Patents

Literature

156results about How to "Not easy to loosen" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

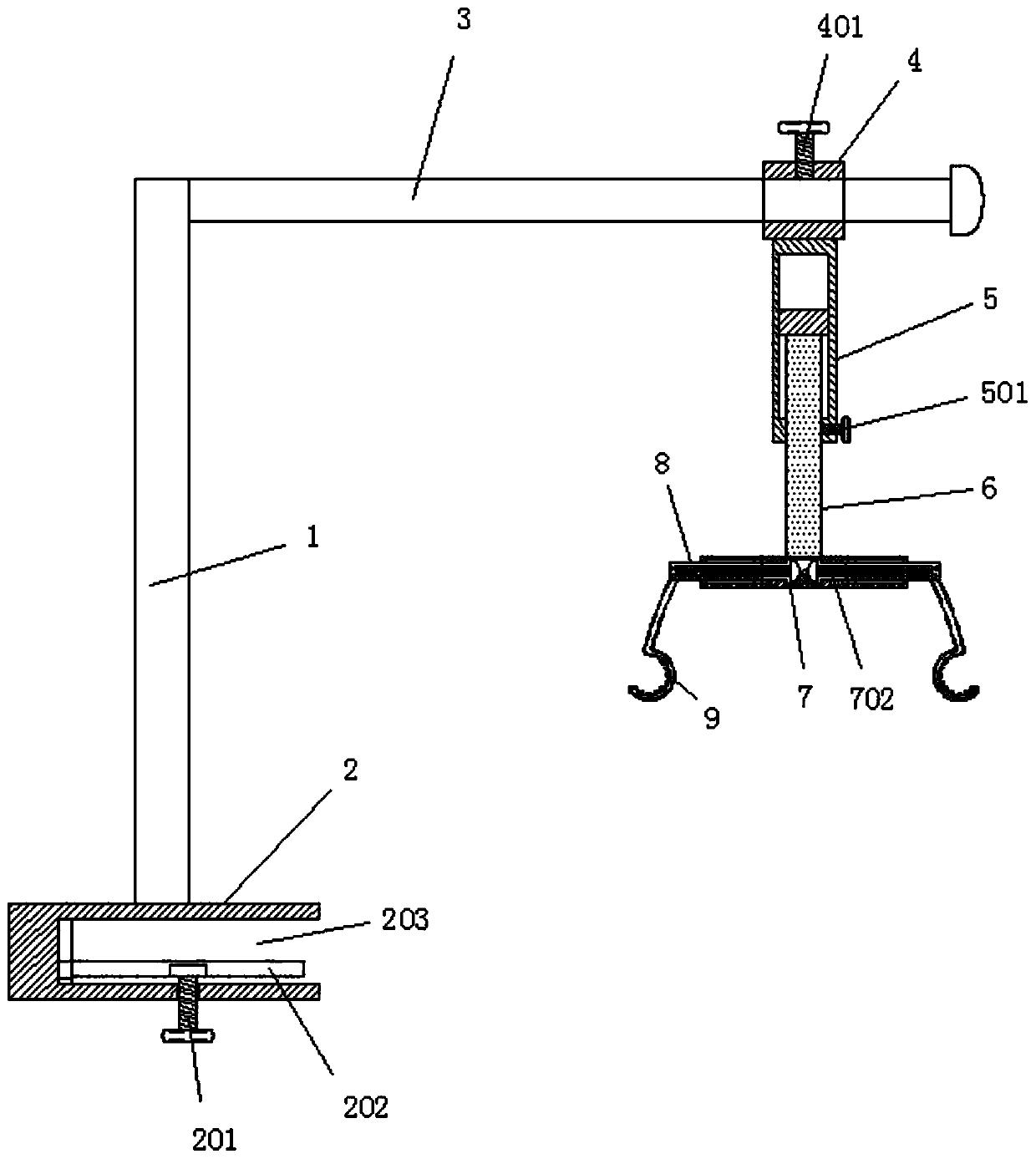

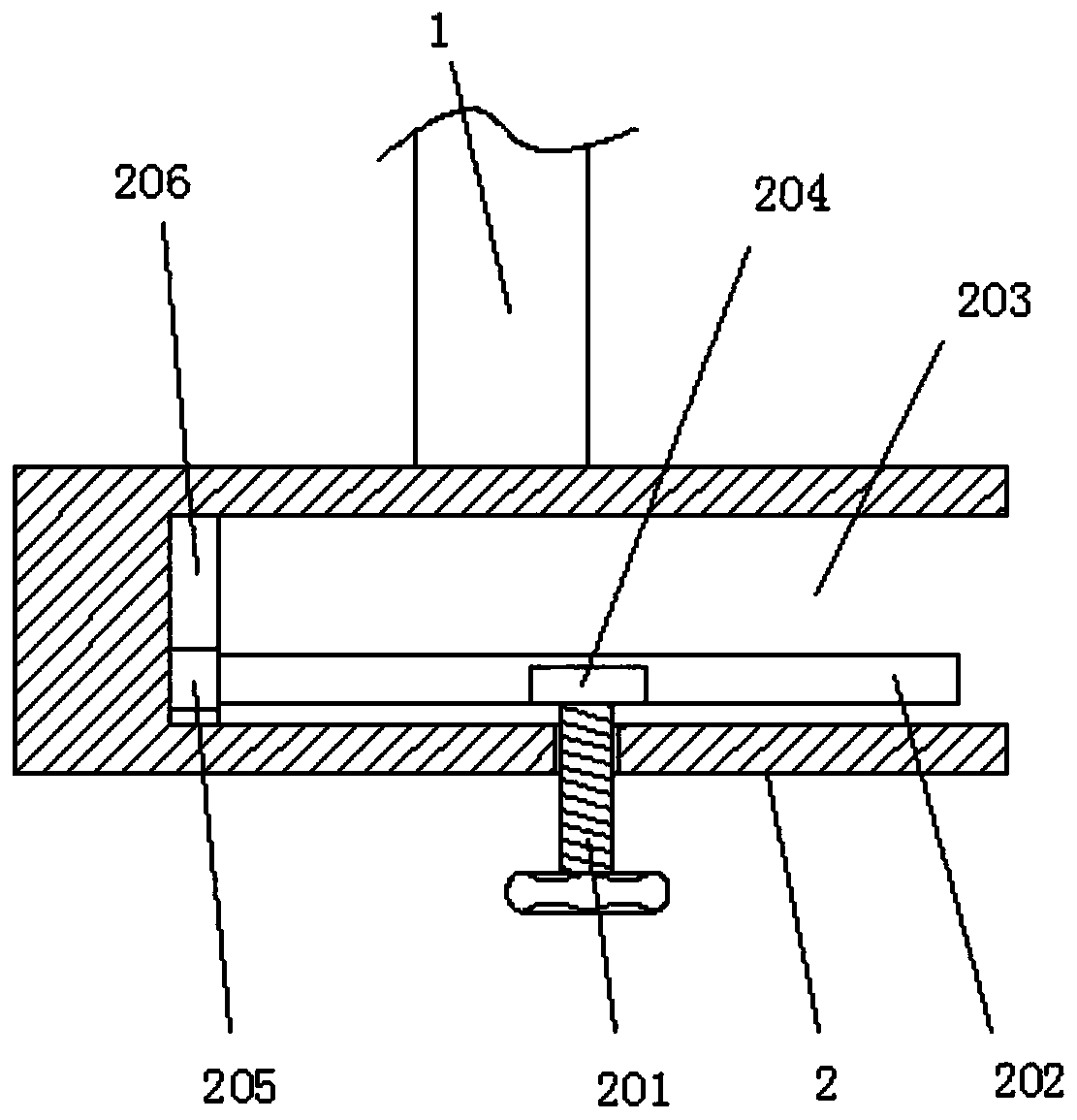

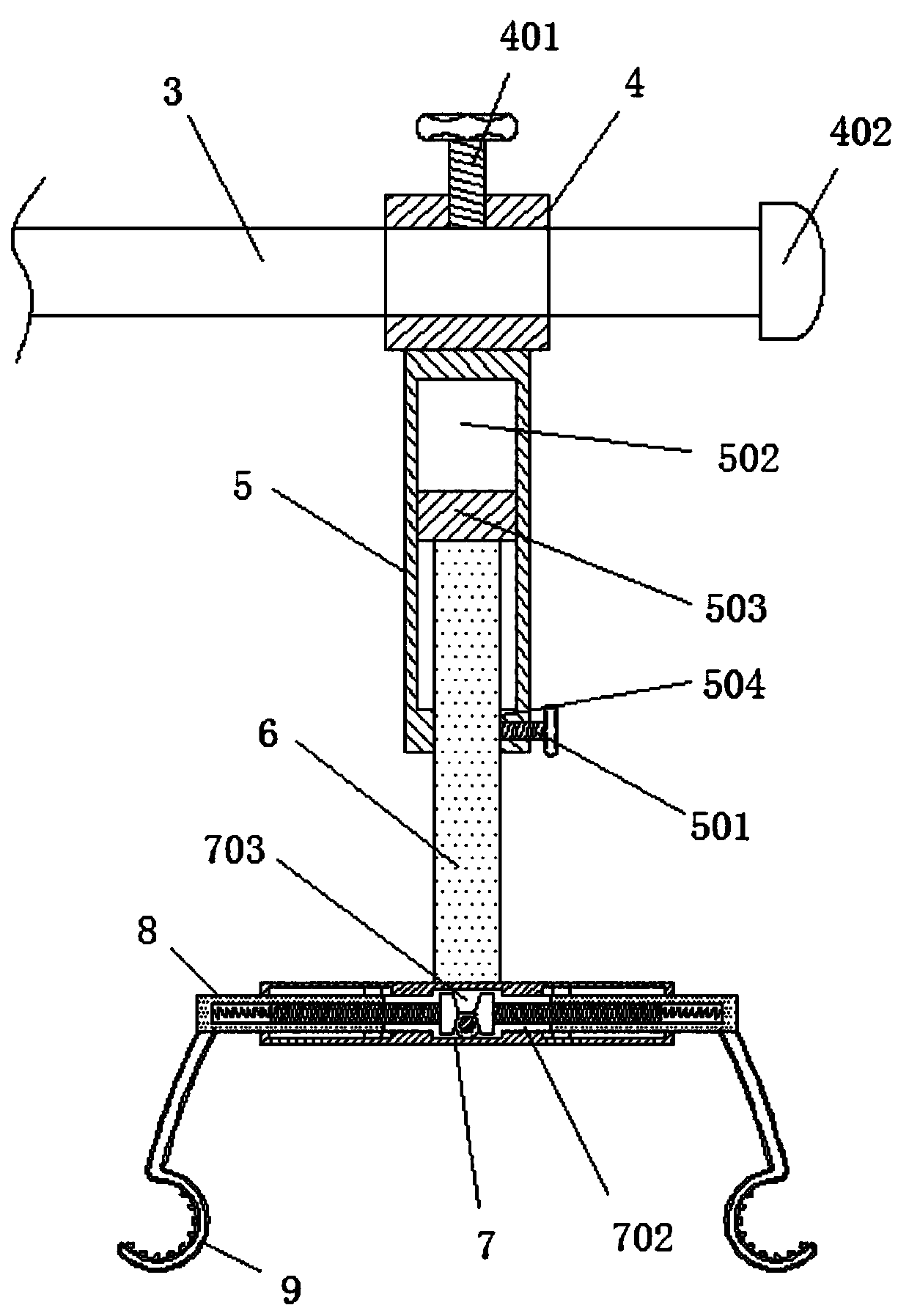

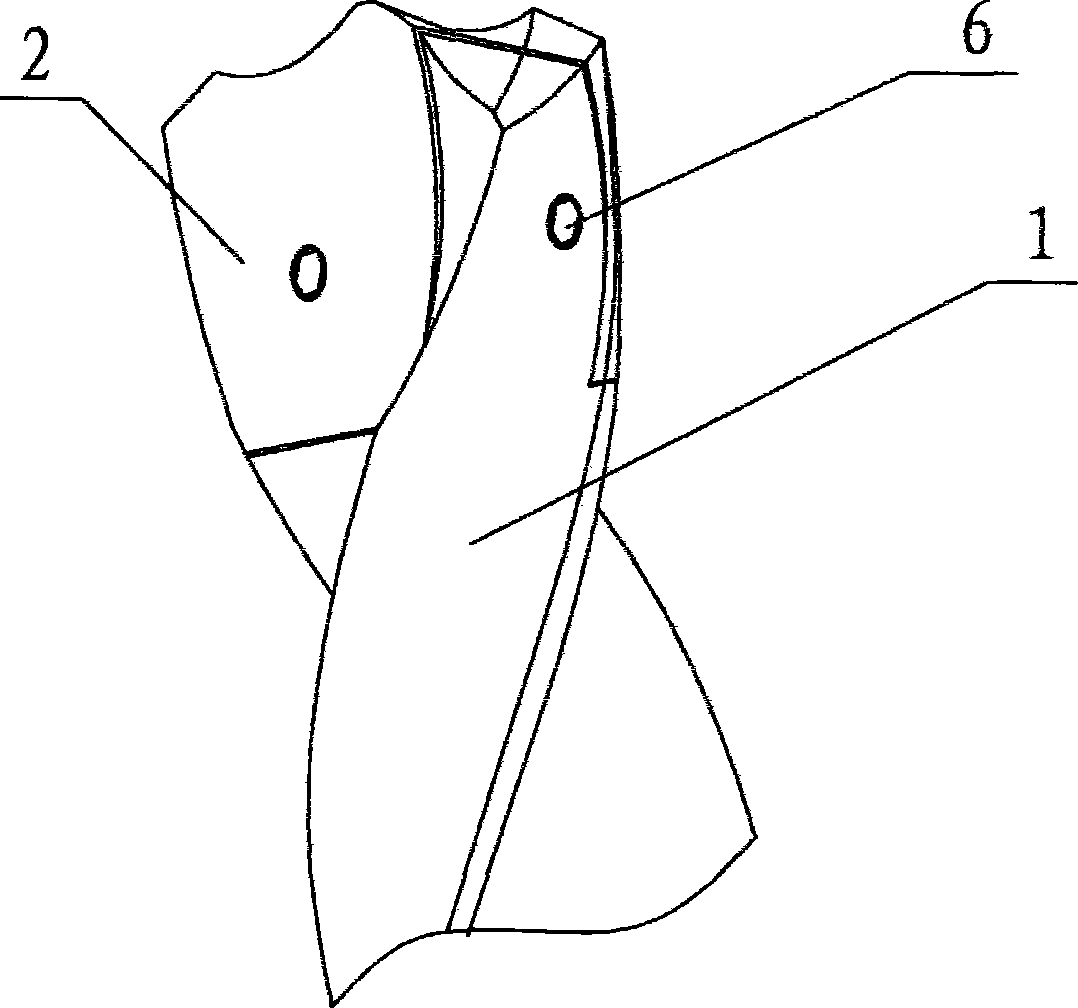

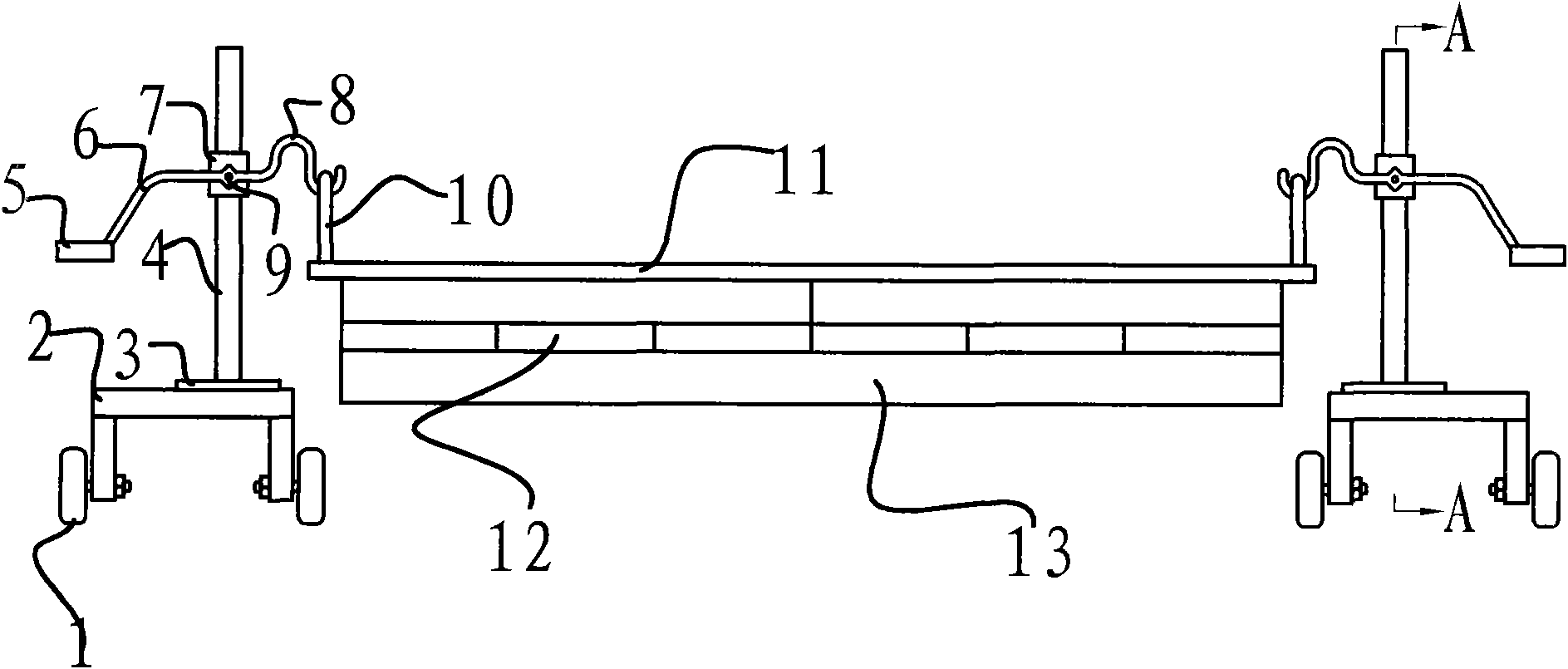

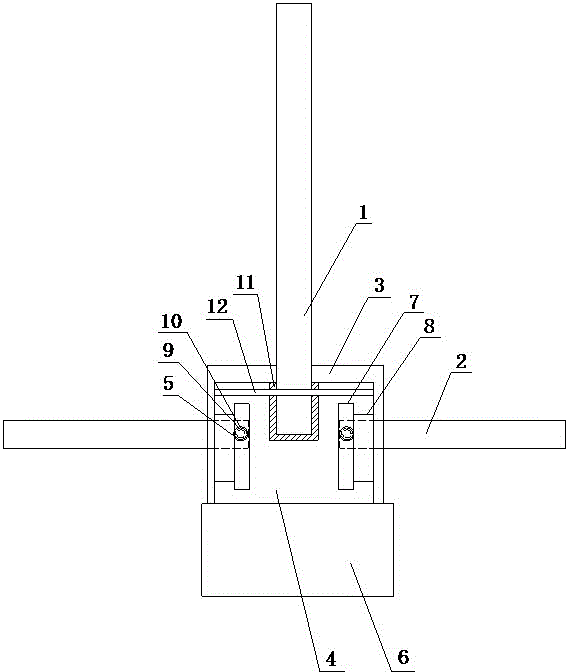

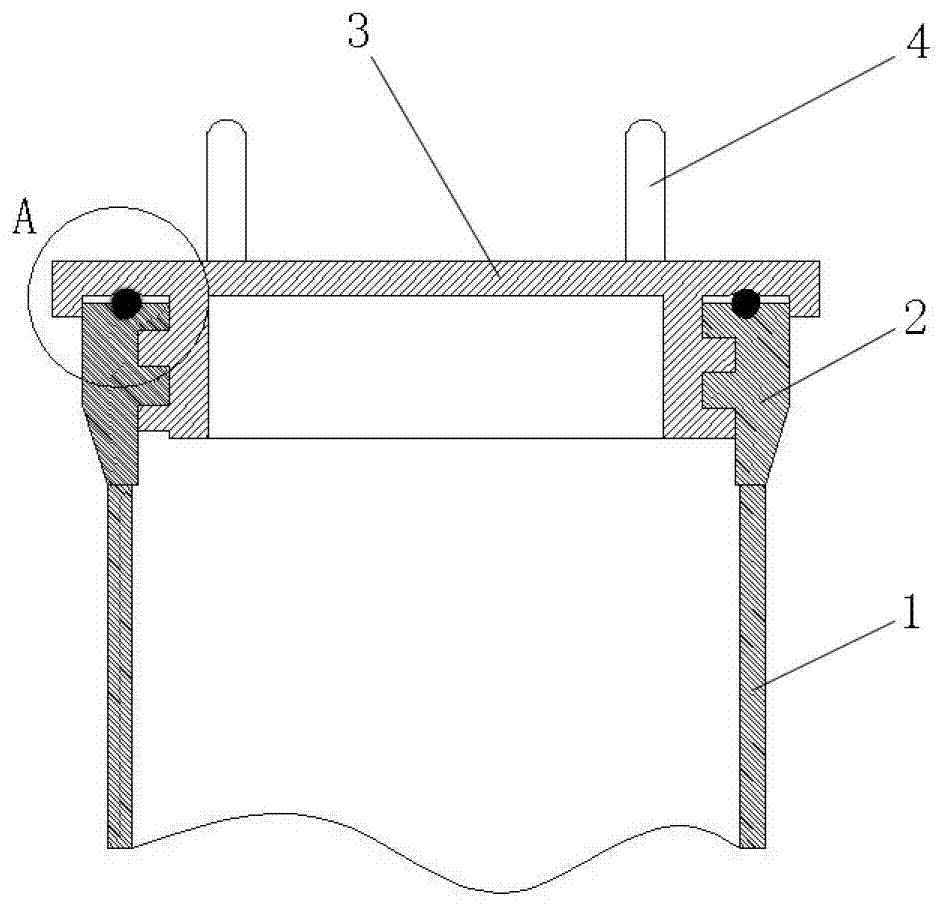

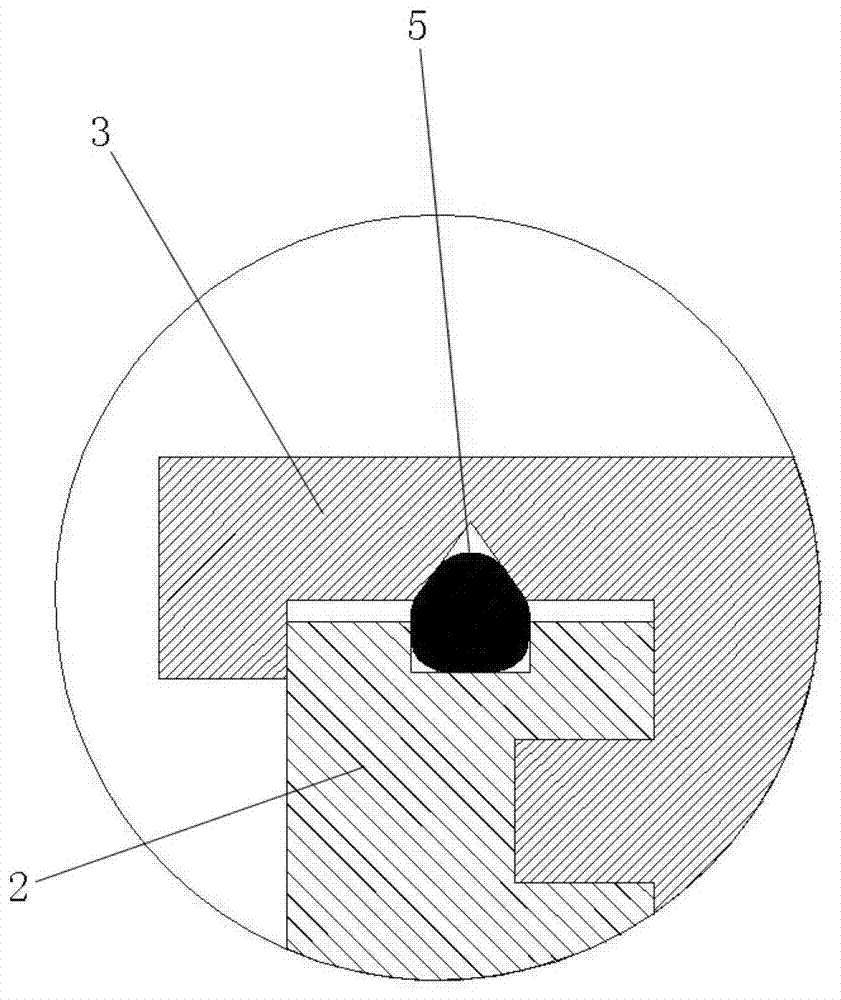

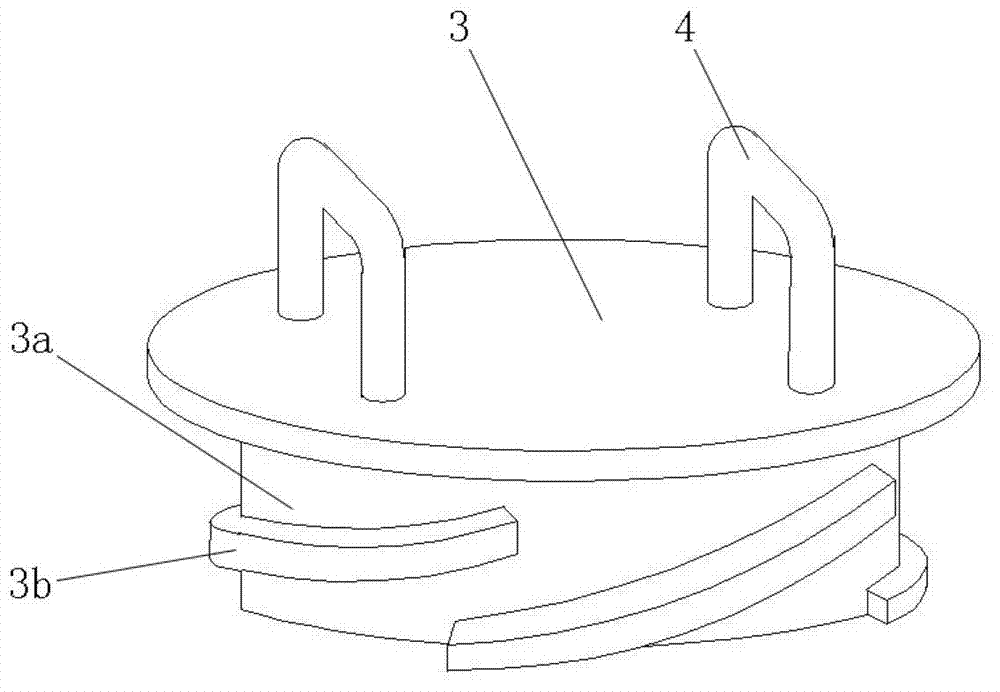

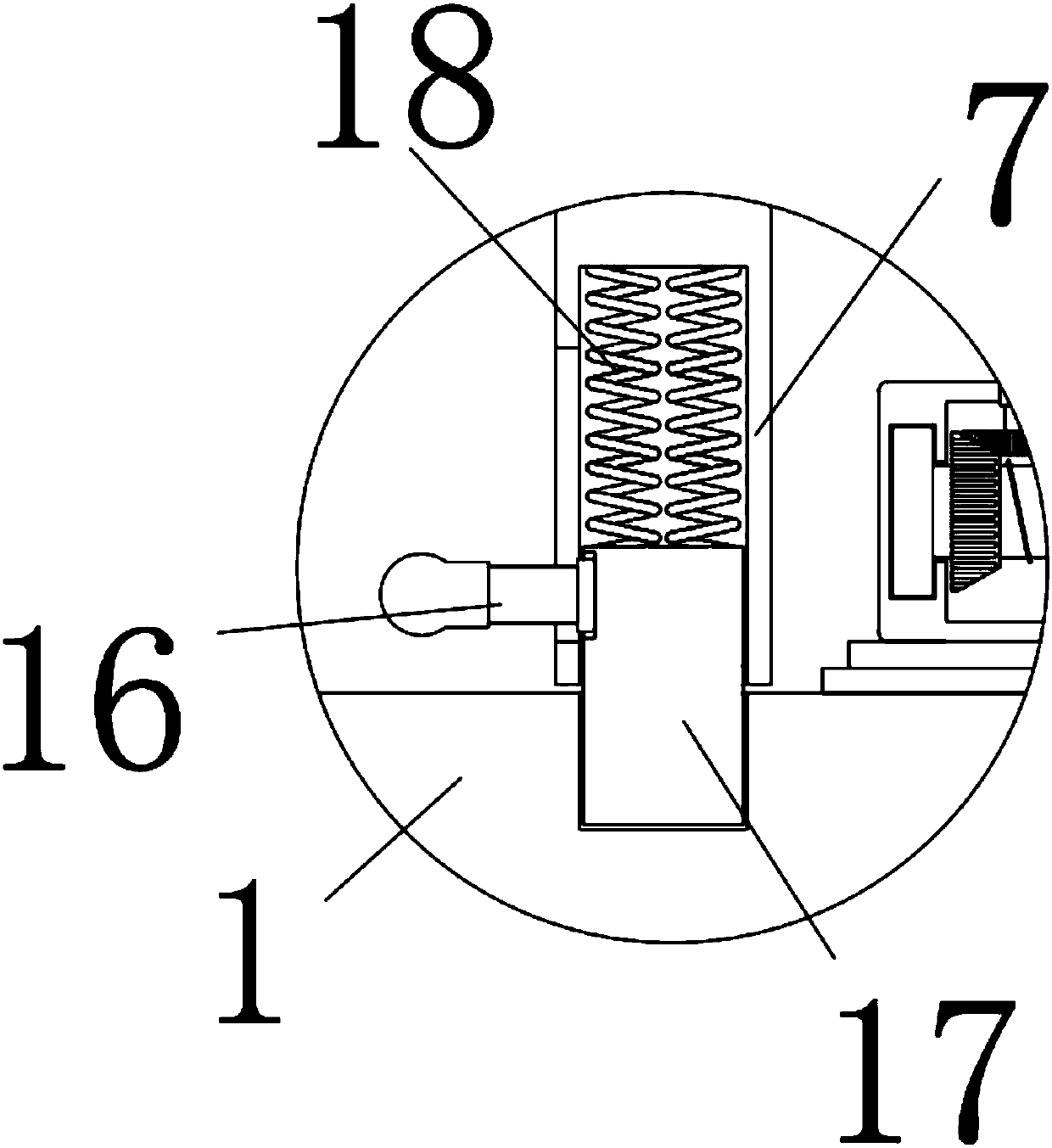

Sliding located draw hook for surgical operations of livers and gallbladders

InactiveCN110893110AEasy to adjustEasy to adjust up and down positionOperating tablesMedical practitionerStructural engineering

