Patents

Literature

32results about How to "Improve thermoforming performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for Producing a Hardened Steel Part

ActiveUS20070256808A1Surprising effectEfficient productionHot-dipping/immersion processesFoundry mouldsAlloyProtection layer

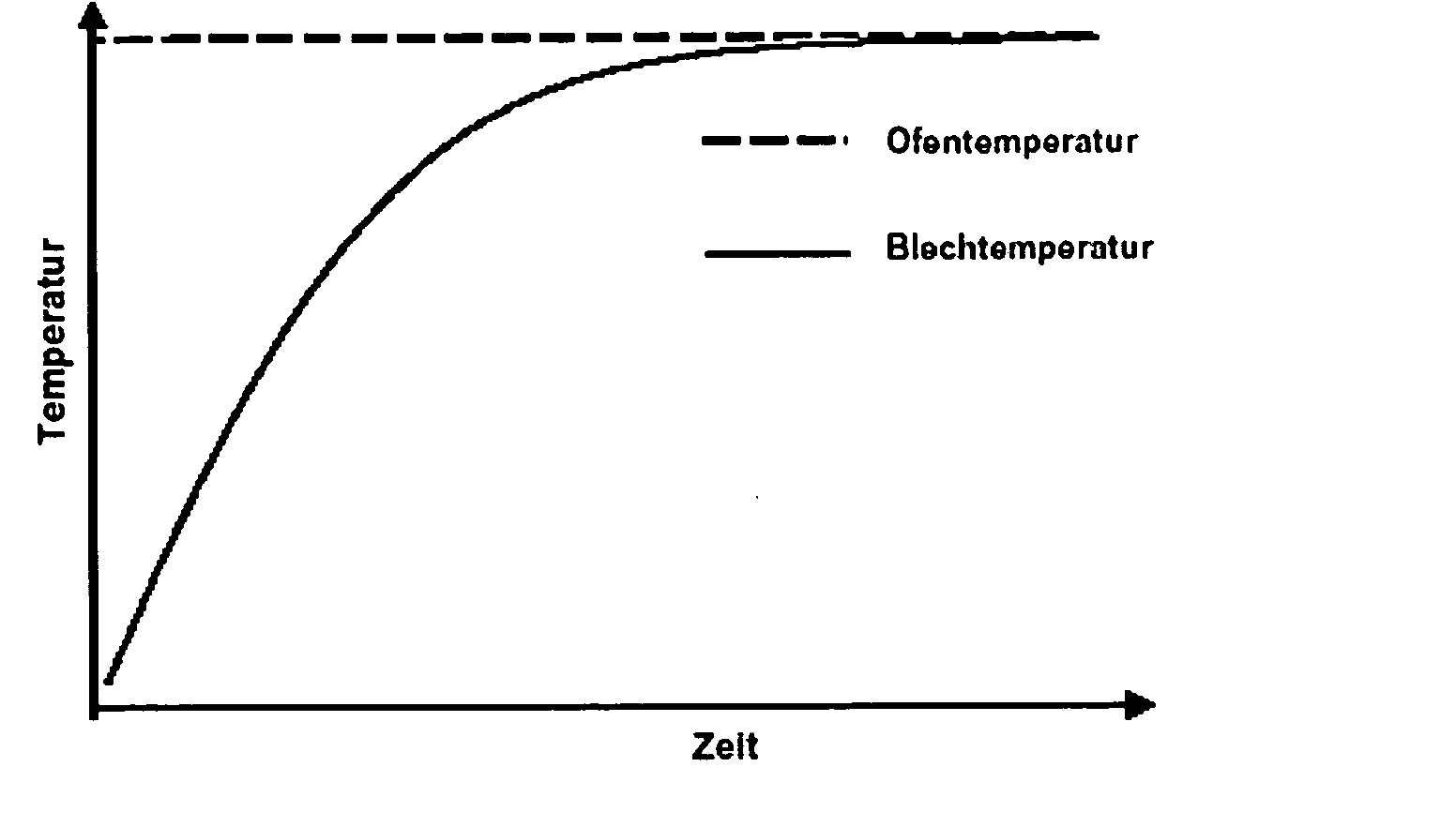

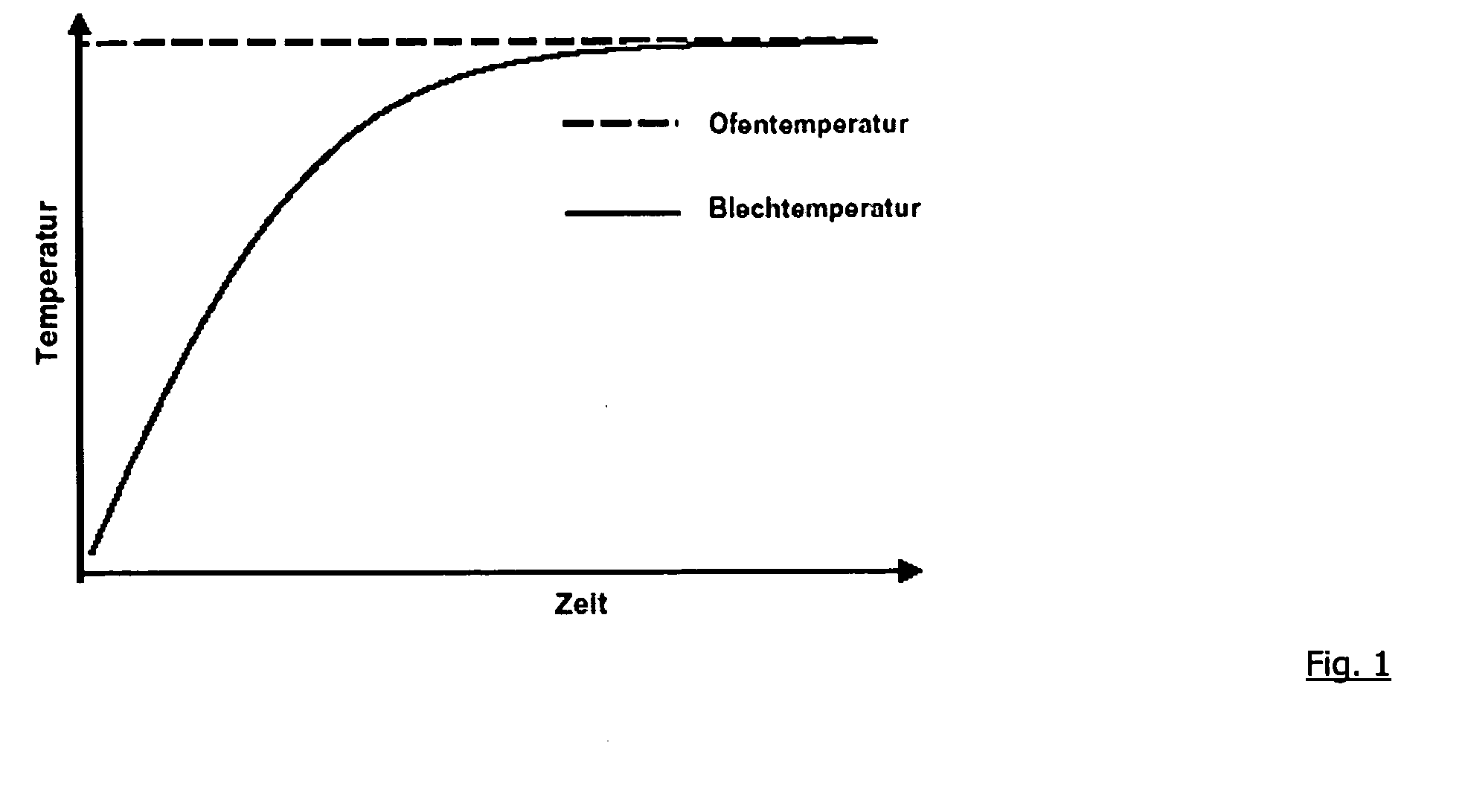

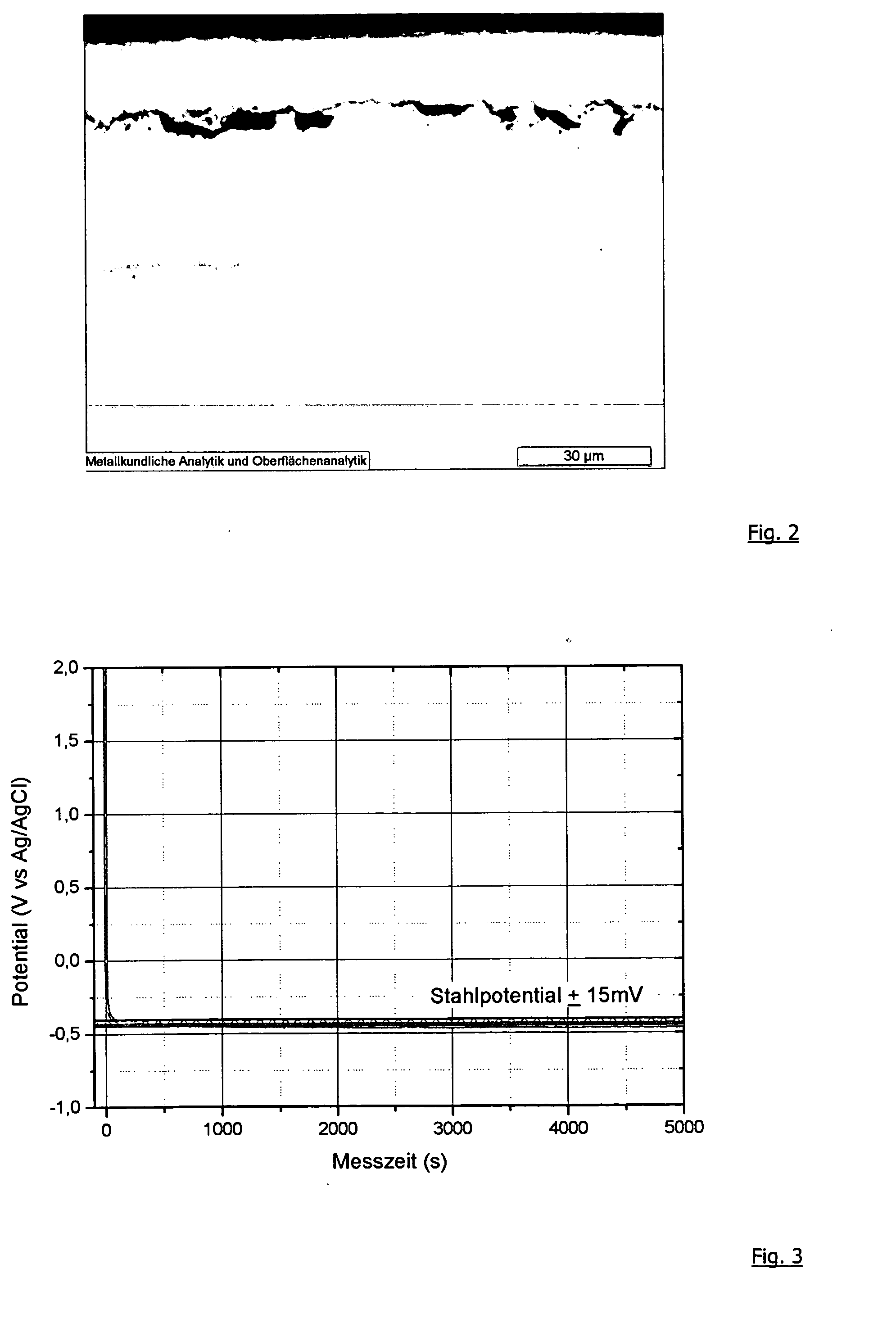

The invention relates to a method for producing a hardened steel part having a cathodic corrosion protection, whereby a) a coating is applied to a sheet made of a hardenable steel alloy in a continuous coating process; b) the coating is essentially comprised of zinc; c) the coating additionally contains one or more oxygen-affine elements in a total amount of 0.1% by weight to 15% by weight with regard to the entire coating; d) the coated steel sheet is then, at least in partial areas and with the admission of atmospheric oxygen, brought to a temperature necessary for hardening and is heated until it undergoes a microstructural change necessary for hardening, whereby; e) a superficial skin is formed on the coating from an oxide of the oxygen-affine element(s), and; f) the sheet is shaped before or after heating, and; g) the sheet is cooled after sufficient heating, whereby the cooling rate is calculated in order to achieve a hardening of the sheet alloy. The invention also relates to a corrosion protection layer for the hardened steel part and to the steel part itself.

Owner:VOESTALPINE STAHL GMBH

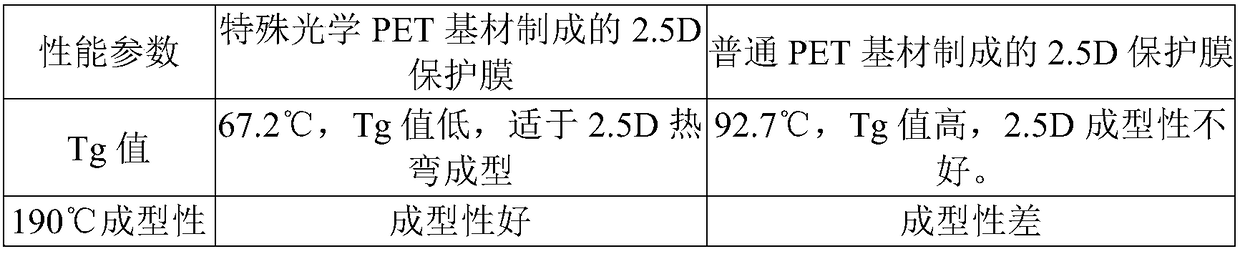

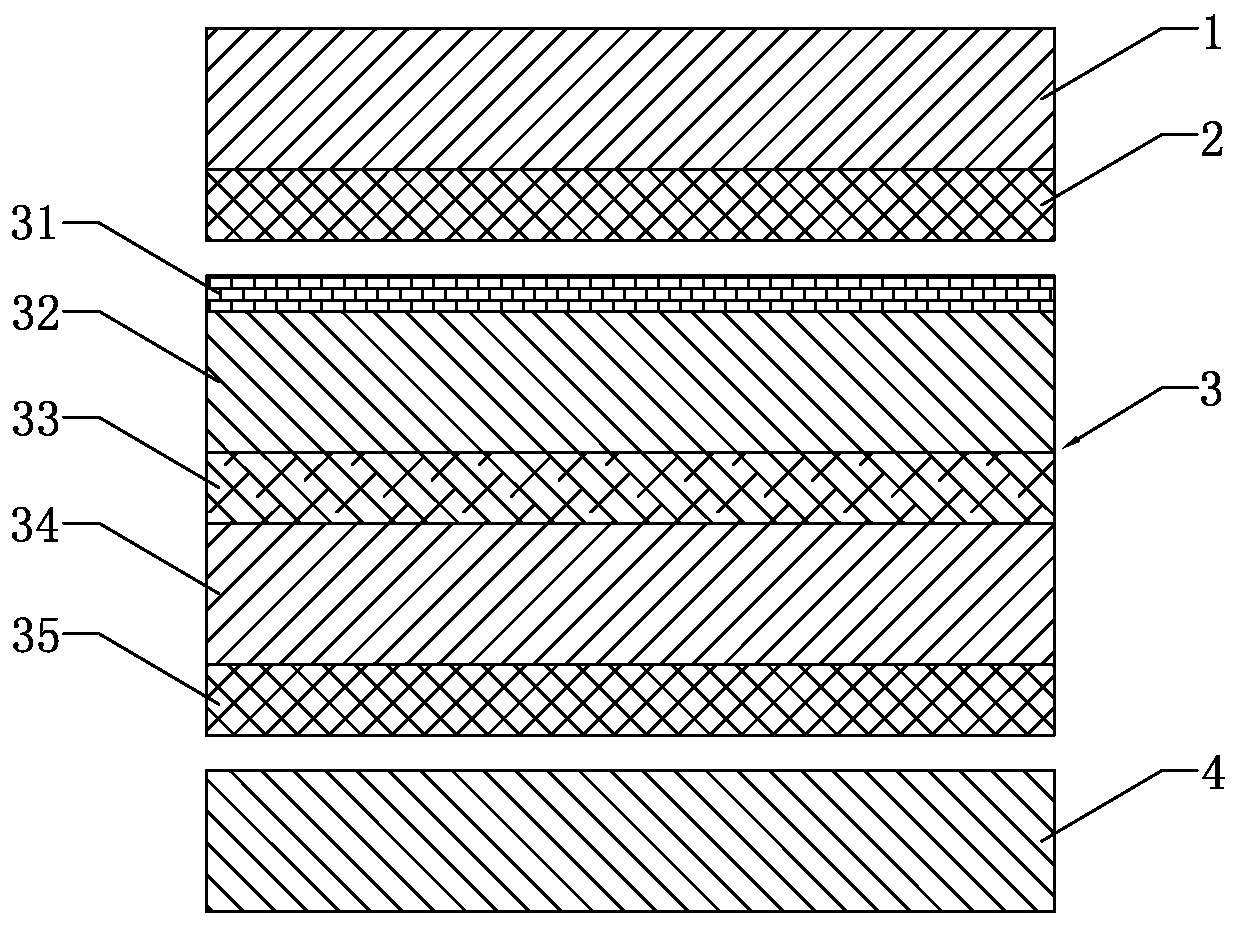

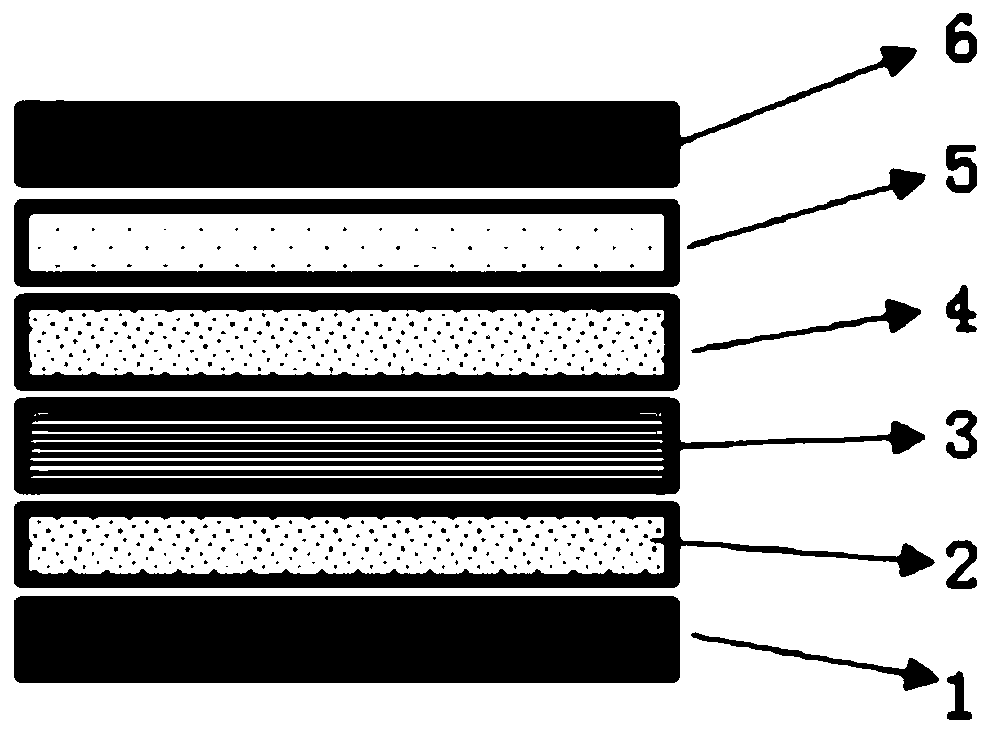

2.5D protective film and preparation method thereof

InactiveCN108192520AHigh light transmittanceLow hazePressure sensitive film/foil adhesivesTectorial membraneGlass cover

