Stamping die for front suspension left-right upper bracket inner side plate

A stamping die and stamping column technology, which is applied in the field of stamping dies for the inner side panels of the left and right upper brackets of the front suspension, can solve the problems of affecting the service life of the dies, high pressure of the upper and lower dies, and low stability, and achieves compact structure, reduced stamping pressure, Improve the effect of using diversity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

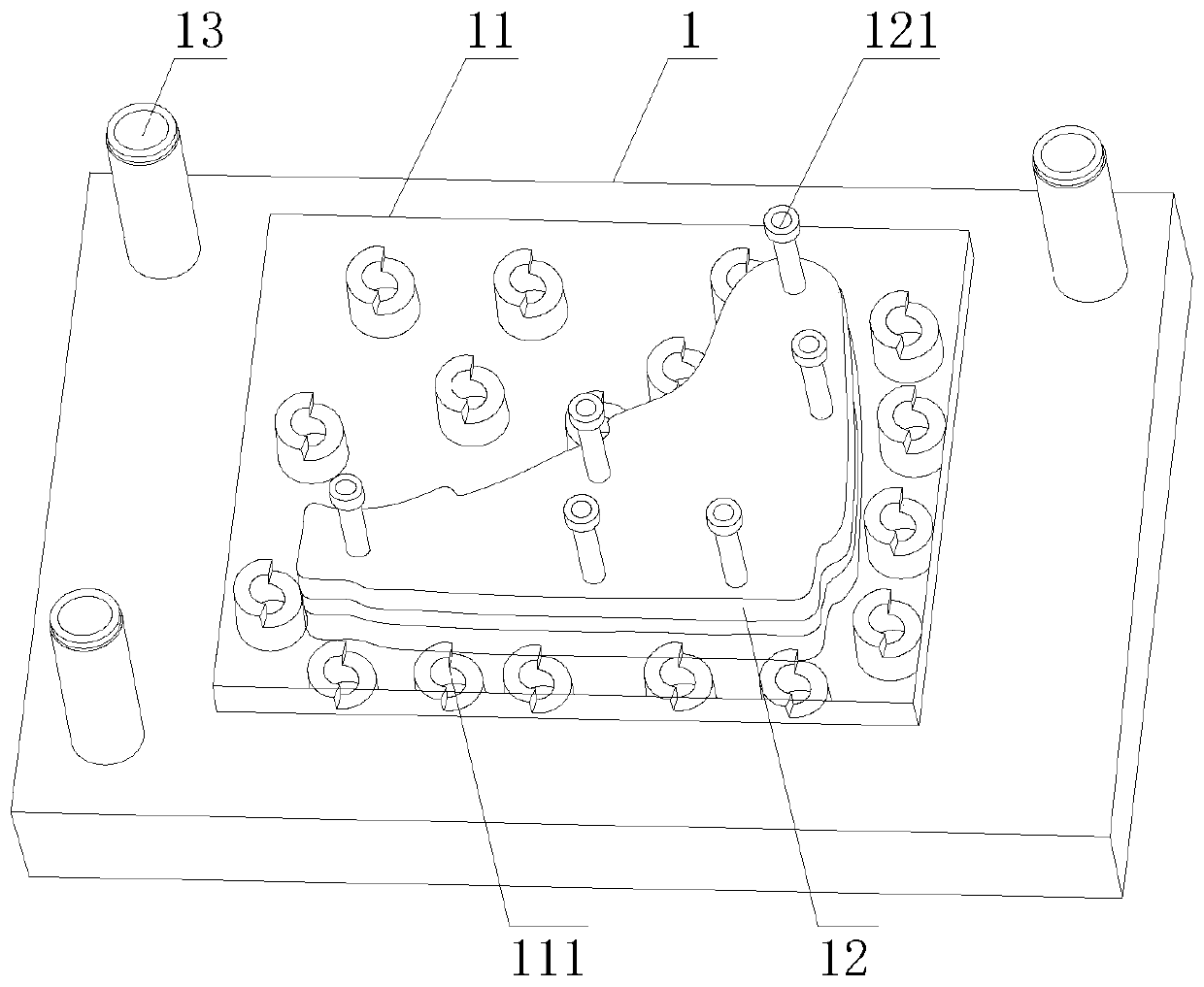

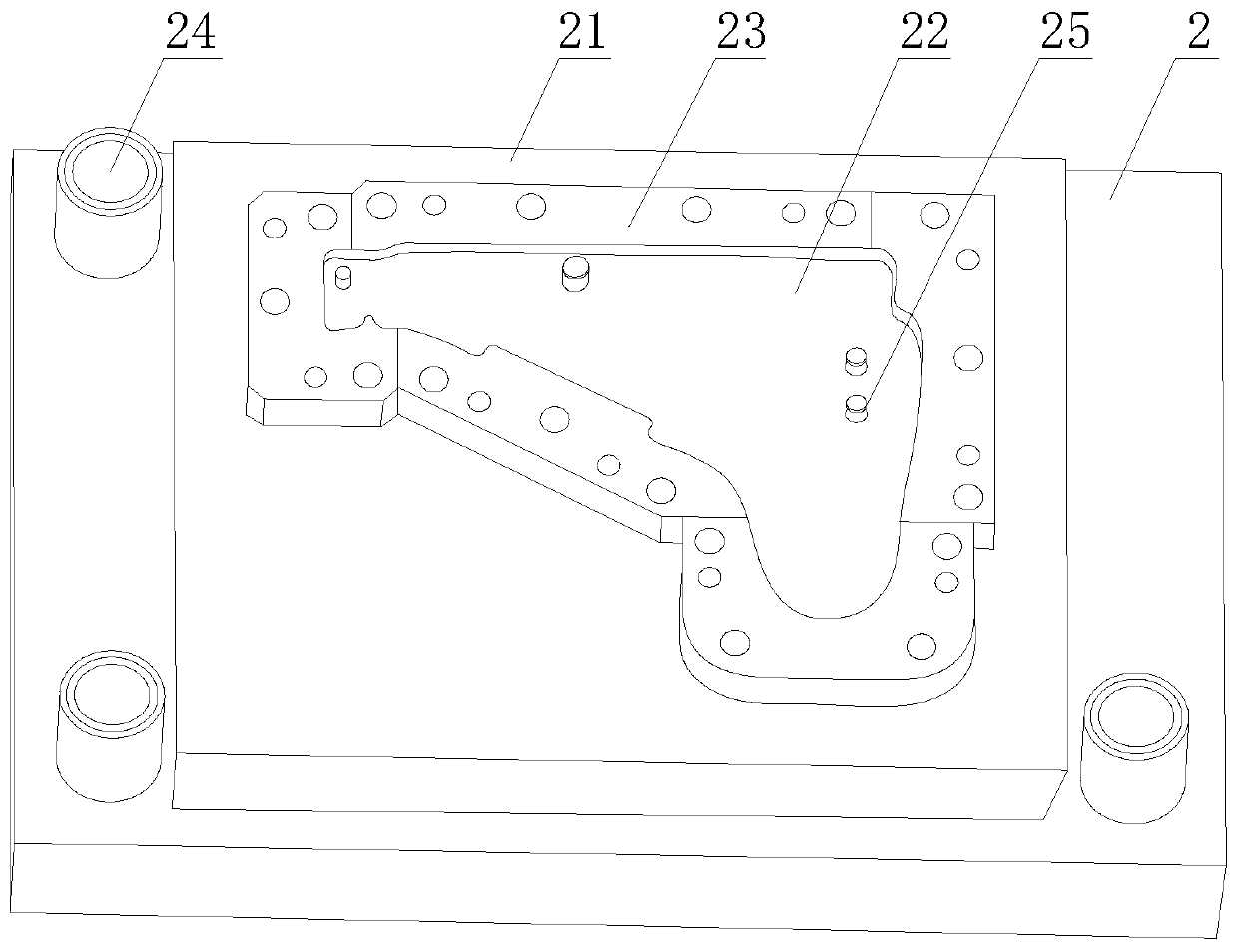

[0023] see Figure 1-2 , a stamping mold for the inner side plate of the left and right upper brackets of the front suspension, comprising an upper die base 1 and a lower die base 2, an upper backing plate 11 is installed on the upper die base 1, an upper template 12 is connected to the upper backing plate 11, and an upper die base 1 is The stamping column 13 is installed on the side, the upper end of the upper backing plate 11 is provided with a guide column 111, the upper template 12 is provided with a stamping rod 121, the lower backing plate 21 is installed on the lower mold base 2, the lower template 22 is installed on the lower backing plate 21, and the outer side of the lower template 22 Cover the butt plate 23, the butt plate 23 is installed on the lower backing plate 21, the guide hole 24 is set on the lower mold base 2, the guide hole 24 is set on the butt plate 23, the punching groove 25 is set on the lower template 22, and the upper backing plate 11 passes through ...