Owner:李捷

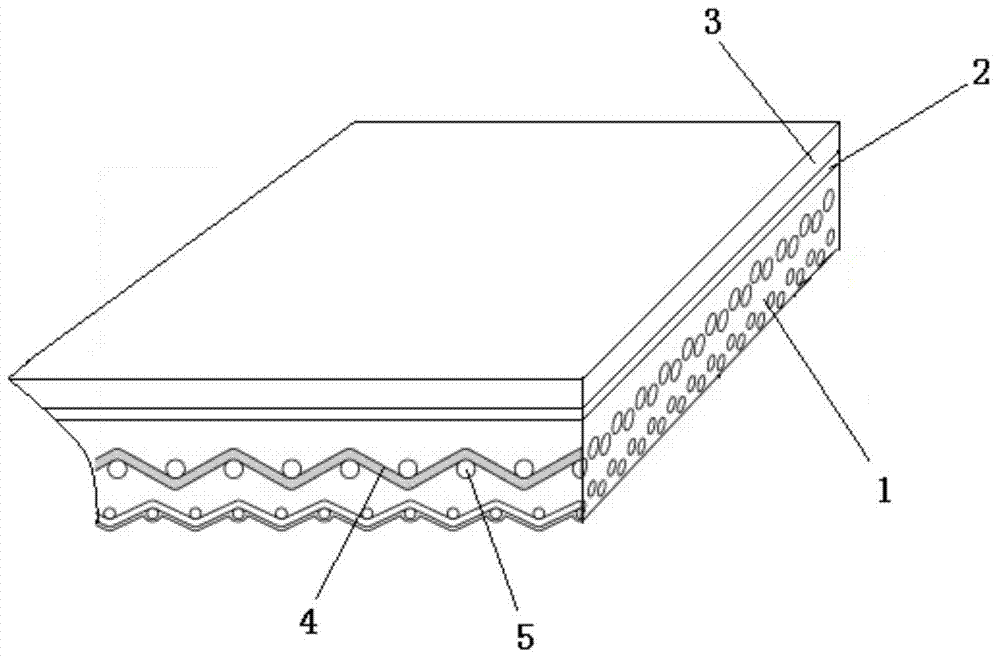

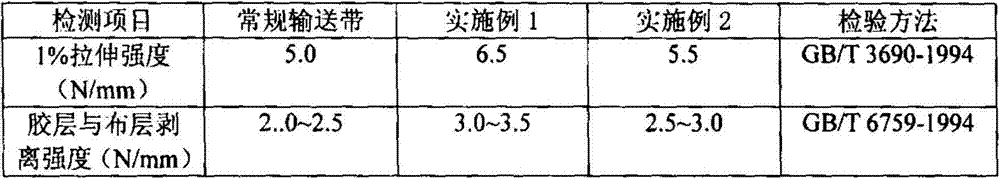

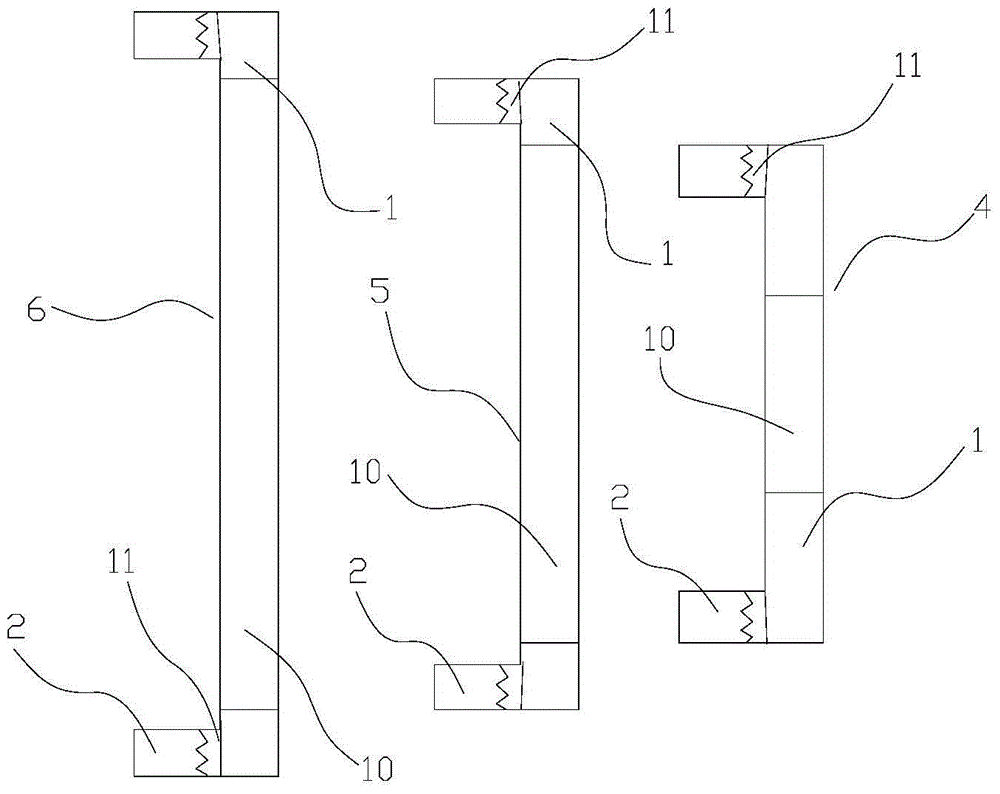

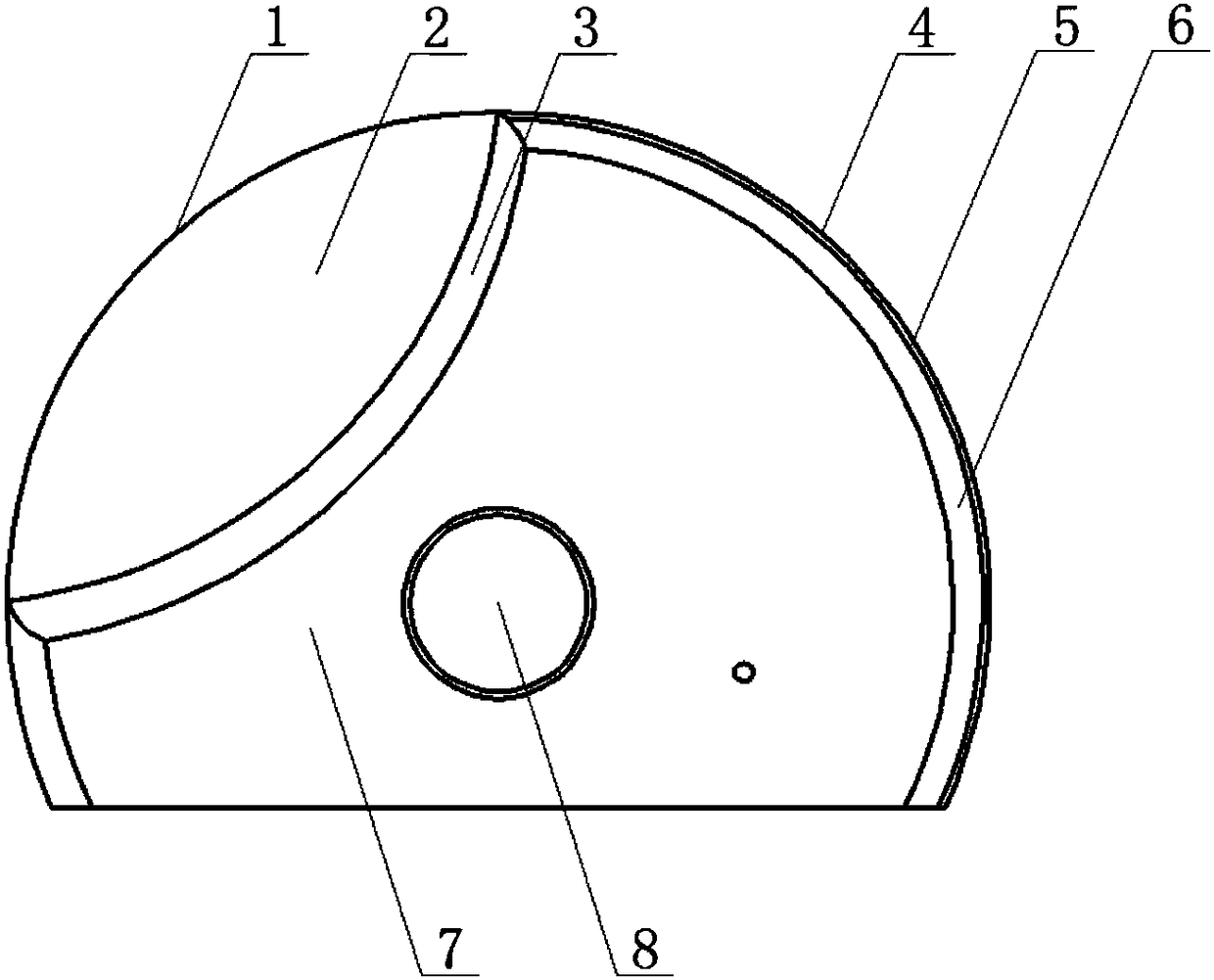

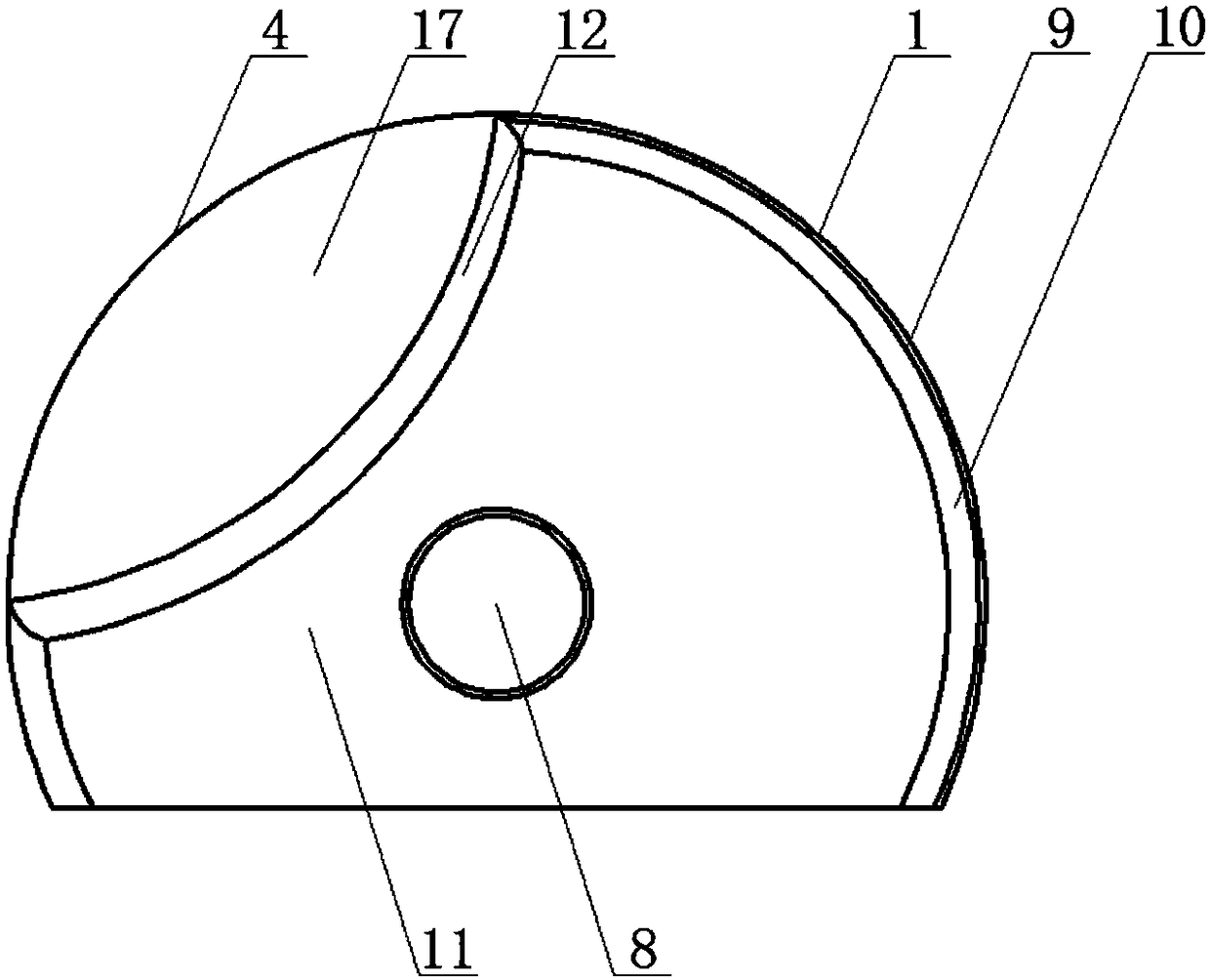

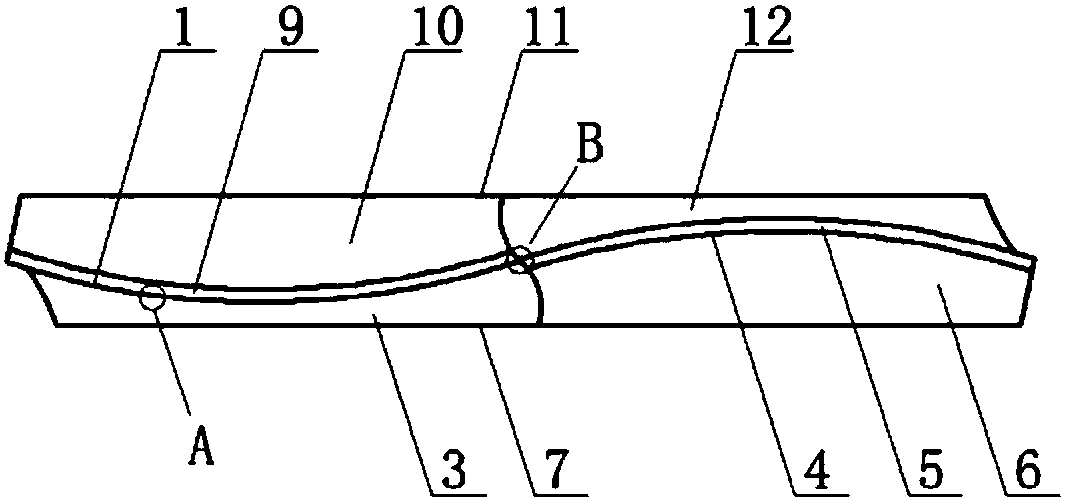

Conveying belt capable of reducing lateral side fuzz amount generation and preparing method of conveying belt

ActiveCN104326212AAvoid bumps or wavesPut an end to the big knife bend phenomenonConveyorsBeltsPre treatmentWear resistant

The invention relates to a conveying belt capable of reducing lateral side fuzz amount generation. The conveying belt comprises a framework layer, a pasting layer and a covering surface layer, wherein the framework layer is formed by single-layer or double-layer fabrics, the pasting layer is arranged between the framework layer and the covering surface layer, the pasting layer and the covering surface layer are respectively made of thermoplastic elastic bodies, the conveying belt is pretreated through immersing the fabrics of the framework layer by polyurethane glue water, then, a coating process is adopted for sequentially coating the pasting layer and the covering surface layer onto the framework layer, and then, the conveying belt is prepared through heat treatment, rolling pressing and edge cutting. Compared with the prior art, the conveying belt prepared by the invention has the advantages that the wear-resistant performance is good, in the use process, the abrasion damage to the two sides of the conveying belt can be obviously reduced, and the generation of lateral side fuzz is effectively prevented, so the pollution to carrying and conveying objects in the production process can be reduced, meanwhile, the prepared conveying belt does not need the later stage processing edge sealing process, the production efficiency can be greatly improved, and good application prospects are realized.

Owner:AA IND BELTING (SHANGHAI) CO LTD

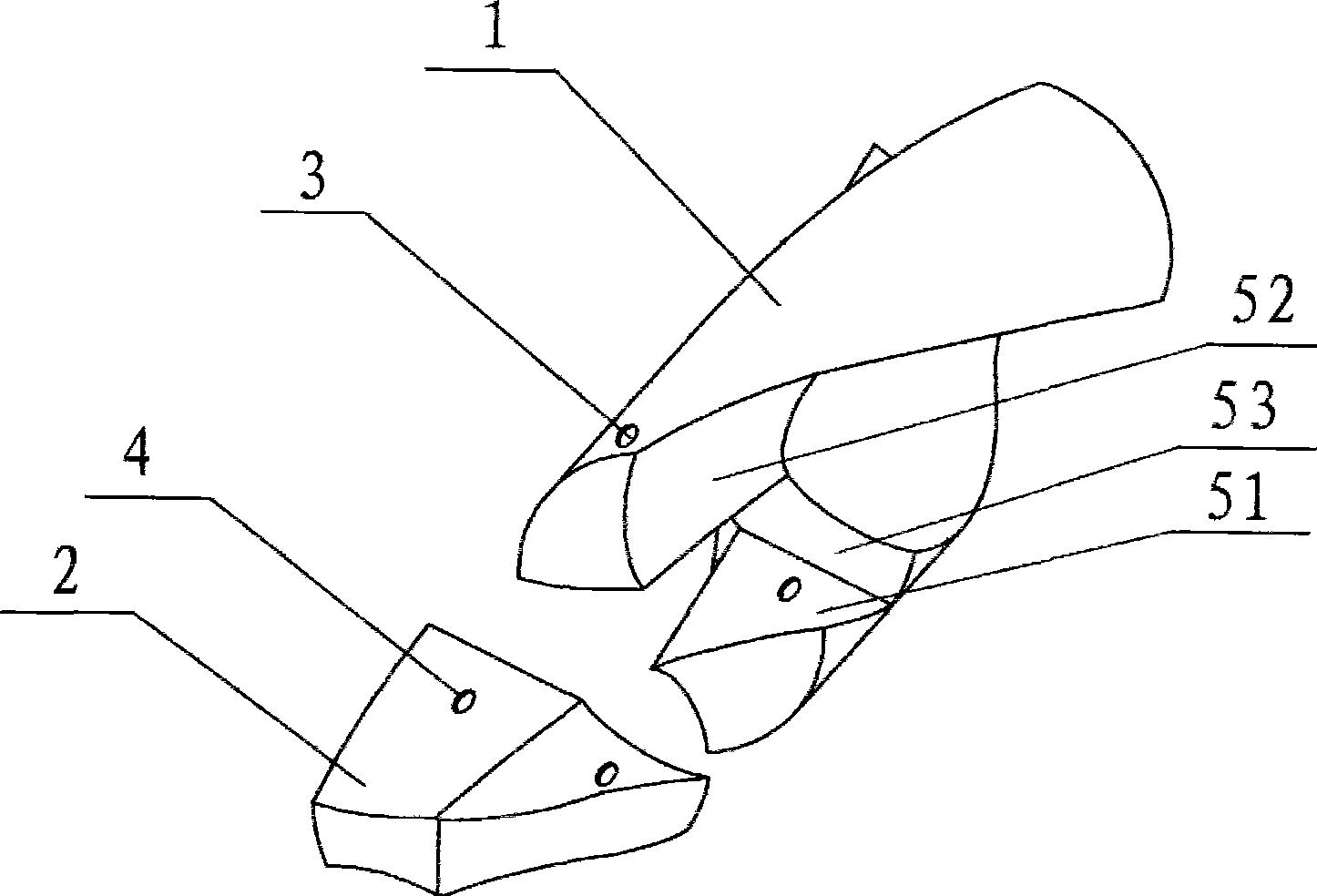

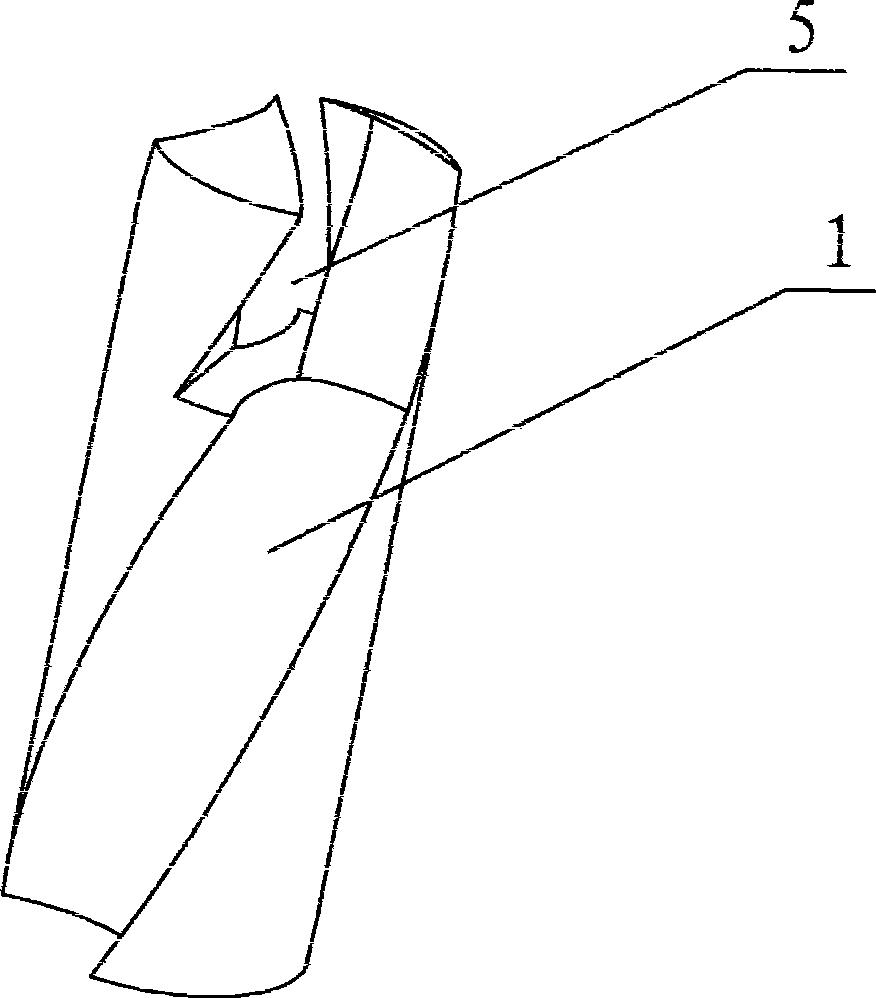

Method for preparing grinding-free drill head and drill head

The invention provides a manufacturing method of a grinding-free drill bit, which comprises a drill body and a detachable cutting blade connected on the front end of the drill body; the manufacturing method is characterized by comprising the following steps: (1) according to the set depth and width, the front end of the drill body is equipped with a spiral groove for holding the cutting blade; both inner side walls of the spiral groove are arcwall faces, and the two arcwall faces are of central symmetry, so that the entire outline of the spiral groove is of S shape; each arcwall surface is a parallelogram after being unfolded; (2) the cutting blade with side walls being two symmetrical arcwall faces and matched with the inner wall shape of the spiral groove is prepared; (3) the cutting blade is placed into the drill spiral groove, and connected to prepare the grinding-free drill bit. No sequence exists between step (1) and step (2). The manufacturing method also provides the grinding-free drill bit prepared by using the method.