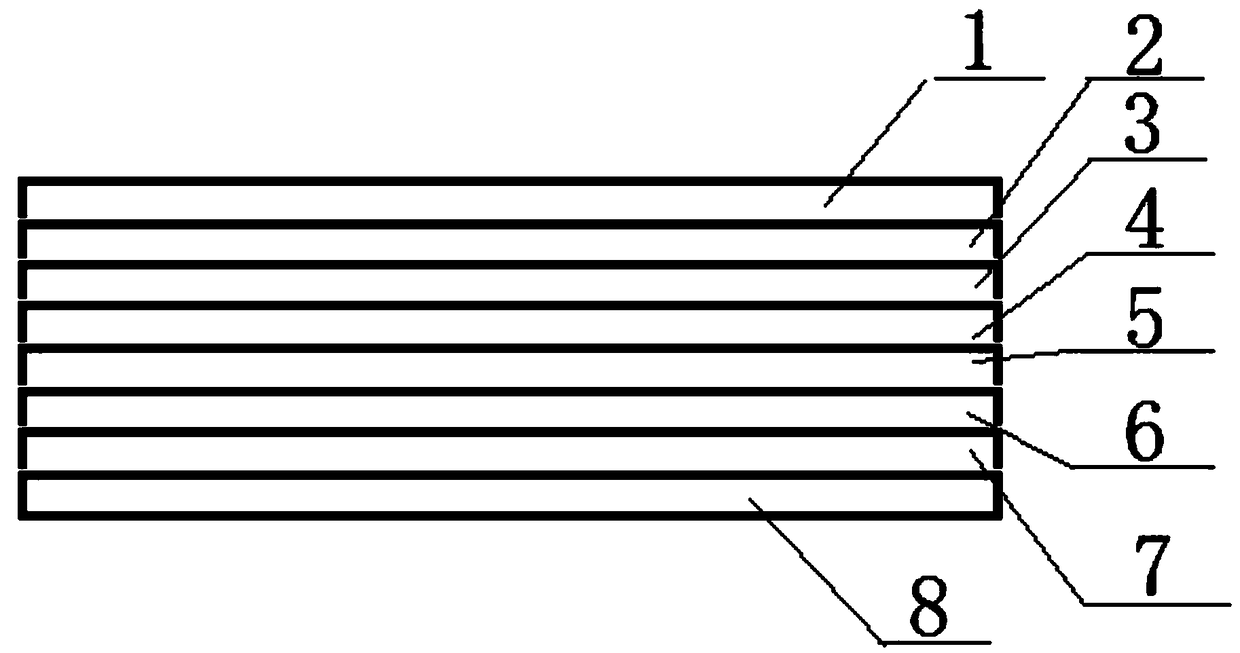

The invention provides 2.5D protective film and a preparation method thereof. The 2.5D protective film is of a multi-layer structure, and comprises a PET substrate layer, a first organosilicon pressure-sensitive adhesive protective layer, a polyacrylic resin hardened layer, a first special optical-grade PET substrate layer, an OCA optical polyacrylic adhesive layer, a second special optical-gradePET substrate layer, a second organosilicon pressure-sensitive adhesive protective layer and a PET fluorine release film layer which are adhered sequentially. The 2.5D protective film has high light transmittance, low haze and good hot press formability, and the problems of corner shelling and edge graying which are easily caused by a PC surface which is unresistant to solvents and has poor adhesion after the PC surface is adhered to a mobile phone screen are solved; the hardened layer has high wear resistance, high hardness, AF anti-fingerprint performance and AG smoothness; and organosiliconpressure-sensitive adhesive has the advantages of moderate viscosity, firm adhesion to a glass cover plate of a mobile phone and excellent gas exhausting properties; through the 2.5D protective film,perfect combination of usability and high performance is achieved.

Owner:新纶电子材料(常州)有限公司

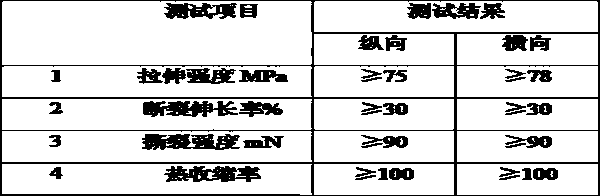

Biodegradable thermal shrinkage film and preparation method thereof

InactiveCN103483789AHigh tensile strengthMeet the basic characteristicsFlat articlesPolymer scienceAntioxidant

The invention discloses a biodegradable thermal shrinkage film. The biodegradable thermal shrinkage film is mainly prepared from the following raw materials in parts by weight: 90 to 100 parts of poly-3-hydroxybutyric acid-4 polyhydroxybutyrate or poly-3 polyhydroxybutyrate, 1 to 5 parts of aid, 2 to 5 parts of lubricating agent, 1 to 3 parts of plasticizer and 2 to 5 parts of antioxidant. The poly-3-hydroxybutyric acid-4 polyhydroxybutyrate or poly-3 polyhydroxybutyrate is a biodegradable macromolecular material and has the advantages of high mechanical strength, thermal formability, biocompatibility and the like, so that the thermal shrinkage film prepared by combining the poly-3-hydroxybutyric acid-4 polyhydroxybutyrate or poly-3 polyhydroxybutyrate with the acid, a toughening agent and thr like has high tensile strength, accords with the basic characteristics of the heat shrinkage film, can be biodegraded completely, and is an environment-friendly biological film.

Owner:太仓市鸿运包装材料有限公司

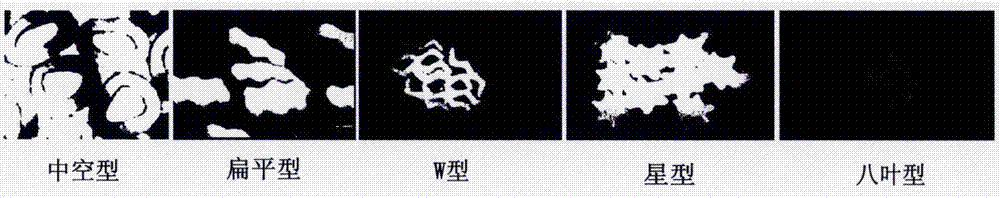

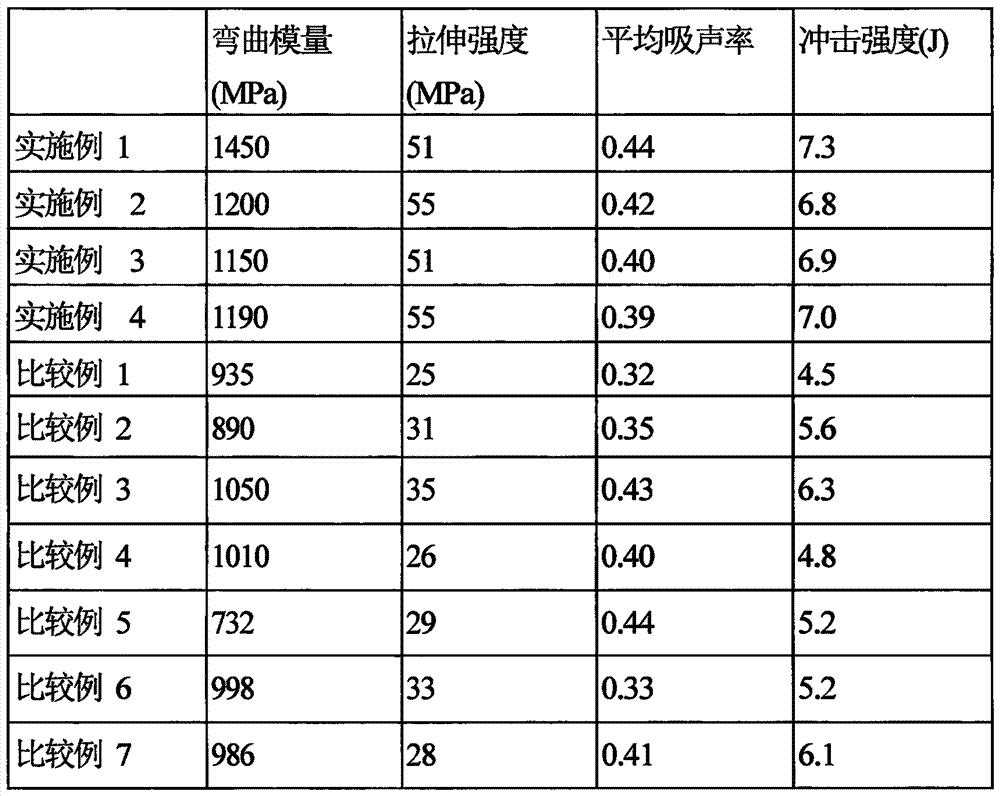

Non-woven fabric board for exterior of vehicle and method for manufacturing same

InactiveCN107313179ALarge specific surface areaImprove bonding efficiencyFilament/thread formingVehicle componentsFiberEngineering

The present invention relates to a non-woven fabric board for an exterior of a vehicle and a method for manufacturing the same. The non-woven fabric board includes: a matrix fiber having a non-circular cross-section and an adhesive fiber having non-circular cross-section. The matrix fiber may be included in an amount of about 50 wt % or greater based on the total weight of the non-woven fabric board. The matrix fiber and the adhesive fiber may have a linear density of about 6 to 15 denier and a degree of the non-circular shape of about 1.3 to 3.0. The non-woven fabric board for an exterior of a vehicle has a substantially increased specific surface area by using the non-circular cross-section fibers, improved adhesion efficiency between fibers, and substantially improved mechanical properties. In addition, heat moldability thereof is improved, weight thereof is reduced, and the sound-absorbing performance thereof is substantially improved.

Owner:HYUNDAI MOTOR CO LTD +1

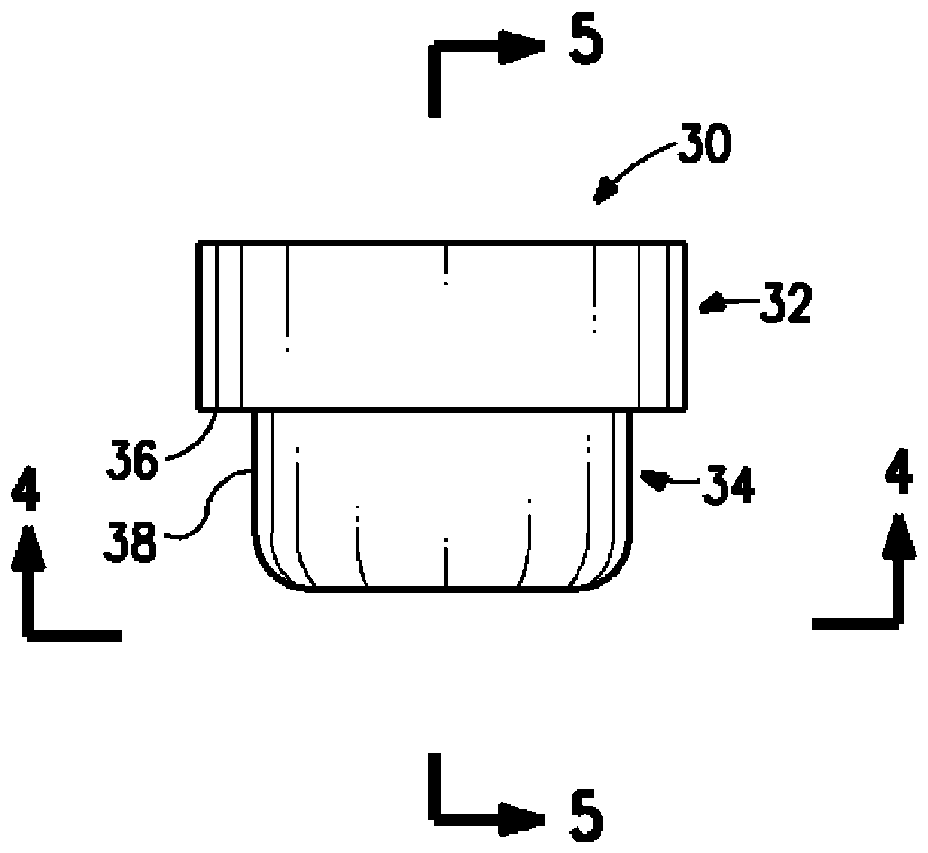

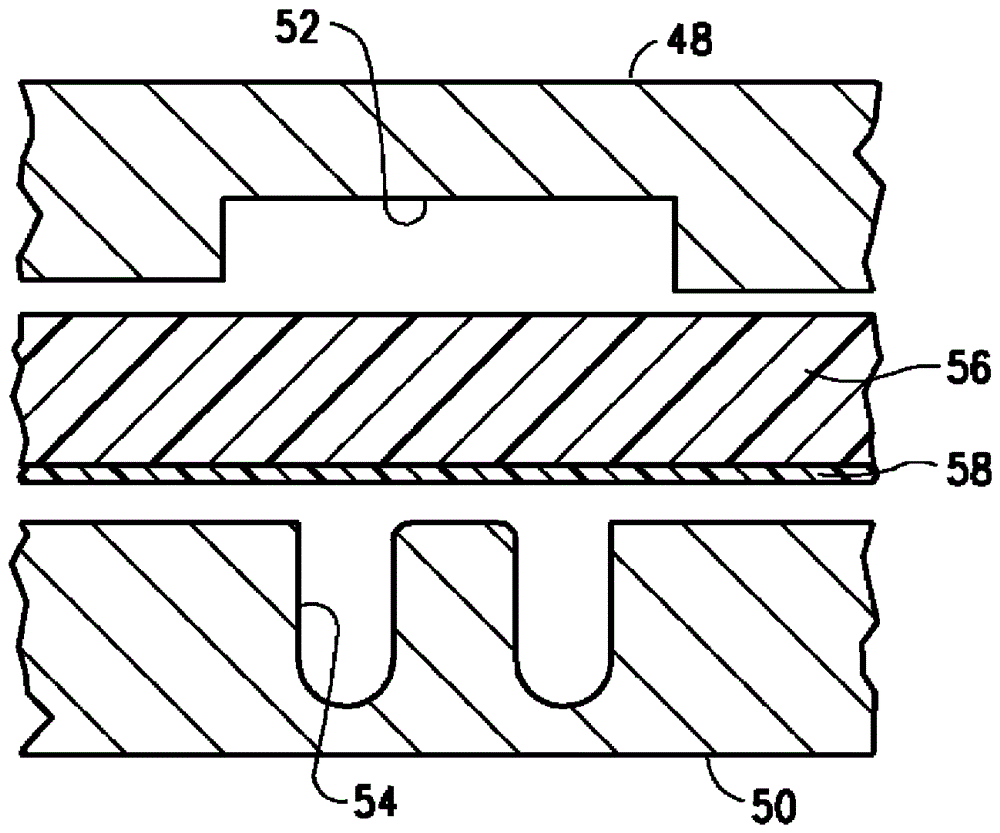

Synthetic resin laminate

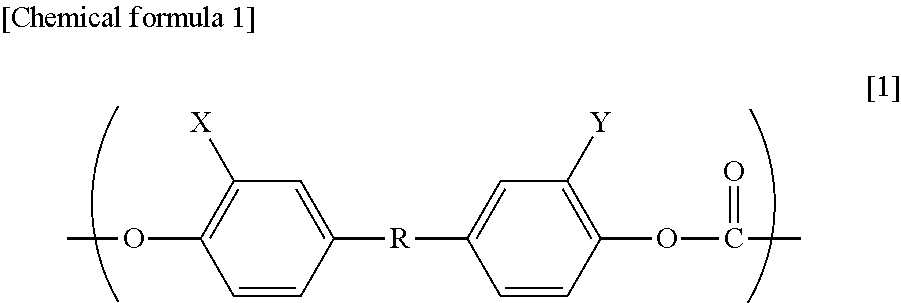

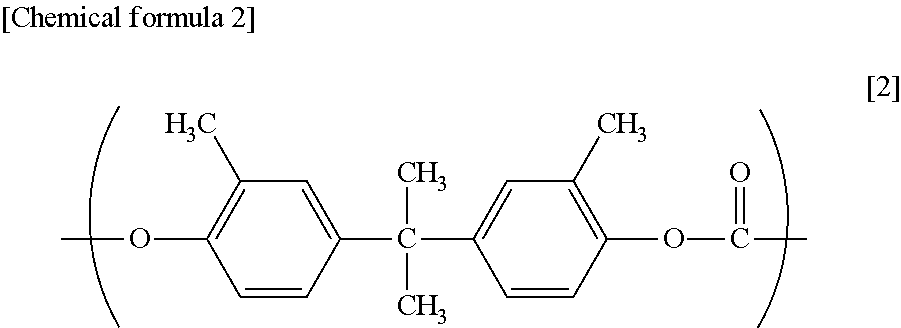

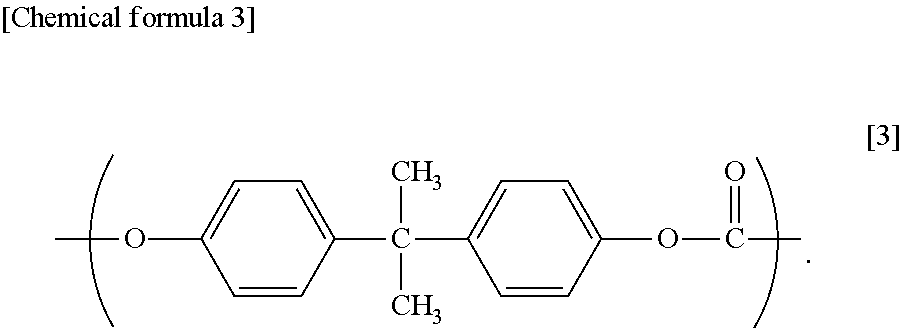

ActiveUS20150224748A1Increase flexibilityHigh surface hardnessDomestic upholsteryDecorative surface effectsPolymer alloyMeth-

The present invention has an object of providing a synthetic resin laminate that is usable for a transparent substrate material or protective material, has high thermoformability (pressure formability, thermal-bending formability), high insert moldability, and high surface hardness and / or impact resistance, and also providing a molded body formed by molding such a synthetic resin laminate. The synthetic resin laminate includes a polycarbonate-based substrate layer; and a resin laminated on one of, or both of, two surfaces of the polycarbonate-based substrate layer, the resin containing a specific (meth)acrylate copolymer resin and a specific polycarbonate resin. The polycarbonate-based substrate layer includes a polymer alloy and thus has a glass transition temperature (Tg) of 110 to 130° C. Thus, the resultant synthetic resin laminate has high thermoformability and high surface hardness.

