Production equipment for one-way carbon fiber prepreg cloth and preparation method thereof

A technology of unidirectional carbon fiber and production equipment, applied in chemical instruments and methods, layered products, thin material processing, etc., can solve problems such as poor efficiency, low cost of packaging materials, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

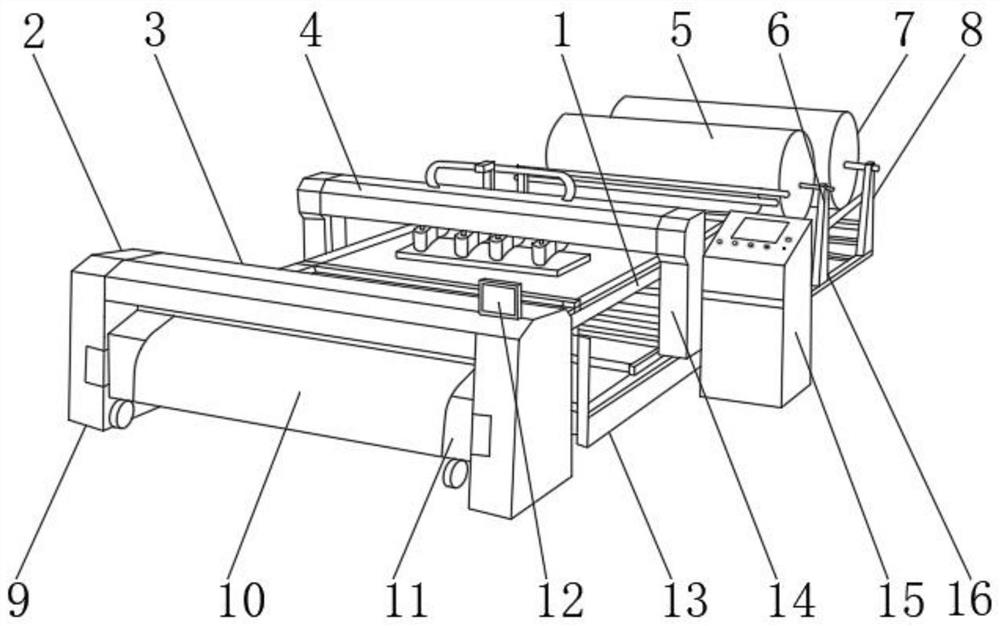

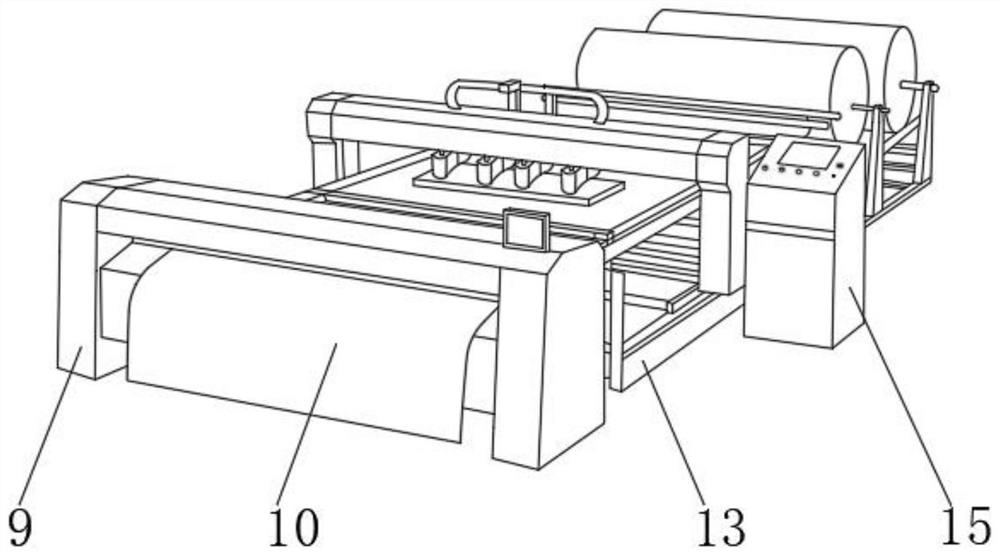

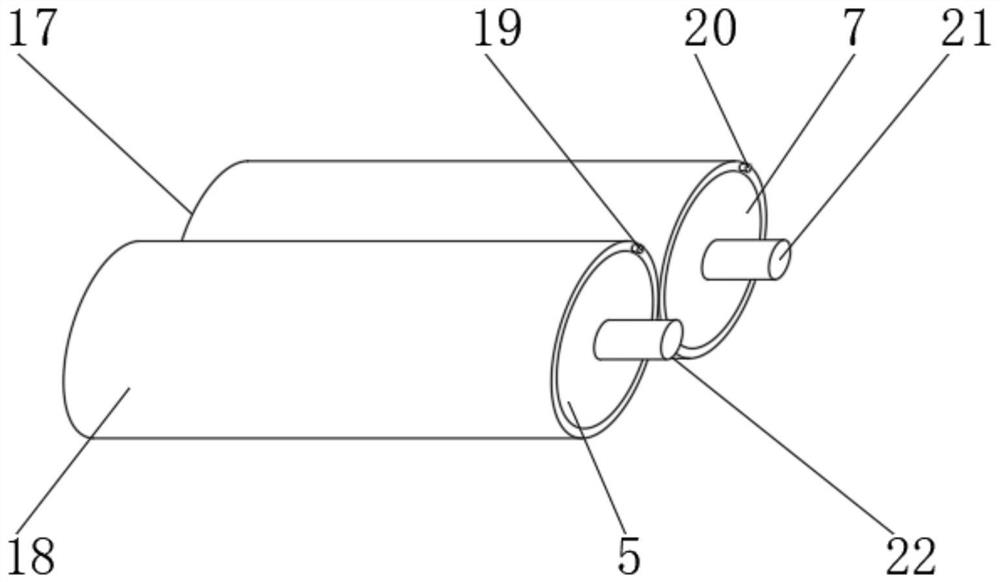

[0033] Such as Figure 1-6 As shown, a production equipment for unidirectional carbon fiber prepreg cloth includes a production equipment main body 1 and a crossbeam 2. The rear end of the crossbeam 2 is equipped with a positioning connection seat 16, and the upper end of the positioning connection seat 16 is installed with No. 1 support frame 6 and two No. support frame 8, No. 1 composite roll 5 is installed on the inside of No. 1 support frame 6, No. 2 composite roll 7 is installed on the inside of No. 2 support frame 8, No. 1 movable deck 24 and No. Movable deck 14, the front end of production equipment main body 1 is equipped with supporting discharge seat 9.

[0034] The upper end of the support discharge seat 9 is equipped with a crossbeam 2, the outside of the crossbeam 2 is equipped with a reinforcing rib 3, the upper end of the crossbeam 2 is equipped with a display panel 12, the side of the production equipment main body 1 is equipped with a control box 15, the produ...

Embodiment 2