Owner:苏茂均

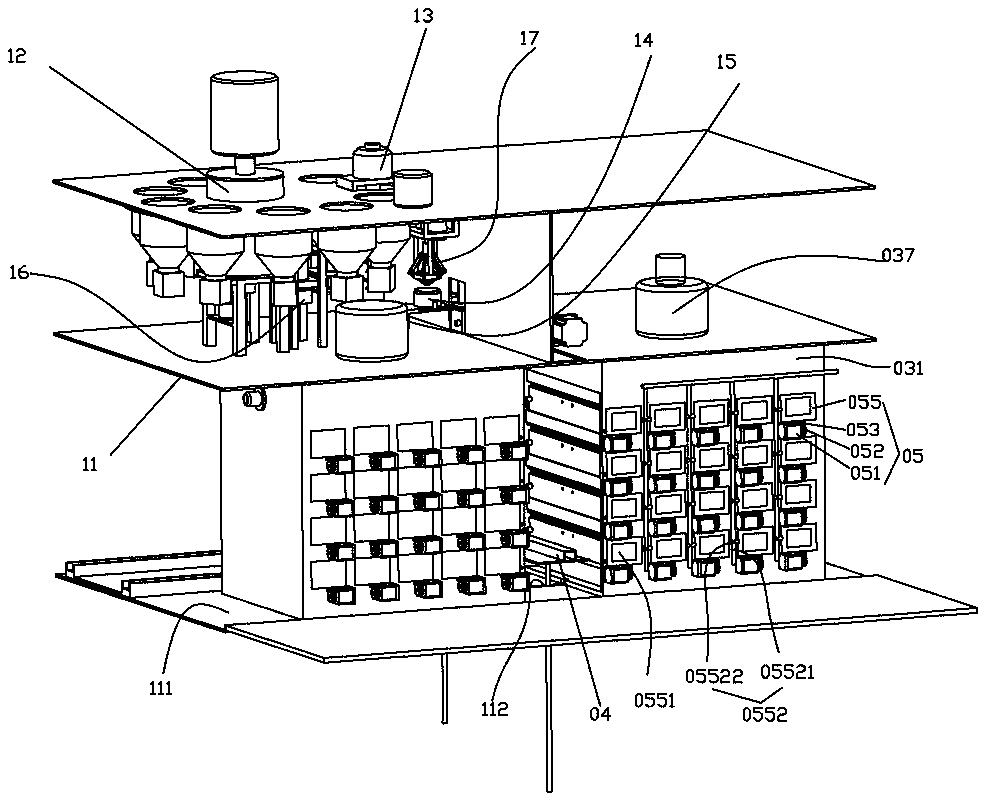

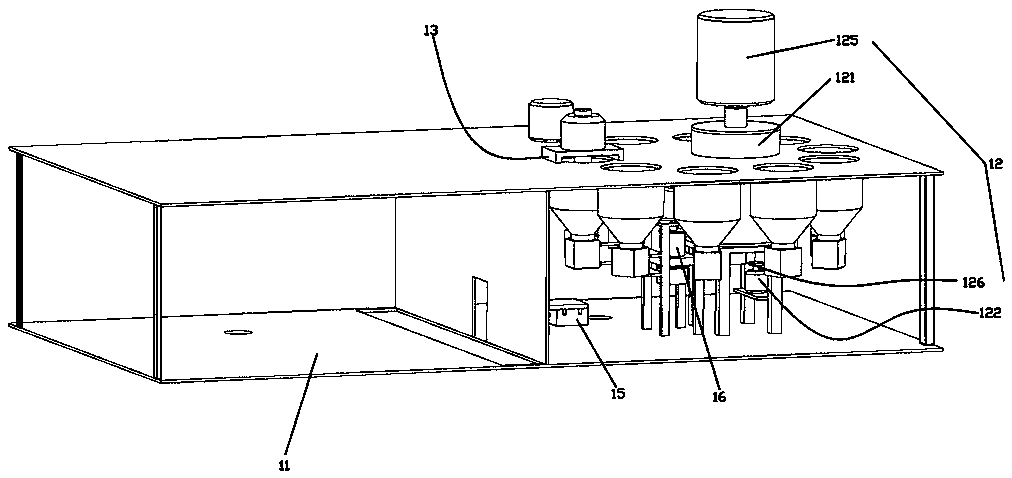

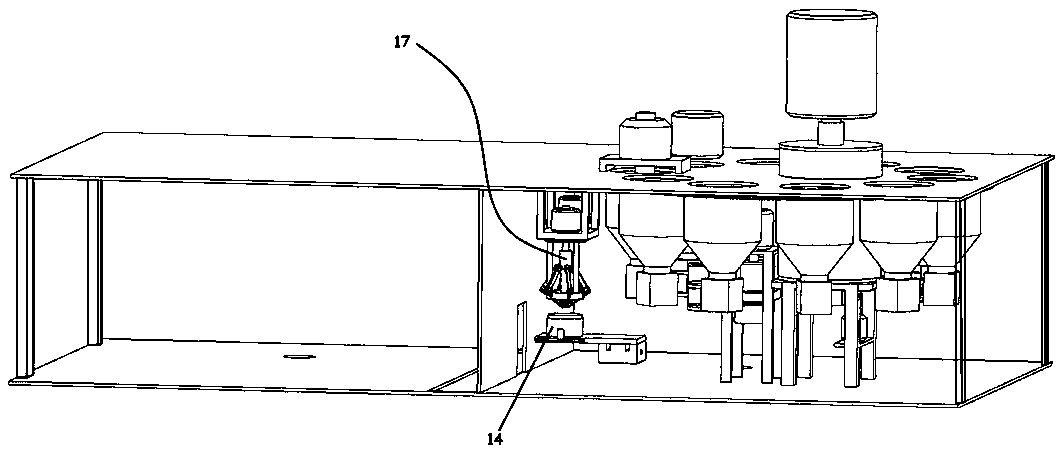

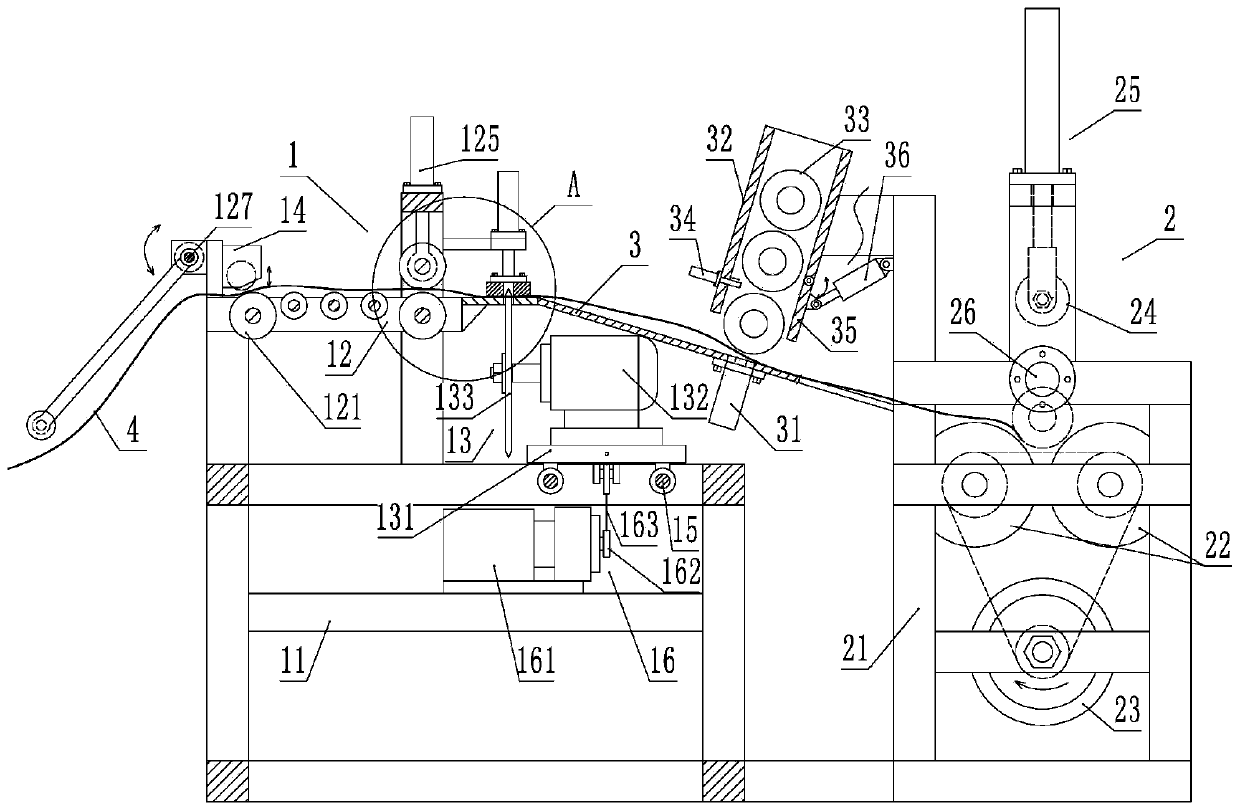

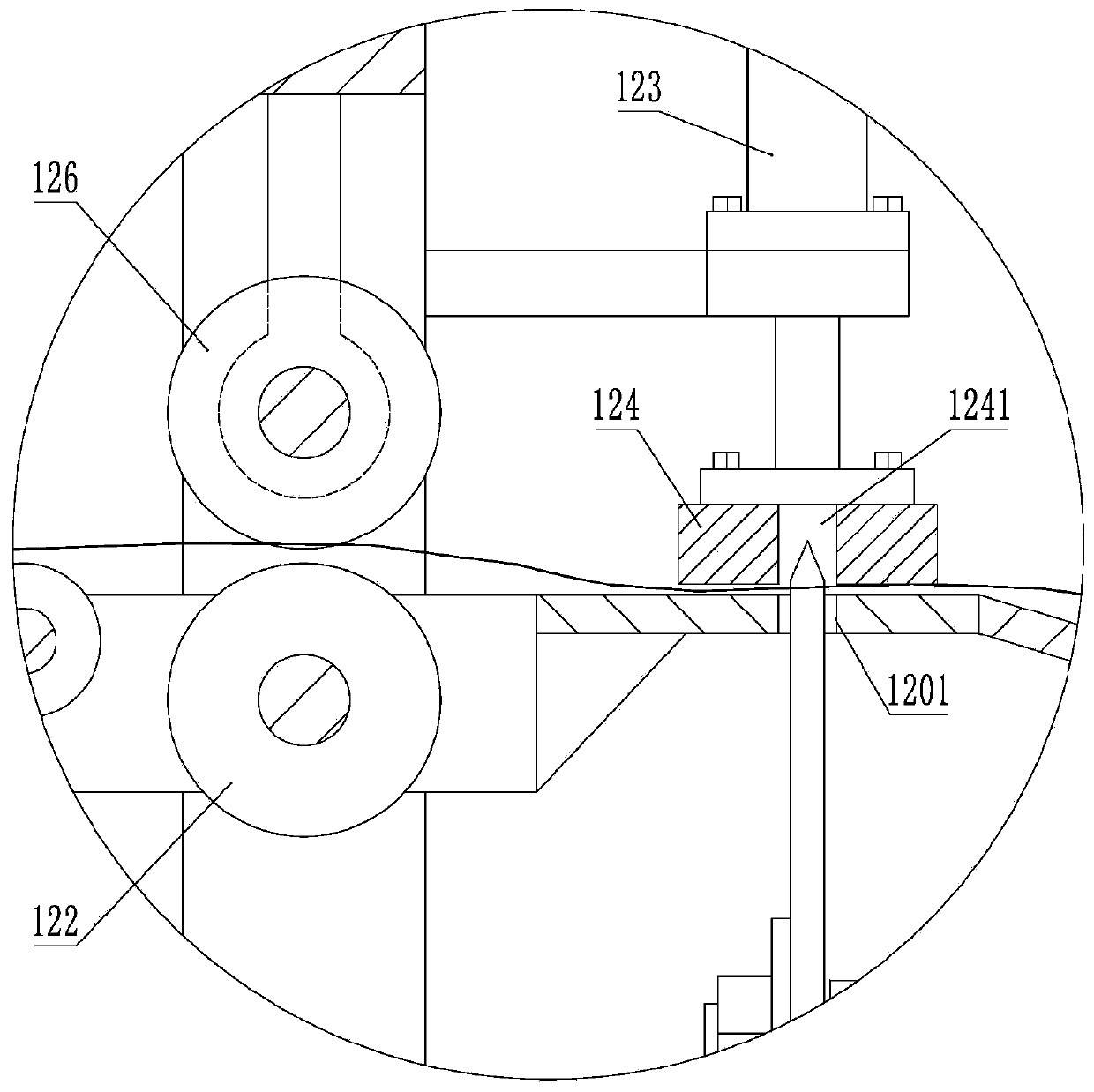

Multi-functional machine for steamed stuffed buns

InactiveCN108433010ASolve the shortcoming that only a single filling can be producedWon't smellDough processingEngineeringMechanical engineering

The invention relates to a multi-functional machine for steamed stuffed buns. The machine comprises a frame, a flour discharging device and a stuffing discharging device which are arranged on the frame, and also comprises a mobile sliding table arranged on the frame, a mounting plate arranged on the mobile sliding table, a dough blank lower die arranged on the mounting plate, an extrusion moldingmechanism, and a steamed stuffed bun sealing mechanism used for sealing steamed stuffed bun wrappers; the dough blank lower die comprises a movable bottom plate which is used for sealing the bottom opening and can open and close; and the mounting plate is provided with a movable bottom plate mounting cavity used for mounting the movable bottom plate and a steamed stuffed bun falling outlet communicating with the bottom of the dough blank lower die. The machine for steamed stuffed buns further comprises a movable bottom plate opening-closing device which controls the opening and closing of themovable bottom plate by utilizing the movement of the mobile sliding table, and comprises a plurality of steamer baskets which are used for receiving steamed stuffed buns falling from the dough blanklower die. According to the invention, the prepared steamed stuffed buns are uniform in wrapper thickness, stuffing is not easy to expose, stuffing filling efficiency of wrappers is high, the moldingeffect of the steamed stuffed buns is good, and after molding, the steamed stuffed buns can be placed into the steamer baskets by the machine instead of man power, and the machine is low in artificialintensity and high in working efficiency.

Owner:HUZHOU VOCATIONAL TECH COLLEGE

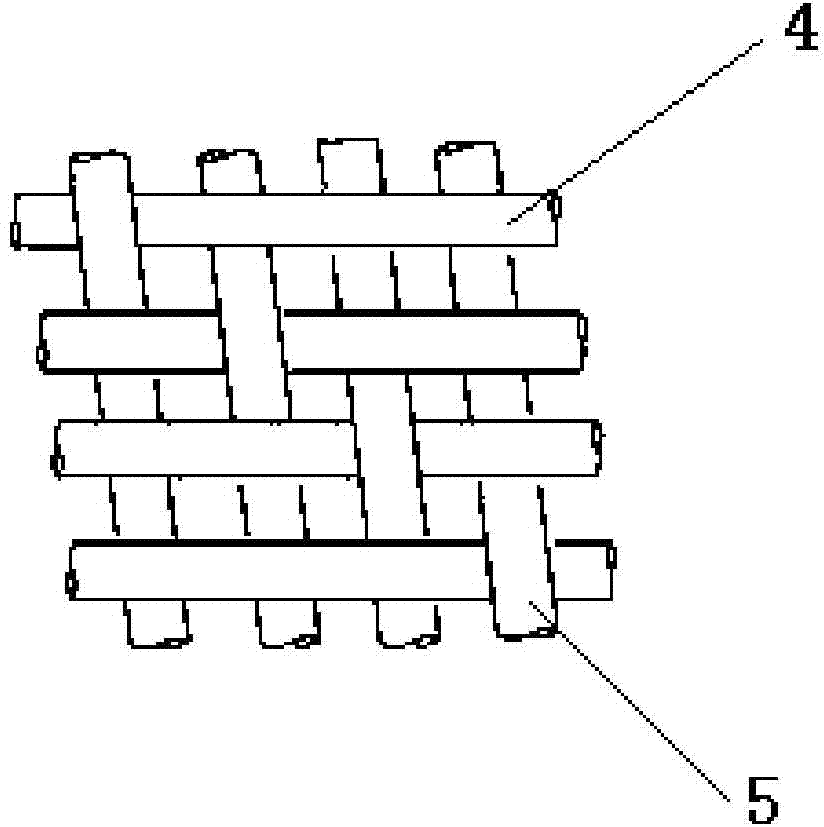

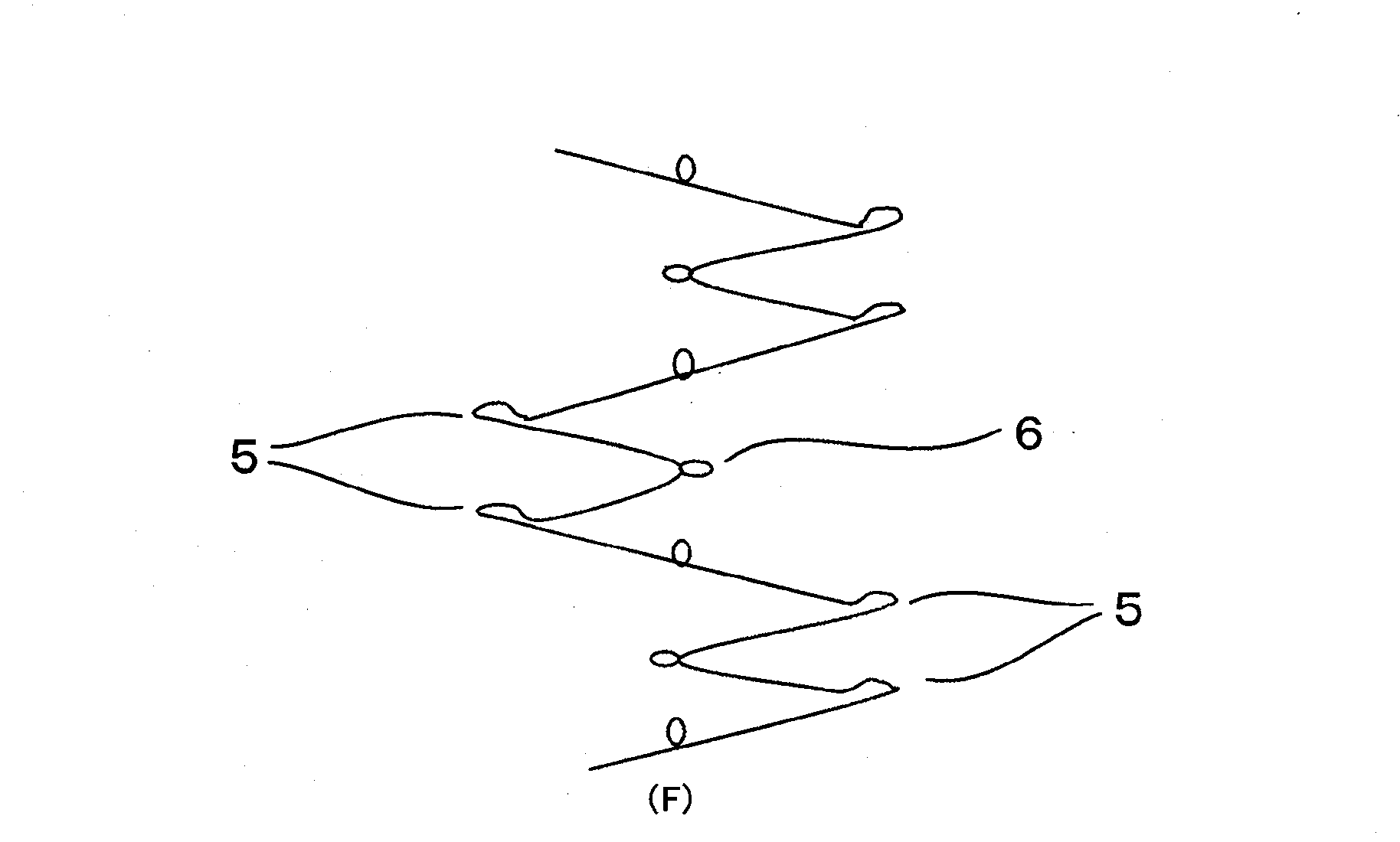

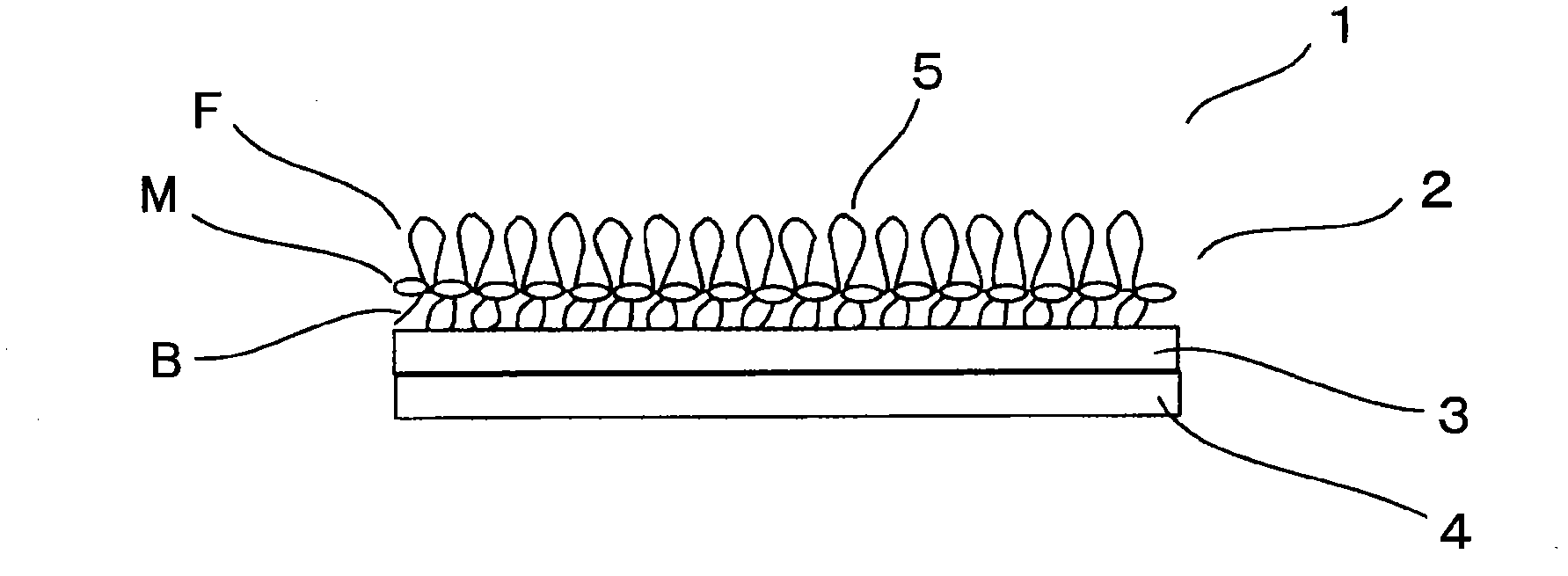

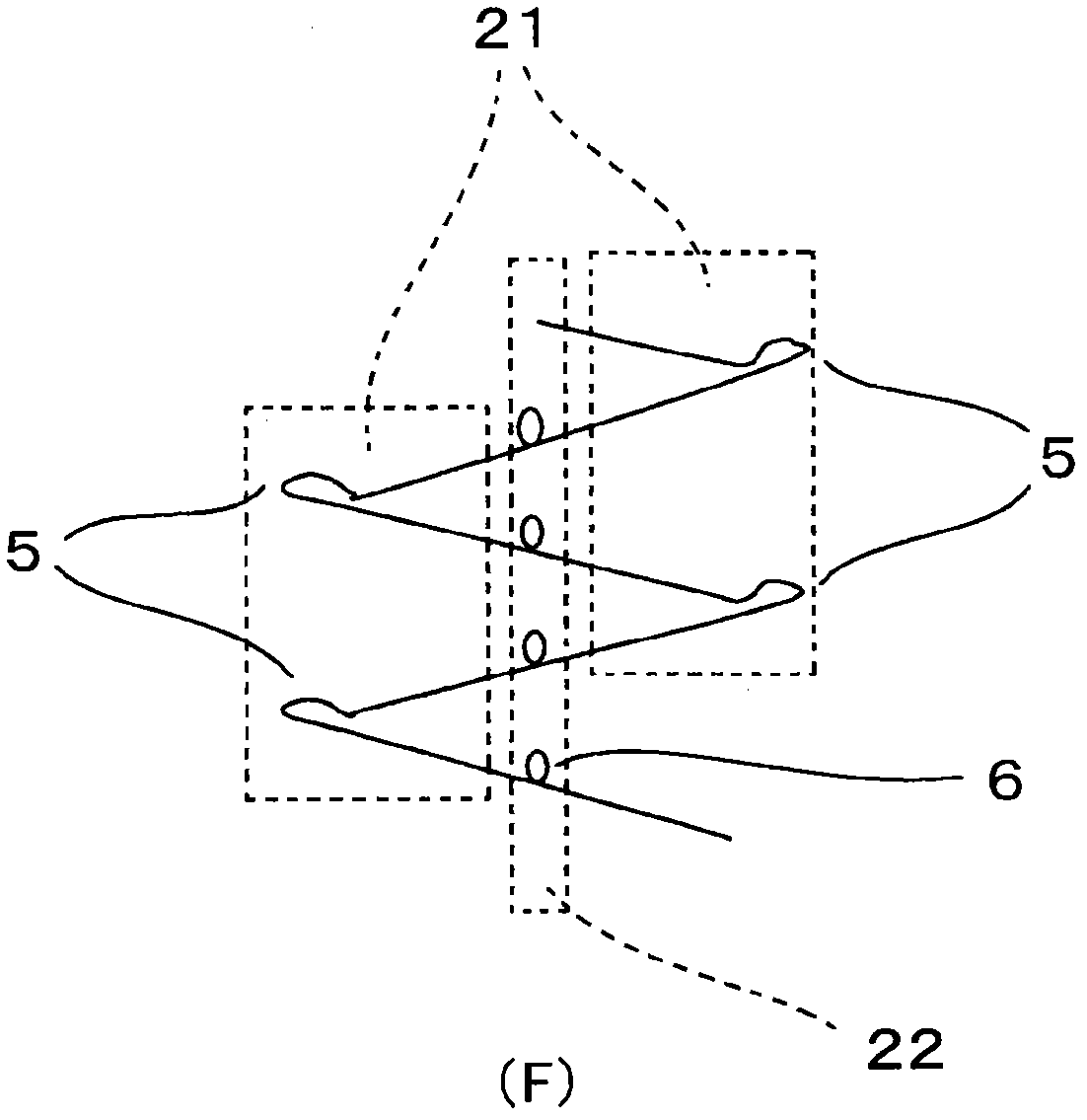

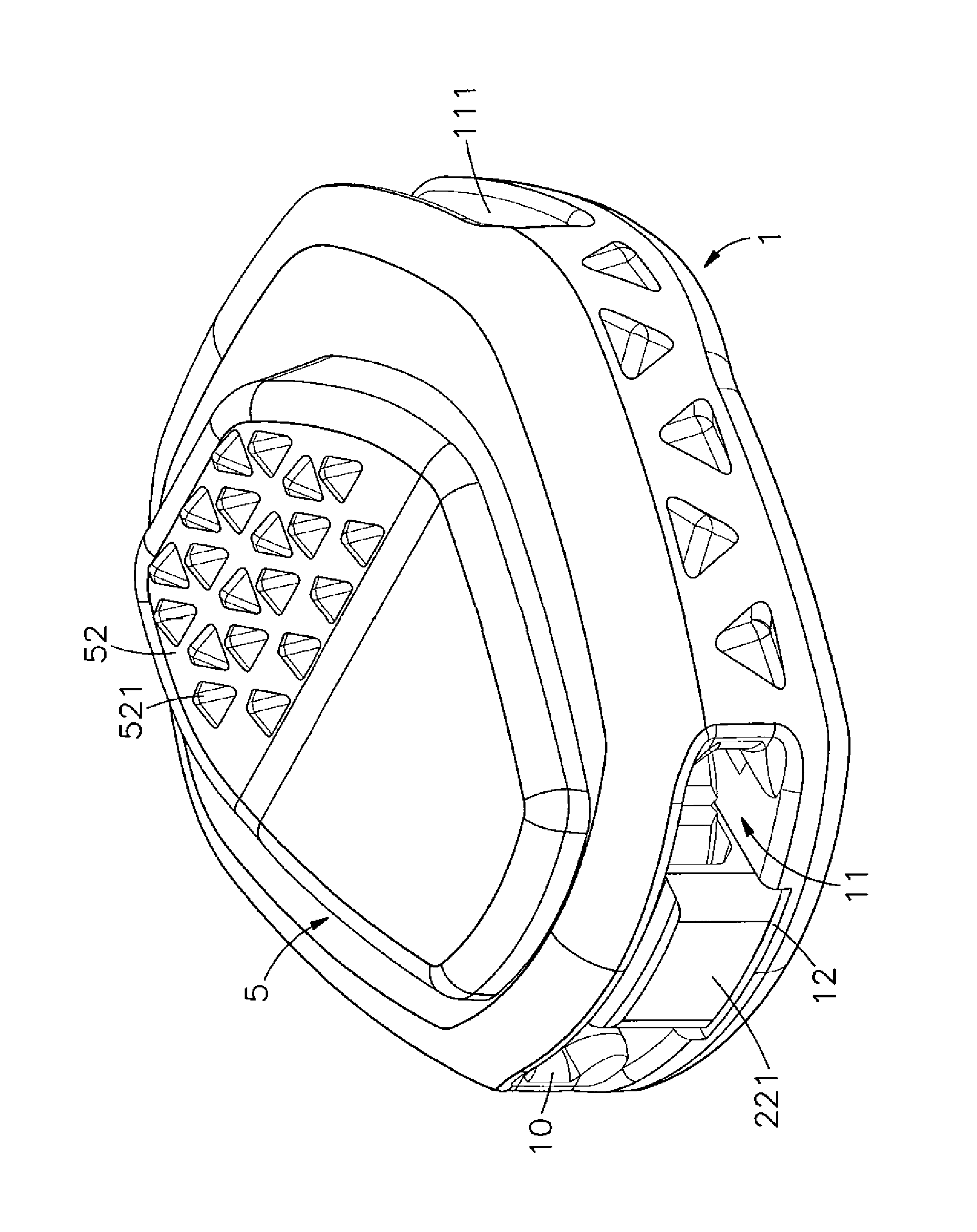

Knitted Fabric For Hook-and-loop Fastener

[Problem] To provide a knitted tricot fabric having a high fabric strength and a low cost, which is to be used in a female member of a hook-and-loop fastener, exhibits a large engagement force with an engaging element and, in the case where said knitted fabric is engaged with engaging elements located on both sides thereof, shows no difference between the engagement forces in both directions. [Solution] A knitted fabric for hook-and-loop fastener, which is a knitted tricot fabric consisting of a knitting yarn in the front face part, a knitting yarn in the middle part and a knitting yarn in the back face part, wherein the knitting yarn in the front face part, the knitting yarn in the middle part and the knitting yarn in the back face part are each provided with loops formed at definite intervals, the loops formed in the knitting yarn in the front face part are connected with the loops formed in the knitting yarn in the middle part, and the loops formed in the knitting yarn in the middle part are connected to the loops formed in the knitting yarn in the back face part. In the knitted tricot fabric, a same number of piles are formed by the knitting yarn in the front face part alternately from side to side, and the knitting direction of the loop-forming knitting yarn in the front face part is opposite to the knitting direction of the loop-forming knitting yarn in the middle part while the knitting direction of the loop-forming knitting yarn in the middle part is opposite to the knitting direction of the loop-forming knitting yarn in the back face part.