Owner:MITSUBISHI GAS CHEM CO INC +1

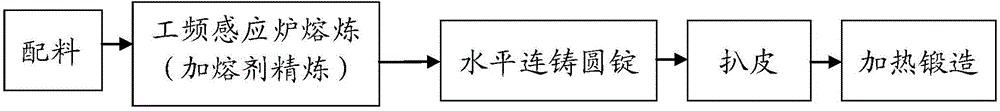

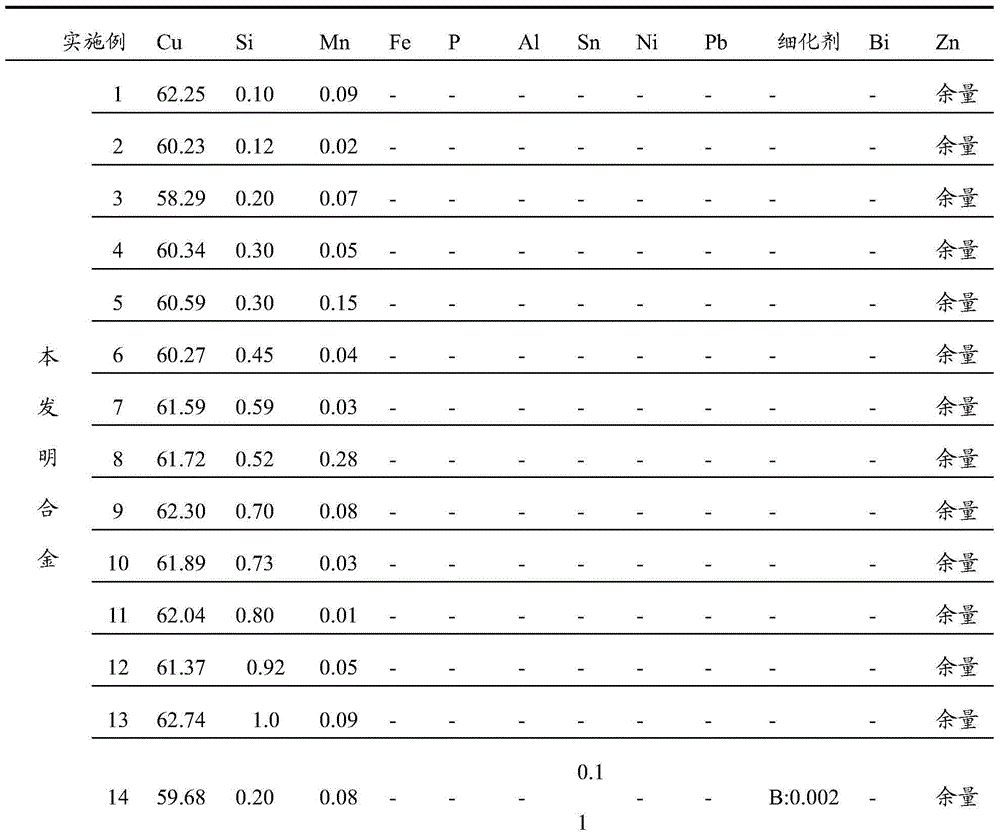

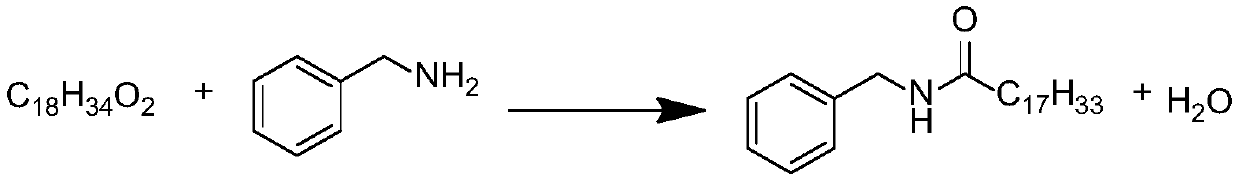

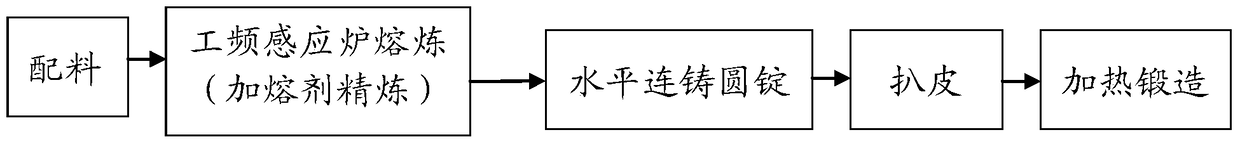

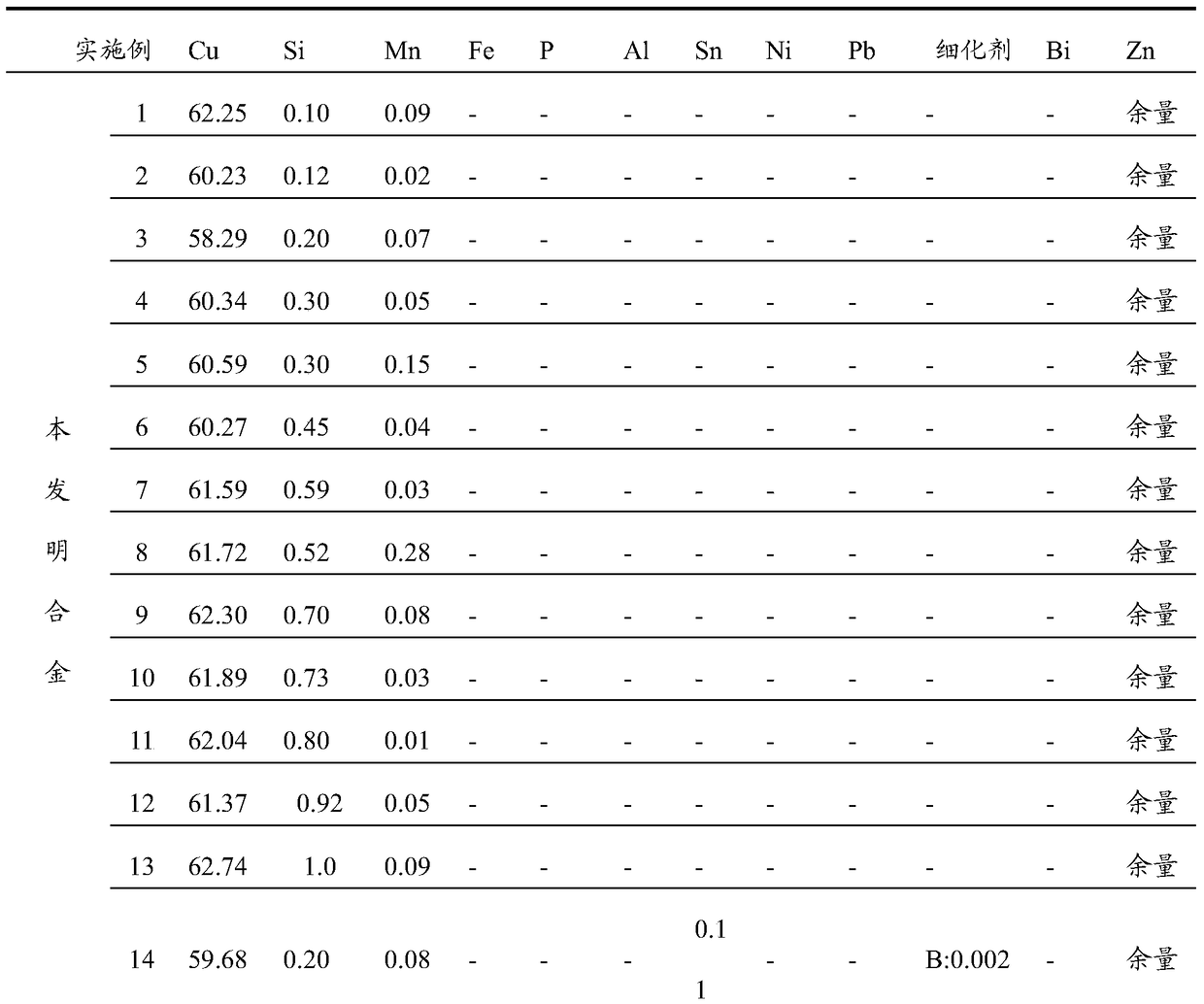

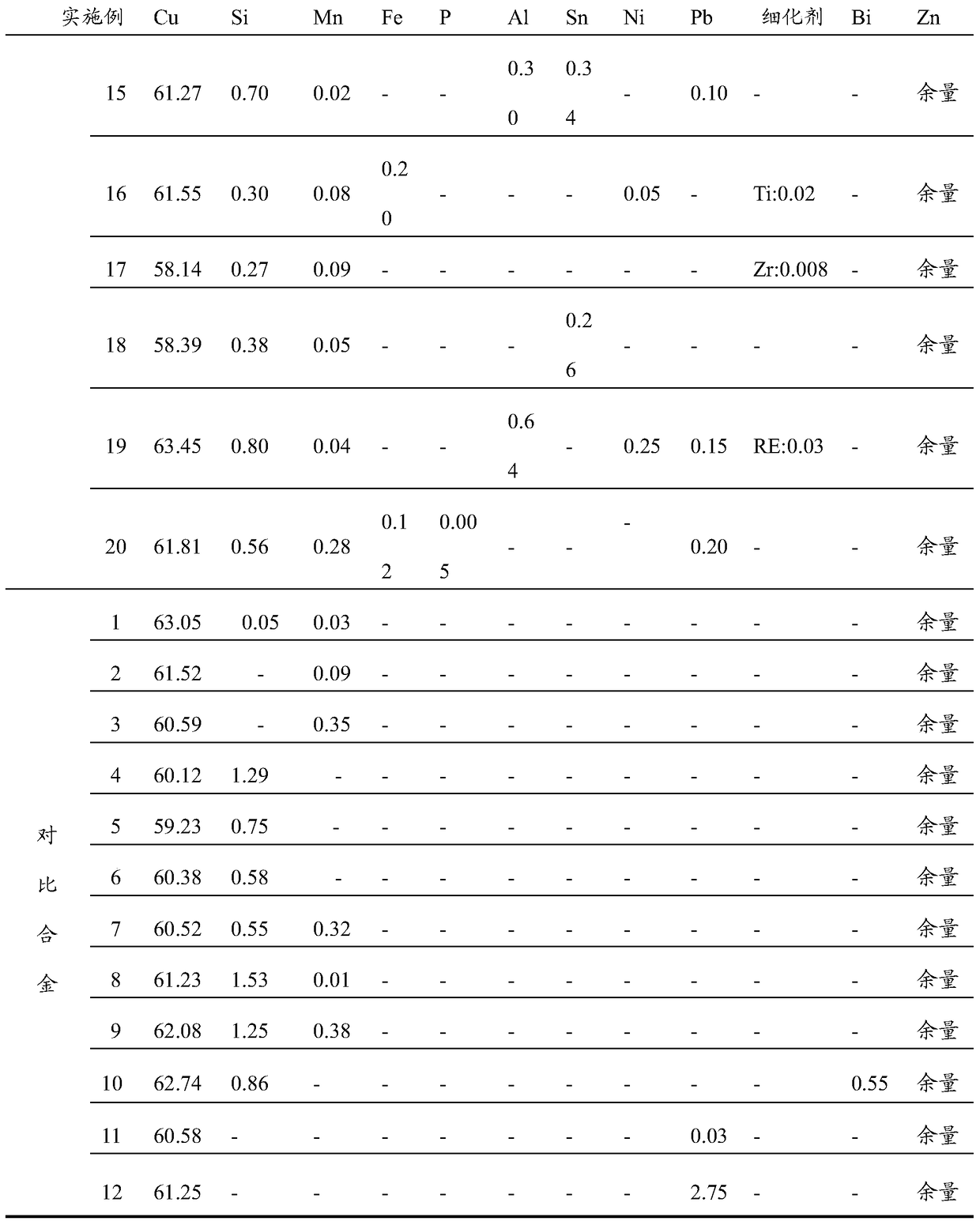

Good-formability environment-friendly brass alloy and manufacturing method thereof

The invention relates to good-formability environment-friendly brass alloy and a manufacturing method thereof. The brass alloy contains 35wt% or more of Zn, 0.1-1.0wt% of Si, 0.01- 0.28wt% of Mn, and the balance Cu and inevitable impurities. The brass alloy has good cold processing formability, hot processing formability, castability, anti-dezincification-corrosion performance, excellent polishing performance and welding performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, used for forging, casting and direct processing.

Owner:LA VIDA IND +1

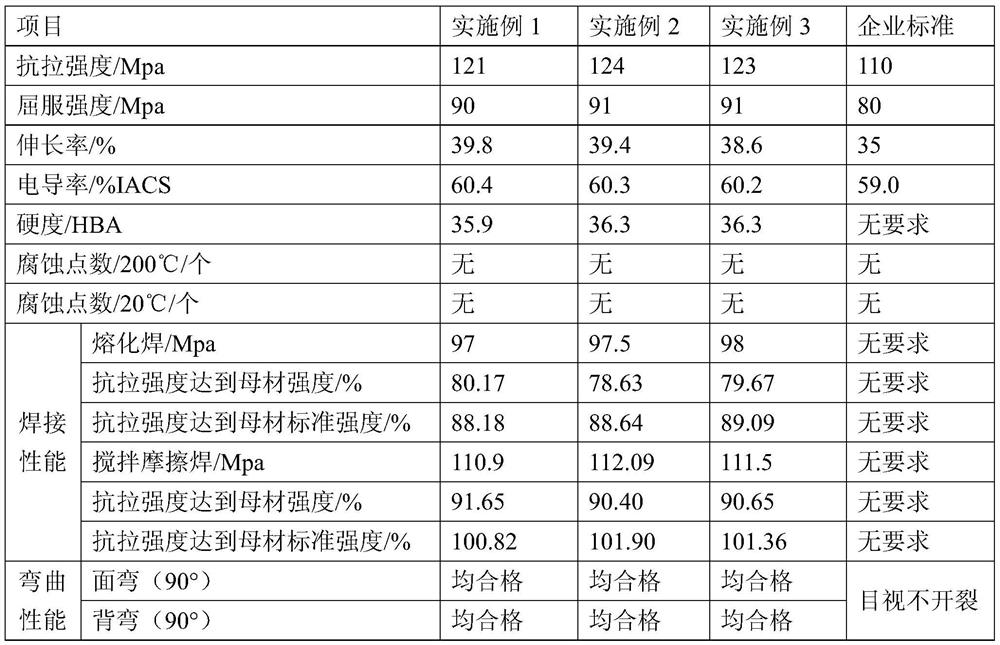

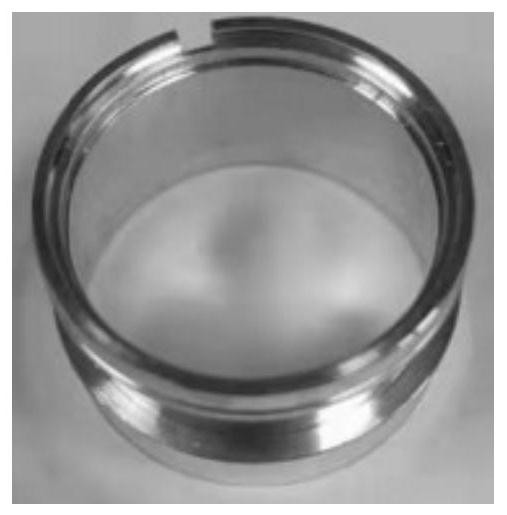

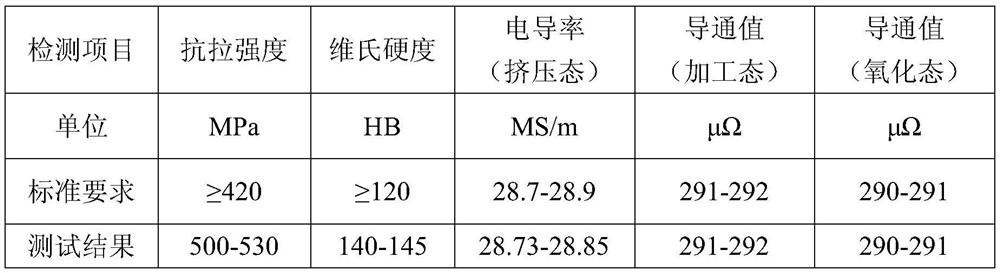

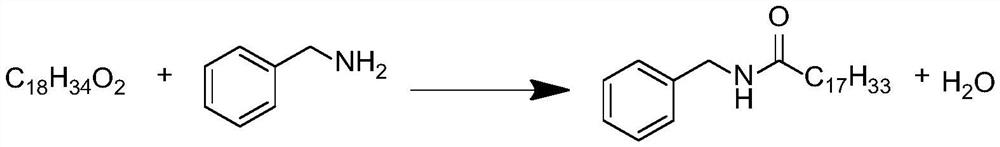

Aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermal forming property and preparation method and application thereof

InactiveCN112522549AExcellent thermoformabilityGood welding performanceHigh conductivityMaterials science

The invention relates to the technical field of aluminum alloys, in particular to an aluminum alloy with high strength, high conductivity, corrosion resistance, weldability and good thermal forming property and a preparation method and application thereof to manufacturing of a magnetic levitation induction plate. The aluminum alloy is prepared from, by mass, 0.1-0.6% of Si, 0.-0.7% of Fe, 0.1-0.5%of Cu, 0.01-0.15% of B, Mn<=0.1%, Mg<=0.01%, Cr<=0.1%, Zn<=0.1%, Ti<=0.1 and 0.001-0.005%of C, wherein the single impurity is less than or equal to 0.05%, the alloy impurity is less than or equal to0.12%, and the balance is AI. The preparation method comprises the steps of fusion casting treatment, homogenization treatment, extrusion treatment, cold deformation treatment and stabilization treatment. Through interaction and coordination of elements, the alloy has high strength, high conductivity, corrosion resistance, weldability and good thermal forming performance.

