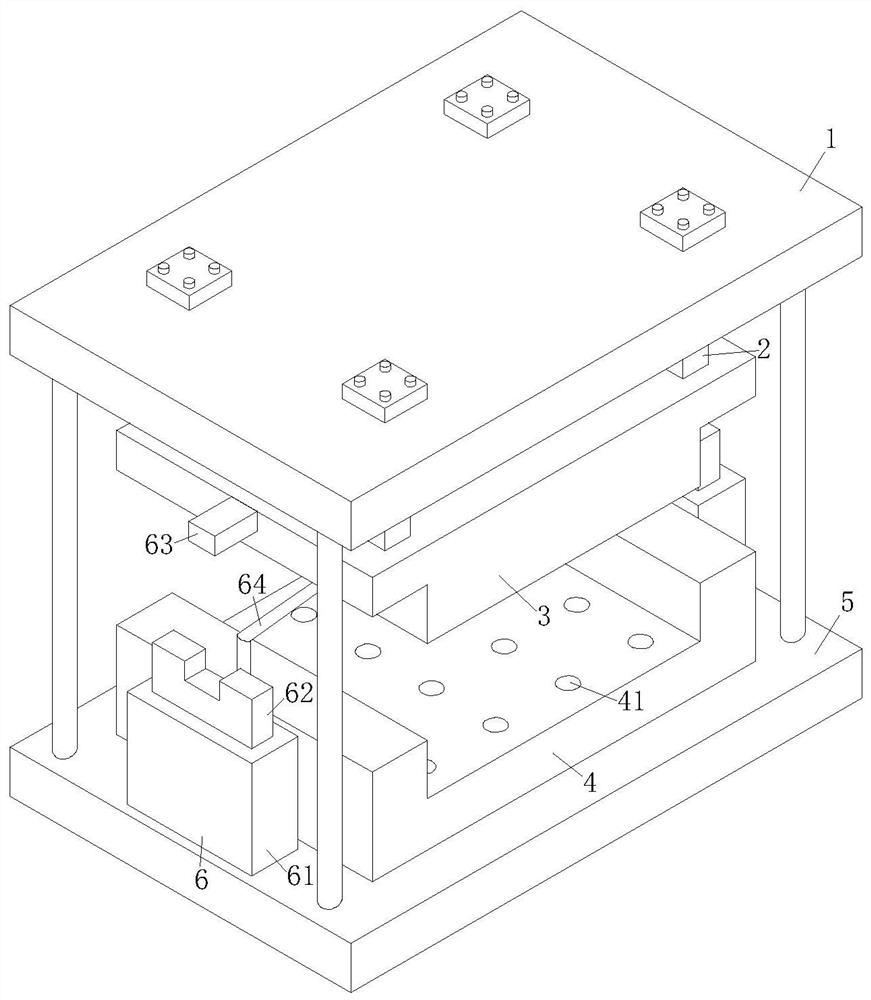

A polymer film thermocompression forming device and film forming process

A technology of polymer film and hot pressing, applied in the field of molds, can solve the problems of low hot pressing accuracy and low hot pressing efficiency, and achieve the effects of improving the thermoforming efficiency, simple structure and improving the thermoforming effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