Owner:LU PU CO LTD

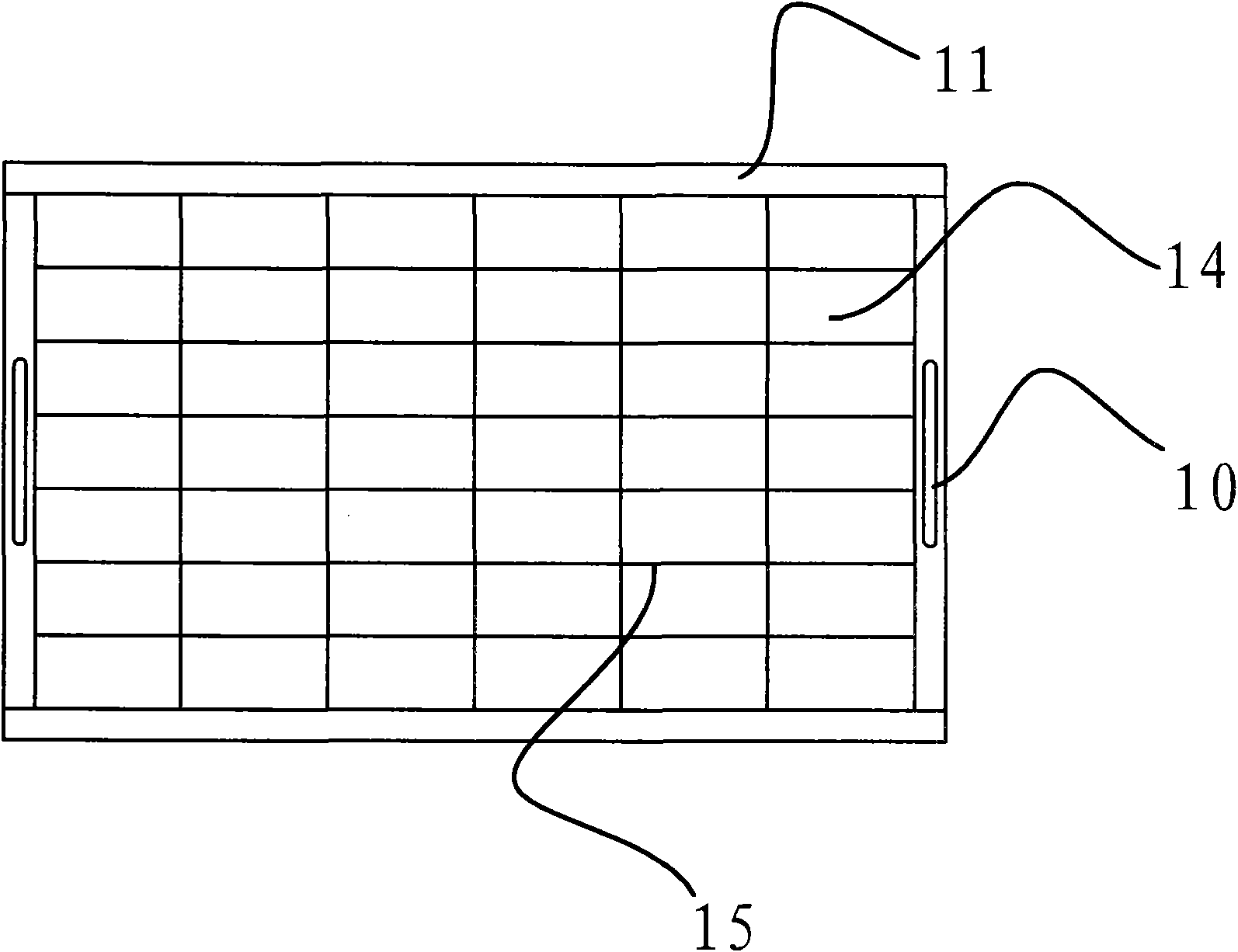

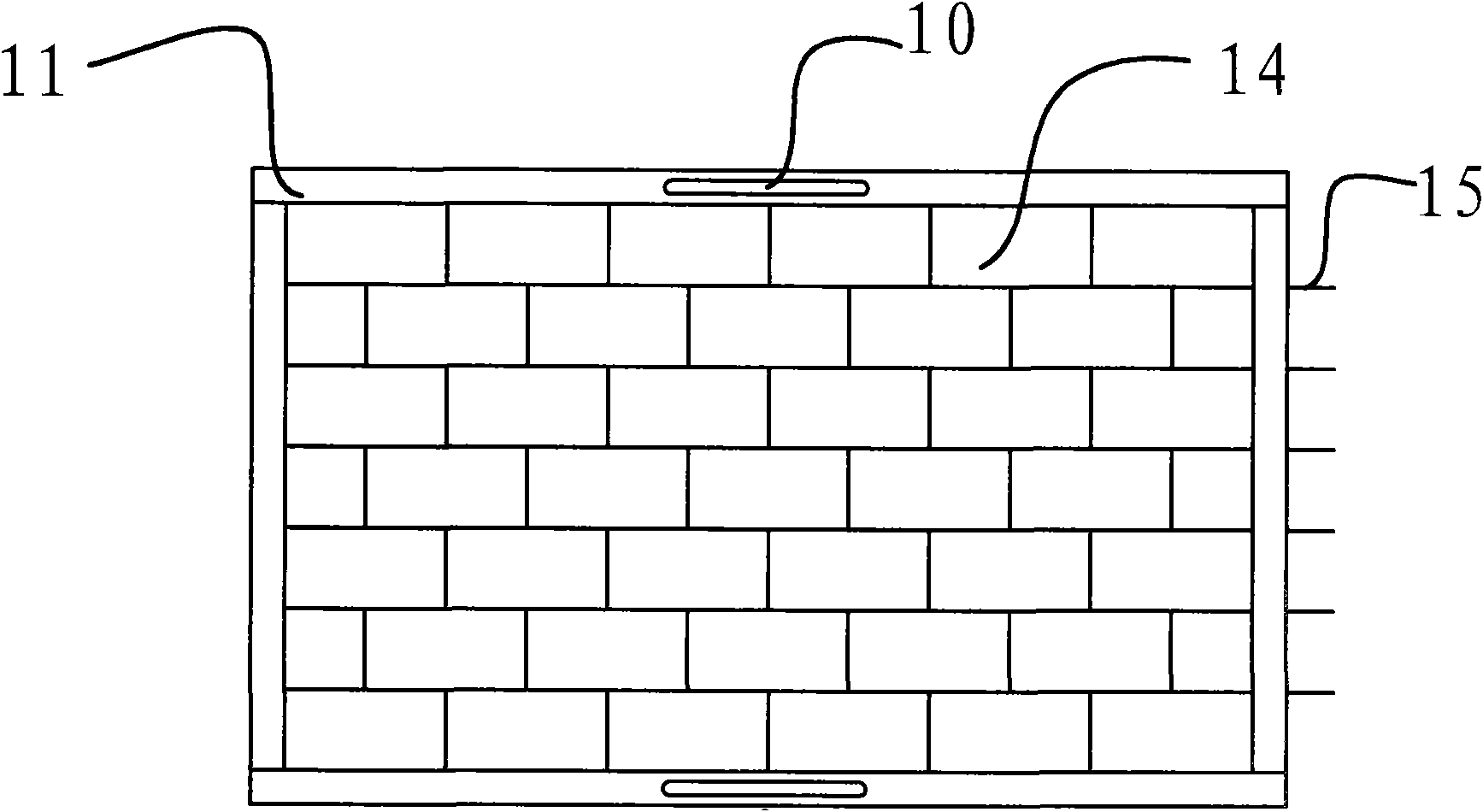

Sidewalk ground tile paving die

InactiveCN101634133AImprove work efficiencyNot easy to looseSidewalk pavingsRoads maintainenceRoad surfaceBrick

The invention relates to a sidewalk ground tile paving die, which comprises a frame used for placing tiles and a lifting structure connected with the frame. The frame comprises interconnected margin frames and a tile die formed by connecting a plurality of side plates. The inside of the tile die is provided with isolated cavities for accommodating tiles. The lifting structure is connected with the margin frames. A certain distance is kept between the margin frames and the tile die. The sidewalk ground tile paving die has the advantages of simple structure, convenient use, capability of effectively guaranteeing the whole effect of the paved road surface, high working efficiency and low labor intensity.