Owner:山东创新精密科技有限公司

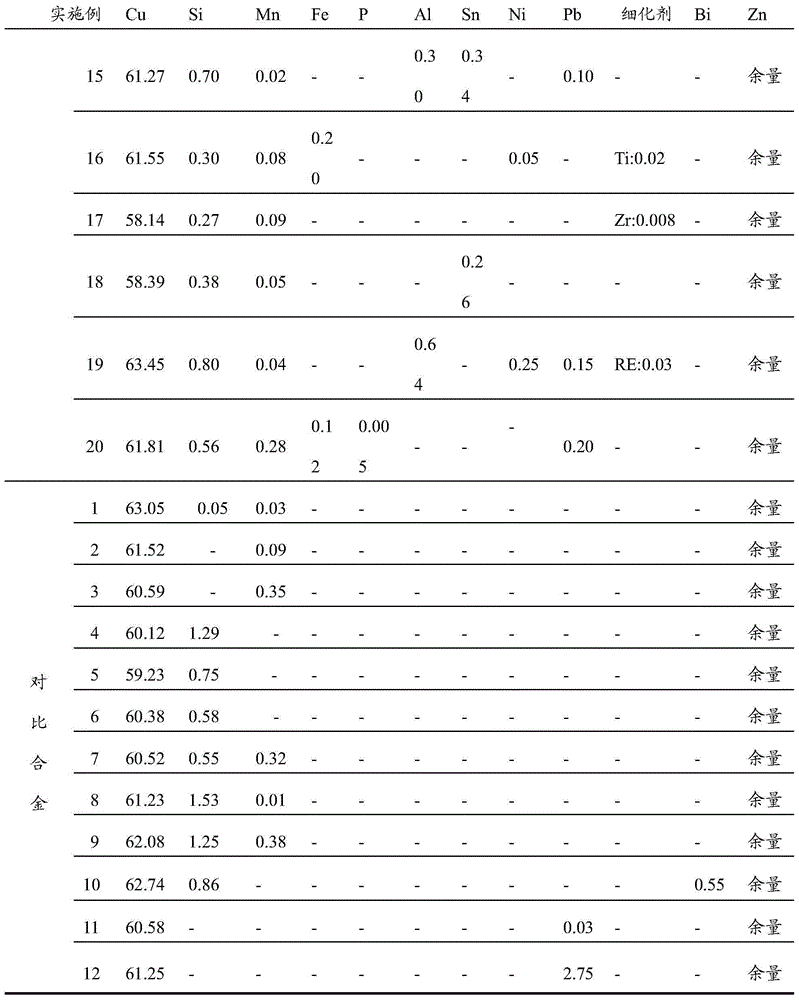

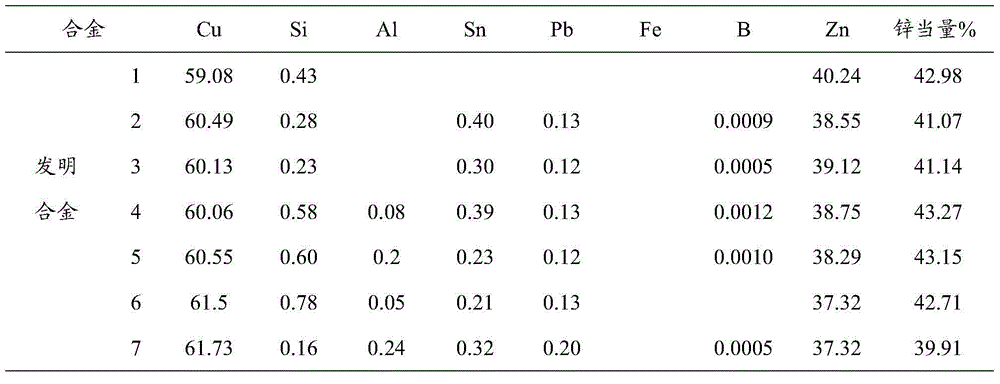

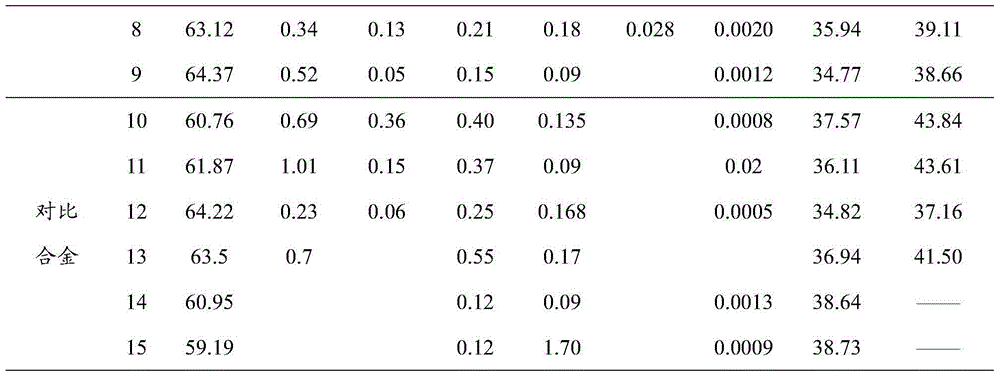

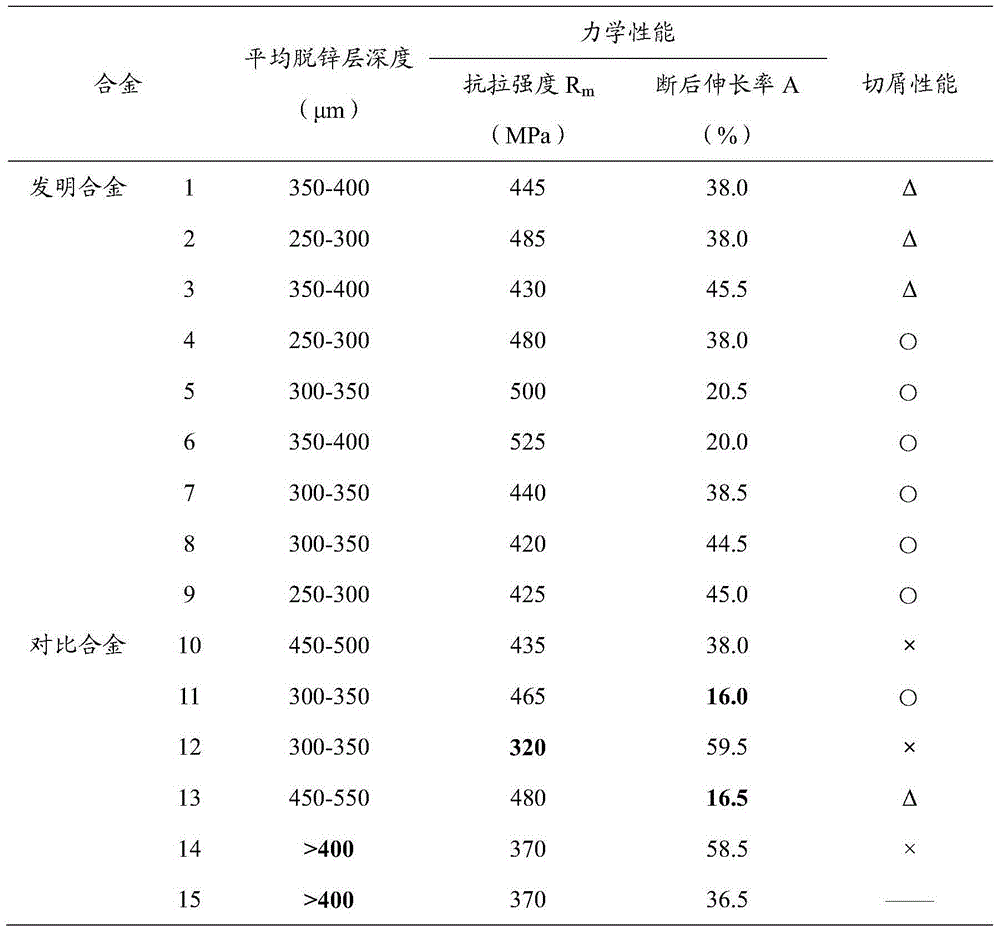

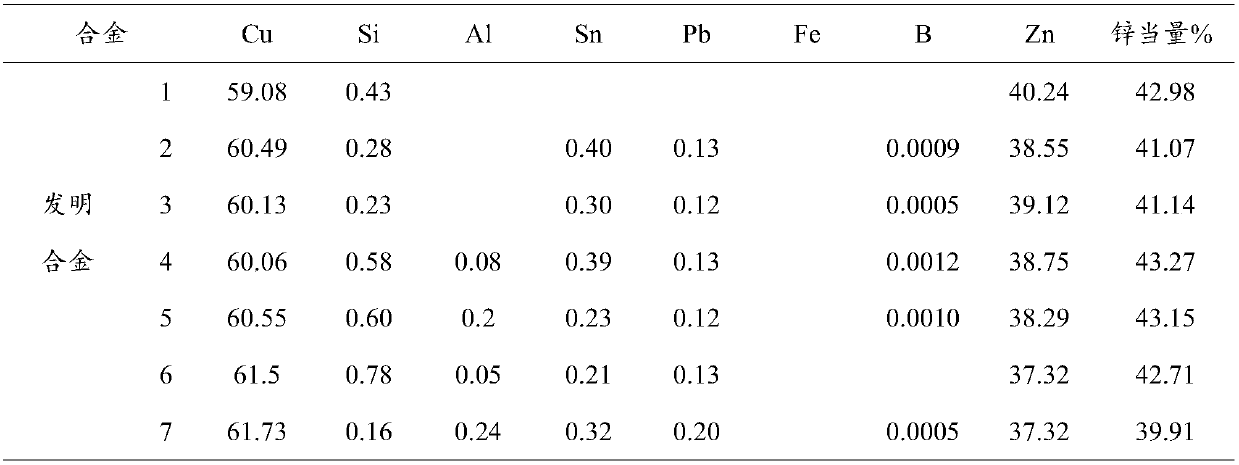

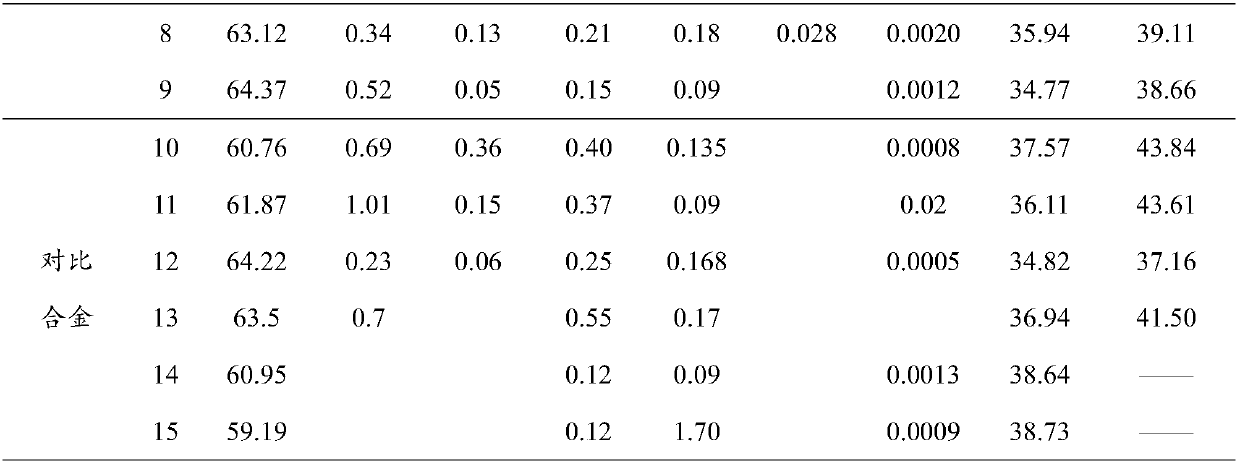

Unleaded brass alloy

The invention provides unleaded brass alloy. The unleaded brass alloy contains 59.0%-65.0% wt% of Cu, 0.1%-1.0% wt% of Si, and the balance Zn and unavoidable impurities, and the Zn equivalent X of the unleaded brass alloy is within the range of 38%-43.5%. The following formula X=(Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt%) / (Cuwt%+Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt %) represents the Zn equivalent X. The unleaded brass alloy has good formability and polishing performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, formed by casting and forging, in particular for water faucets and other products with complex structures.

Owner:LA VIDA IND +1

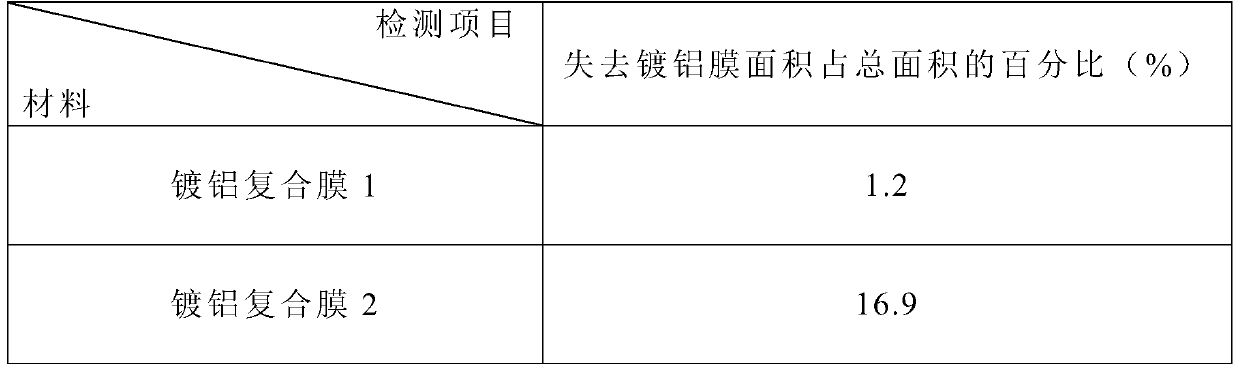

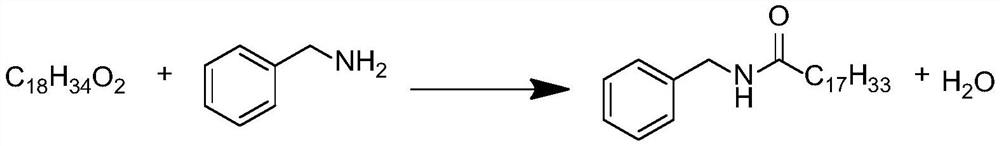

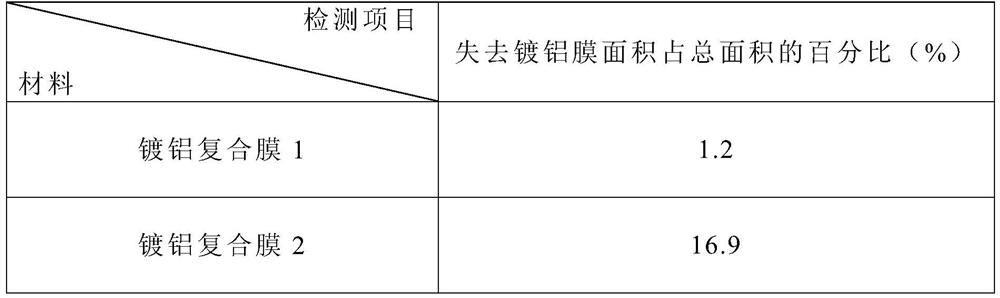

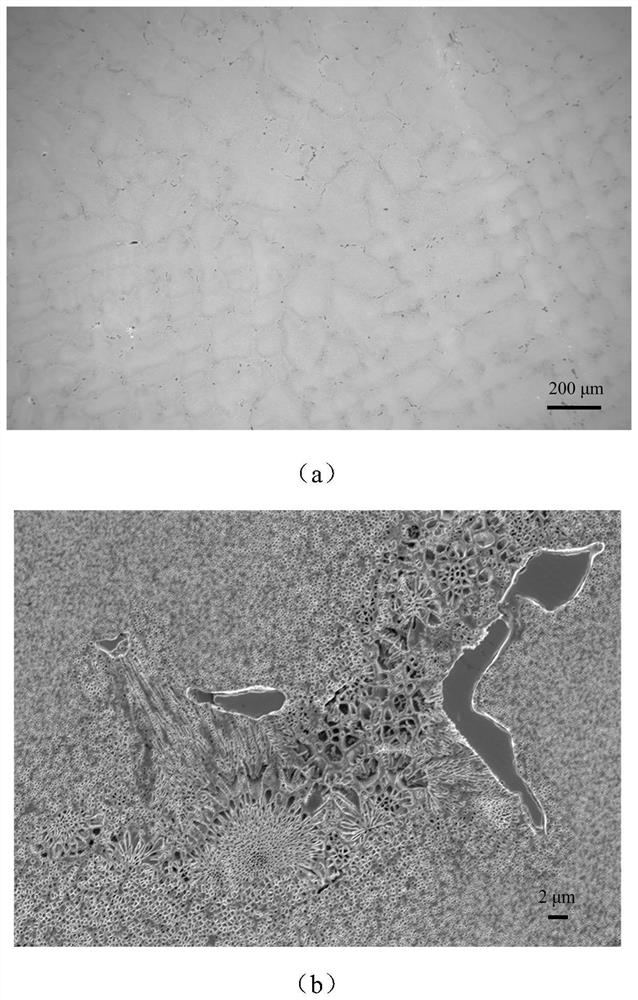

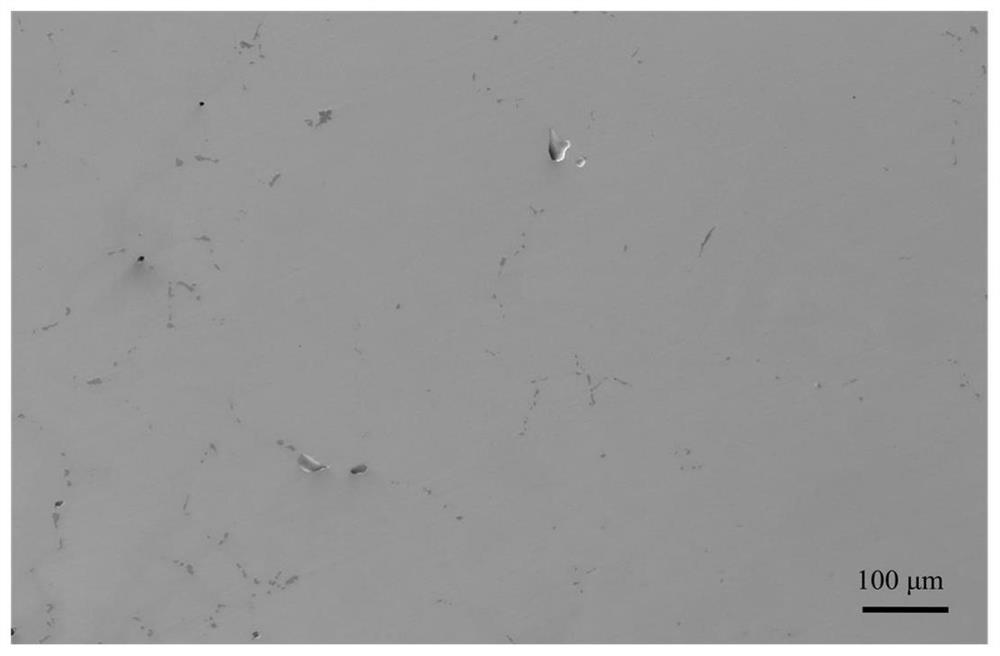

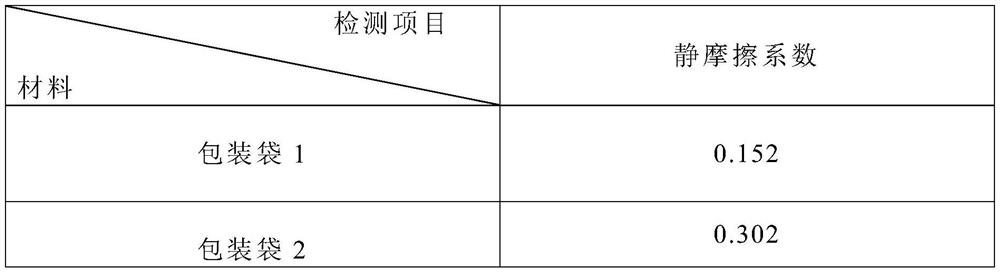

PE vacuum aluminized composite film and preparation method thereof

ActiveCN110722857AImprove adhesionInhibit sheddingSynthetic resin layered productsVacuum evaporation coatingLow-density polyethylenePolymer science

