Steel plate bending device for lap joint of steel structure parts

A bending device and steel structure technology, which is applied in the field of steel plate bending devices for lap joints of steel structure parts, can solve problems such as prone to springback, inability to ensure the bending effect, and affect use, so as to achieve bending state optimization, Controllable, quality-assured effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

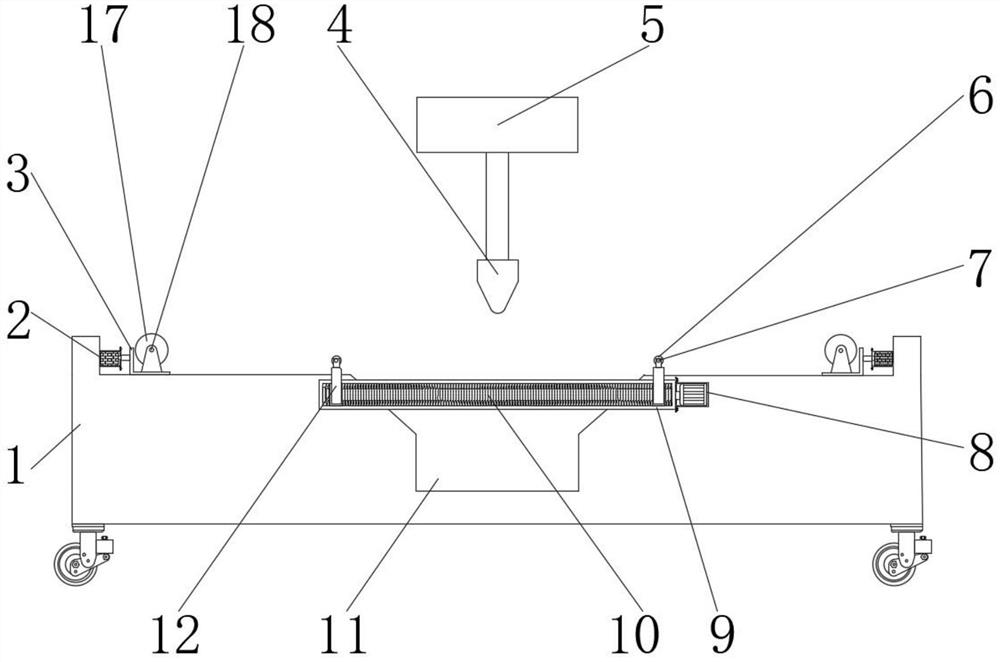

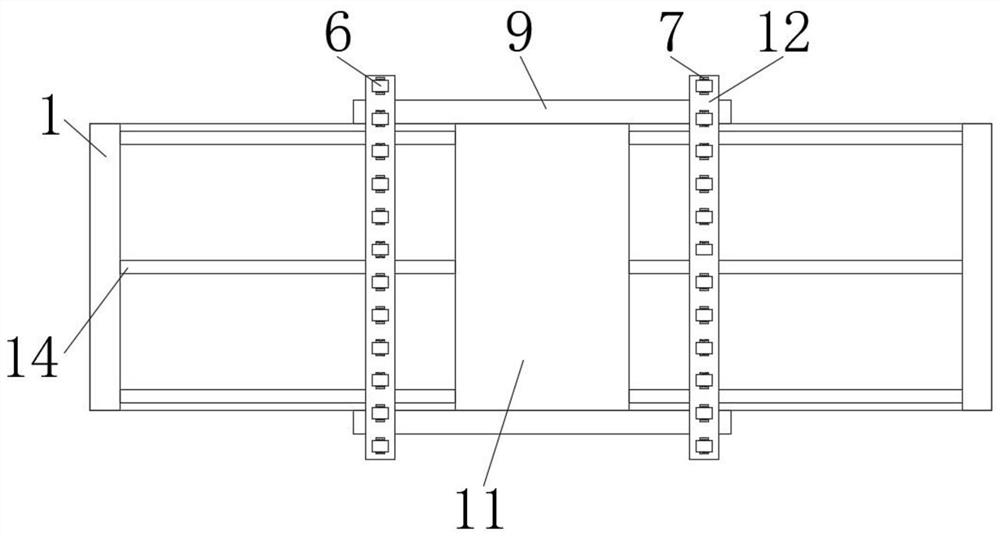

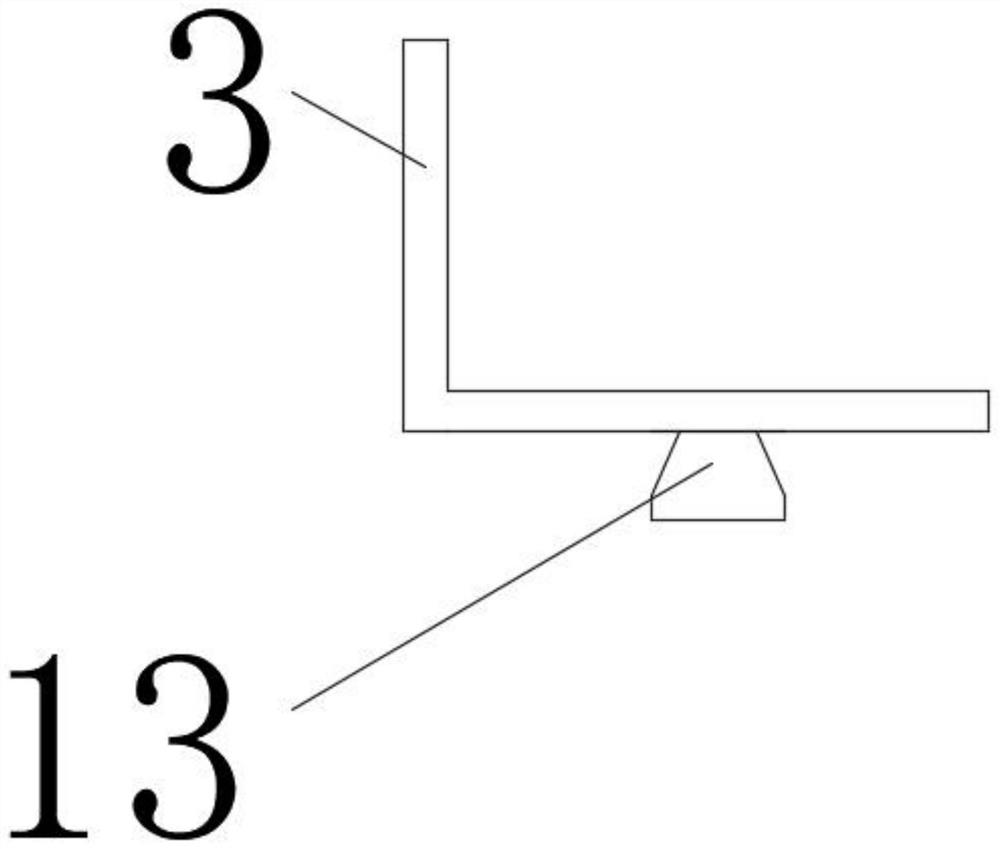

[0027] Such as Figure 1-5 As shown, the embodiment of the present invention provides a steel plate bending device for overlapping steel structure parts, including a bending table 1, two brake cylinders 2, a punch driving cylinder 5, a bending punch 4 and a servo motor 8 , the inside of the bending workbench 1 is provided with a steel plate bending groove 11, the front and rear side walls of the bending workbench 1 are fixedly connected with fixed installation boxes 9, and the insides of the two fixed installation boxes 9 are provided with adjusting threaded rods 10 One end of the adjusting threaded rod 10 is rotationally connected with the inner side wall of the fixed installation box 9 through a bearing, the other end of the adjusting threaded rod 10 is fixedly connected with the output end of the servo motor 8, and both sides of the steel plate bending groove 11 are provided with adjustable Bracket 12, both ends of the two adjustable brackets 12 extend through the outer wal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com