Owner:张锋

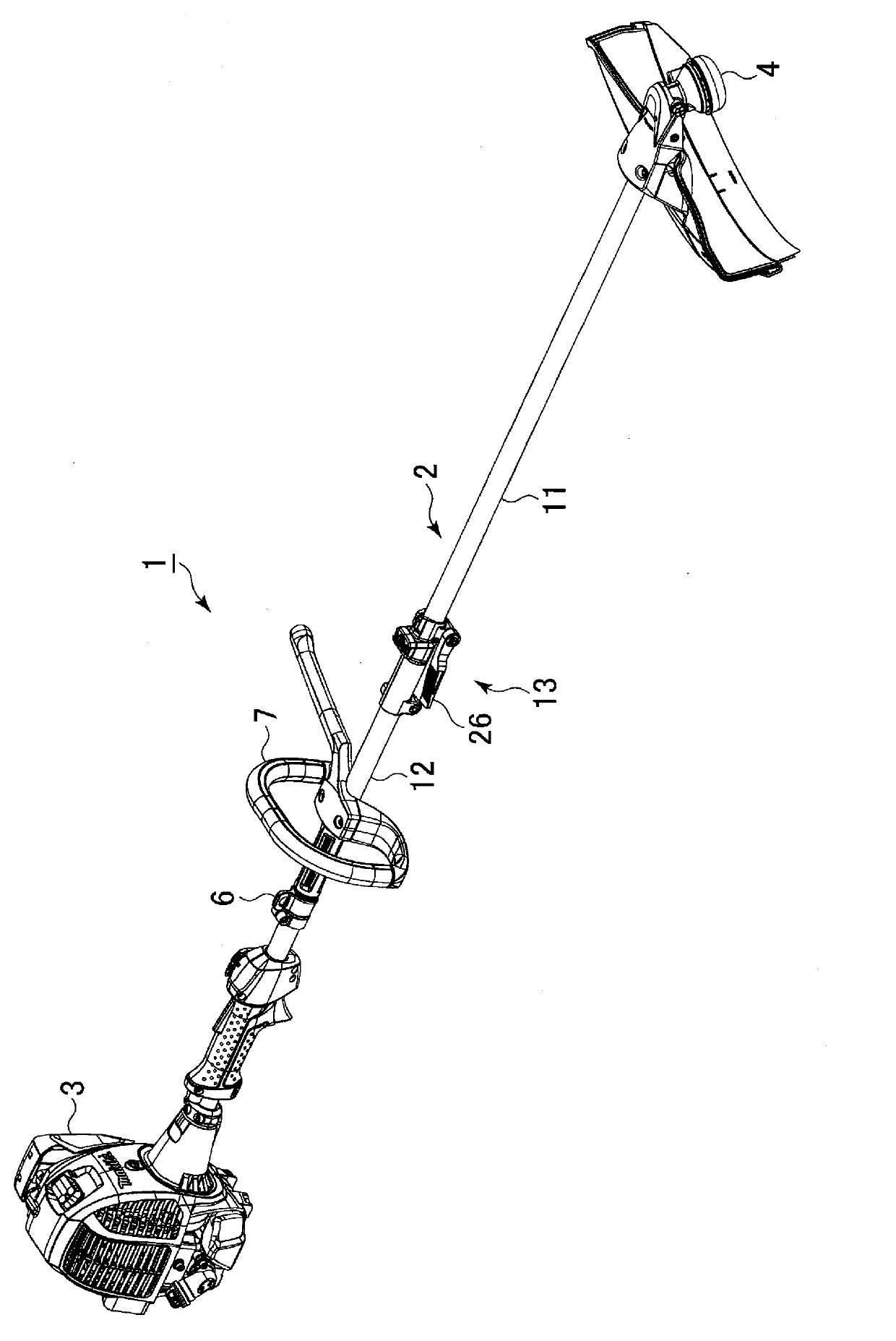

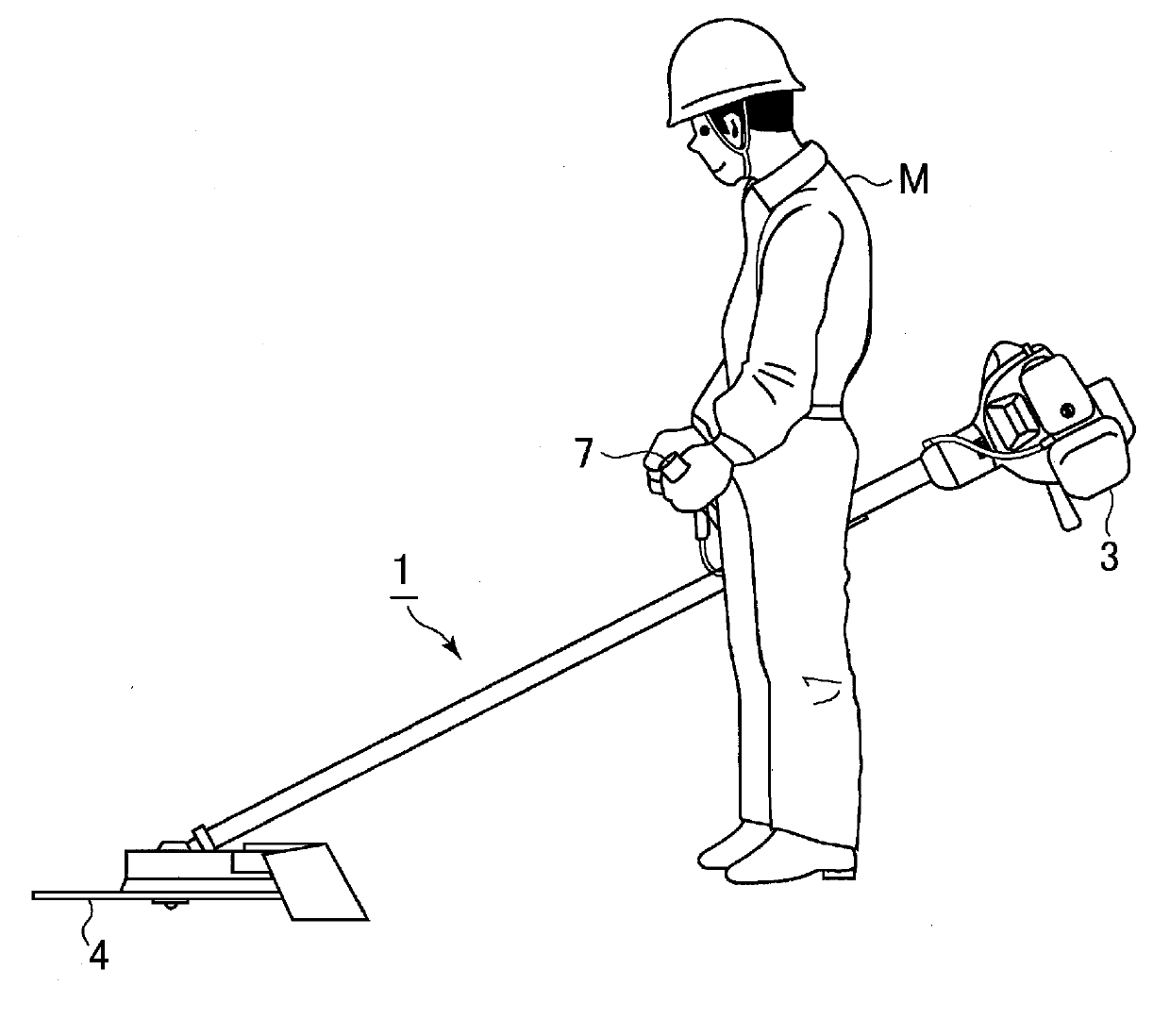

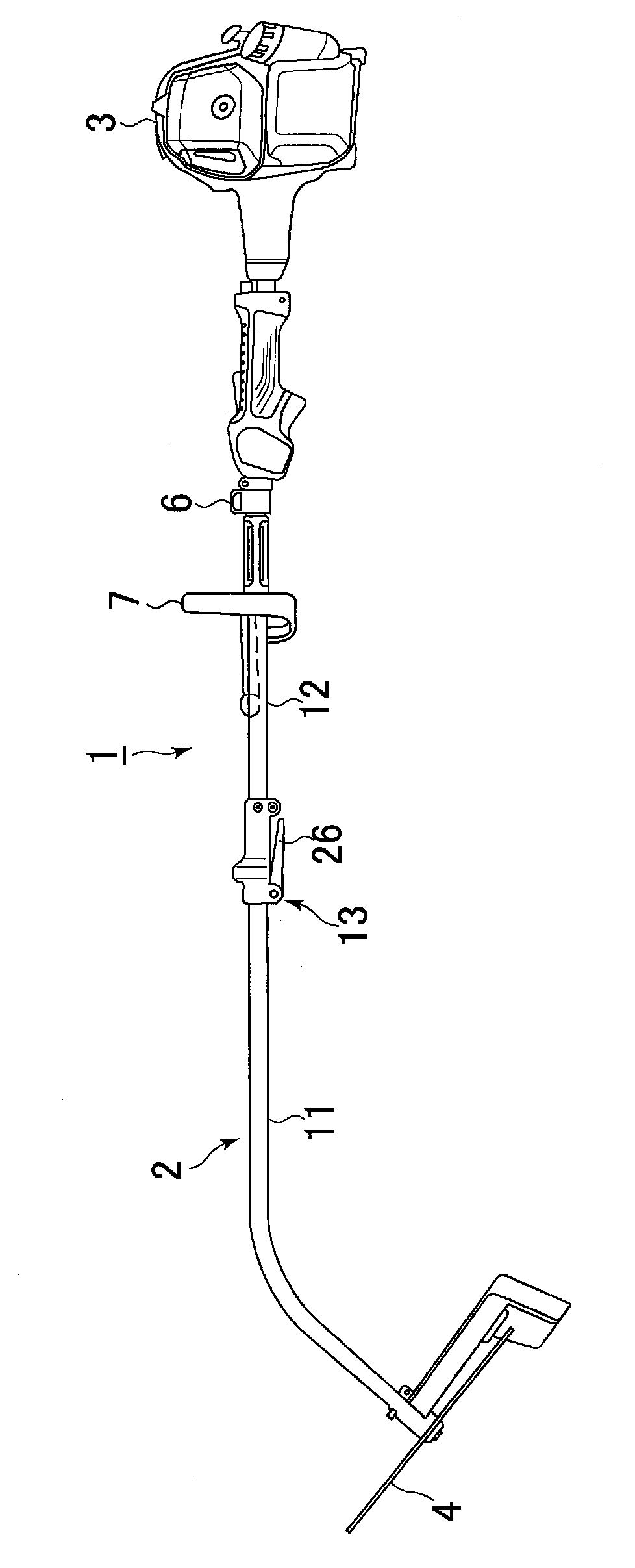

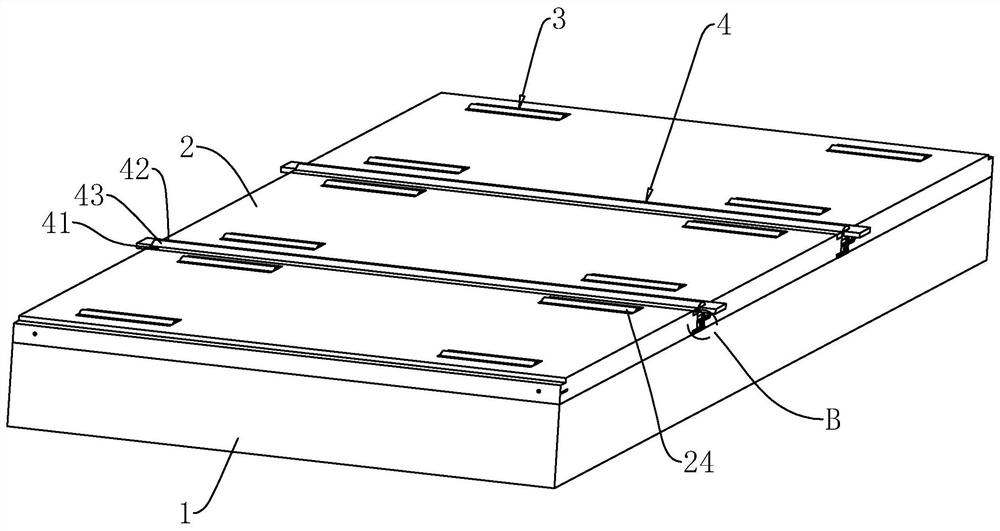

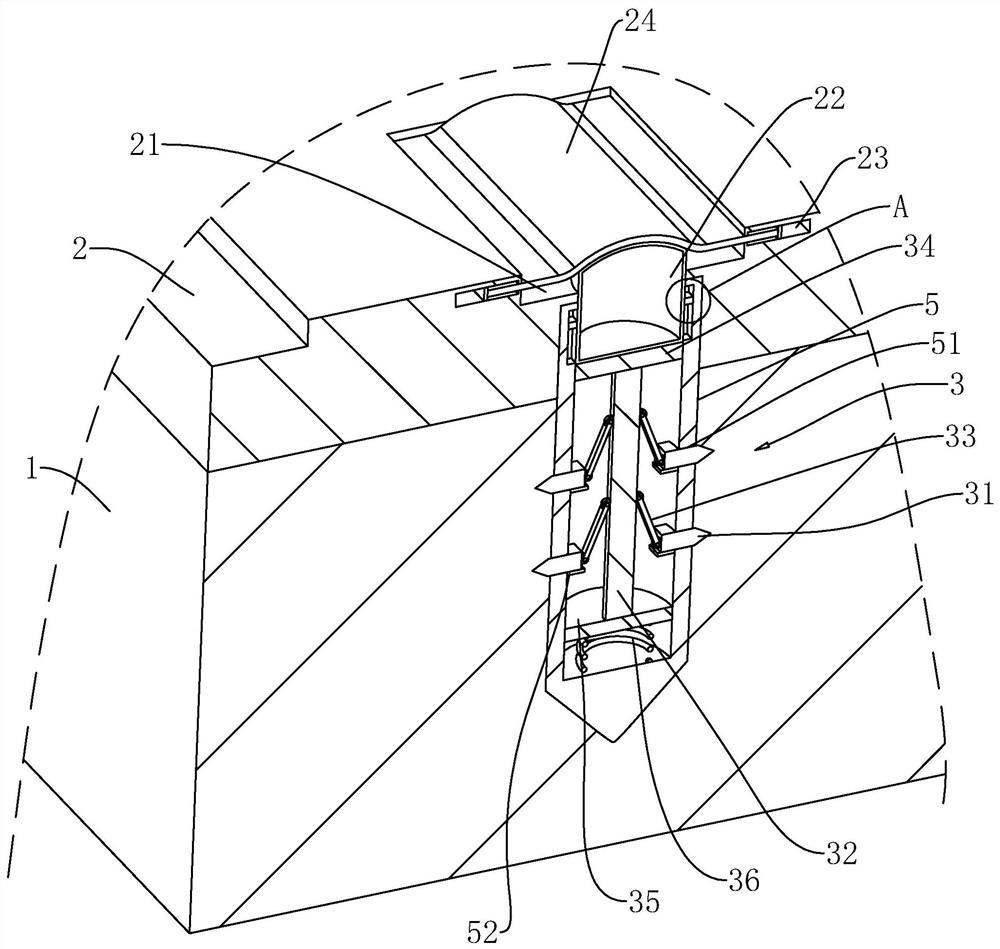

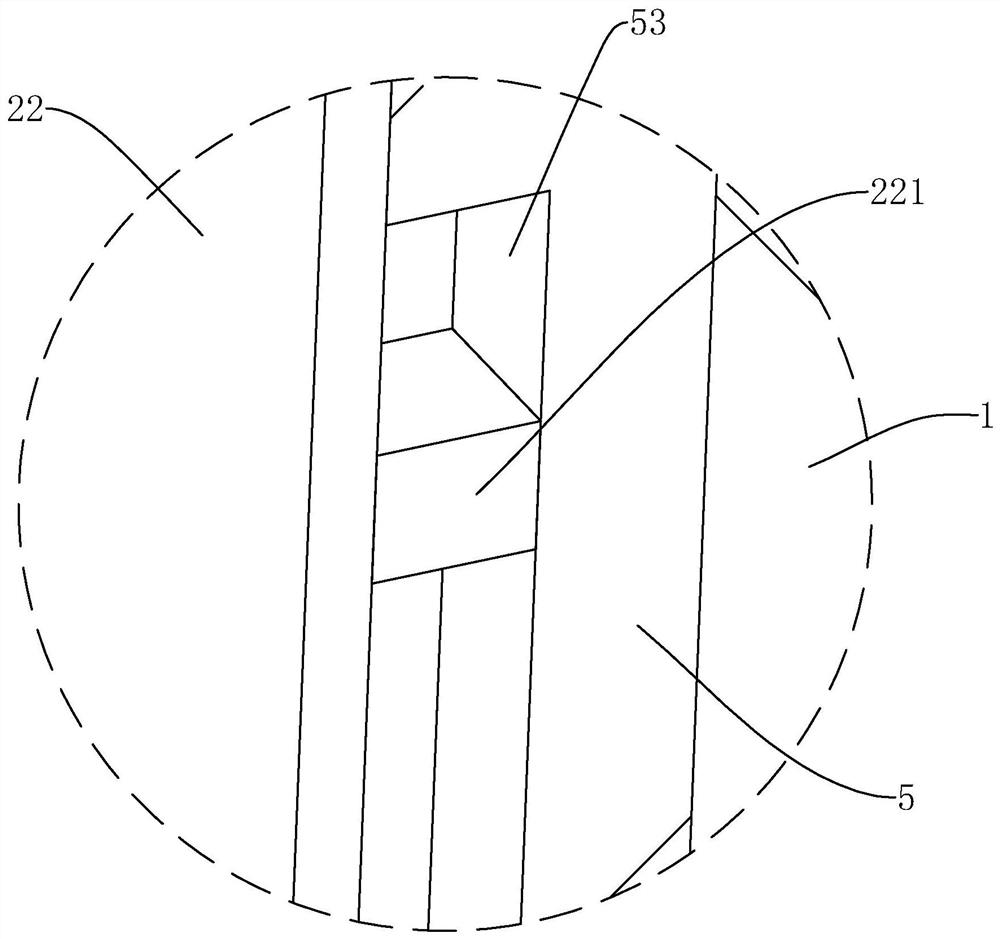

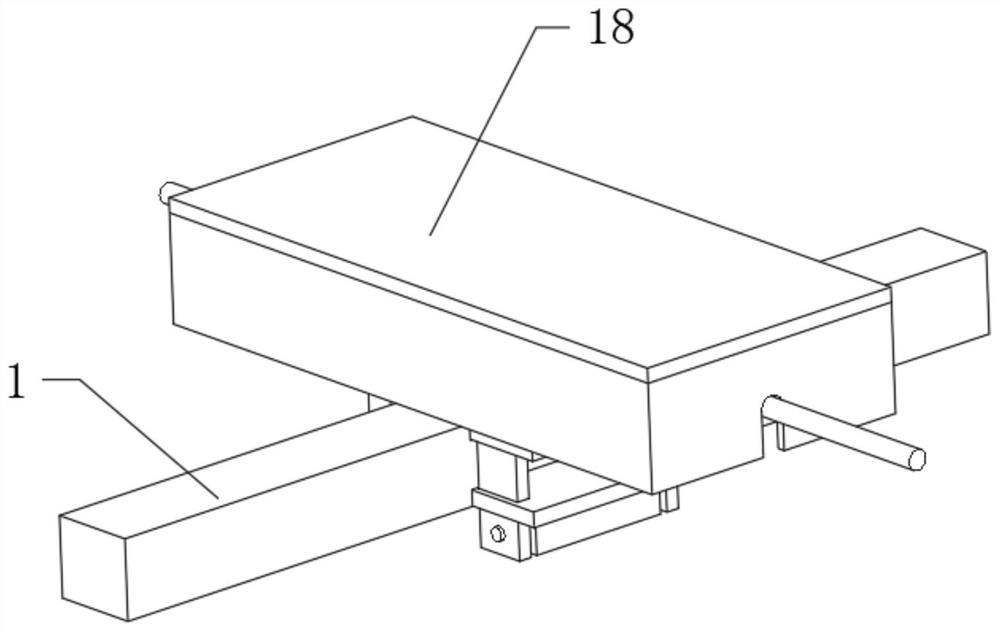

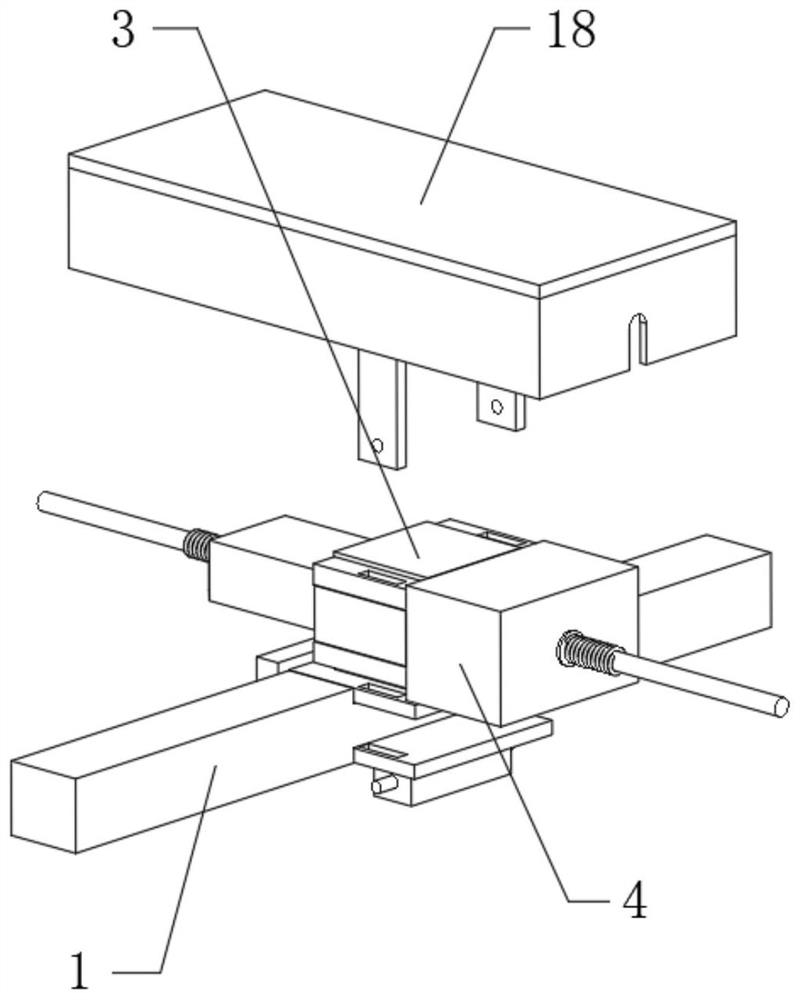

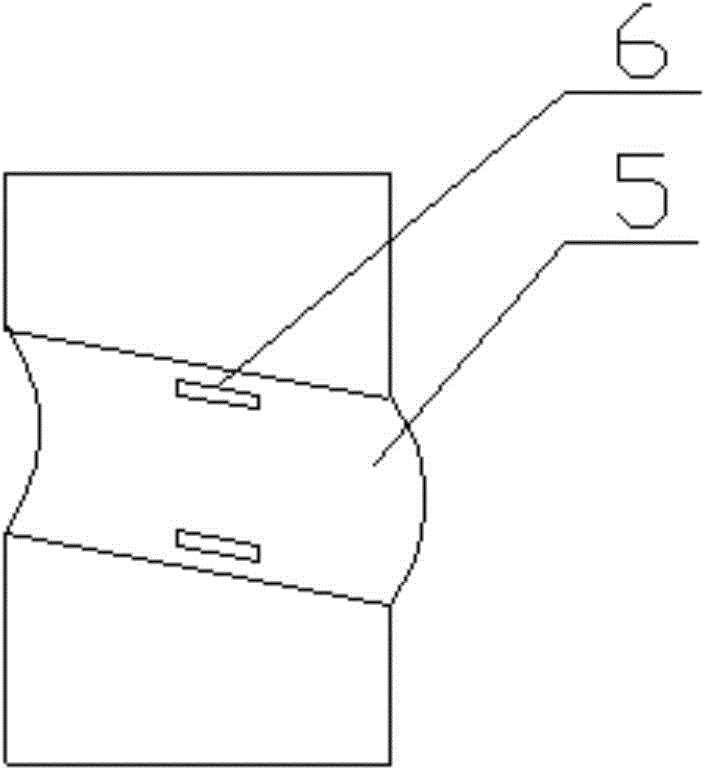

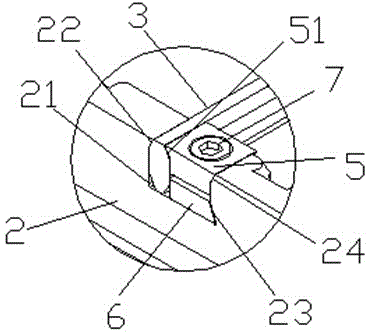

Portable working machine

The present invention provides a portable working machine to solve the problems occurs when a control rod of the conventional portable working machine forms a split structure. A power source (3) is arranged on one end of the control rod (2) of the portable working machine (1), a working portion (4) is arranged on the other end of the control rod (2), and the control rod (2) can be split into two rods. The split rods (11, 12) are fixedly connected to each other by tightening a fasten part (24) of a joint part (13) using a lever (26), the fasten part (24) is combined with the lever (26), and the lever (26) is located at a position along with the control rod (2) when the fasten part (24) is tightened with the lever (26).

Owner:MAKITA CORP

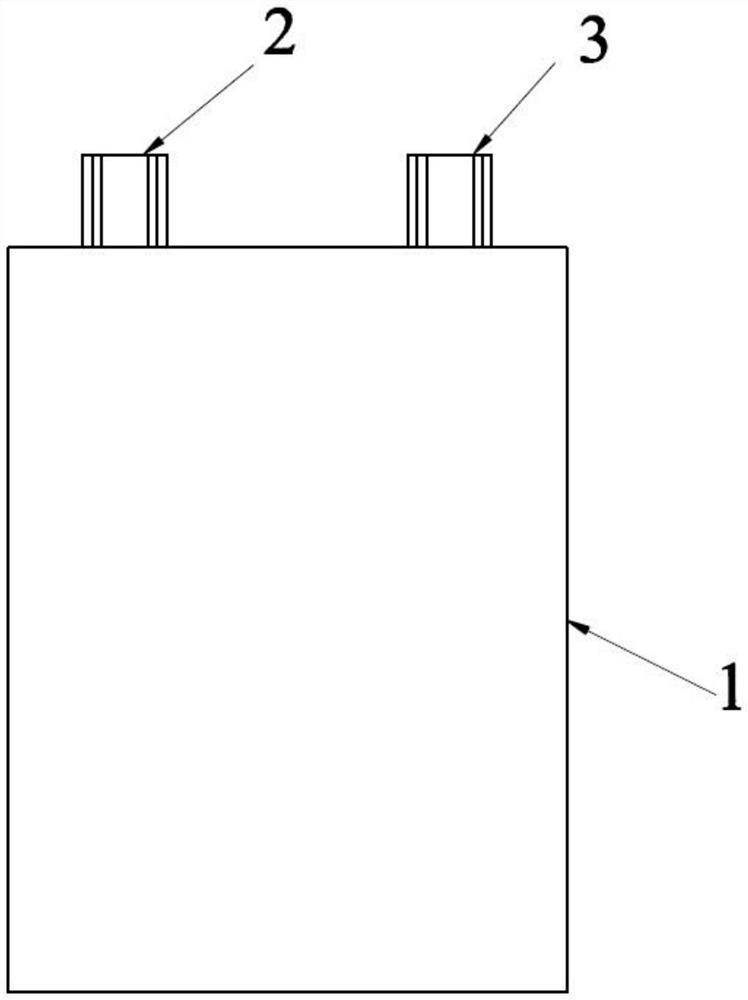

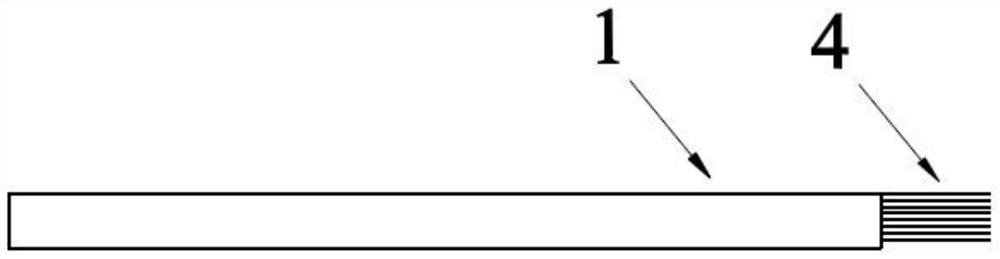

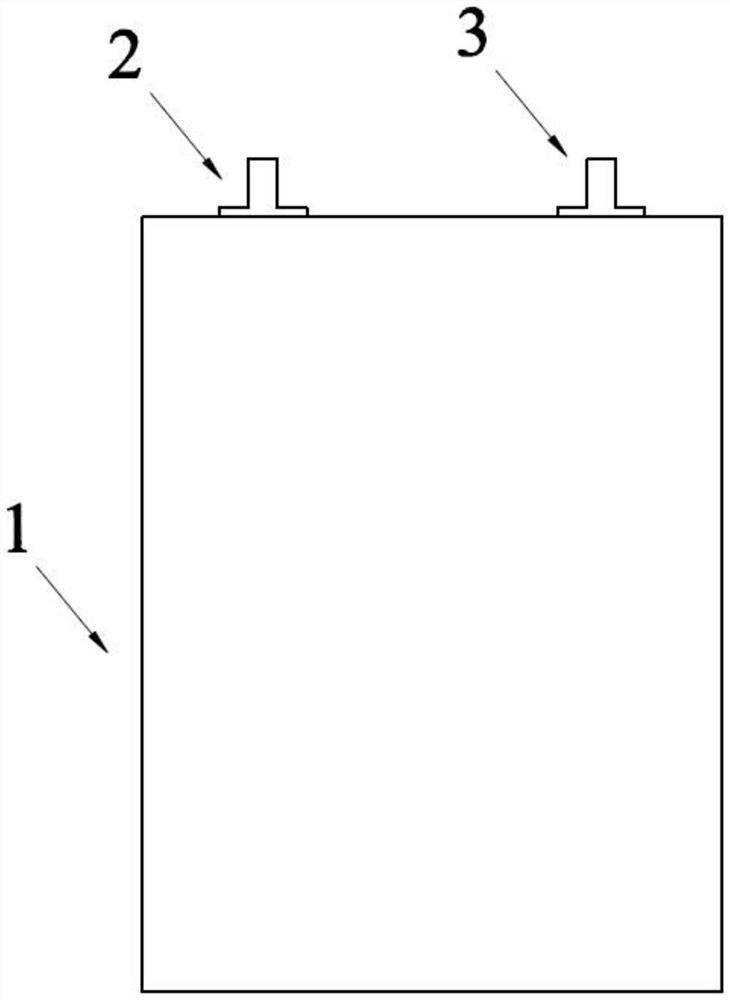

Tab bending method for multi-tab battery cell

ActiveCN113571845AImprove consistencyEasy to pass throughFinal product manufactureSecondary cellsElectrical polarityEngineering

The invention belongs to the technical field of batteries, and particularly relates to a tab bending method of a multi-tab battery cell. The method comprises the following steps of 1, respectively cutting tabs on two pole pieces, and sequentially winding the two pole pieces and a diaphragm to prepare a naked battery cell with a multi-tab structure; 2, overlapping a plurality of tabs with the same polarity and then cutting, hot-pressing and bending into a foil tab group with a preset shape, meanwhile, bending a metal strap tab with a through hole by a preset angle, wherein tab glue is pasted to the surface of the metal strap tab; 3, enabling the foil tab group to pass through the through hole, wrapping the root of the metal strap tab, and then fixedly connecting the foil tab group with the metal strap tab; and 4, pasting protective adhesive paper on the foil tab group and the metal strap tab. By optimizing the multi-tab process, the stability of the multi-tab structure is improved, and the position consistency of the bent tabs can be improved.

Owner:HUIZHOU LIWINON NEW ENERGY TECH CO LTD

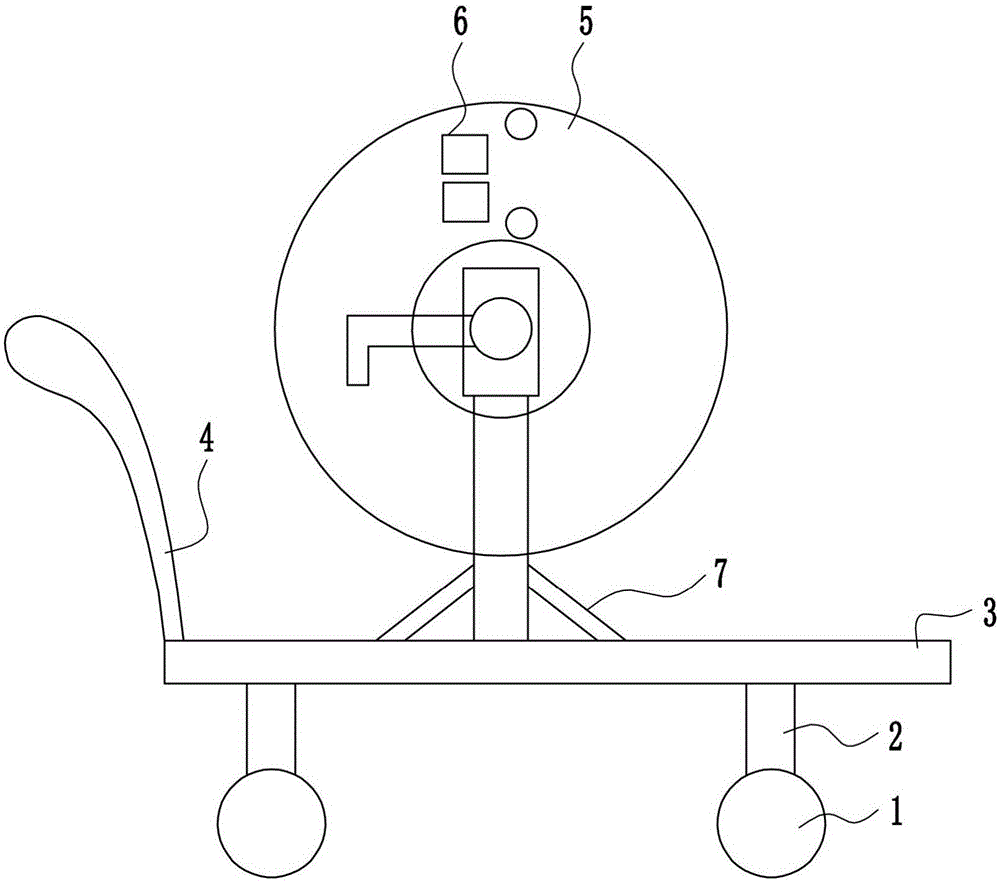

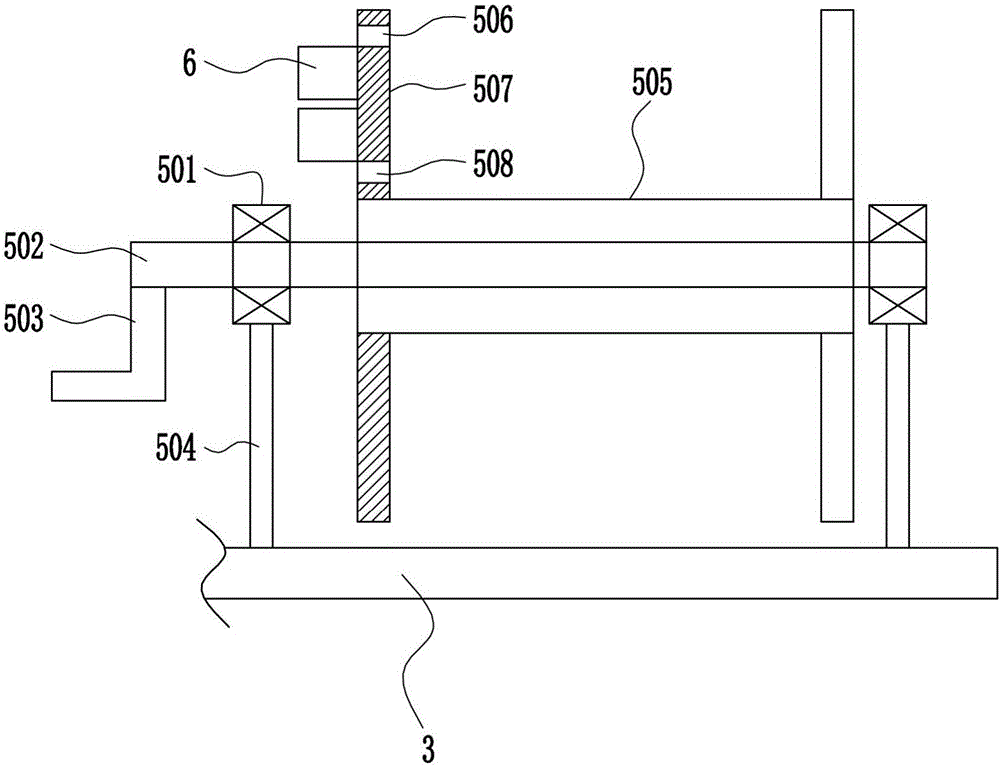

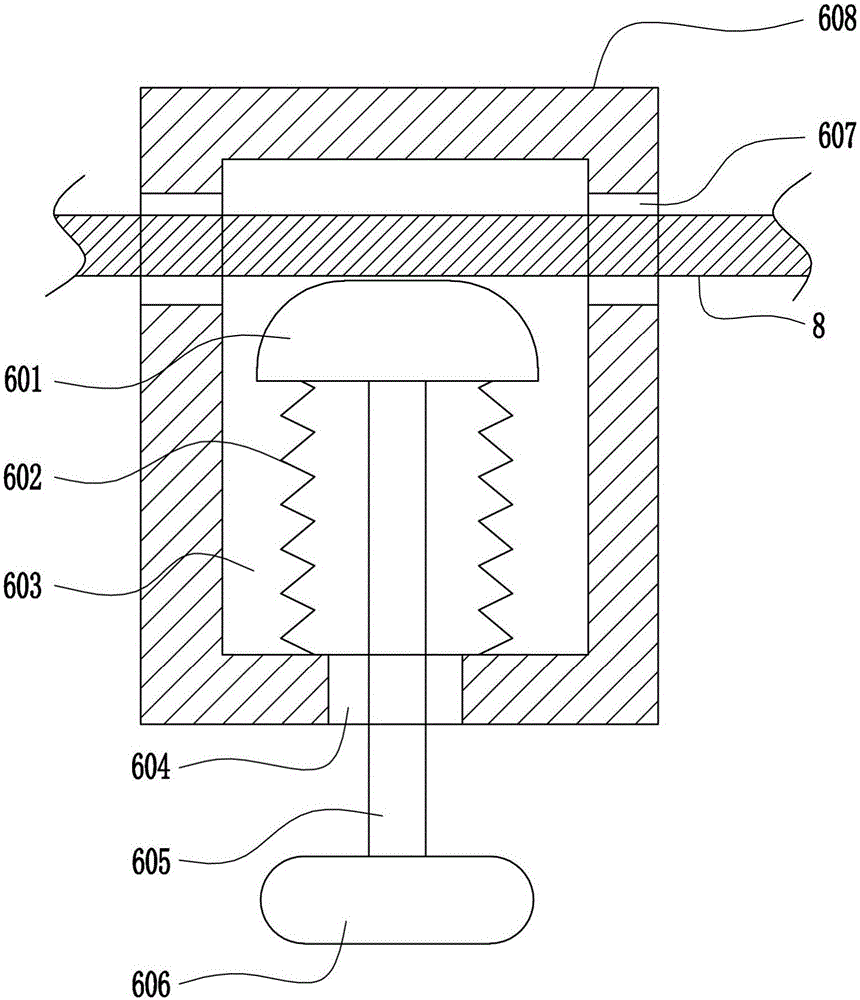

Waste cable recycling device for electric power project

ActiveCN106847428AEasy to fixWon't let goBasic electric elementsElectronic waste recyclingElectric powerCart

The invention relates to a recycling device, and in particular relates to a waste cable recycling device for an electric power project. The invention aims at solving the technical problem of providing the waste cable recycling device for the electric power project. For solving the technical problem, the waste cable recycling device provided by the invention comprises rollers and the like, wherein a first strut is arranged at the left side and the right side of the bottom of a cart respectively, the rollers are arranged at the bottoms of the first struts, a handle is arranged at the left side of the top of the cart, a winding device is arranged at the middle position of the top of the cart, reinforcing ribs are connected between the left side of the lower part of the winding device and the top of the cart and between the right side of the lower part of the winding device and the top of the cart respectively, and a clamping device is arranged at the upper part of the front side of the winding device. The waste cable recycling device provided by the invention achieves the effects that fixation effect on a cable is good, the cable is hardly loosened, stability of the device is good, the device can not move around, the cable can be effectively recycled and wound and cyclic utilization of resources is facilitated.

Owner:ELECTRIC ENG CO LTD OF CHINA RAILWAY NO 9 GRP

Mung bean cake and preparation method thereof

InactiveCN102428994AExcellent adhesionEasy to shapeDough treatmentBakery productsCooking & bakingSugar

The invention discloses mung bean cake. The mung bean cake is prepared from the following raw materials in parts by weight: 80-90 parts of mung bean flour, 10-30 parts of flour, 10-20 parts of starch, 2-5 parts of table salt, 2-5 parts of white granulated sugar, 1-3 parts of essence, 5-8 parts of peanut oil and 2-4 parts of baking soda. The preparation method of the mung bean cake comprises the following steps of: (1) mixing the mung bean flour, the flour and the starch in water uniformly; (2) adding the white granulated sugar and the baking soda to mix and stir, and adding the table salt, the essence and the peanut oil to stir uniformly; (3) forming circular raw mung bean cake from the stirred raw materials; and (4) baking the raw mung bean cake in a baking oven for 1-2h, and taking out to obtain the mung bean cake. The mung bean cake disclosed by the invention has the advantages of simpleness and easiness for obtaining the raw materials and low cost; the preparation method of the mung bean cake, disclosed by the invention, is simple and can be handled by common families; and the prepared mung bean cake is fragrant, sweet and tasty, has unique nice taste and is popular in the people.