The invention belongs to the technical field of packaging materials, and particularly relates to a PE vacuum aluminized composite film and a preparation method thereof. The PE composite film comprisesa PE composite base film and an aluminized film connected to one side of the PE composite base film, and the PE composite base film comprises low-density polyethylene, metallocene polyethylene, surface adhesive resin, linear polyethylene, an antioxidant, a heat stabilizer, an ultraviolet blocking agent and an anti-blocking agent. The surface adhesive resin is added into the PE composite base film, so the adhesive force of the PE composite base film to the aluminized film is greatly improved, and the problem that the aluminized film falls off is solved; and the anti-blocking agent is added into the PE composite base film, so a prepared packaging bag is not prone to adhesion and has good opening properties.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

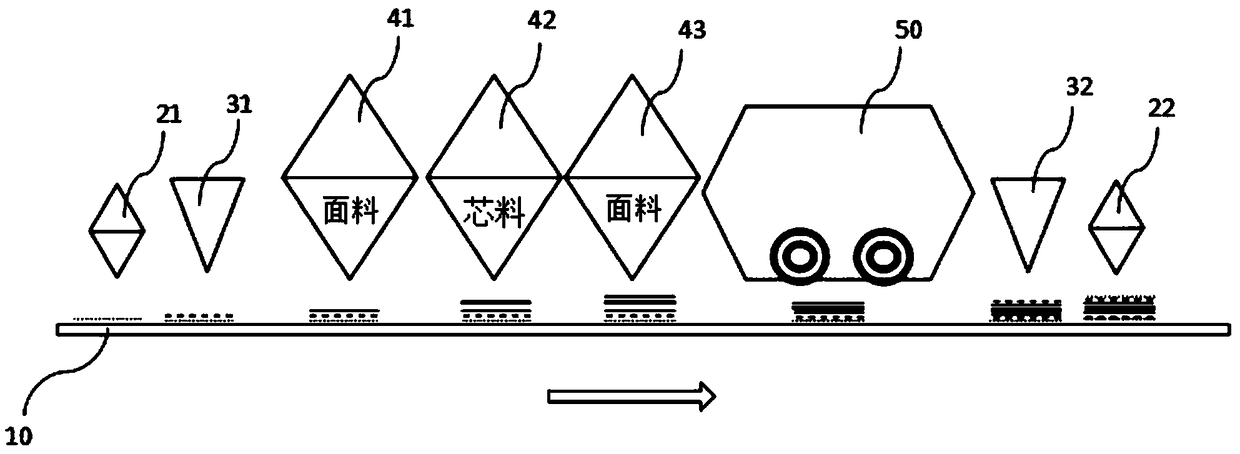

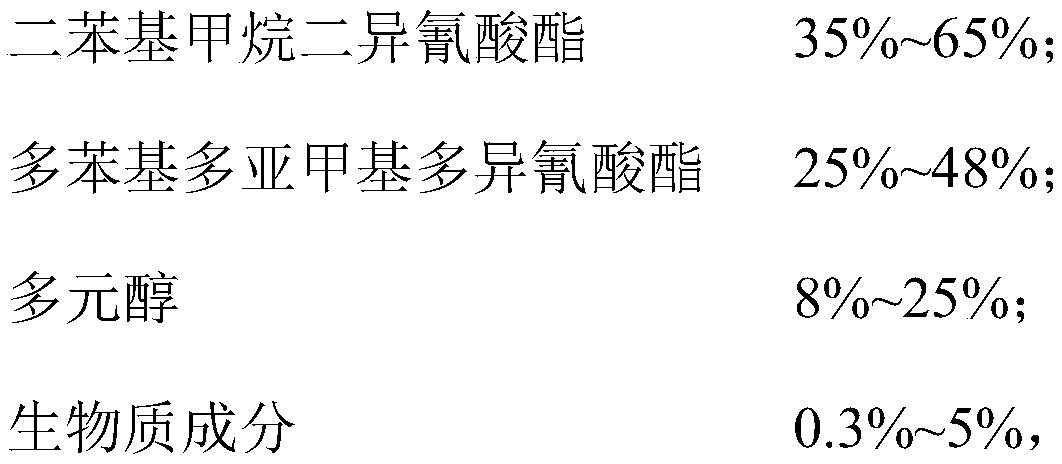

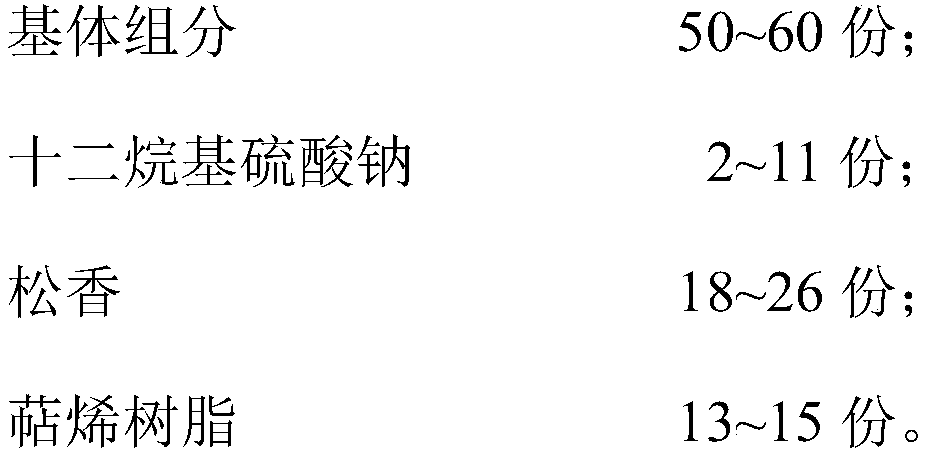

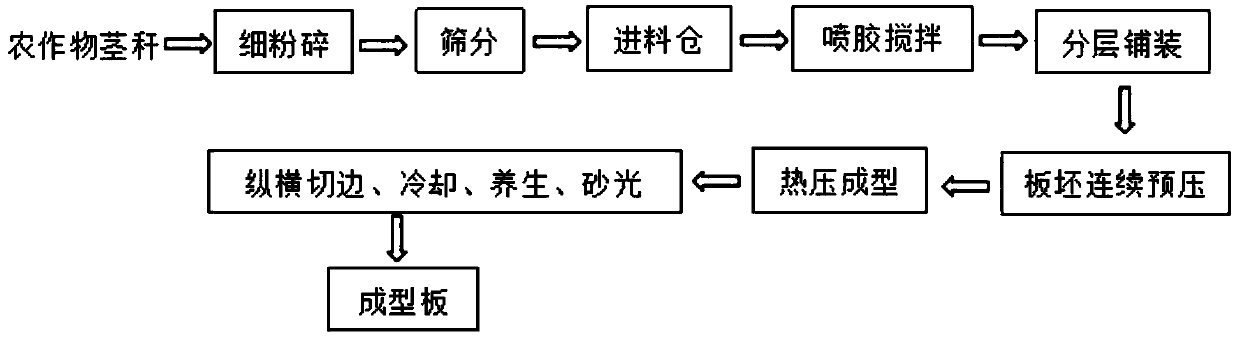

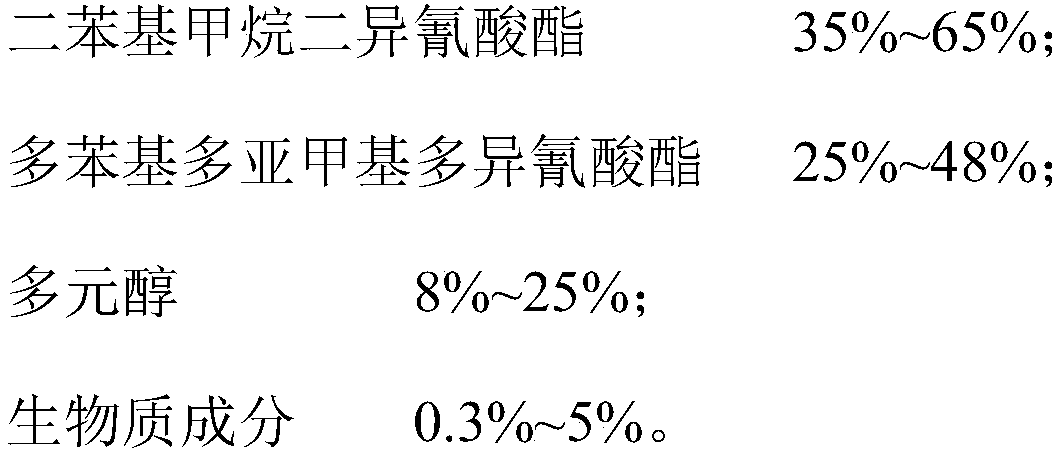

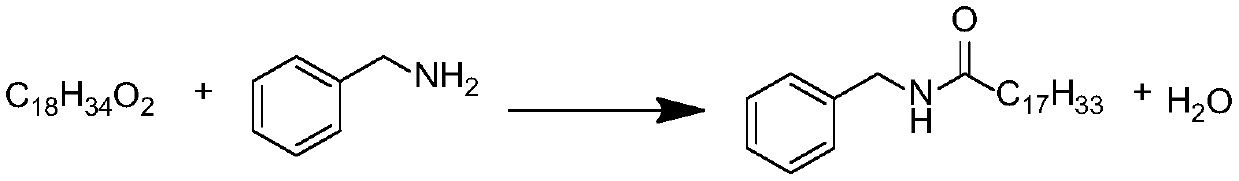

Technology for increasing pre-pressing strength of formaldehyde-free artificial board by using hot melt adhesive

InactiveCN109227860AIncrease preload strengthIncrease the initial strength of the preloadDomestic articlesFlat articlesPolymeric MDICompressive strength

The invention provides a technology for increasing the pre-pressing strength of a formaldehyde-free artificial board by using a hot melt adhesive. The technology is characterized by comprising the steps that 1, crop stalks are smashed into the fineness of 10-60 mesh, polymer MDI glue accounting for 2-8% of the weight of the crop stalks is added for stirring and mixing, and a stirred mixture is obtained; 2, before the stirred mixture is laid, a layer of sanding powder is laid, then a layer of hot melt adhesive film is laid on the sanding powder, and the stirred mixture is laid on the hot melt adhesive film so as to be used as a plate blank; 3, the plate bland is subjected compression rolling by using a continuous pre-pressing machine under the condition of 250-500 kN / m<2>, a layer of hot melt adhesive film is laid on the upper surface of the plate blank obtained after pre-pressing forming, and then a layer of sanding powder is laid on the hot melt adhesive film on the upper layer; 4, the plate blank is fed into a hot pressing machine, under the conditions that the hot press temperature is 150-220 DEG C, and the pressure is 2400-3800 kN / m<2>, a rough board is formed through hot pressing and solidification, and the artificial board is obtained through aftertreatment.

Owner:李杰

Oriented fluoropolymer film

InactiveCN105916920AExcellent thermoforming propertiesImprove thermoforming performanceVinyl etherPolymer science

The present invention provides oriented film comprising the composition 55 to 95 wt% tetrafluoroethylene / hexafluoropropylene / perfluoro(alkyl vinyl ether) copolymer and 45 to 5 wt% tetrafluoroethylene / perfluoro(alkyl vinyl ether) copolymer to total 100 wt% based on the combined weight of said copolymers, wherein the alkyl in each copolymer comprises 1 to 4 carbon atoms and wherein the presence of the tetrafluoroethylene / perfluoro(alkyl vinyl ether) copolymer in the composition and the presence of perfluoro(alkyl vinyl ether) in both copolymers improves the thermoformability of the film as compared to oriented film of the same film thickness comprising the tetrafluoroethylene / hexafluoropropylene / perfluoro(alkyl vinyl ether) copolymer by itself.

Owner:THE CHEMOURS CO FC LLC

A kind of protective film that does not rebound under hot pressing and preparation method thereof

ActiveCN105969233BImprove thermoforming performanceImprove curing effectSynthetic resin layered productsFilm/foil adhesive release linersTectorial membraneEngineering

Owner:NALI OPTICAL MATERIAL DONGGUAN

A kind of environment-friendly brass alloy with excellent formability and its manufacturing method

The invention relates to good-formability environment-friendly brass alloy and a manufacturing method thereof. The brass alloy contains 35wt% or more of Zn, 0.1-1.0wt% of Si, 0.01- 0.28wt% of Mn, and the balance Cu and inevitable impurities. The brass alloy has good cold processing formability, hot processing formability, castability, anti-dezincification-corrosion performance, excellent polishing performance and welding performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, used for forging, casting and direct processing.

Owner:LA VIDA IND +1

PE vacuum aluminized composite film and its preparation method

ActiveCN110722857BImprove adhesionInhibit sheddingSynthetic resin layered productsVacuum evaporation coatingLow-density polyethylenePolymer science

The invention belongs to the technical field of packaging materials, and in particular relates to a PE vacuum aluminized composite film and a preparation method thereof. The present invention comprises a PE composite base film and an aluminized film connected to one side of the PE composite base film, and the PE composite base film includes low-density polyethylene, metallocene polyethylene, surface adhesive resin, linear polyethylene, anti- Oxygen, heat stabilizer, UV blocker and antiblocking agent. The PE composite base film provided by the present invention is added with surface adhesive resin, which greatly improves the adhesion of the PE composite base film to the aluminized film, and prevents the problem of the aluminized film from falling off, and the PE composite provided by the present invention An anti-blocking agent is added to the base film, so that the prepared packaging bag is not easy to block and has better opening property.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

Span-bonded nonwoven fabric

InactiveCN1969074BSmall modulusEasy to stretchNon-woven fabricsPolytetramethylene terephthalateWarming process

A span-bonded nonwoven fabric, wherein (A) it comprises continuous fibers having an aromatic polyester (melting point: Tm1) and 1 to 15 wt % of an aromatic copolymerized polyester (melting point: Tm2= 150 DEG C to (Tm1 - 20) DEG C) incorporated in the aromatic polyester, characterized in that said nonwoven fabric exhibits an elongation of 20 % to 100 % and a load at 5 % elongation of 1.2 N / 50 mmor less per g / m2 of the fabric, (B) the aromatic polyester is polybutylene terephthalate, and (C) it exhibits, in the temperature rise step in the measurement by a differential scanning calorimeter, astarting temperature for heat absorption of a heat-absorbing peak indicating a melting point of 140 DEG C or higher. The above span-bonded nonwoven fabric exhibits an excellent low modulus, retains high extension property, is particularly excellent in processability and following property, and also excellent in the dimensional stability after being formed, and thus is suitable for a back cloth for an automobile interior material.

Owner:TOYOBO CO LTD

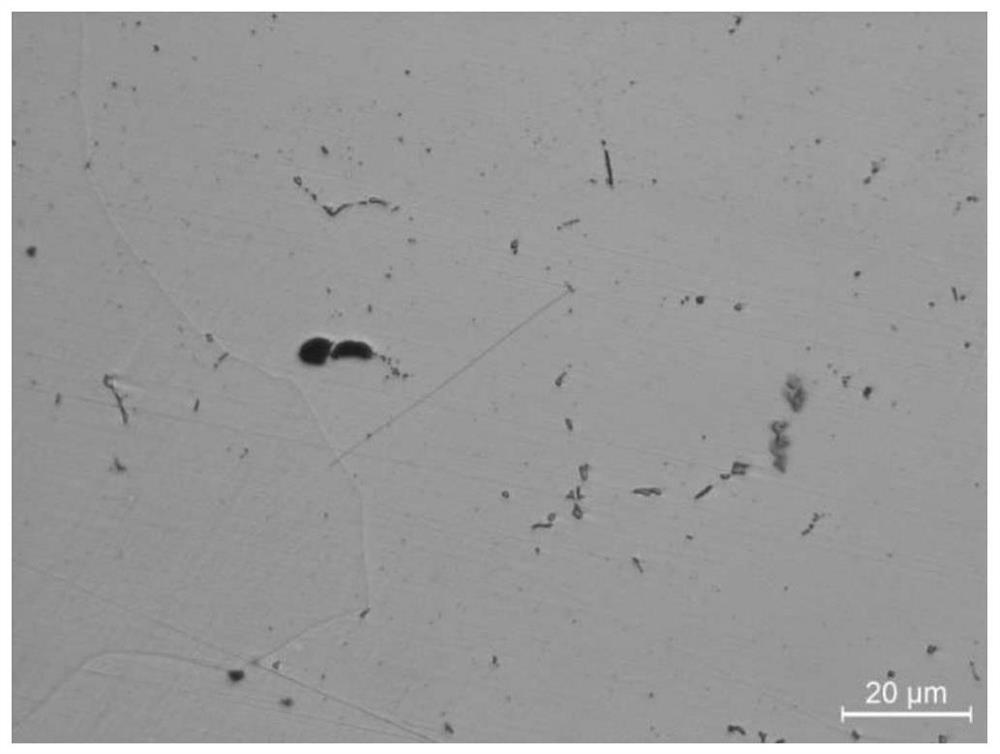

Two-stage homogenization heat treatment method for high-strength nickel-based superalloy cast ingot

PendingCN113981274AImprove thermal deformation abilityReduced rheological resistanceMetallic materialsNickel alloy

The invention discloses a two-stage homogenization heat treatment method for a high-strength nickel-based superalloy cast ingot, and belongs to the technical field of metal materials. The alloy comprises the following basic components: 15%-18% of Cr, 15%-20% of Co, 0.5%-1.5% of Ti, 3.5%-4.5% of Al, 5%-8.5% of W, less than or equal to 0.5% of Si, less than or equal to 0.5% of Mn, 0.5%-1.5% of Nb, 0.03%-0.08% of C and the balance of Ni. The method comprises the following treatment steps of: loading a nickel alloy ingot into a heat treatment furnace at the temperature of less than or equal to 600 DEG C; heating to 1180-1100 DEG C, controlling the heating speed to be 5-10 DEG C / min, and carrying out first-stage heat treatment; carrying out heat preservation for 12-48 hours at 1180-1100 DEG C, carrying out second-stage heat treatment, controlling the heating speed to be 5 DEG C / min, and carrying out heat preservation for 48-120 hours at 1200-1240 DEG C; and cooling the ingot subjected to heat treatment to below 700 DEG C along with the furnace, and then air-cooling to room temperature, or directly air-cooling. According to the high-strength nickel alloy cast ingot treated through the technology, the eutectic structure in the cast ingot can be effectively eliminated, meanwhile, composition segregation is eliminated, the obtained structure is uniform, the homogenizing heat treatment time is effectively shortened, and energy consumption and production cost are reduced.