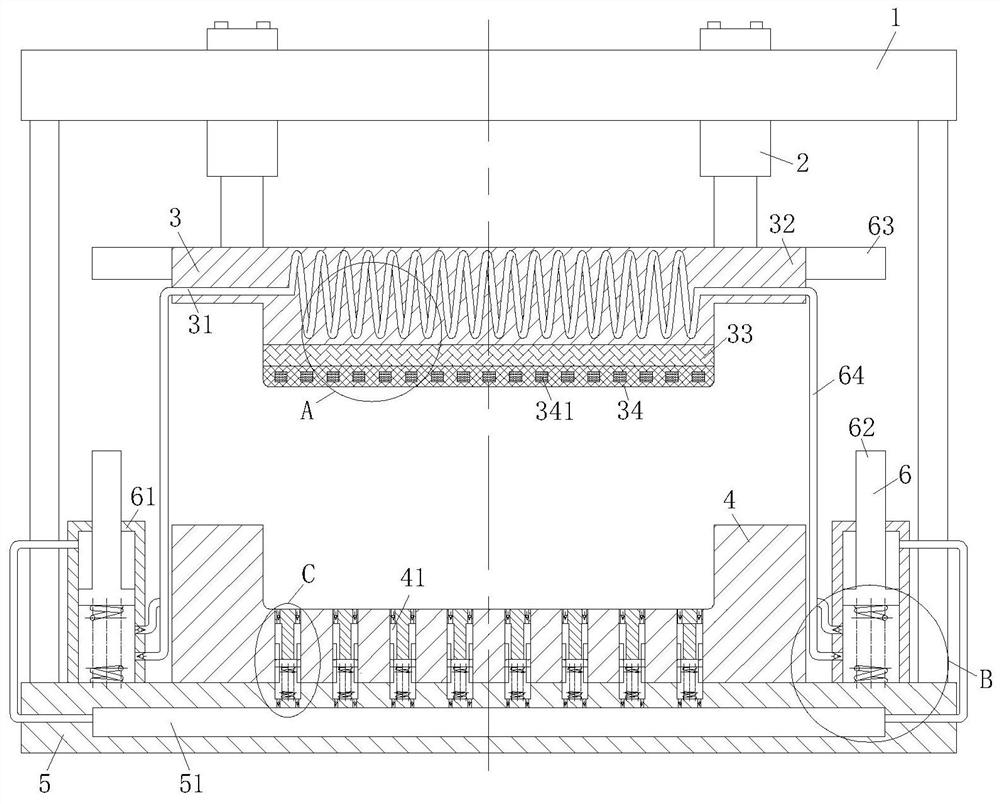

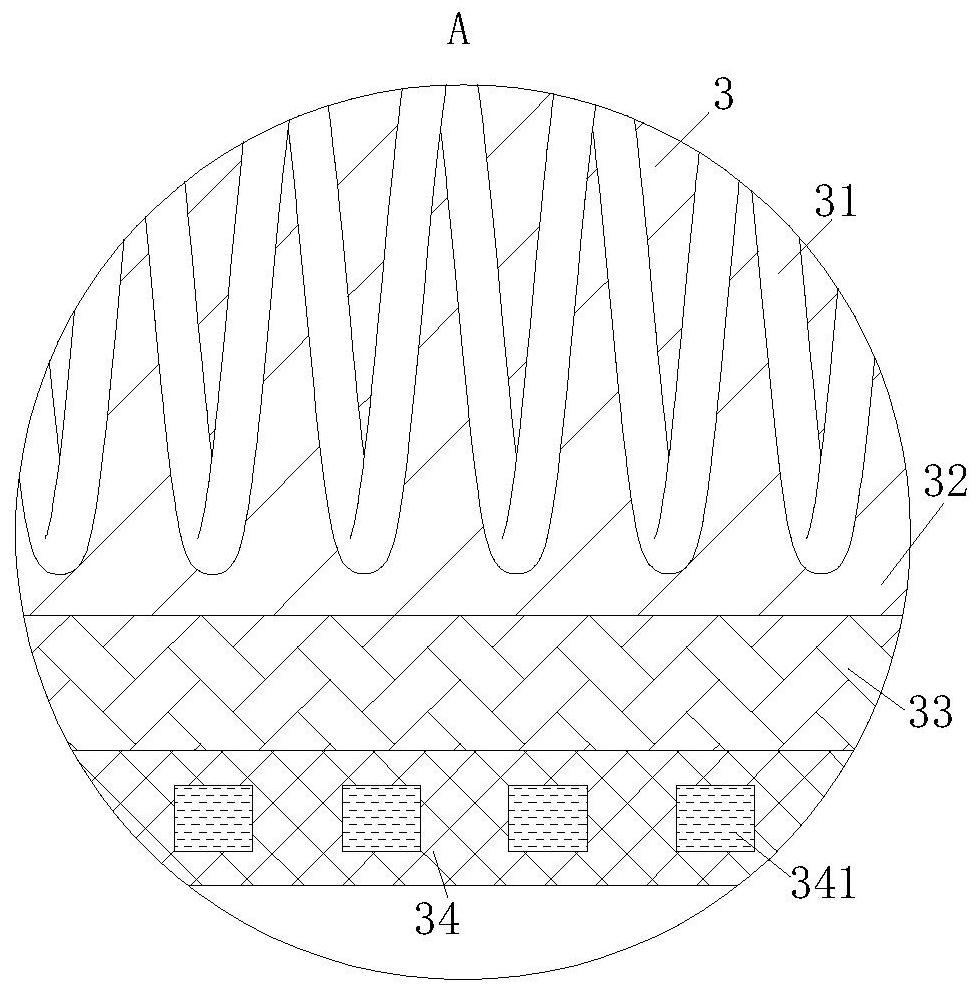

[0028] As a specific embodiment of the present invention, the shape of the No. 1 channel 31 is spiral, and the contact area between the hot gas and the upper die 3 is increased through the No. 1 channel 31 of the spiral shape; the present invention adopts this design , so that the hot gas input into the No. 1 pipeline fully contacts with the upper die 3, and makes the upper die 3 fully heated, which improves the thermoforming effect of the polymer film.

[0029] As a specific embodiment of the present invention, the upper die 3 is composed of a metal seat 32, a transition layer 33 and a rubber release layer 34; one end of the transition layer 33 is connected to the rubber release layer 34, and the other end is connected to the metal seat 32 connection; through the mutual cooperation between the metal seat 32, the transition layer 33 and the rubber anti-sticking layer 34, the rupture of the polymer film is avoided; through this design, the transition layer 33 can bear a part of ...

specific Embodiment approach

[0031] As a specific embodiment of the present invention, a No. 1 chamber 51 is provided on the lower bottom plate 5, and the No. 1 chamber 51 communicates with the housing 61 through a hose, and the communication point is located above the T-shaped movable plate 62; The No. 1 hole 41 is provided with an ejection unit 7; the ejection unit 7 includes a No. 1 plate 71, a T-shaped ejector rod 72 and a locking block 73; one end of the No. 1 plate 71 is connected to the T-shaped top The outlet rod 72 is connected, and the T-shaped part of the T-shaped ejector rod 72 is provided with an air outlet, and the other end of the No. 1 plate 71 is fixedly connected to the groove of the upper bottom plate through a spring, and communicates with the No. 1 chamber 51 through the channel; The locking block 73 is fixedly connected to the side wall of the No. 1 hole 41, and the locking block 73 and the No. 1 plate 71 are engaged with each other; Cooperate with each other to realize the ejection ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com