Owner:任思睿

Connection fixing device with separation/loosening preventing structure

ActiveCN106837979ANot easy to loosenNot easy to happenNutsBoltsEngineeringElectrical and Electronics engineering

The invention discloses a connection fixing device with a separation / loosening preventing structure. The connection fixing device comprises a screw, a nut and a lock washer, wherein at least two lock round holes are formed uniformly in the lock washer, propping round holes communicated with the lock round holes are formed in the centers of side surfaces of the lock washer, arc-shaped position locking elastic pieces are arranged in the lock round holes, L-shaped clamping blocks are arranged at outer side ends of the arc-shaped position locking elastic pieces, middles of the L-shaped clamping blocks are connected to the edge of the lock washer through rotating shafts, clamping holes are uniformly formed in the surface of the nut, propping columns are arranged in the propping round holes, and bottom ends of the propping columns are fixed in centers of outer arc edges of the arc-shaped position locking elastic pieces. The connection fixing device is reasonable in structural arrangement, the screw and the nut are not prone to loosening or separation even in a vibration environment, the technical defect that the screw and the nut are prone to loosening during use in the traditional technology is overcome, and the connection fixing device is good in use stability and high in adaptability.

Owner:平湖市天龙机械制造有限公司

Mixing shaft with adjustable angle

InactiveCN104056574AEfficient mixingSimple structureMixer accessoriesEngineeringMechanical engineering

The invention discloses a mixing shaft with an adjustable angle. The mixing shaft comprises a shaft body and a mixing blade, wherein an adjustable mechanism is installed between the shaft body and the mixing blade; the adjustable mechanism comprises shaft sleeves, a boss, a bolt and a base; the boss is positioned on the base to form a whole, vertical sliding grooves are formed in the left and right sides of the boss, and through holes which are communicated with the sliding grooves are formed in both ends of the boss; a bolt hole through which a bolt can pass is formed in the end of the mixing blade; the outer parts of the boss and the shaft body are covered with the shaft sleeves; the end of the mixing blade passes through the through holes to extend to the sliding grooves and is fastened by the bolt; a round hole used for holding the shaft body is formed in the boss. The mixing shaft has the beneficial effects of simple structure, convenience in installation and use and stable and reliable performance, different materials can be efficiently mixed by adjusting the angle of the mixing blade, so that energy consumption is greatly reduced, and the phenomenon of looseness is unlikely to occur.

Owner:杜欣荣

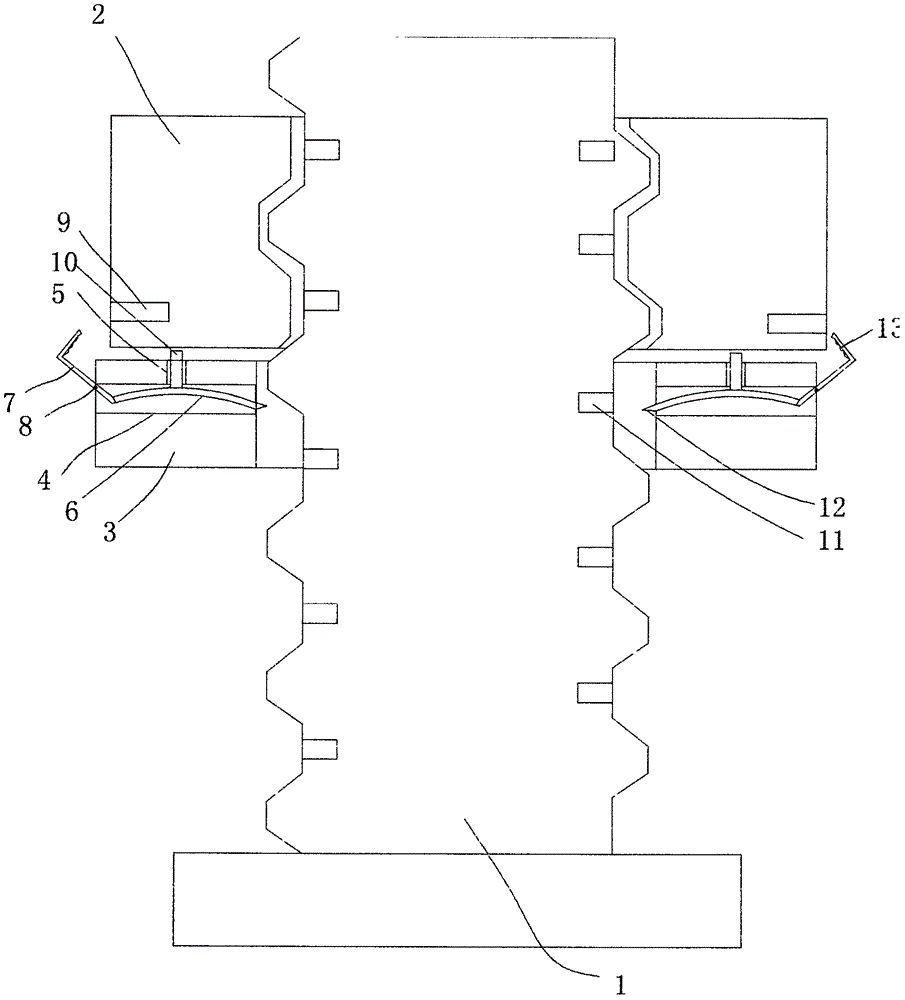

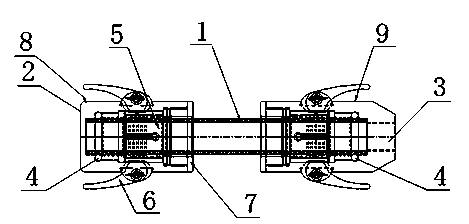

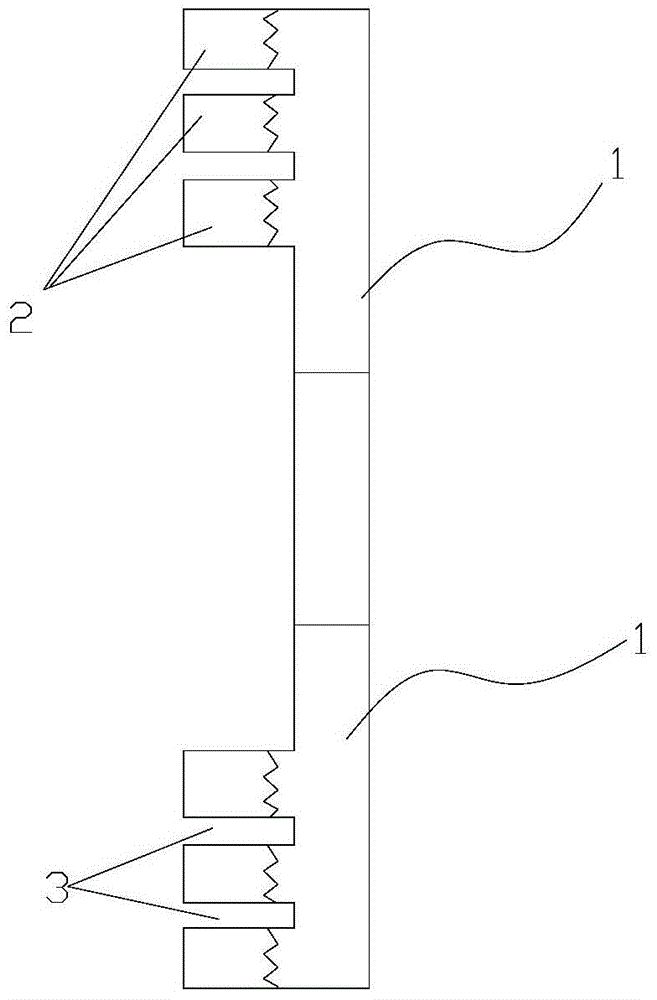

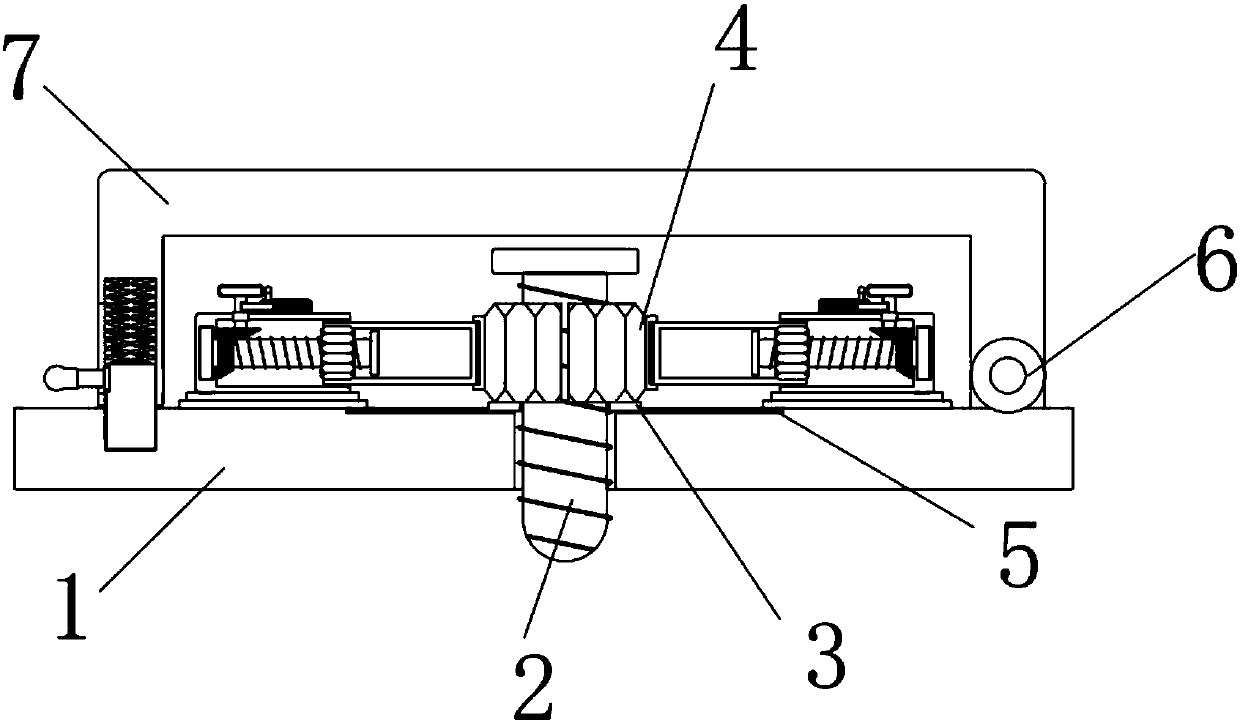

Sealing device for end parts of pipe

InactiveCN103471772AEasy to installFast installationMaterial strength using tensile/compressive forcesFluid-tightness measurement using fluid/vacuumEngineeringPressure measurement

The invention relates to the field of pressure measurement of a pipe and more specifically, relates to a sealing device for end parts of a pipe. The sealing device includes a sealing-end sealing body and an air-inlet-end sealing body, which are respectively installed at the end parts at the two ends of the pipe. One end of the sealing-end sealing body is provided with an opening and the two ends of the air-inlet-end sealing body are provided with openings. Both the sealing-end sealing body and the air-inlet-end sealing body are hollow cavities inside. Sealing rings and spring sleeve clamping tools which allow the pipe to penetrate are installed in the hollow cavities. Clamping wrenches contacting with the spring sleeve clamping tools are installed at the outer sides of the sealing-end sealing body and the air-inlet-end sealing body. The spring sleeve clamping tools can be squeezed through wrenching the clamping wrenches and deformed so as to lock the pipe which penetrates the spring sleeve clamping tools. End-part sealing heads are arranged at one opening end of the sealing-end sealing body and one opening end of the air-inlet-end sealing body. After the sealing device for the end parts of the pipe is assembled, the two ends of the pipe are inserted directly into the sealing-end sealing body and the air-inlet-end sealing body and the clamping wrenches are wrenched so that installation is completed. The sealing device is convenient to install and the installation is high in speed and efficiency.

Owner:HENAN LIANSU IND

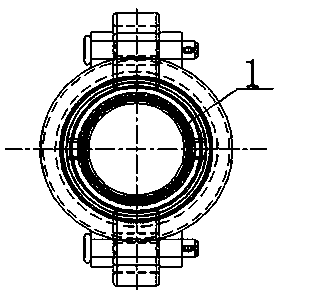

Novel edge grinding wheel and manufacturing method thereof

InactiveCN104802101ASize is easy to controlNot easy to loosenBonded abrasive wheelsGrinding devicesEngineeringGrinding wheel

The invention relates to a novel edge grinding wheel. The edge grinding wheel comprises N concentrically-distributed grinding wheels, wherein N is an integer being larger than or equal to 2; each grinding wheel comprises a grinding wheel base body and an annular grinding layer compounded with the grinding wheel base body; an annular water sealing tank is arranged between any two adjacent annular grinding layers in the N grinding wheels; the N grinding wheels are different in outer diameter; any adjacent grinding wheel base bodies in the N grinding wheels are fixedly connected with each other. The invention also provides a manufacturing method of the novel edge grinding wheel. The novel edge grinding wheel has the advantages of long service life, safety in use and the like; the manufacturing method of the novel edge grinding wheel is low in cost and easy to operate; the large-scale industrial production is liable to implement.

Owner:FOSHAN DINGSHUN TECH CO LTD

Foamed rubber cloth cutting and winding integrated treatment equipment

PendingCN110683405ASmall footprintImprove crop qualityArticle deliveryWebs handlingWinding machineEngineering

The invention discloses foamed rubber cloth cutting and winding integrated treatment equipment. The integrated treatment equipment comprises a cutting device and a winding device, wherein a material guiding plate is arranged between the discharging end of the cutting device and the feeding end of the winding device; the cutting device comprises a cutting machine frame, a cutting workbench, a transverse cutting mechanism and edge aligning cutting mechanisms, and the cutting device is used for transmitting rubber cloth to the winding device after carrying edge aligning and fixed length cutting on the rubber cloth; and the winding device comprises a winding machine frame, a winding roller and a winding speed reducer, and the winding device is used for carrying out winding on the rubber cloththrough a winding barrel. The invention aims to provide the foamed rubber cloth cutting and winding integrated treatment equipment, the cutting device on the integrated treatment device can be used for carrying out edge aligning and cutting-off operations on the rubber cloth, the cutting quality is high, and the production efficiency is improved; the winding device can effectively wind the rubbercloth into bundle, the winding is compact, the winding is not easy to loosen, the occupied space of a finished product is small, and transportation is facilitated.

Owner:JIHUA 3517 RUBBER PROD +1

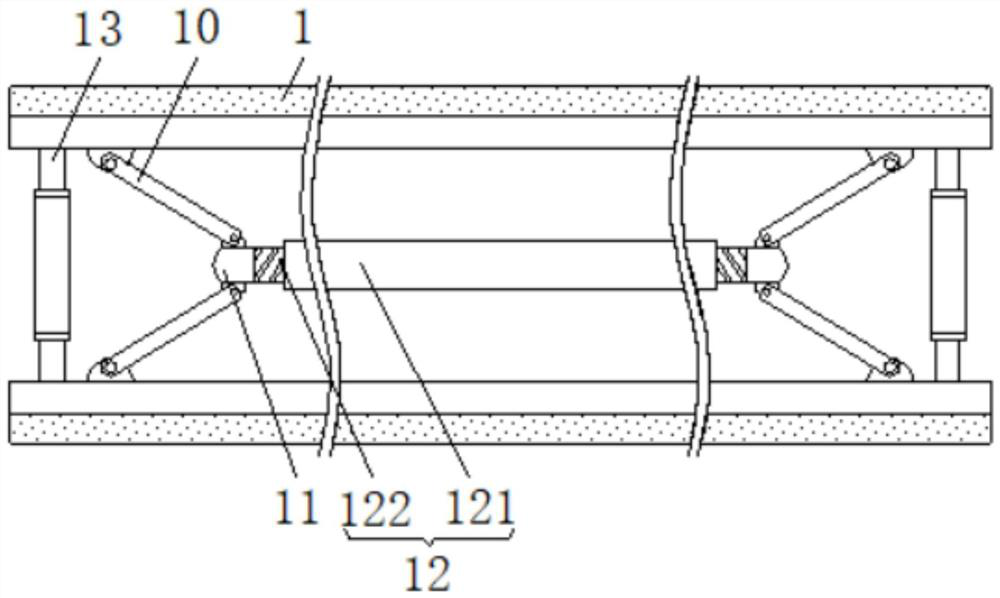

Constructional engineering temporary road structure and construction method thereof

PendingCN112962384ANot easy to loosenFirmly connectedTemporary pavingsClimate change adaptationArchitectural engineeringStructural engineering

The invention relates to a constructional engineering temporary road structure and a construction method thereof. The constructional engineering temporary road structure comprises a plurality of rectangular base plates laid on a roadbed, and the adjacent base plates are fixedly connected through connecting devices; an insertion rod inserted into the roadbed is arranged on the lower end surface of each base plate; each base plate is provided with a fixing device used for enhancing the connecting strength of the insertion rod and the roadbed; sliding grooves are formed in the outer side walls of the insertion rods; the fixing device comprises a positioning rod slidably arranged in each sliding groove and a vertical driving rod slidably arranged in the insertion rod; an inclined movable rod is hinged to the driving rod; the other end of the movable rod is hinged with the positioning rod; a mounting groove connected with the interior of the insertion rod is formed in each base plate; an elastic air bag is inserted into the mounting groove, and the upper surface of the elastic air bag is higher than the upper end surface of each base plate; the lower end of the elastic air bag is inserted into the insertion rod and abuts against the driving rod; and a reset spring is arranged at the lower end of the driving rod, and the lower end of the reset spring is fixedly connected with the inner bottom wall of the insertion rod. The structure has the effect of being conveniently and quickly put into use.

Owner:安徽同建建设集团有限公司

Ball-end mill for milling curved surface splicing molds

InactiveCN108480731AImprove surface finish qualityReduce milling forceMilling cuttersMilling cutterEngineering

The invention provides a ball-end mill for milling curved surface splicing molds, relates to a ball-end mill, and solves the problems that by an existing blade type ball-end mill, the surface qualityof a machined workpiece is poor, and the machining cost is high. Two cutting blades are machined on the ball-end mill, one side of the first cutting blade is connected with a first front knife face, the first front knife face is lower than the upper surface of the ball-end mill and is parallel to the upper surface of the ball-end mill, the first front knife face is in transitional connection withthe upper surface of the ball-end mill through a first groove surface, and the other side of the first cutting blade is connected with a first rear knife face; and one side of the second cutting bladeis connected with a second front knife face, the second front knife face is lower than the lower surface of the ball-end mill and is parallel to the lower surface of the ball-end mill, the second front knife face is in transitional connection with the lower surface of the ball-end mill through a second groove surface, the other side of the second cutting blade is connected with a second rear knife face, and a knife point is arranged at a position where the first cutting blade is connected with the second cutting blade. The ball-end mill is used for milling the curved surface splicing molds.

Owner:HARBIN UNIV OF SCI & TECH

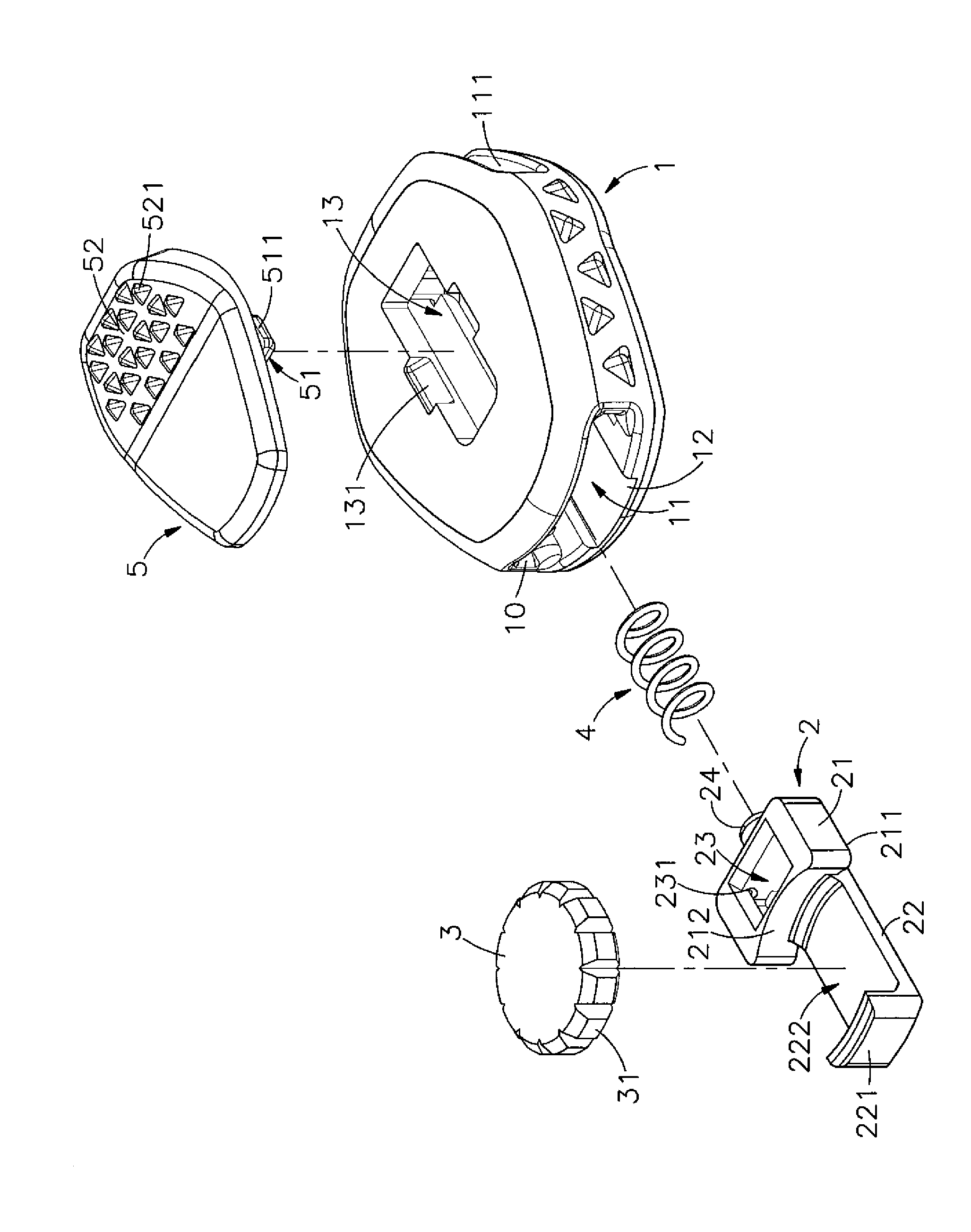

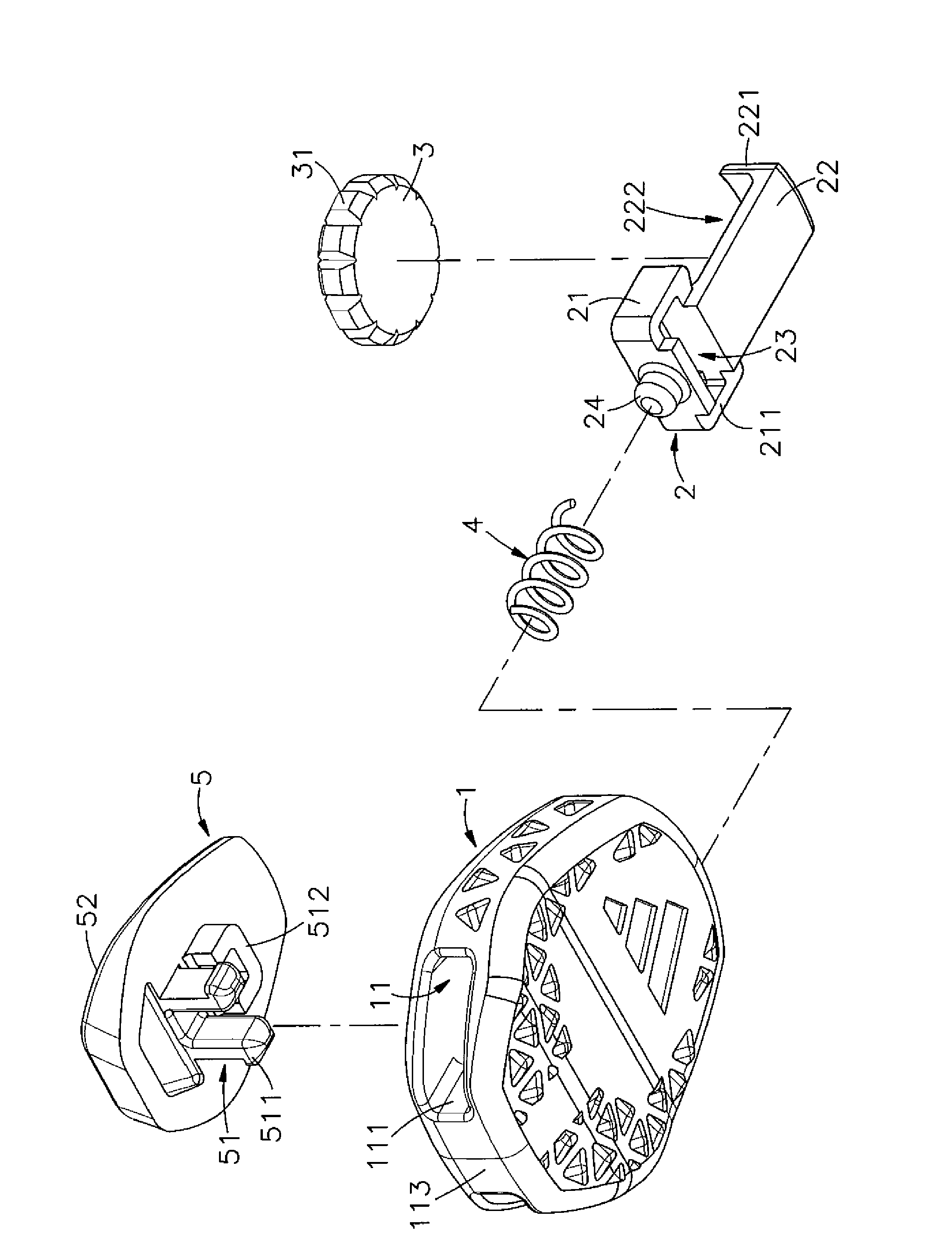

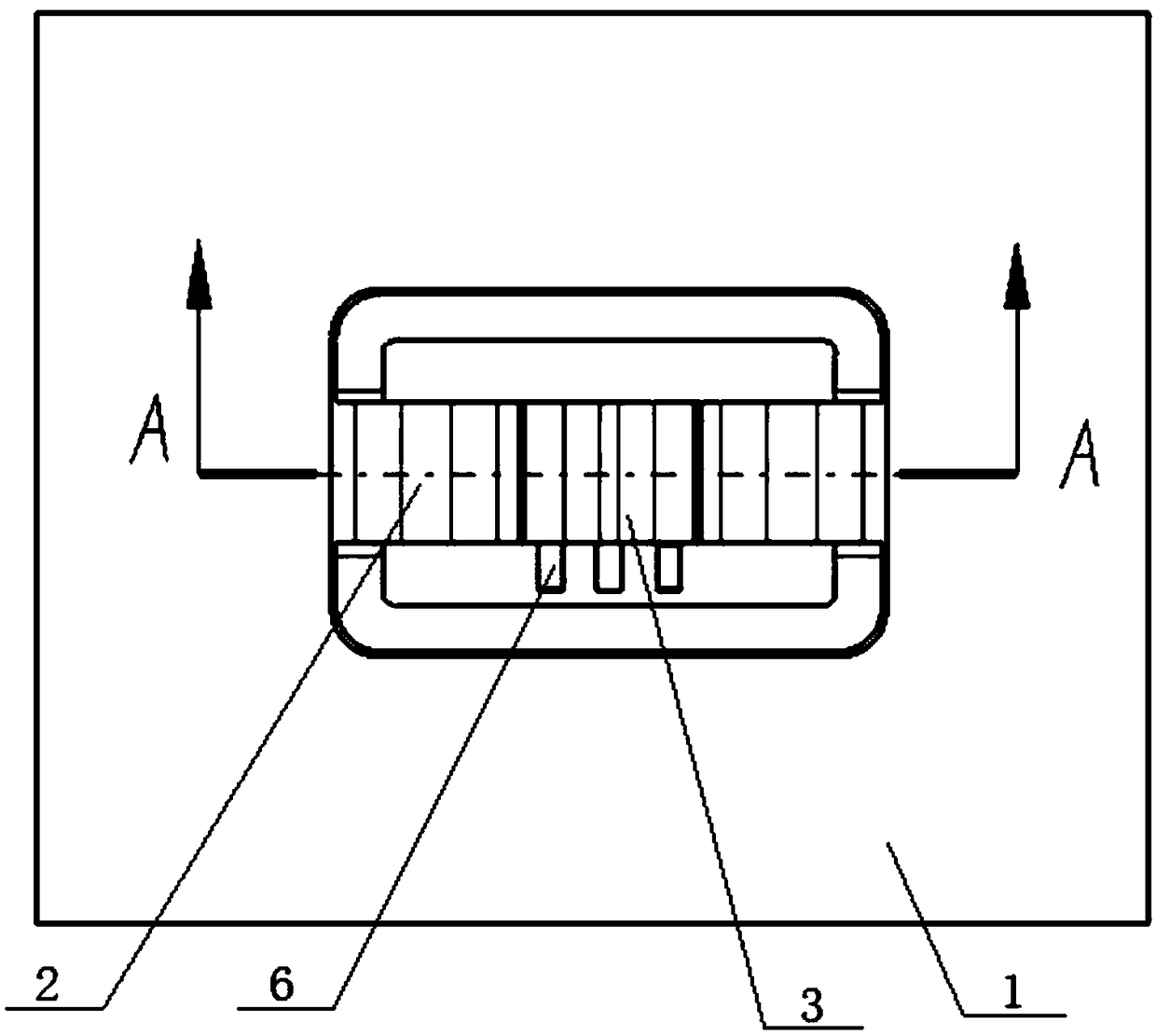

Rope buckle

Provided is a rope buckle. A channel capable of containing a sliding base is formed in a base body, through holes are formed in wall faces at two sides of the channel, an elastic assembly is located between the base body and the sliding base, a sliding part located in a guide rail at the bottom of the channel extends outward from the bottom of the sliding base, and a locating body is contained in a bearing groove formed in the sliding part. When a rope penetrates through the inside of the channel, an outer cover on the base body can be pushed so that a locating column on the bottom face of the outer cover drives the sliding base to move in the channel in a reciprocating, the rope penetrates out of the through holes and is released in the outer cover, and therefore the sliding base drives the locating body to move synchronously through elastic reset force of the elastic assembly, and is meshed with the rope through the fact that a preset distance formed by a plurality of clamping parts on the circumference of the locating body and the channel decreases. Therefore, the effects that the rope is fixed and clamped firmly, precise in locating and not prone to loosen or slide out of the base body are achieved.