Owner:CHINA HUANENG GRP CO LTD +1

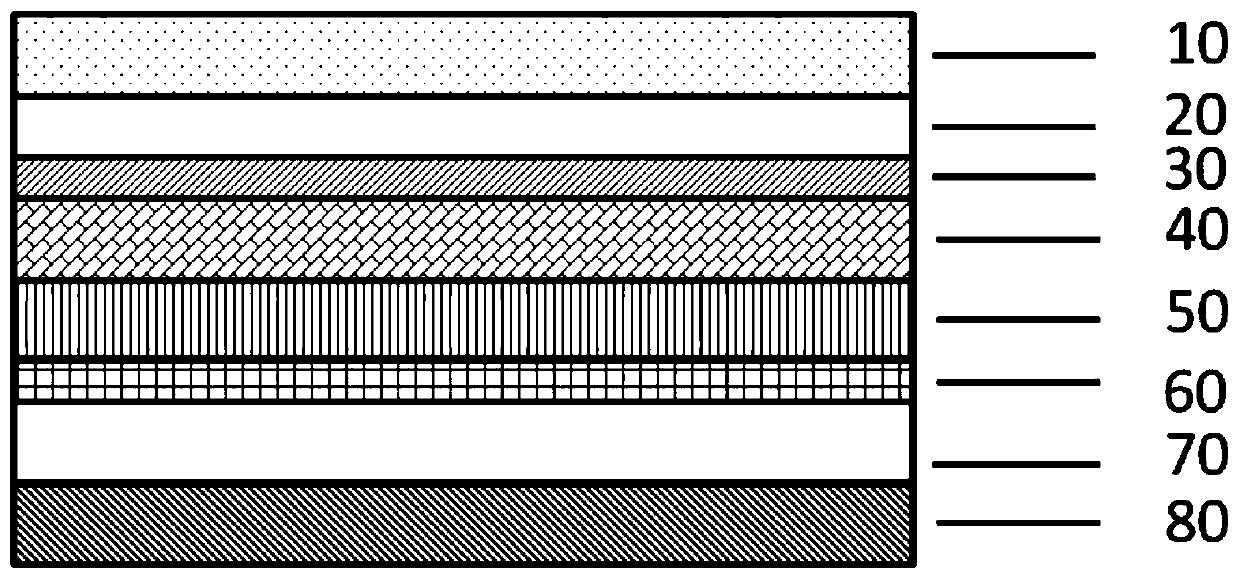

3D screen protective film and preparation method thereof

InactiveCN111019544AGood thermoformabilityImprove edge warping and gray edgeFilm/foil adhesivesTelephone set constructionsComposite substratePolymer chemistry

The invention discloses a 3D screen protective film and a preparation method thereof. The protective film comprises a composite base material structure, a sealing coating and a second pressure-sensitive adhesive protective layer which are sequentially arranged in a stacked mode from top to bottom, the composite base material structure comprises a second optical-grade base material layer and an amorphous polymer elastomer base material layer which are stacked up and down, and the amorphous polymer elastomer base material layer is stacked on the sealing coating. The composite structure composedof the optical base material and the amorphous polymer elastomer material is adopted, so the attaching effect on a 3D curved screen is improved; and in addition, the high-crosslinking-density organicmatter coating is adopted for sealing the amorphous polymer elastomer base material layer, so the problem that an existing protective film is large in smell when stored for a long time is solved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

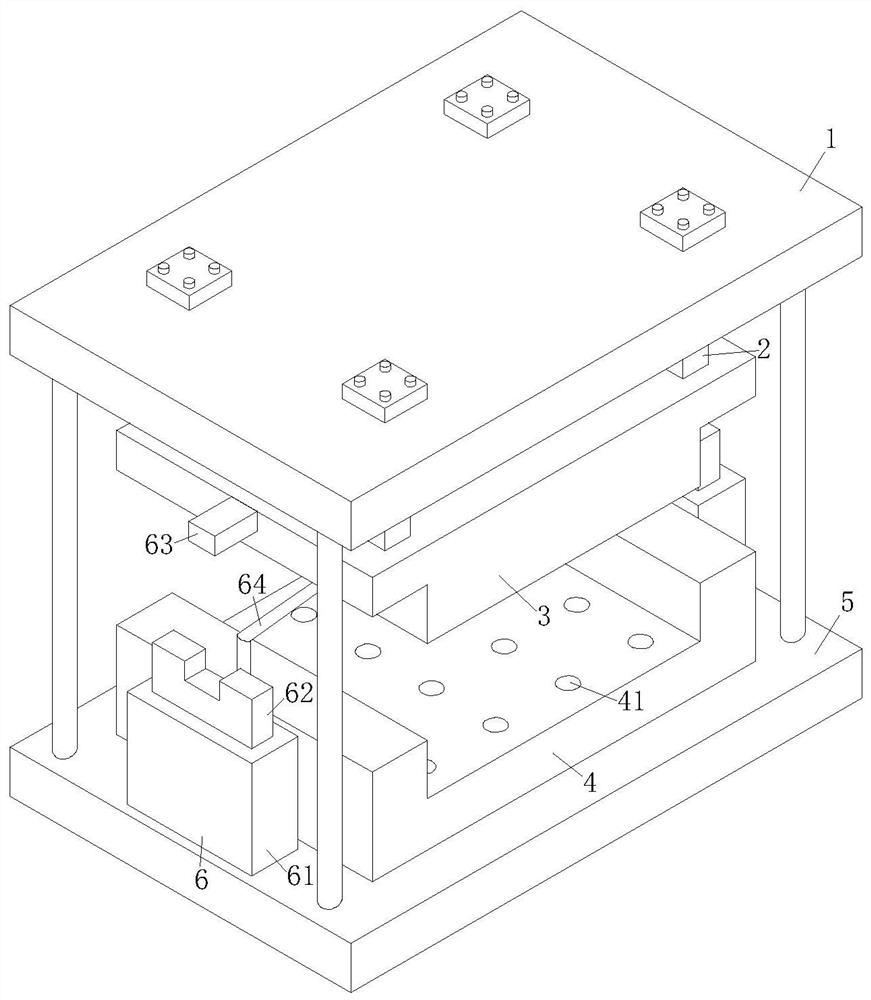

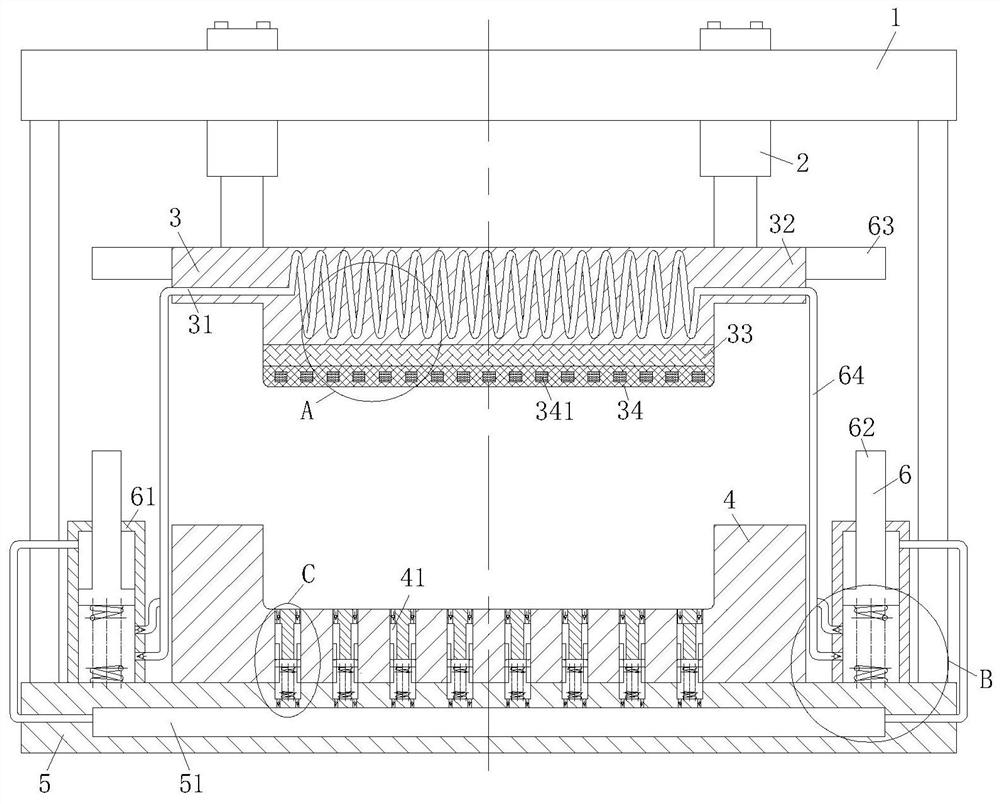

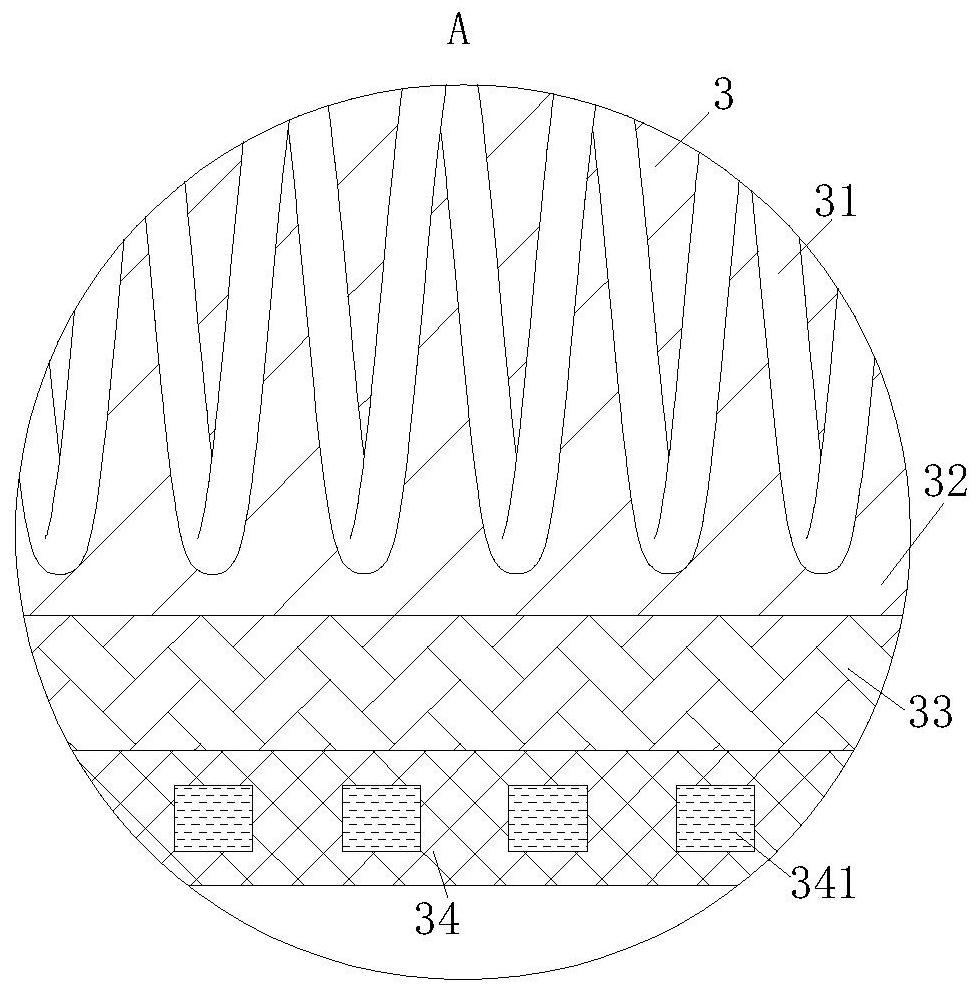

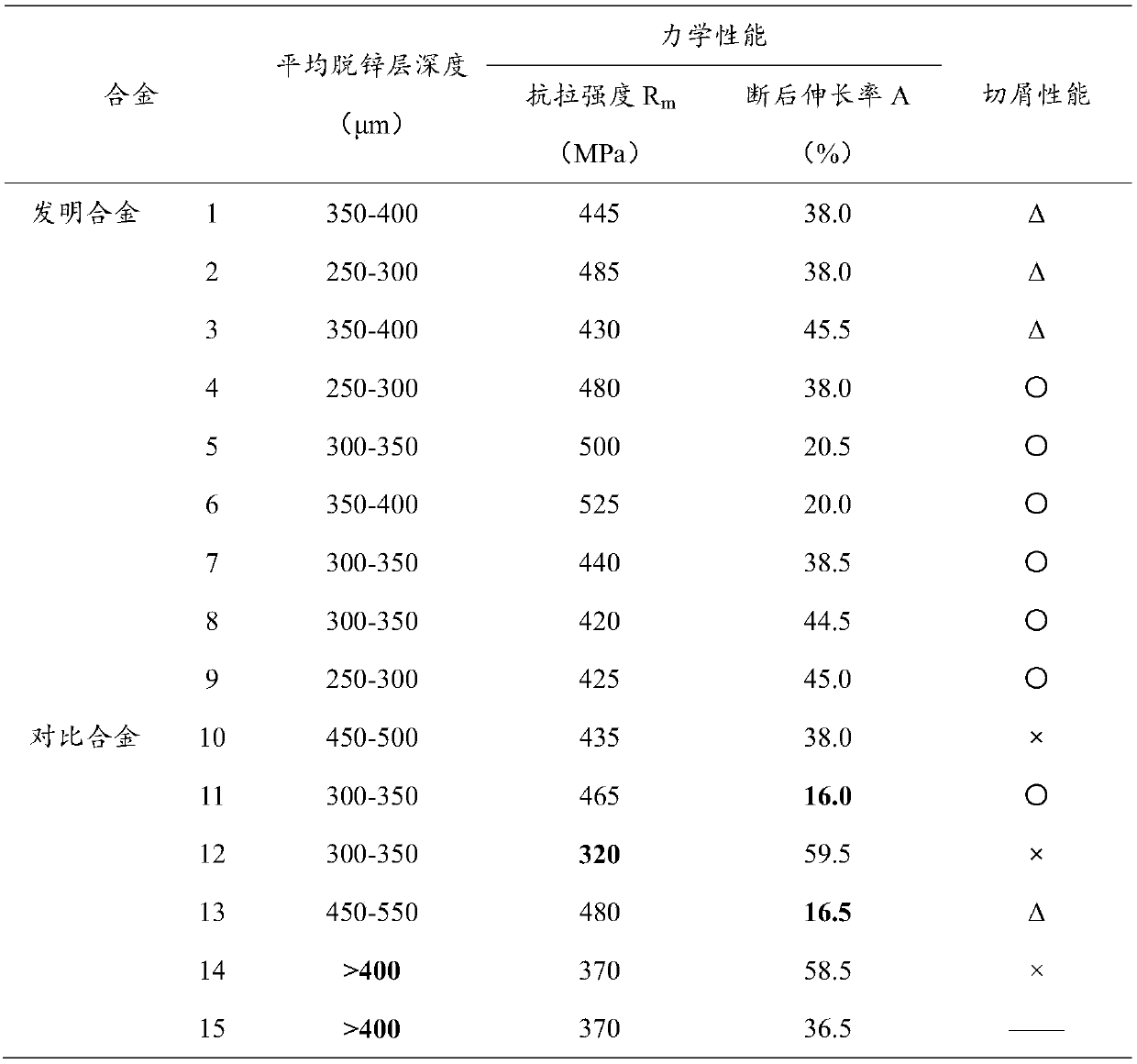

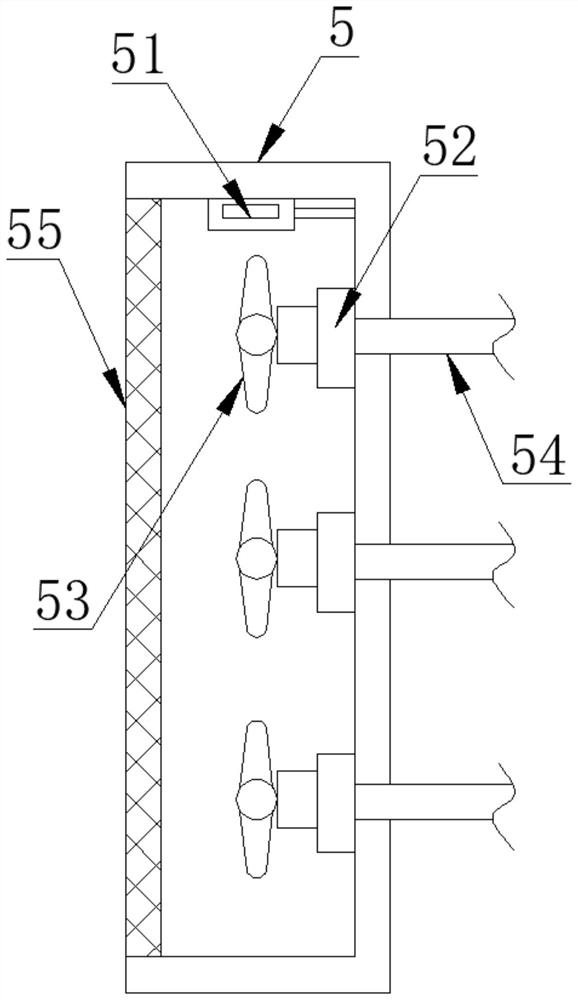

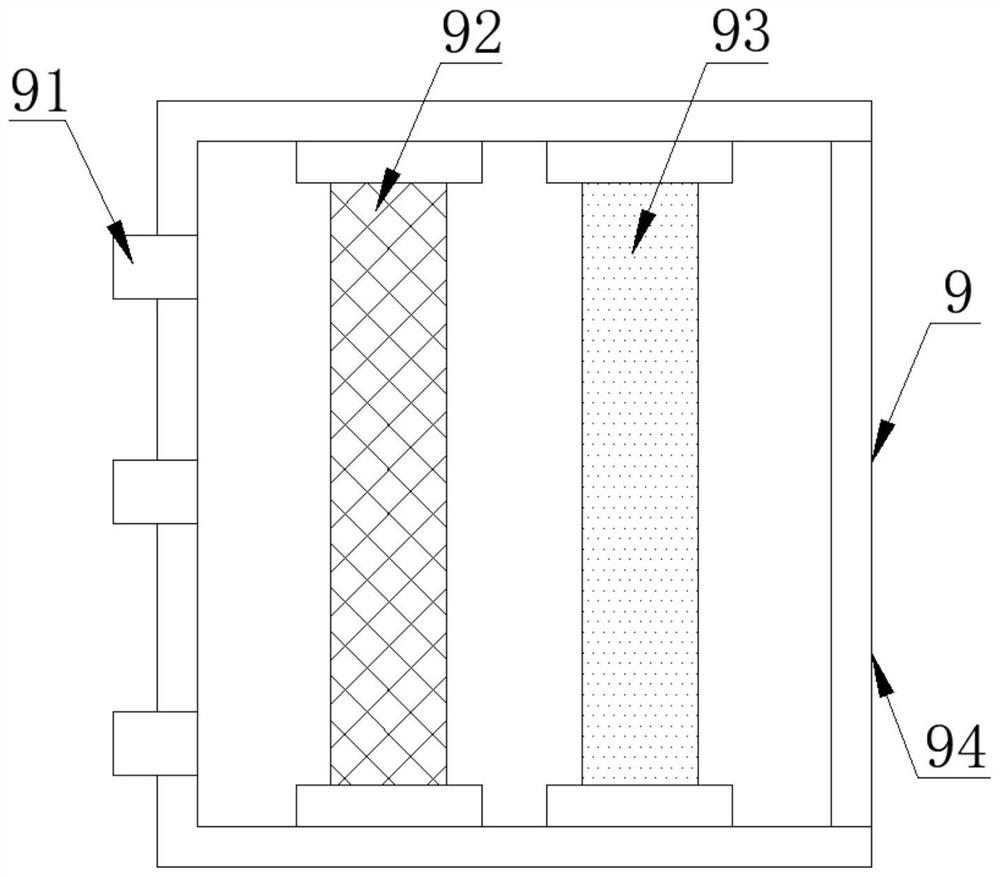

A polymer film thermocompression forming device and film forming process

ActiveCN110328833BAffects thermoforming qualityImprove thermoforming performancePolymer scienceThermoforming

