Propylene resin composition for stretched sheet, and stretched sheet and thermally molded article each comprising the composition

A technology of propylene resin and resin composition, which is applied in the field of stretched sheet and thermoformed body, can solve the problems of equipment cost (high manufacturing cost, difficult roll film forming, difficult to say is sufficient, etc.), and achieve uniform stretching Good properties, excellent shape stability, and good thermoformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

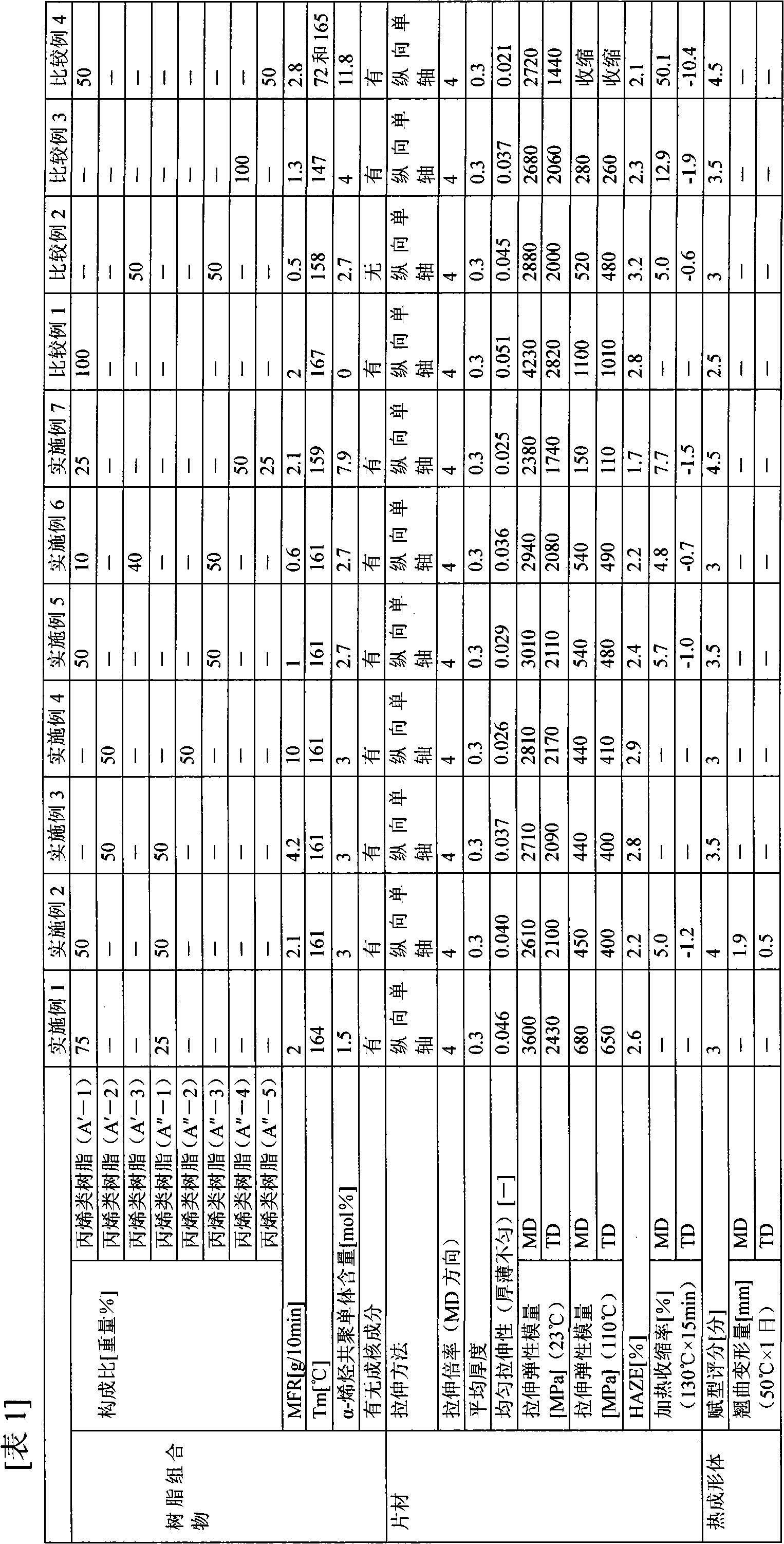

Embodiment 1

[0102] After prepolymerizing 3-methyl-1-butene (3MB-1) as a nucleating component, 0.1 parts by weight of tetrakis[methylene-3-( 3,5-di-tert-butyl-4-hydroxyphenyl) propionate] methane (IRGANOX1010, manufactured by Ciba Specialty Chemicals, trademark) and 0.1 parts by weight of tris(2,4-di-tert-butylphenol) phosphate (IRGAFOS168, produced by Ciba Specialty Chemicals, trademark), as a neutralizing agent, mixed with 0.1 parts by weight of calcium stearate (produced by Nippon Oils and Fats Co., Ltd.), using a single-screw extruder, melting and kneading with a resin temperature of 230° C. to produce Granules become granular. Wherein, the resin composition is obtained by 75% by weight of high melting point propylene resin (A′-1) obtained by homopolymerization of propylene with Tm=167°C, MFR=2g / 10min, mmmm=0.972, and 6mol% of propylene and ethylene by copolymerization Tm = 135 ° C, MFR = 2g / 10min low melting point propylene resin (A"-1) 25% by weight combined. At this time, the ratio...

Embodiment 2

[0106] In addition to using a resin combination in which 50% by weight of the high-melting propylene-based resin (A'-1) used in Example 1 and 50% by weight of the low-melting propylene-based resin (A"-1) used in Example 1 were used Table 1 shows the results in the same manner as in Example 1 except that the ratio of the 3MB-1 polymer was 0.018% by weight in the resin composition.

Embodiment 3

[0108] After pre-polymerization of 3-methyl-1-butene as a nucleating component, a high-melting propylene-based resin (A'- 2) A resin composition obtained by combining 50% by weight and 50% by weight of the low-melting propylene resin (A″-1) used in Example 1 (the ratio of the 3MB-1 polymer in the resin composition is 0.017% by weight ) except that it was carried out in the same manner as in Example 1, and the results are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com