Control Method Based on Fast Compressor Electromagnetic Braking System

A technology of electromagnetic braking and control methods, which is applied in the direction of engine testing, machine/structural component testing, instruments, etc., can solve the problems of experimental result deviation, thermodynamic state change, piston rebound, etc., and reduce the phenomenon of piston rebound , reduce braking noise, and the experimental data is accurate and reliable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to this specific embodiment, and this description is not intended to limit the present invention.

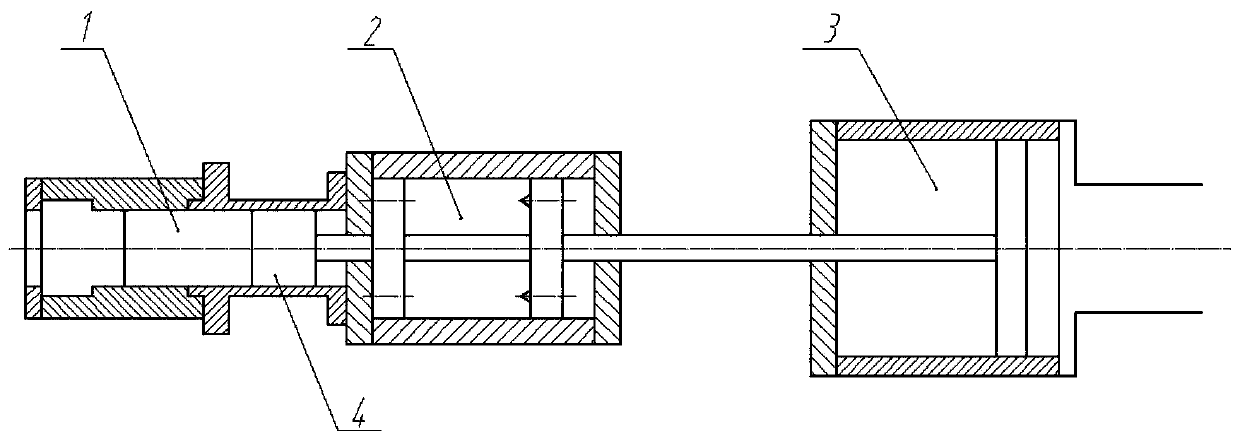

[0022] Such as figure 1 As shown, it is a structural schematic diagram of a fast compressor adopting the electromagnetic braking system of the present invention, including a combustion device 1 , an electromagnetic braking system 2 , a driving device 3 and a piston 4 .

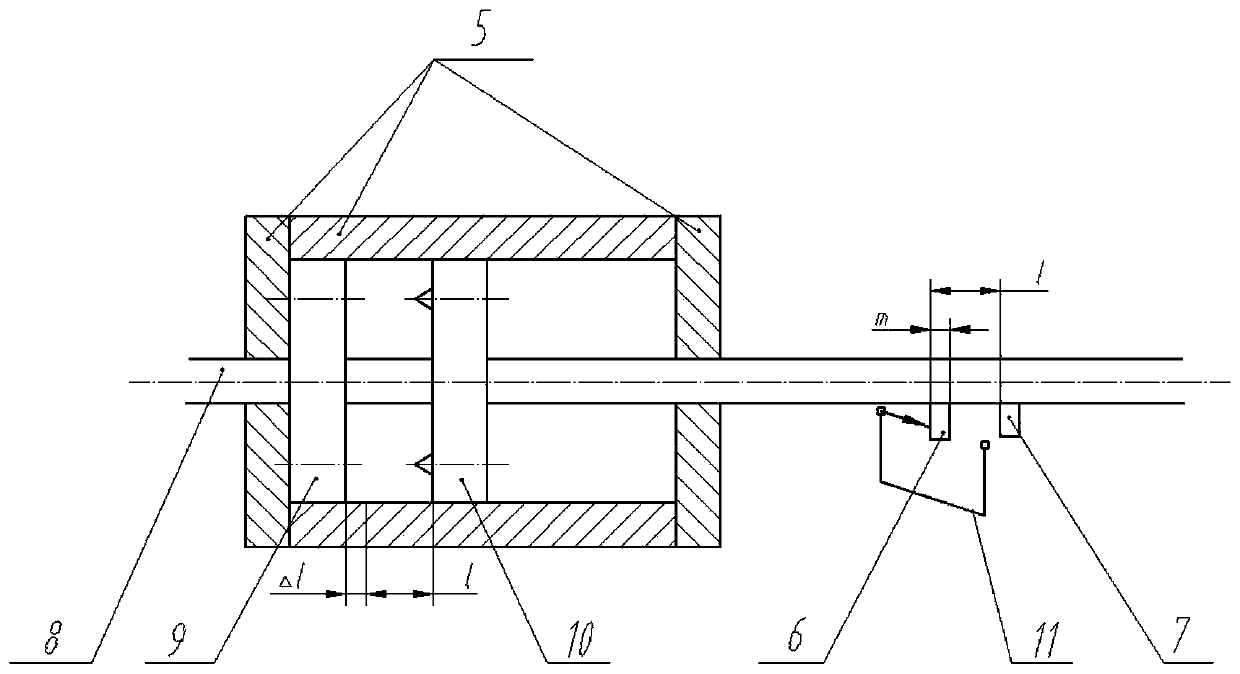

[0023] figure 2 It is a structural schematic diagram of the electromagnetic braking system of the present invention. It consists of a brake cylinder 5 made of magnetic isolation material, a push rod 8 passing through the brake cylinder, an electromagnetic brake ring 9 fixed on the brake cylinder 5 and an electromagnetic brake piston 10 fixed on the push rod 8 And two light-shielding plates 6,7 and the pho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com