Owner:肇庆市宏华电子科技有限公司

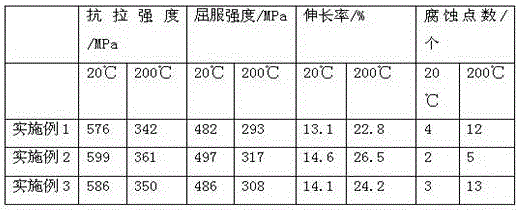

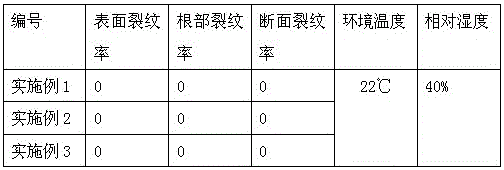

An alloy with good hot formability, corrosion resistance, fatigue properties, toughness and weldability

Owner:SHANDONG YUHANG SPECIAL ALLOY EQUIP

a brass alloy

The invention provides unleaded brass alloy. The unleaded brass alloy contains 59.0%-65.0% wt% of Cu, 0.1%-1.0% wt% of Si, and the balance Zn and unavoidable impurities, and the Zn equivalent X of the unleaded brass alloy is within the range of 38%-43.5%. The following formula X=(Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt%) / (Cuwt%+Znwt%+10.0xSiwt%+2.0xSnwt%+6.0xAlwt %) represents the Zn equivalent X. The unleaded brass alloy has good formability and polishing performance, and is suitable for parts, of bathroom plumbing, electric products, automobiles and the like, formed by casting and forging, in particular for water faucets and other products with complex structures.

Owner:LA VIDA IND +1

Hot-pressing device for plastic processing

InactiveCN112976448AFlat surfaceImprove cleanlinessDispersed particle filtrationDirt cleaningEngineeringWorkbench

The invention discloses a hot-pressing device for plastic processing, and particularly relates to the field of plastic processing. The hot-pressing device comprises a workbench, wherein a control box is fixedly arranged on one side of the top of the workbench, a mold base is fixedly arranged at the top of the workbench, a hot-pressing mold is fixedly arranged at the top of the mold base, racks are fixedly arranged on the left side and the right side of the top of the workbench, gas recovery mechanisms are fixedly arranged on the left side and the right side of the racks, and a portal frame is fixedly connected to one side of the racks. According to the scheme, the gas recovery mechanisms are arranged inside the hot-pressing device so as to recover pungent smell generated when an internal hot-pressing plate is used for carrying out hot-pressing work on plastic, pollution-free recovery and emission of gas are realized through the cooperation between a suction fan and a gas treatment box, the suction fan can be used for rapidly sucking the gas inside the device, the sucked gas is fed into the gas treatment box on one side for treatment through an air supply pipeline on one side, and pollution-free emission is realized.

Owner:罗祖颂

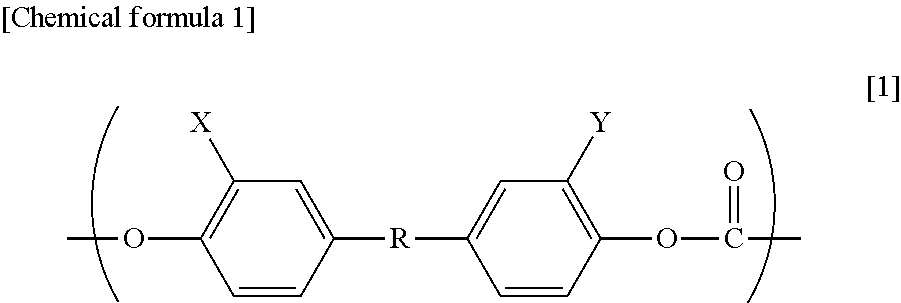

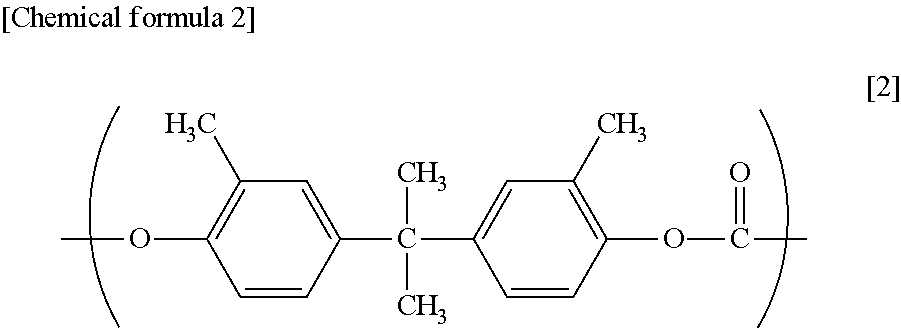

Synthetic resin laminate

ActiveUS9446567B2Increase flexibilityHigh surface hardnessDomestic upholsterySynthetic resin layered productsPolymer alloyHigh surface

The present invention has an object of providing a synthetic resin laminate that is usable for a transparent substrate material or protective material, has high thermoformability (pressure formability, thermal-bending formability), high insert moldability, and high surface hardness and / or impact resistance, and also providing a molded body formed by molding such a synthetic resin laminate. The synthetic resin laminate includes a polycarbonate-based substrate layer; and a resin laminated on one of, or both of, two surfaces of the polycarbonate-based substrate layer, the resin containing a specific (meth)acrylate copolymer resin and a specific polycarbonate resin. The polycarbonate-based substrate layer includes a polymer alloy and thus has a glass transition temperature (Tg) of 110 to 130° C. Thus, the resultant synthetic resin laminate has high thermoformability and high surface hardness.

Owner:MITSUBISHI GAS CHEM CO INC +1

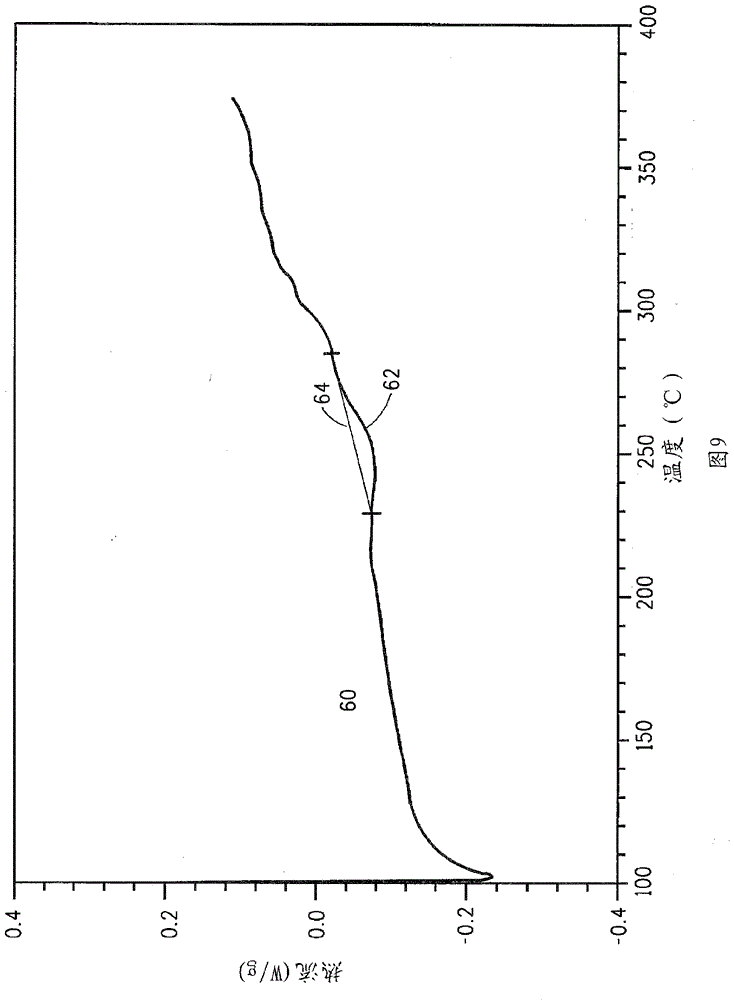

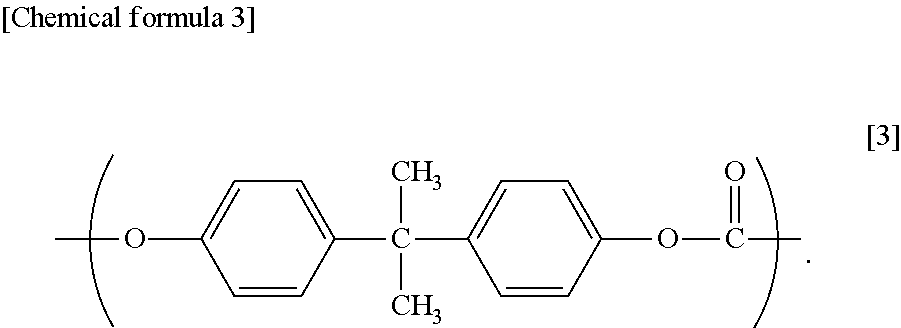

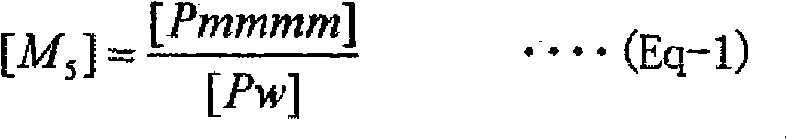

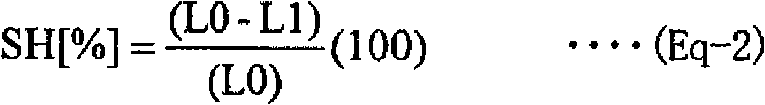

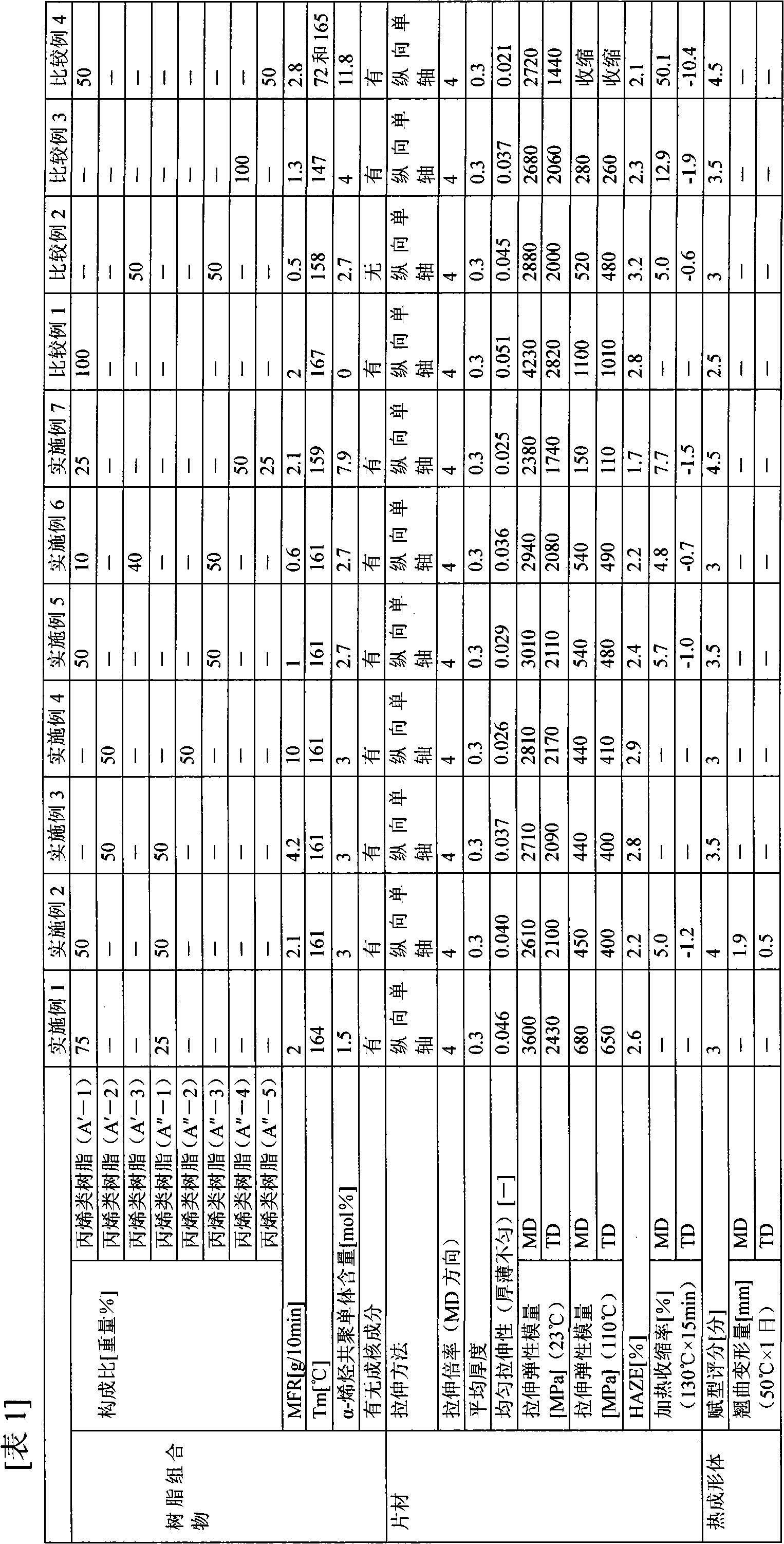

Propylene resin composition for stretched sheet, and stretched sheet and thermally molded article each comprising the composition

InactiveCN101855289AGood uniform stretchabilityExcellent thermoformabilitySynthetic resin layered productsPolymer chemistryComonomer

Disclosed are: a propylene resin composition for a stretched sheet having excellent stiffness, heat resistant stiffness, transparency, uniform stretchability and thermal moldability; and a stretched sheet and a thermally molded article, each of which comprises the resin composition. The propylene resin composition for a stretched sheet comprises 10 to 90 wt% of a high-melting-point propylene resin (A') having a melting point of 156 to 170 DEG C as measured by DSC and 10 to 90 wt% of at least one low-melting-point propylene resin (A'') having a melting point of 70 to 155 DEG C as measured by DSC (provided that the total amount of the components (A') and (A'') is defined as 100 wt%), and fulfils the following requirements [1] to [4]: [1] the propylene resin composition has a melt flow rate (230 DEG C, 2.16 kg load) of 0.5 to 10.0 g / 10 min; [2] the propylene resin composition has a melting point of 150 to 170 DEG C as measured by DSC; [3] the propylene resin composition (A) contains an a-olefin comonomer at a content of 1 to 11 mol%; and [4] the propylene resin composition contains a nucleating agent.

Owner:PRIME POLYMER CO LTD

Aluminum alloy with high conductivity uniformity and preparation method and application thereof

InactiveCN113897524AUniform tissueGuaranteed dimensional stabilityApparatus for heat treatmentConductive materialResidual deformationMachining

The invention relates to the technical field of aluminum alloys, in particular to an aluminum alloy with high conductivity uniformity and a preparation method and application thereof. The aluminum alloy comprises the following components: Si, Fe, Cu, Mn, Mg, Cr, Zn, Ni, Ti, Sn, Sb, Pb, Bi, Ga, V, Zr, C, B, less than or equal to 0.05 wt% of a single impurity, less than or equal to 0.12 wt% of an alloy impurity, and the balance Al. The preparation method comprises the steps of casting, homogenizing, extruding, cold deformation, quenching, stretching and stabilizing treatment. the aluminum alloy can be used for preparing a sensor shell. The aluminum alloy produced through the preparation method has the advantages of being high in strength, narrow in conductivity value range, good in machining formability, good in size consistency, high in size precision and the like, no residual deformation stress exists after high-speed multi-tool simultaneous machining, drilling aluminum scraps are evenly broken, turning spiral aluminum scraps are not wound, and the aluminum alloy can be used as a sensor shell, and can effectively guarantee the accuracy of exploration data transmission.

Owner:山东创新精密科技有限公司

PE dazzling heat-shrinkable film and preparation method thereof

The invention belongs to the technical field of packaging materials, and in particular relates to a PE colorful heat-shrinkable film and a preparation method thereof. The present invention includes low-density polyethylene, metallocene polyethylene, high-density polyethylene, colorful synthetic polyethylene, antioxidant, heat stabilizer, ultraviolet blocking agent and anti-blocking agent. The heat-shrinkable film provided by the present invention adds an anti-blocking agent, so that the packaging bag made of the heat-shrinkable film is not easy to be blocked, and the opening is better, and the present invention adds high-density polyethylene and low-density polyethylene to low-density polyethylene. The low-density polyethylene with melt index is modified to obtain good transparency and surface gloss, and the mechanical properties are greatly improved.