[0043] On the basis of Example 1, as Figure 1-6 As shown, a production equipment for unidirectional carbon fiber prepreg cloth includes a production equipment main body 1 and a crossbeam 2. The rear end of the crossbeam 2 is equipped with a positioning connection seat 16, and the upper end of the positioning connection seat 16 is installed with No. 1 support frame 6 and two No. support frame 8, No. 1 composite roll 5 is installed on the inside of No. 1 support frame 6, No. 2 composite roll 7 is installed on the inside of No. 2 support frame 8, No. 1 movable deck 24 and No. Movable deck 14, the front end of production equipment main body 1 is equipped with supporting discharge seat 9.

[0044] The upper end of the support discharge seat 9 is equipped with a crossbeam 2, the outside of the crossbeam 2 is equipped with a reinforcing rib 3, the upper end of the crossbeam 2 is equipped with a display panel 12, the side of the production equipment main body 1 is equipped with a con...

Embodiment 3

[0053] On the basis of Example 2, such as Figure 1-6 As shown, a production equipment for unidirectional carbon fiber prepreg cloth includes a production equipment main body 1 and a crossbeam 2. The rear end of the crossbeam 2 is equipped with a positioning connection seat 16, and the upper end of the positioning connection seat 16 is installed with No. 1 support frame 6 and two No. support frame 8, No. 1 composite roll 5 is installed on the inside of No. 1 support frame 6, No. 2 composite roll 7 is installed on the inside of No. 2 support frame 8, No. 1 movable deck 24 and No. Movable deck 14, the front end of production equipment main body 1 is equipped with supporting discharge seat 9.

[0054] The upper end of the support discharge seat 9 is equipped with a crossbeam 2, the outside of the crossbeam 2 is equipped with a reinforcing rib 3, the upper end of the crossbeam 2 is equipped with a display panel 12, the side of the production equipment main body 1 is equipped with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com