Embodiment 2

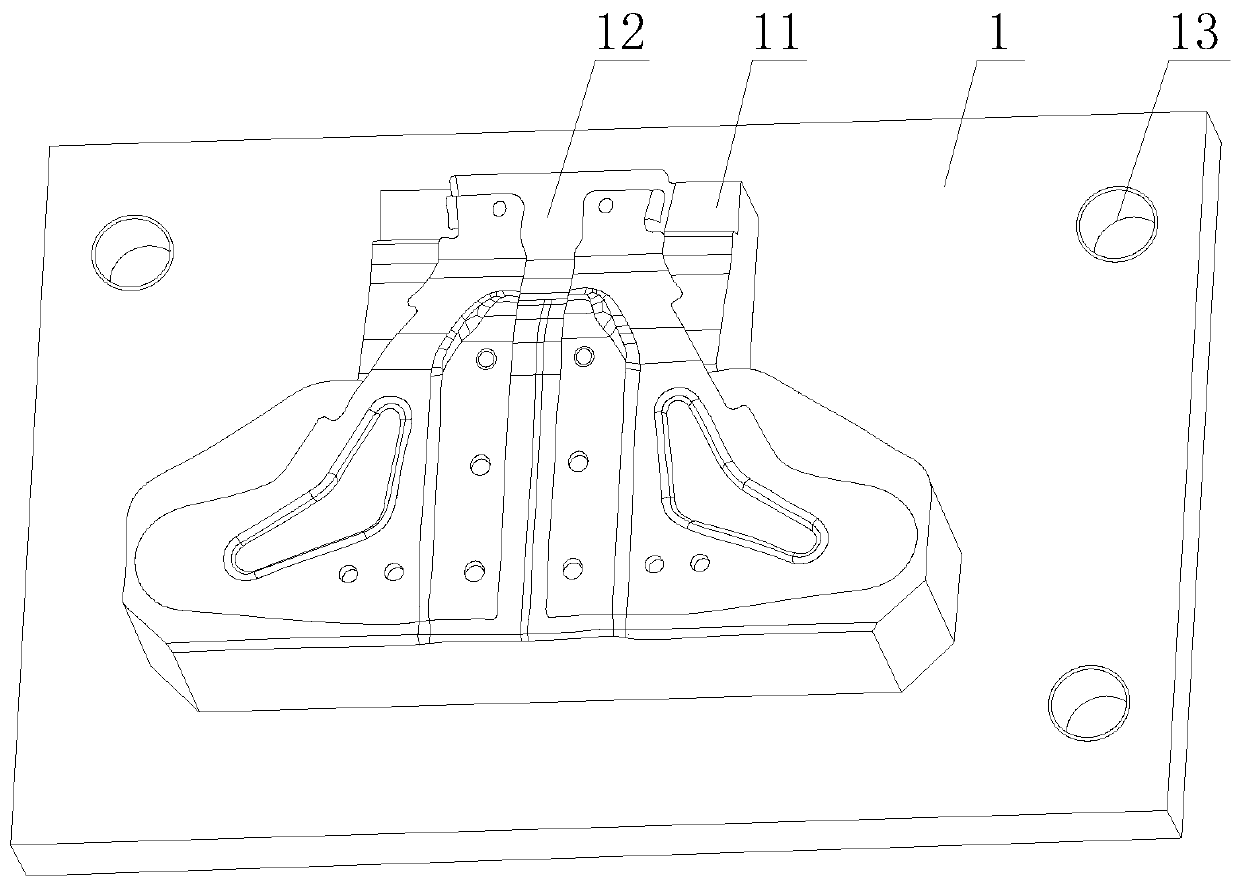

[0025] see Figure 3-4 , the structure of the upper formwork 12 and the lower formwork 22 is a T-shaped symmetrical structure, and the upper formwork 12 is arranged in the upper backing plate 11, two pairs of triangular grooves are opened on the upper formwork 12, and the upper formwork 12 and the lower formwork 22 of the symmetrical structure , The symmetrical structure reduces the stamping pressure and reduces the wear of the mold, and different mold structures meet the needs of different structures and increase the diversity of use.

Embodiment 3

[0027] see Figure 5-6 , the upper backing plate 11, the upper formwork 12 and the lower formwork 22 are half-angle structures, and are all arranged at the opposite corners of the upper mold base 1, and the butt plate 23 covers the lower formwork 22 and the lower backing plate 21 inside, and the butt plate 23 is provided with a docking groove, and the upper backing plate 11 and the upper template 12 are docked with the docking groove. By covering the upper backing plate 11 and the upper template 12 with the butt plate 23 for guidance, the overall structure of the guide column 111 is reduced, which is more convenient and compact. Reasonable design, increase punching space.

[0028] To sum up: in the present invention, the stamping mold for the inner side plate of the left and right upper brackets of the front suspension, the height of the lower template 22 is lower than the butt plate 23, and the butt plate 23 wraps the butt plate 23 inside to form a lower die groove 221. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com