Owner:NIFCO TAIWAN

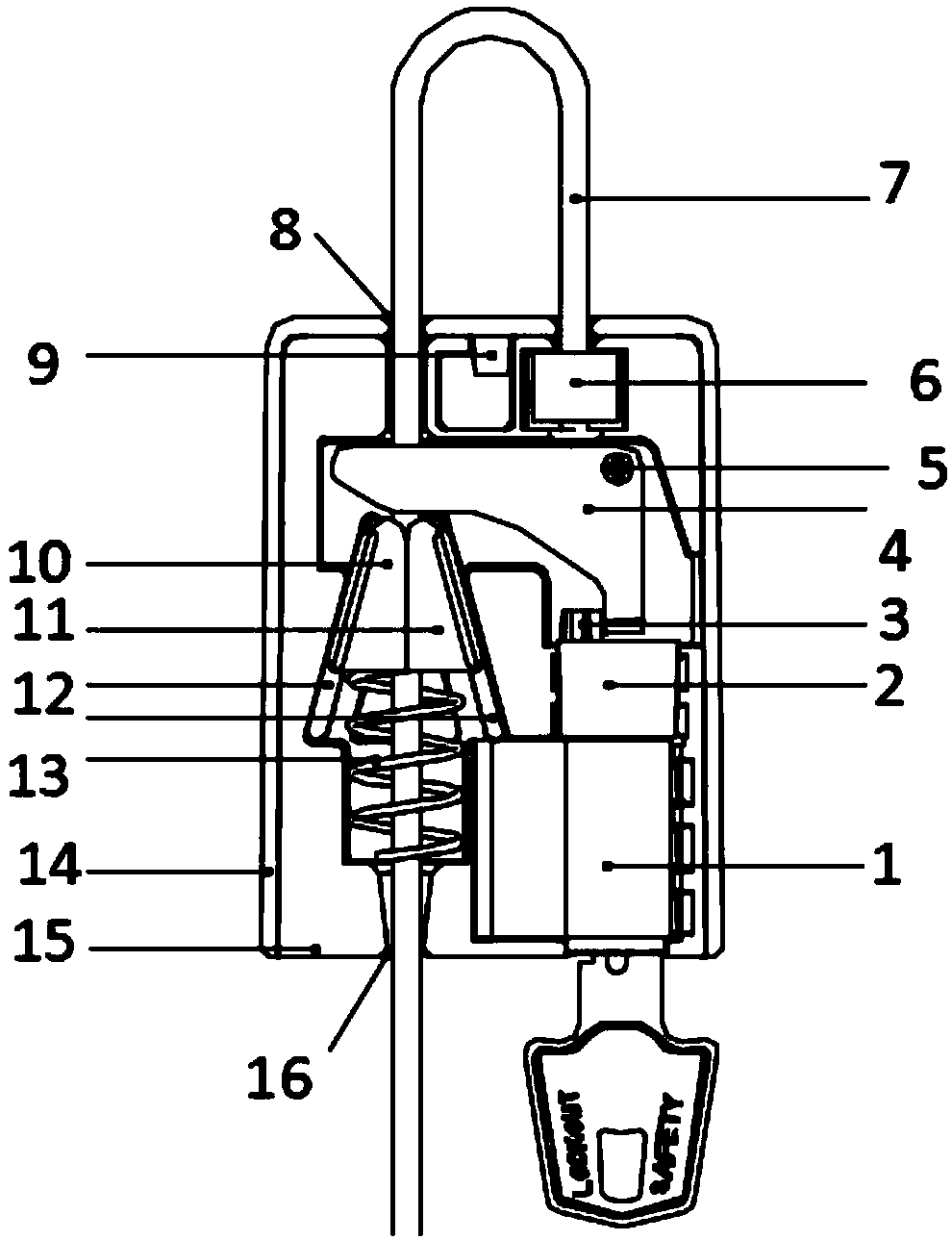

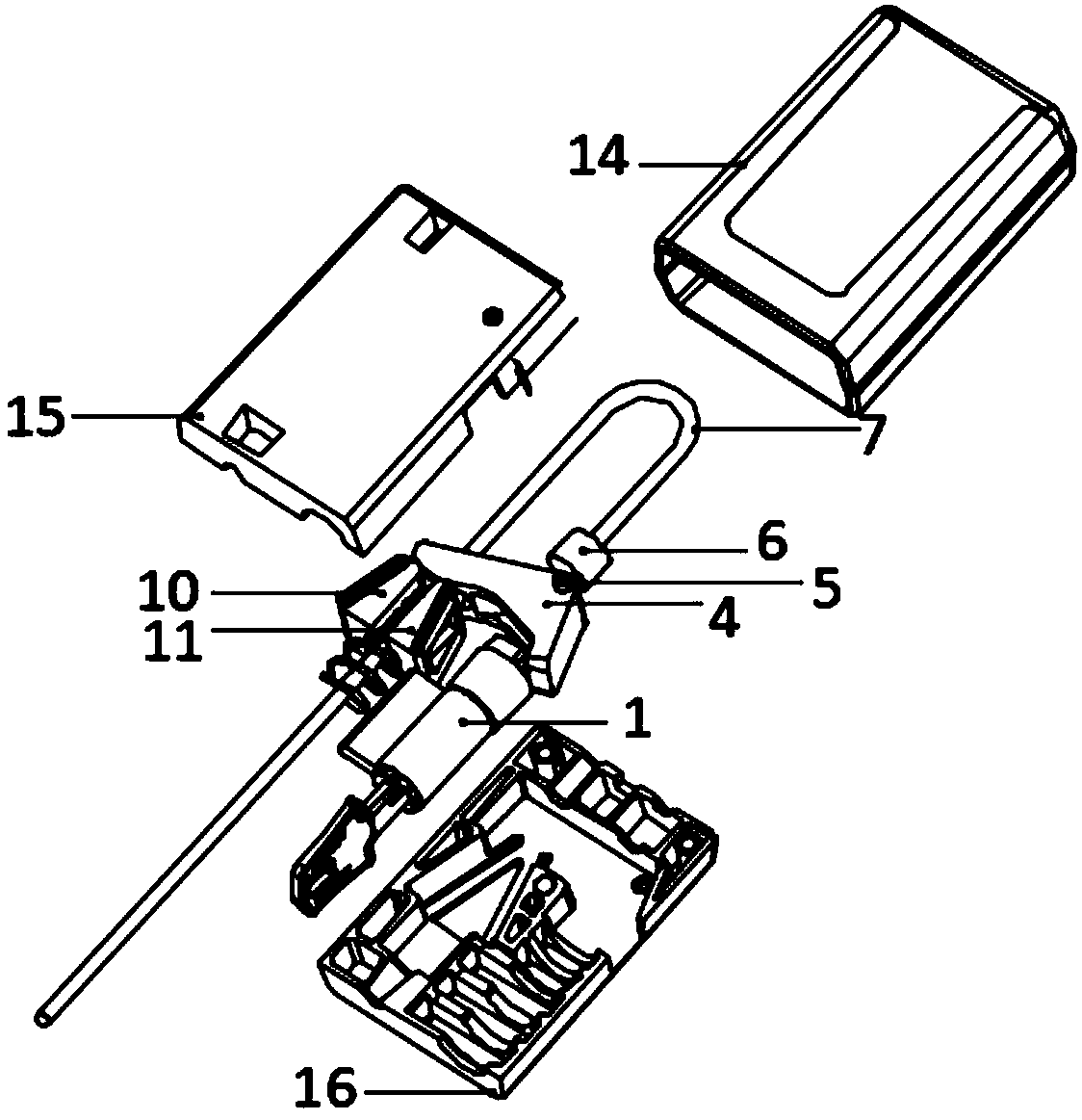

Mooring rope lock device

The invention belongs to the technical field of lock devices, and discloses a mooring rope lock device. A lock cylinder is arranged in a shell, an oval transmission part is clamped above the lock cylinder, an oval transmission part cam is welded to the left side of the upper portion of the oval transmission part, a moving block is arranged in the shell through a moving block shaft, a metal fixed base is arranged above the moving block, the right end of a steel cable is clamped to the metal fixed base, the left end of the steel cable is inserted from a steel cable inlet, and extends out from asteel cable outlet, a shell clamping hook is welded to the breaking position of the upper portion of the interior of the shell, guide grooves are sleeved with rear ends of a first inverted tooth extrusion block and a second inverted tooth extrusion block, and the lower portion of a spring is placed on an upper pressing plate. A mooring rope penetrates many targets to be locked, for example, the mooring rope penetrates a disc valve to be fixed to a pipeline, the locking effect is obvious, the rope is not prone to loosening, the protection effect on safety production and maintaining is achieved,many industrial safety accidents can be avoided, and meanwhile, unnecessary economic losses are avoided, and production efficiency is improved.

Owner:SUZHOU DUKE SECURITY TECH

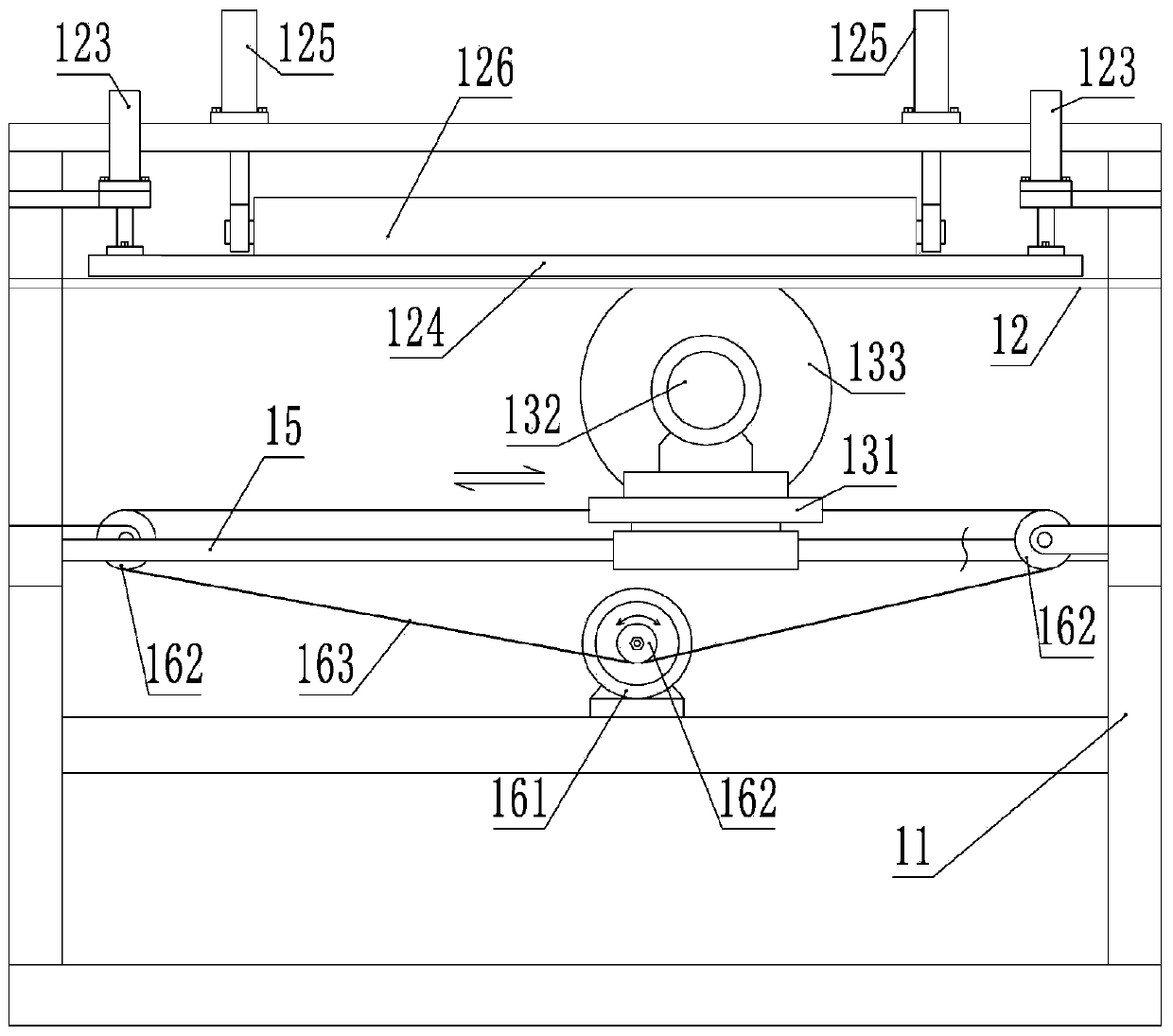

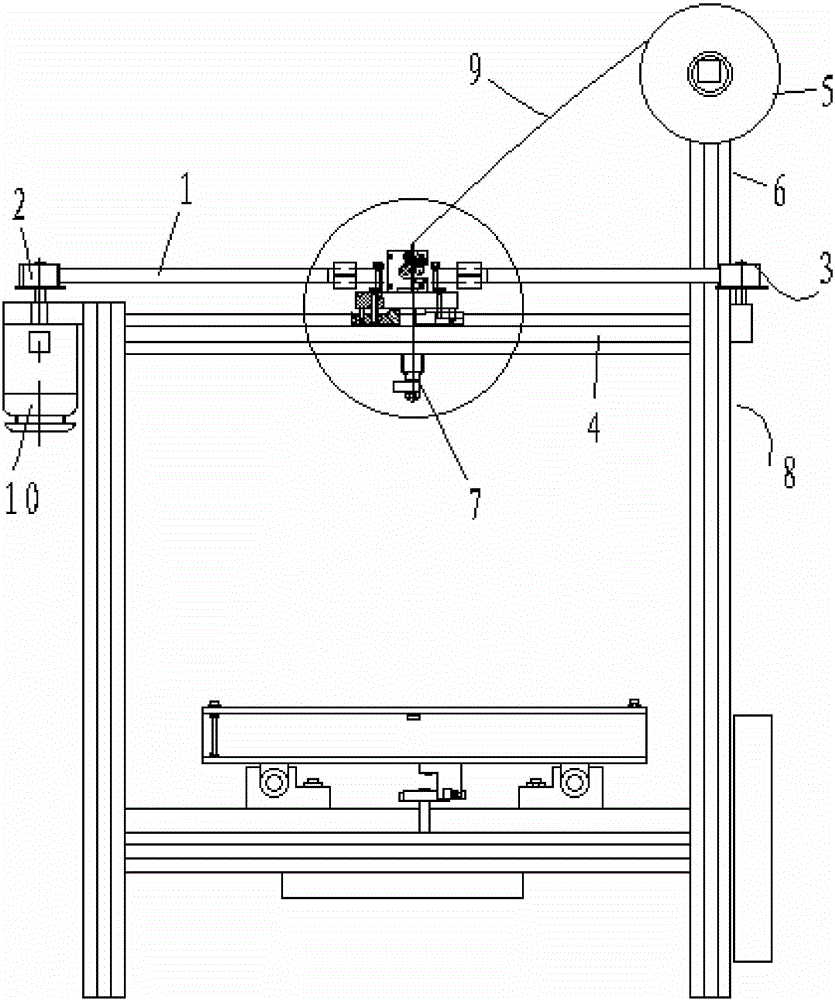

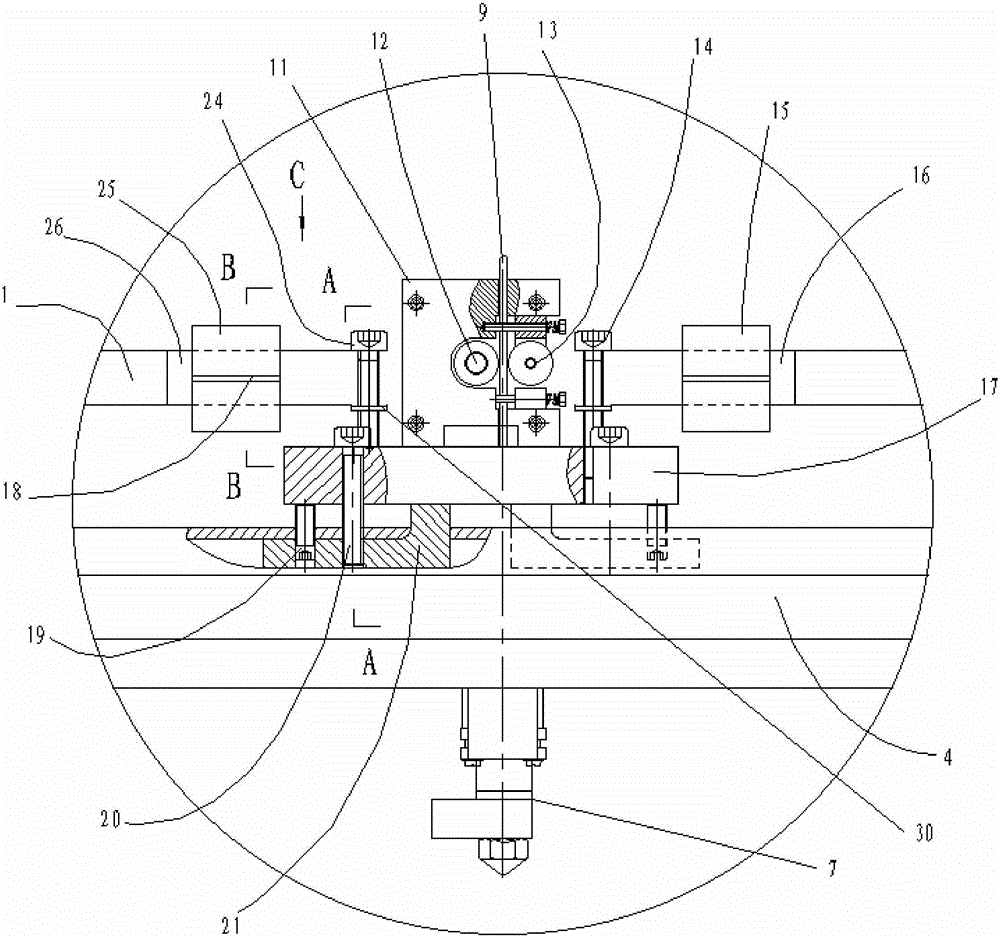

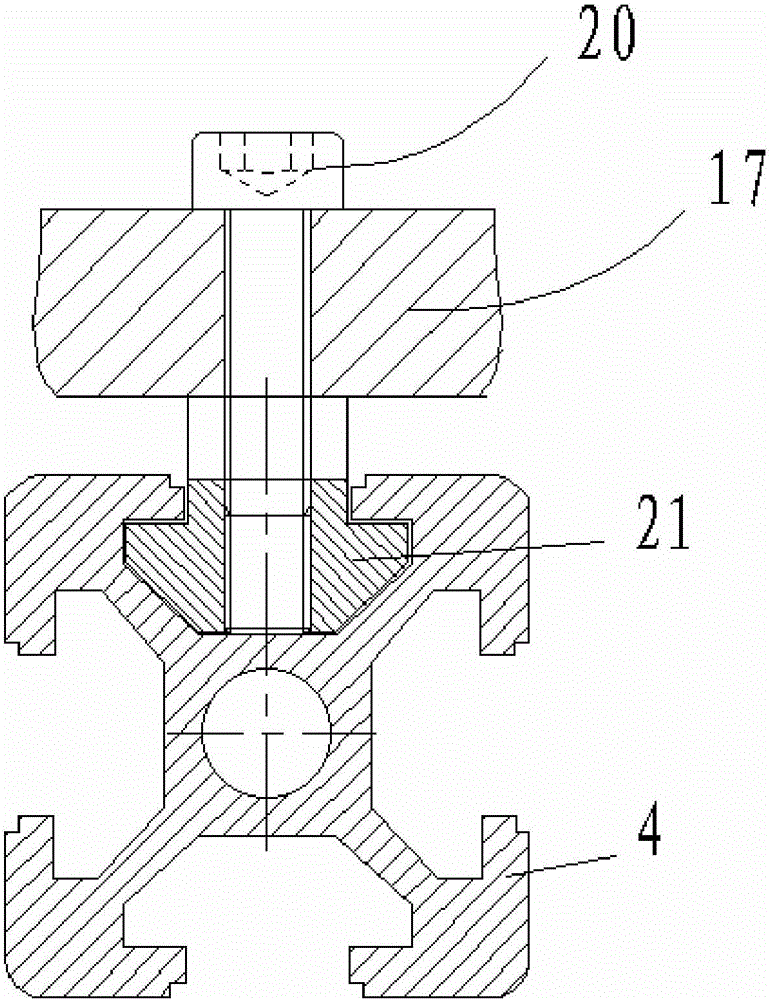

Printing head walking structure of 3D printer

InactiveCN105014969AEasy tension adjustmentExtended service lifeAdditive manufacturing apparatus3d printAgricultural engineering