Owner:ZHEJIANG BILI POLYMER TECH CO LTD

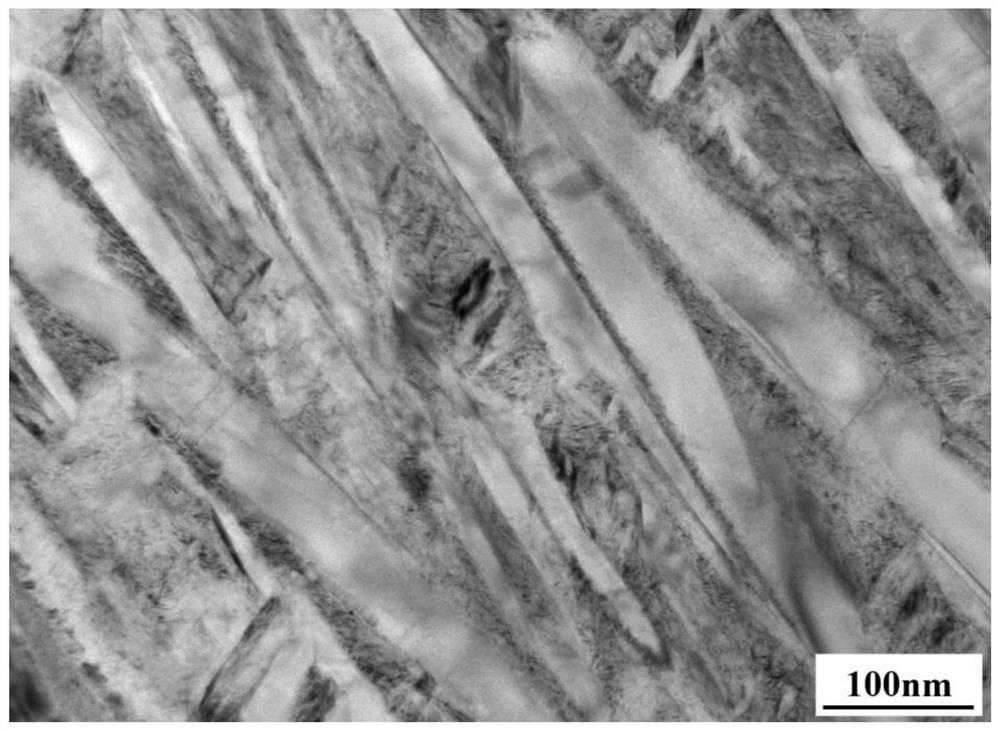

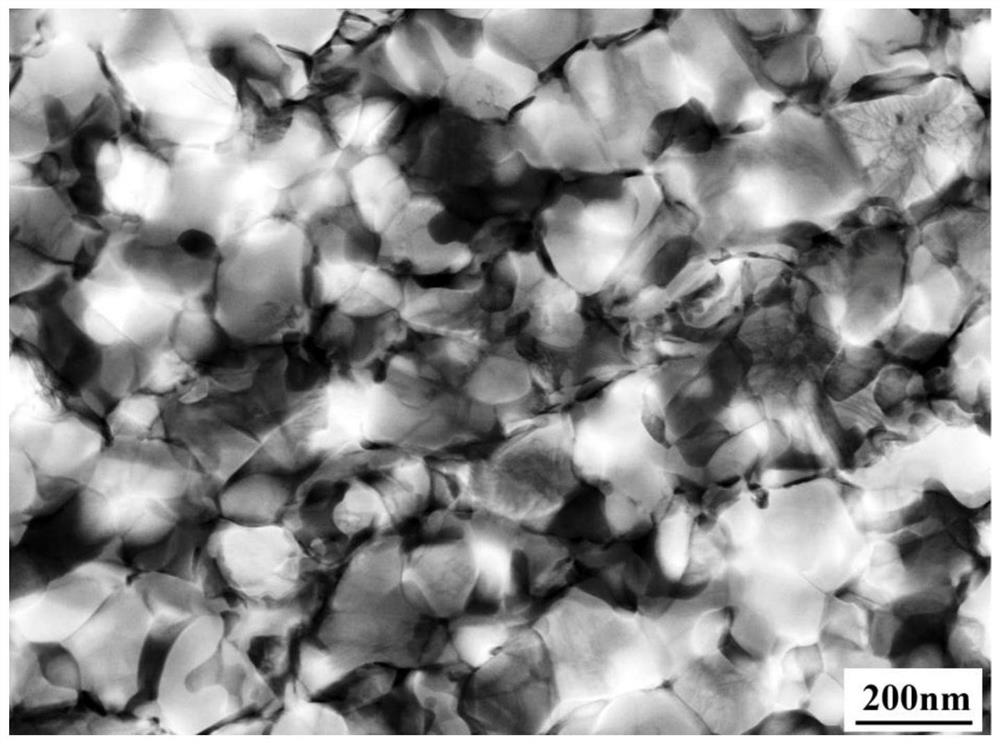

Superplastic forming nanocrystalline antibacterial martensitic stainless steel and preparation method thereof

ActiveCN113174544AAchieve preparationMeet the needs of large-scale industrial productionMartensitic stainless steelThermal deformation

The invention relates to the technical field of materials, and discloses superplastic forming nanocrystalline antibacterial martensitic stainless steel and a preparation method thereof. The superplastic forming nanocrystalline antibacterial martensitic stainless steel is characterized by being prepared from the following chemical components in percentage, by weight, 0.16 to 0.32 of C; 12.8 to 14.4 of Cr; 1.4 to 3.0 of Cu; 1.2 to 2.8 of W; 0.04 to 0.20 of V; 0.01 to 0.03 of La; Mn is less than 0.15; N is less than 0.03; and the balance Fe. The preparation method of the stainless steel comprises the following steps of (1) preserving heat at 980-1060 DEG C for a period of time, and then quickly cooling to room temperature; (2) carrying out thermal deformation within the temperature of 820-900 DEG C and the strain rate of 0.1-1s <-1 >, and converting the nanolath precursor into an equiaxial nanocrystal structure, wherein the total strain capacity is greater than or equal to 70%; (3) carrying out superplastic forming under the conditions that the temperature is 760-840 DEG C and the strain rate of 0.001-0.02 s <-1 >; and (4) aging the material subjected to superplastic forming at the temperature of 460-500 DEG C for 3-5 hours. The prepared superplastic forming nanocrystalline antibacterial martensitic stainless steel has excellent hot working performance, corrosion resistance, antibacterial performance and comprehensive mechanical performance, and can be widely applied to medical instruments in the cutting fields of knives, scissors and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A kind of high-content carbon fiber reinforced nylon composite material and preparation method thereof

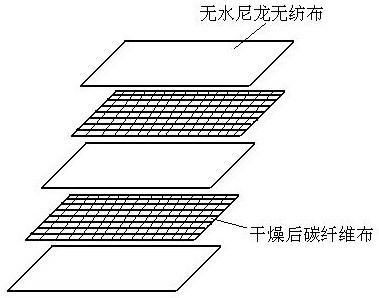

A method for preparing a high-content carbon fiber reinforced nylon composite material. First, impregnate an impurity-free carbon fiber cloth in an alcohol-soluble nylon anhydrous ethanol solution to obtain an impregnated carbon fiber cloth, then take out the impregnated carbon fiber cloth, and dry it to remove water After obtaining the dried carbon fiber cloth, select several pieces of the above-mentioned dried carbon fiber cloth and several pieces of anhydrous nylon non-woven fabric, and the quality of the dried carbon fiber cloth accounts for 65% of the sum of the dried carbon fiber cloth and anhydrous nylon non-woven fabric. 80%, then alternately superimpose the dried carbon fiber cloth and anhydrous nylon non-woven fabric to obtain a laminate, then put the laminate into a mold, and then hot press to obtain the composite material. This design not only has a better interface between carbon fiber and resin, but also has better mechanical properties of the obtained composite material, and has a higher carbon fiber content and is easy to operate.

Owner:WUHAN TEXTILE UNIV

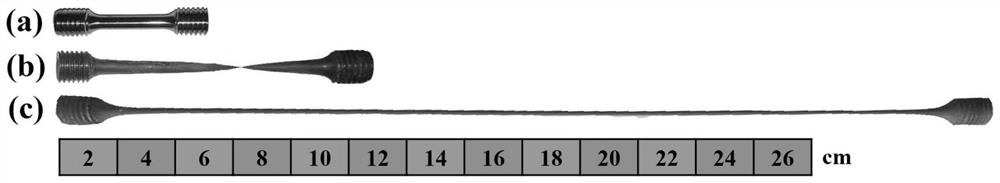

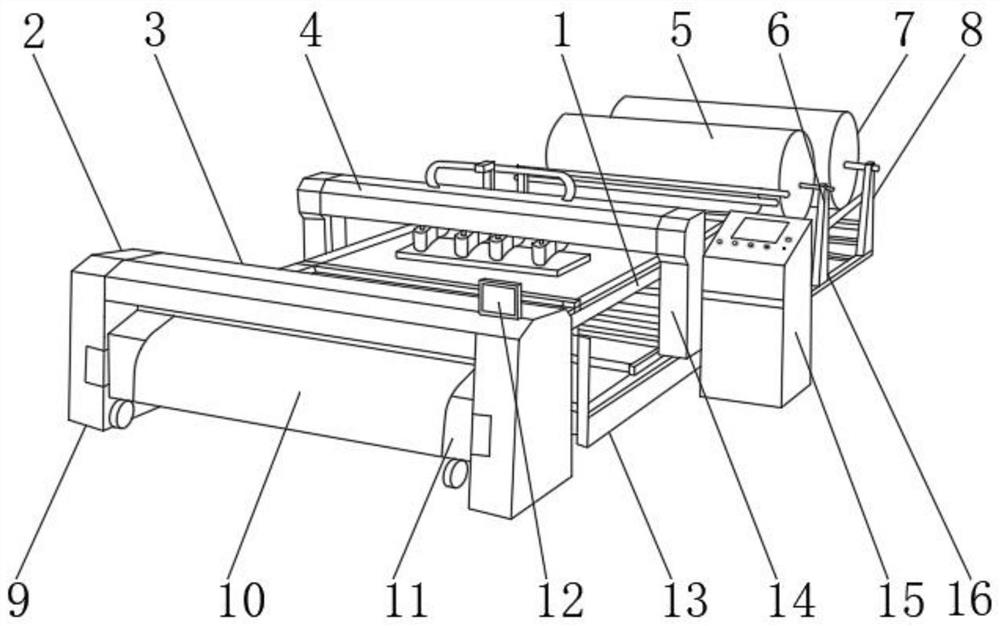

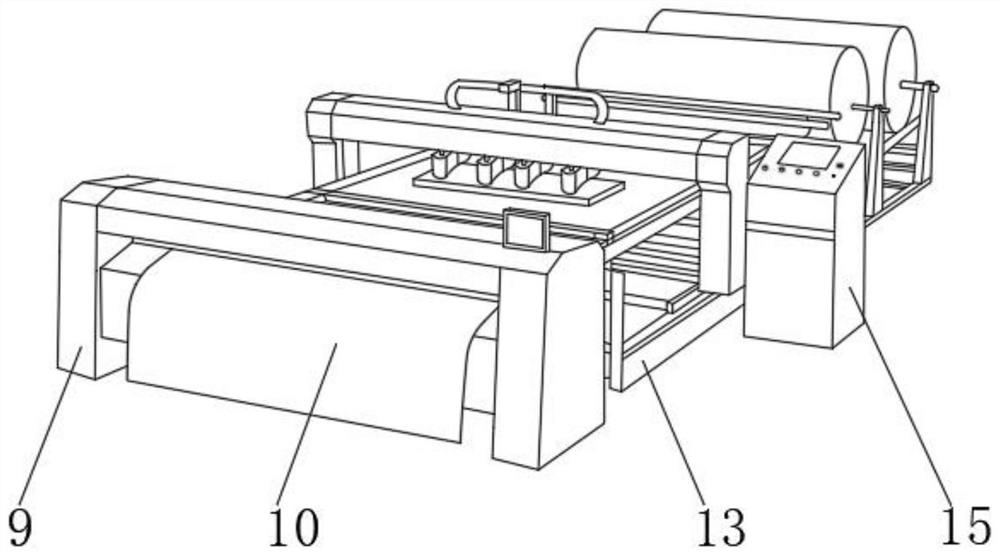

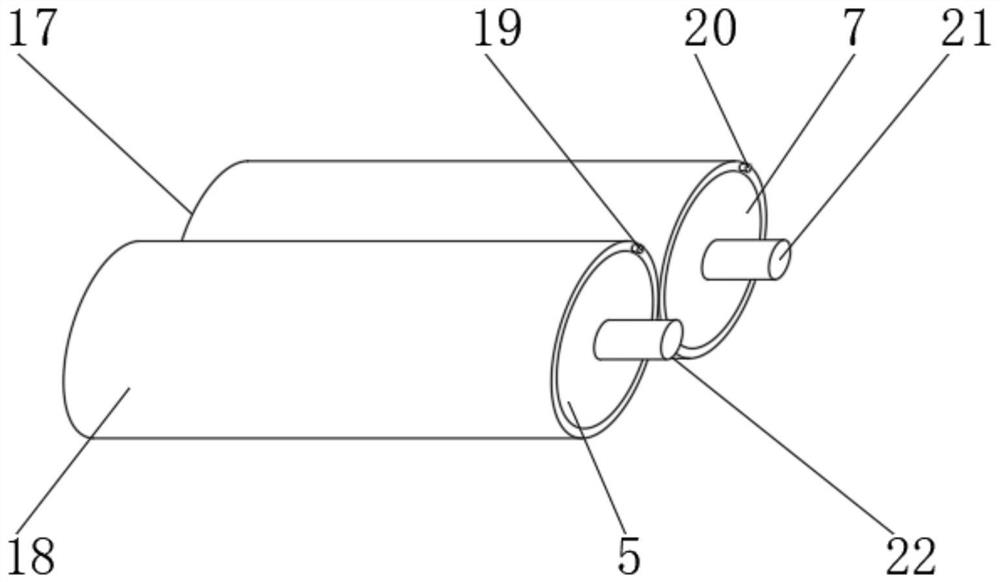

Production equipment for one-way carbon fiber prepreg cloth and preparation method thereof

PendingCN113548521AIncrease production capacityEasy to operateLaminationLamination apparatusFiberCarbon fibers

The invention discloses production equipment for one-way carbon fiber prepreg cloth and a preparation method thereof. The production equipment comprises a production equipment main body and a cross beam, wherein a positioning connecting seat is mounted at the rear end of the cross beam; a first supporting frame and a second supporting frame are mounted at the upper end of the positioning connecting seat; a first composite roller is mounted on the inner side of the first supporting frame; a second composite roller is mounted on the inner side of the second supporting frame; and a first movable clamping seat and a second movable clamping seat are mounted on the outer side of the production equipment main body. According to the production equipment for the one-way carbon fiber prepreg cloth and the preparation method thereof, a double-roller-way composite mechanism with a tensioning structure, a waxing and coating mechanism and a discharging and rolling mechanism are arranged, so that composite forming operation can be conveniently and better carried out, a good hot-press forming effect is achieved, the condition of loosening is not easy to occur, the production effect of the cloth is improved, coating operation is facilitated, discharging operation can be conveniently and better carried out, discharging is simpler, and carrying is convenient.

Owner:广东德晴复合材料有限公司

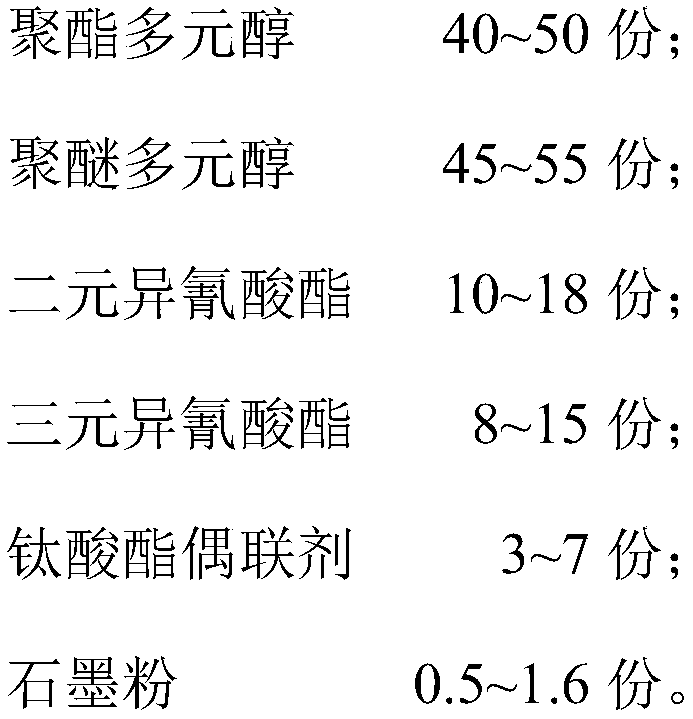

Process of using polyurethane tackifier to improve prepressing strength of formaldehyde-free artificial board

InactiveCN109093815AImprove initial strengthImprove efficiencyFlat articlesDomestic articlesPolymeric MDIEngineering

The invention provides a process of using a polyurethane tackifier to improve prepressing strength of a formaldehyde-free artificial board. The process includes following steps: step 1, smashing cropstalk to be 20-50 meshes in fineness, adding polymerization MDI glue accounting for 2-8% of weight of the crop stalk and the polyurethane tackifier accounting for 1-5% of the weight of the crop stalk,stirring and mixing, and paving to form a board blank; step 2, adopting a continuous prepress to press-roll the board blank at pressure of 250-500kN / m2; step 3, feeding the board blank into a hot press for hot-press curing at hot pressing temperature of 150-220 DEG C and at pressure of 2400-3800kN / m2 to form a rough board, and performing aftertreatment on the rough board to obtain the artificialboard.

Owner:李杰

PE colorful heat-shrinkable film and preparation method thereof

The invention belongs to the technical field of packaging materials, and particularly relates to a PE colorful heat-shrinkable film and a preparation method thereof. The PE colorful heat-shrinkable film comprises low-density polyethylene, metallocene polyethylene, high-density polyethylene, colorful synthetic polyethylene, an antioxidant, a heat stabilizer, an ultraviolet blocking agent and an anti-blocking agent. According to the heat-shrinkable film provided by the invention, the anti-blocking agent is used, so a packaging bag prepared from the heat-shrinkable film is not prone to adhesion and has good opening ability; and the high-density polyethylene and low-density polyethylene with a low melt index are added the low-density polyethylene for modification, so the obtained heat-shrinkable film is good in transparency and surface gloss, and greatly improved in mechanical properties.

Owner:ZHEJIANG BILI PACKAGING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com