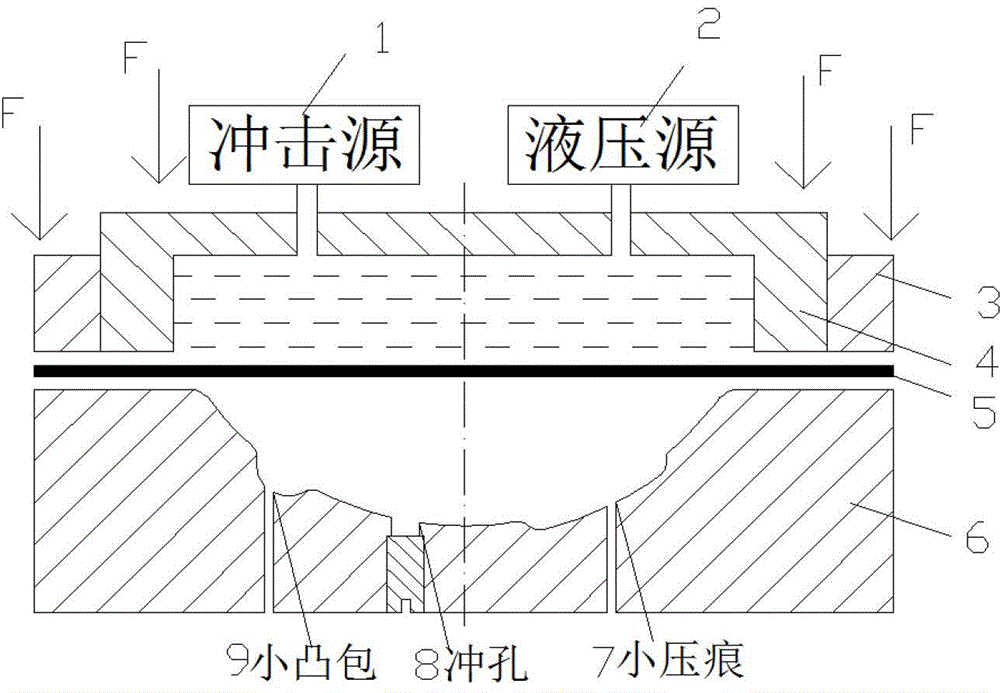

[0018] The impact hydraulic composite forming process for the small feature parts of complex parts provided by the present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

[0019] like figure 1 As shown, the impact hydraulic composite forming process for small feature parts of complex parts provided by the present invention includes the following steps in sequence:

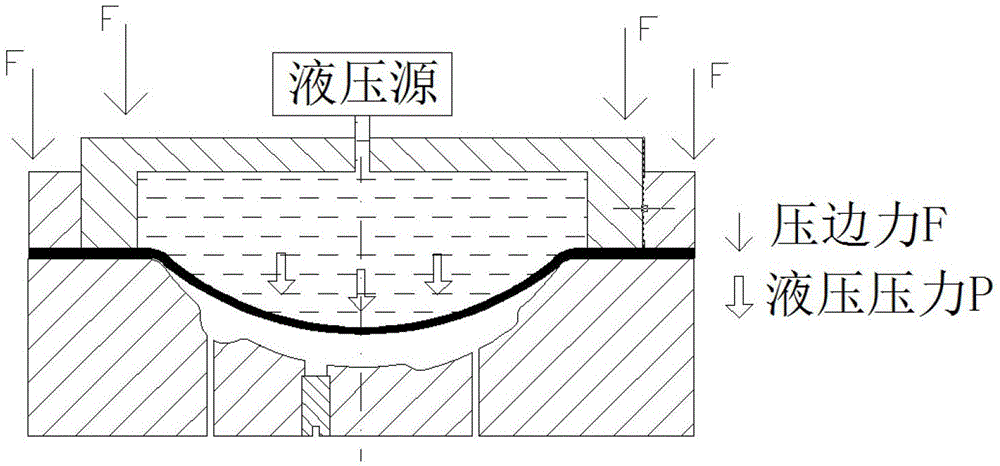

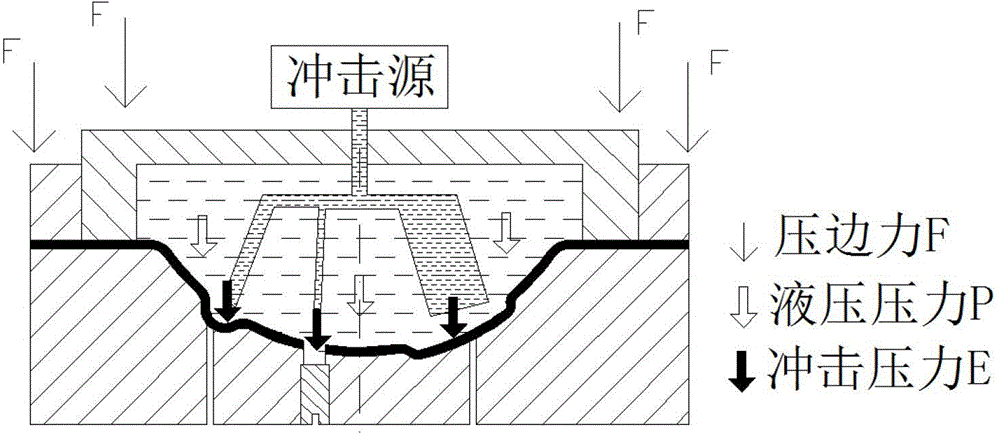

[0020] 1) If the formed part is a plate, the plate 5 is used as the blank, the blank holder 3 presses the plate 5 on the plate forming die 6, and the plate forming liquid chamber 4 is lowered for clamping and sealing. The plate forming liquid chamber 4 is filled with high pressure medium by the high pressure hydraulic pressure source 2, and the pressure is maintained for 2-5min to carry out the liquid filling forming. Under the action of high-pressure liquid pressure, the plate 5 undergoes elastic-plastic deformation according to the shape of the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com