Owner:UNIV OF JINAN

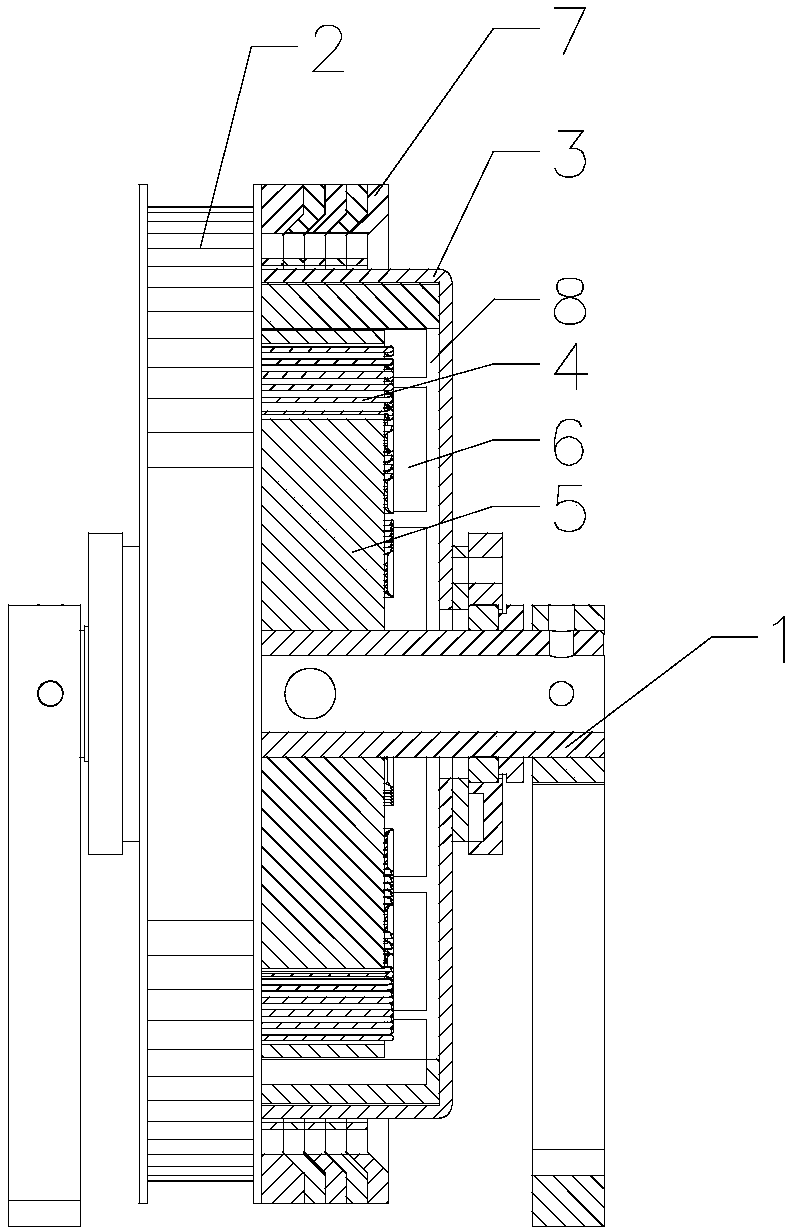

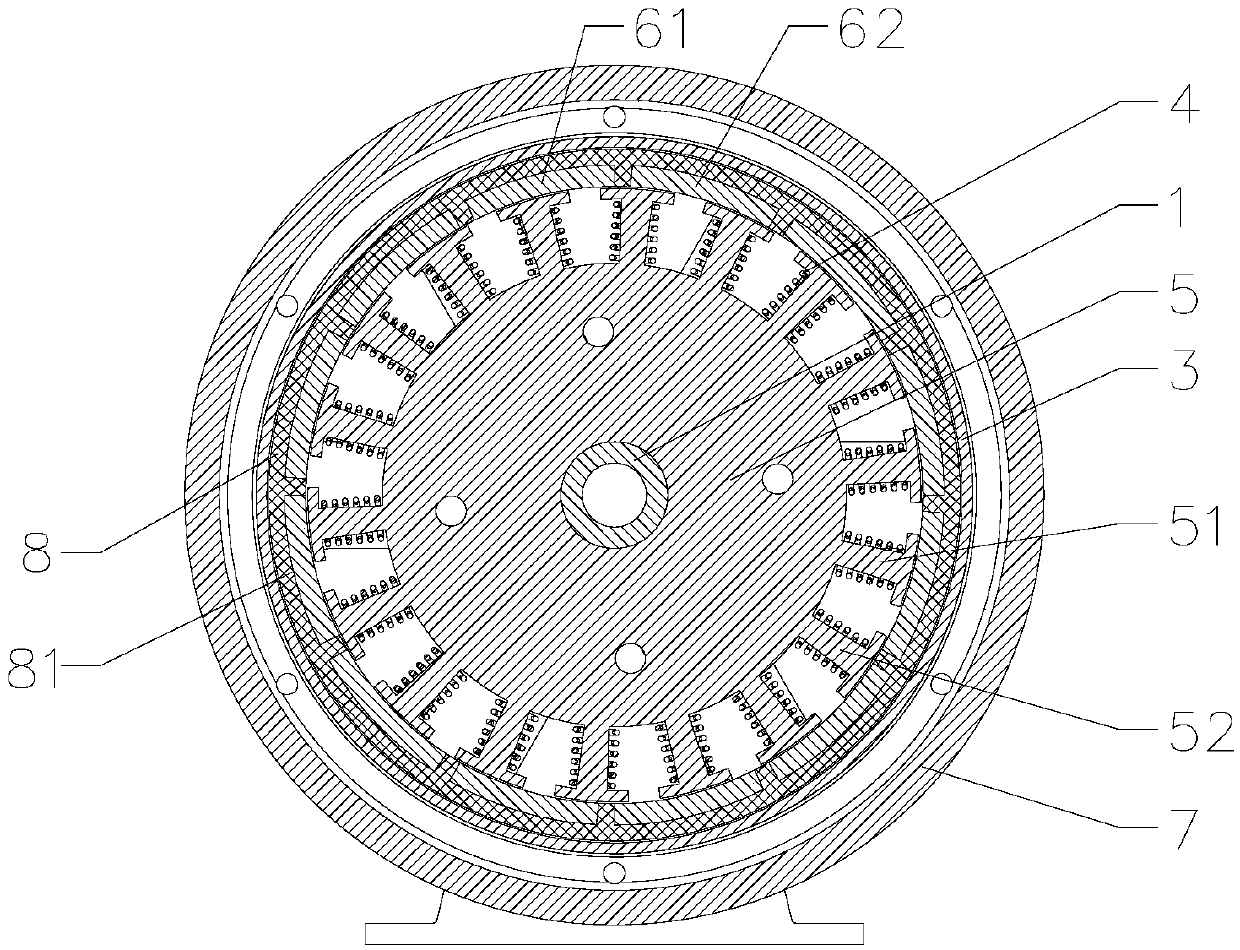

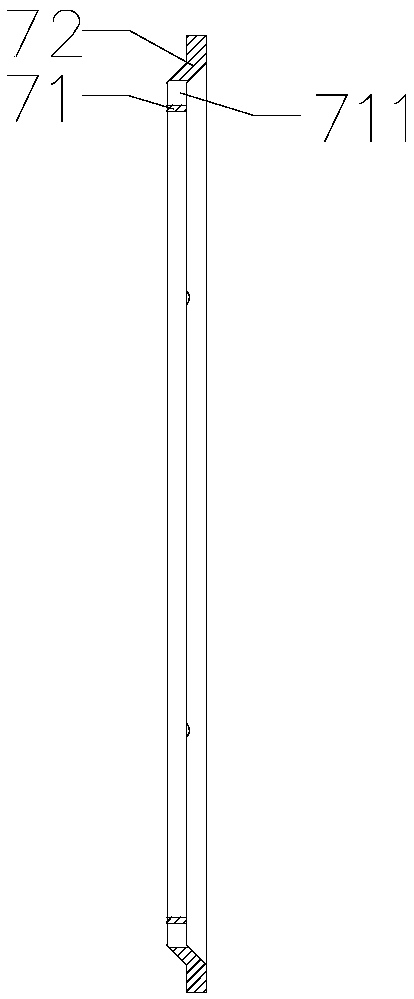

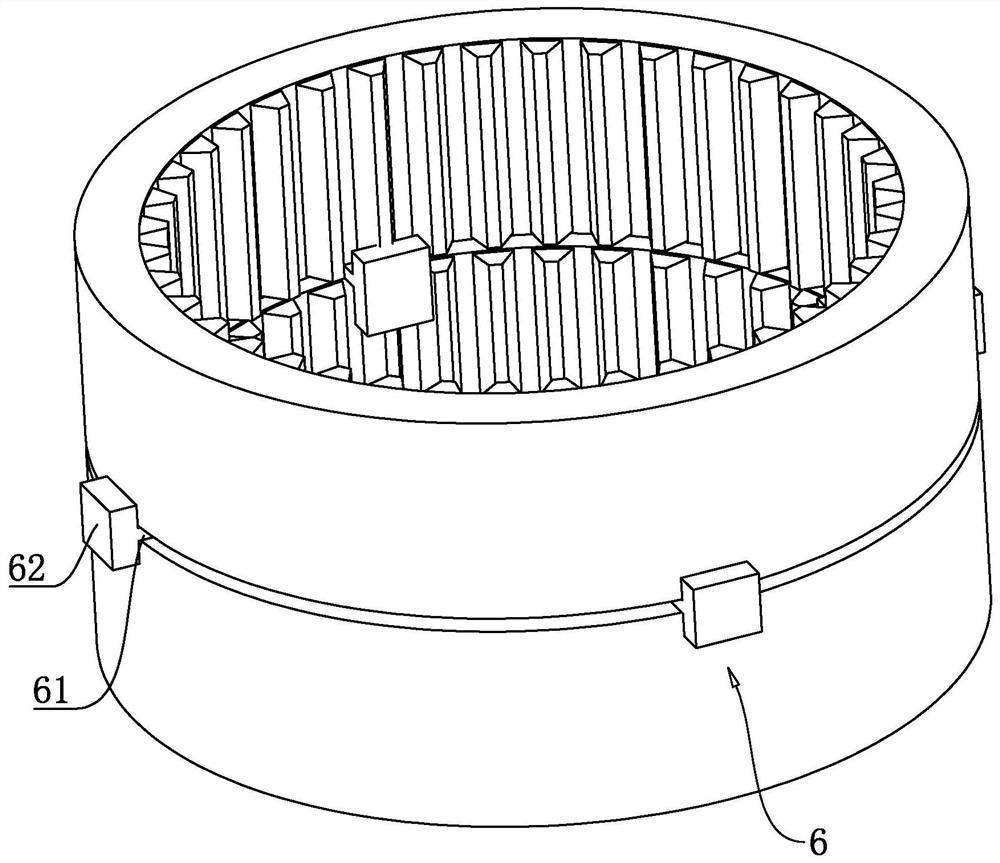

Starter generator

PendingCN107947462APlay a protective effectWeight increaseMechanical energy handlingSynchronous machines with stationary armatures and rotating magnetsStarter generatorDrive wheel

The invention provides a starter generator, which comprises a fixation shaft, a driving wheel sleeved on the fixation shaft and in driving connection with the fixation shaft, and a housing arranged onthe driving wheel. The driving wheel is in driving connection with an external power source; and the housing is internally provided with a power generation assembly. The power generation assembly comprises an excitation coil arranged on the fixation shaft and permanent magnets arranged on the inner wall of the housing. Since the housing is arranged on the driving wheel, the permanent magnets rotate with the driving wheel, and magnetic force lines are cut to generate power; through arrangement of an outer rotor and an inner stator, the rotor is fixed to the housing, the housing not only playsa protection effect, but also increases the weight of the rotor to enable rotational inertia of the rotor to increase, so that under the condition of the same power, start energy consumption of the generator can be reduced, and the generator is allowed to be started more economical and efficient; and the housing is externally provided with a counterweight member for increasing the rotational inertia of the housing to increase, and thus the generator is allowed to be started more economical and efficient.

Owner:浙江力俭新能源科技有限公司

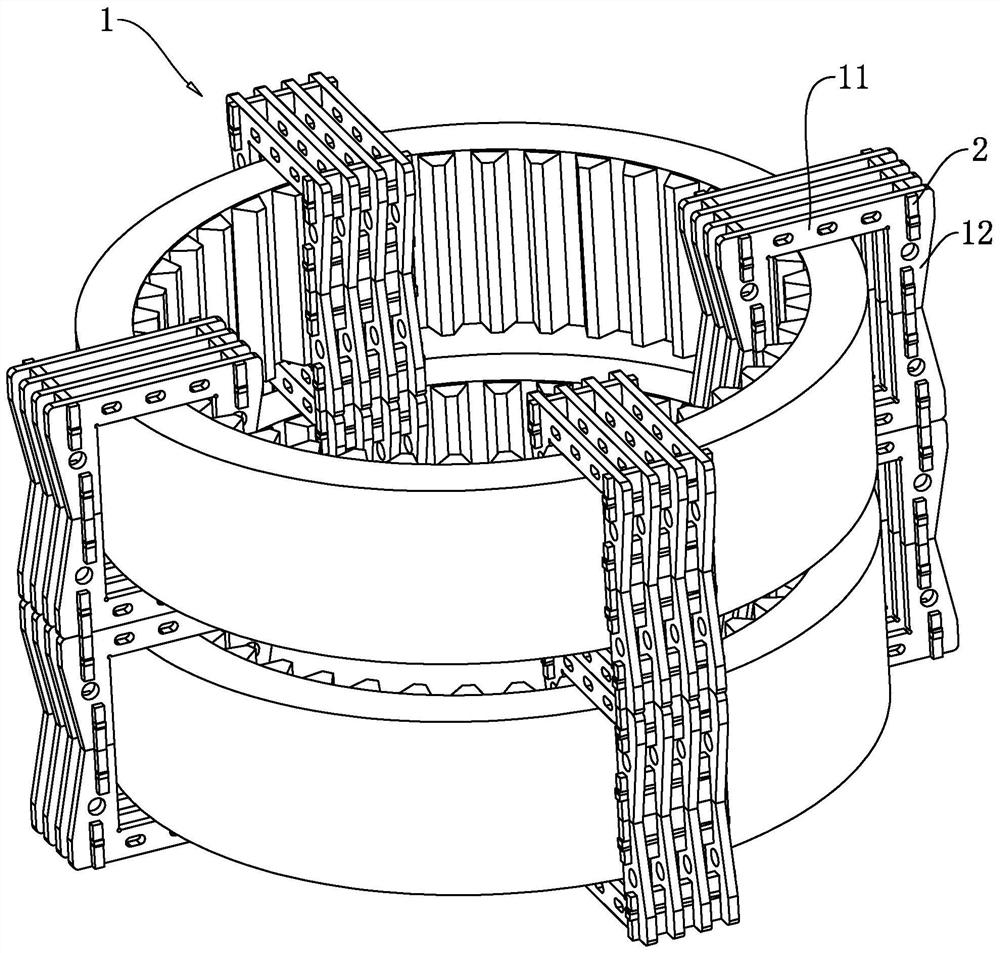

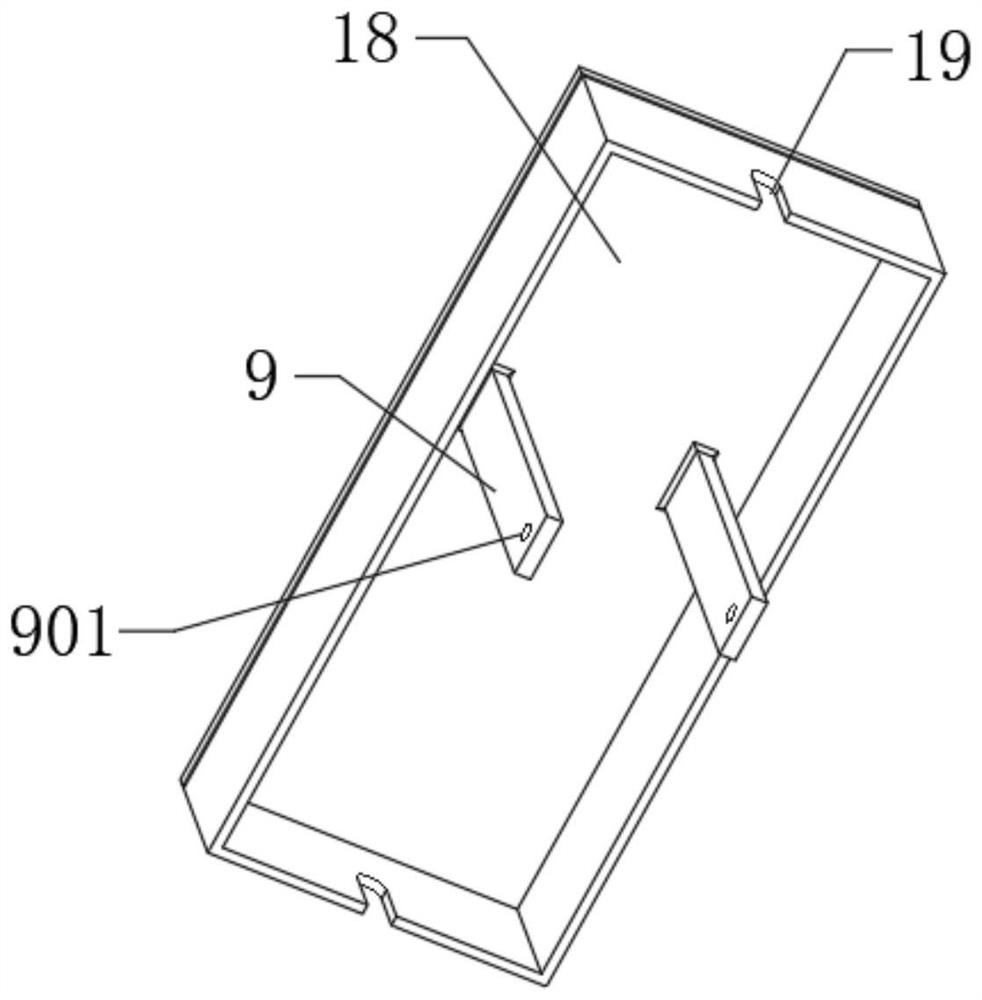

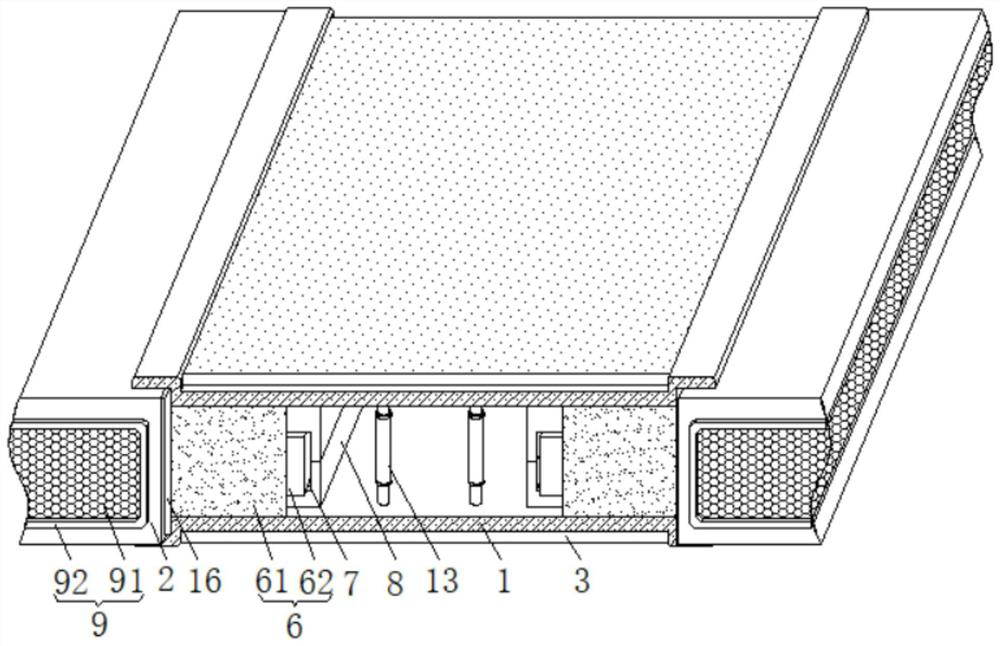

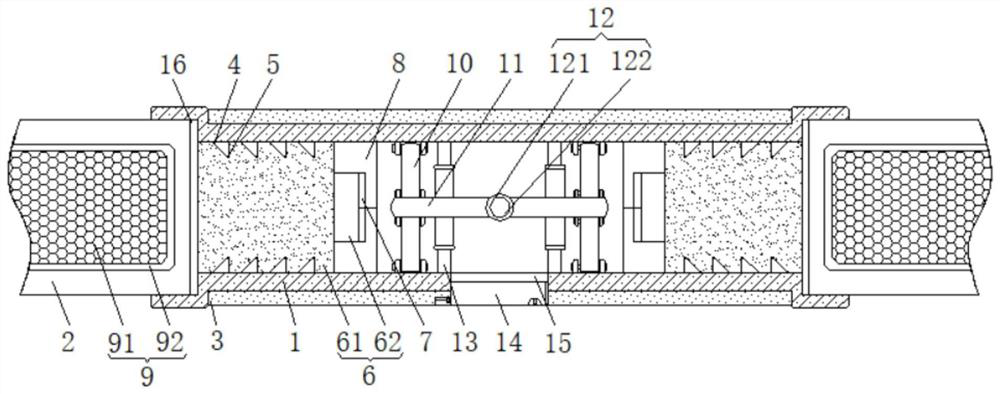

Assembly type cushion for heat treatment of ring workpieces

PendingCN112126769AExtended service lifeNot easy to loosenFurnace typesHeat treatment furnacesEngineeringHeat stress

The invention relates to an assembly type cushion for heat treatment of ring workpieces, and belongs to the technical field of heat treatment auxiliary tools. The assembly type cushion comprises a plurality of supporting plates arranged side by side, wherein each supporting plate comprises a supporting base and supporting stand columns fixed to the two ends of the supporting base; a containing space is formed between the supporting base and the supporting stand columns; assembly holes are formed in the supporting stand columns; and at least one rib plate used for connecting the plurality of supporting plates is inserted in the assembly holes. The supporting plates are arranged in an assembly type, heat stress is not likely to be generated at the joints of the supporting stand columns and the supporting bases, the tearing phenomenon at the joints of the supporting stand columns and the supporting bases is reduced, and therefore the service life of the supporting plates is prolonged.

Owner:溧阳市永恒热处理有限公司

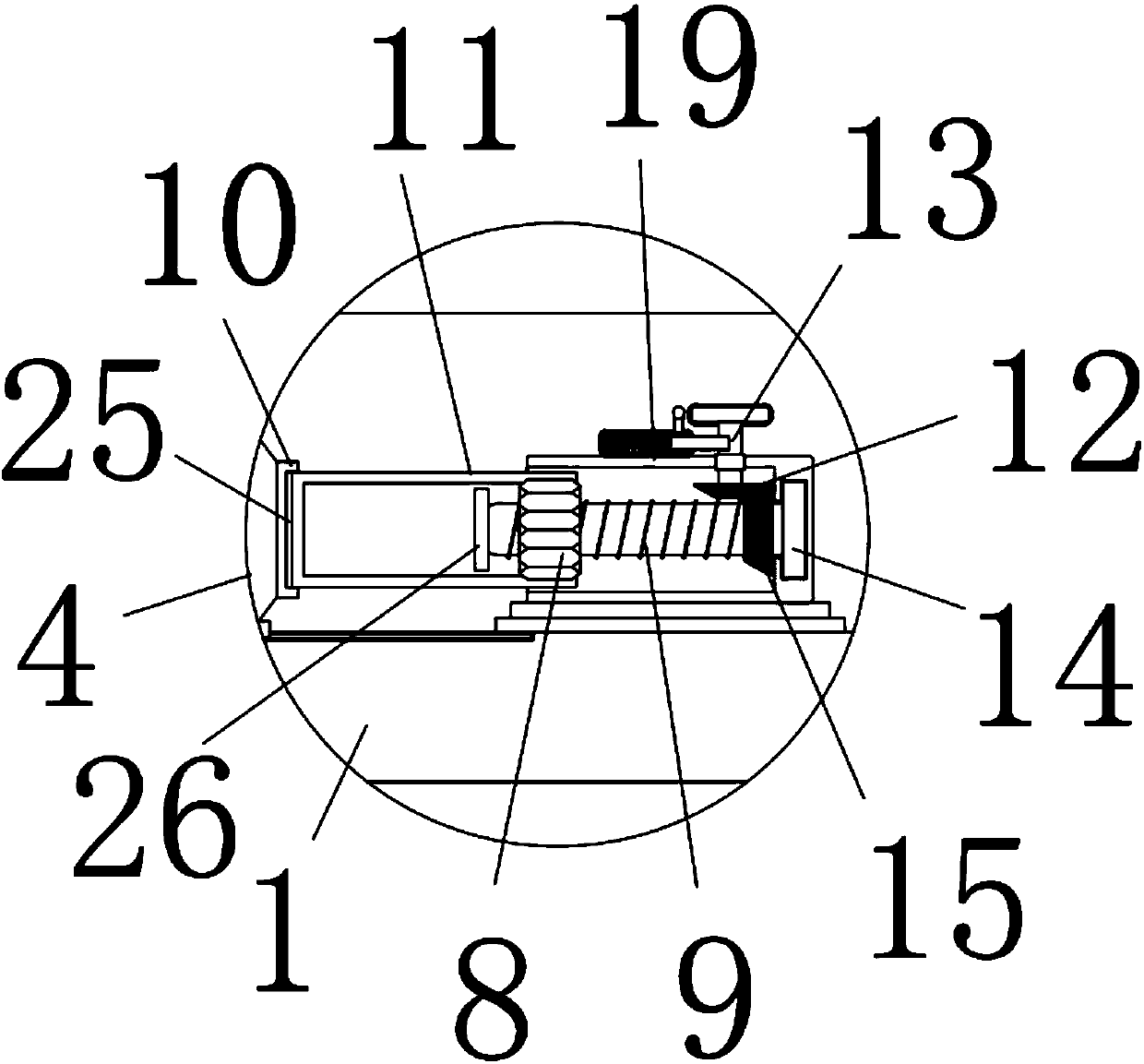

Battery anti-loose wiring device for new energy automobile

ActiveCN112821004AConvenient card connectionNot easy to loosenCoupling device detailsCell component detailsNew energyBattery cell

The invention discloses a battery anti-loose wiring device for a new energy automobile, and relates to the field of new energy automobiles. The battery anti-loose wiring device for the new energy automobile comprises a mounting beam column, a bayonet is formed in the middle of the mounting beam column, a first wiring seat is fixedly mounted on the bayonet, a second wiring seat is movably clamped to the first wiring seat, a rubber block is fixedly connected to the back face of the first wiring seat, and a first connecting wire is fixedly connected to the back face of the rubber block; the first connecting wire is connected with the battery module, the front surface of the first wiring seat is fixedly connected with a socket main body, and two sides of the first wiring seat are fixedly connected with side blocks. When the device is used, the first wiring seat and the second wiring seat can be conveniently clamped and simultaneously mounted and fixed on a mounting beam column; during mounting and fixing, operation is simple and convenient, time and labor are saved, and after butt joint, the connecting and fixing effect at the joint of the first wiring seat and the second wiring seat is good.

Owner:HENAN LI POWER SUPPLY

A kind of preparation method of mung bean cake

InactiveCN102273501AEasy to prepareDelicious and uniqueBakery productsSodium bicarbonateCooking & baking

The invention discloses a method for preparing mung bean cake, which is prepared from the following components in parts by weight: 80-100 parts of mung bean powder, 10-20 parts of starch, 5-15 parts of honey, and 5-15 parts of raisins , 5-15 parts of soybean oil, 2-5 parts of table salt, 2-5 parts of white sugar, 2-5 parts of baking soda; the preparation method is: (1) mix mung bean powder and starch, add water and mix well; (2) add raisins , white granulated sugar, baking soda are mixed, stir, then add honey, soybean oil, salt, stir evenly; (3) molding: make the raw mung bean cake of the round cake shape of above-mentioned stirred raw material; (4) baking. The preparation method of the mung bean cake of the present invention has simple and easy-to-obtain raw materials, low cost, and a simple preparation method that can be mastered by ordinary families. Loved by the majority of the people.

Owner:解玉洁

Antiknock container sealing structure

InactiveCN102862735AAvoid influenceNot easy to loosenLocking devicesElectromagnetic inductionRetaining ring

The invention relates to an antiknock container sealing structure which comprises an antiknock container body, an annular sleeve ring and a cover, wherein the sleeve ring is fixed at the position of an opening of the antiknock container body; a first circular groove is arranged on a top plane of the sleeve ring, and a first thread is arranged on an inner lateral face of the sleeve ring; the upper portion of the cover is disc-shaped, the lower portion of the cover is column-shaped or cylindrical, a handle is arranged on a top face of the upper portion of the cover, a retaining ring is arranged on a lateral face of the upper portion of the cover, and a second thread matched with the first thread on the inner lateral face of the sleeve ring is arranged on an outer lateral face of the lower portion of the cover; a second circular groove anastomotic with the first circular groove on the top plane of the sleeve ring is arranged on a disc-shaped bottom surface of the upper portion of the cover; and a sealing ring is arranged in an annular hole formed by the first circular groove on the top plane of the sleeve ring and the second circular groove on the disc-shaped bottom face of the upper portion of the cover. With the adoption of an antiknock container using the sealing structure, electrostatic induction and electromagnetic induction can be shielded; and the an antiknock container has the advantages of saving labor and being convenient during operation of closing a top cover of the antiknock container.

Owner:蒋友明

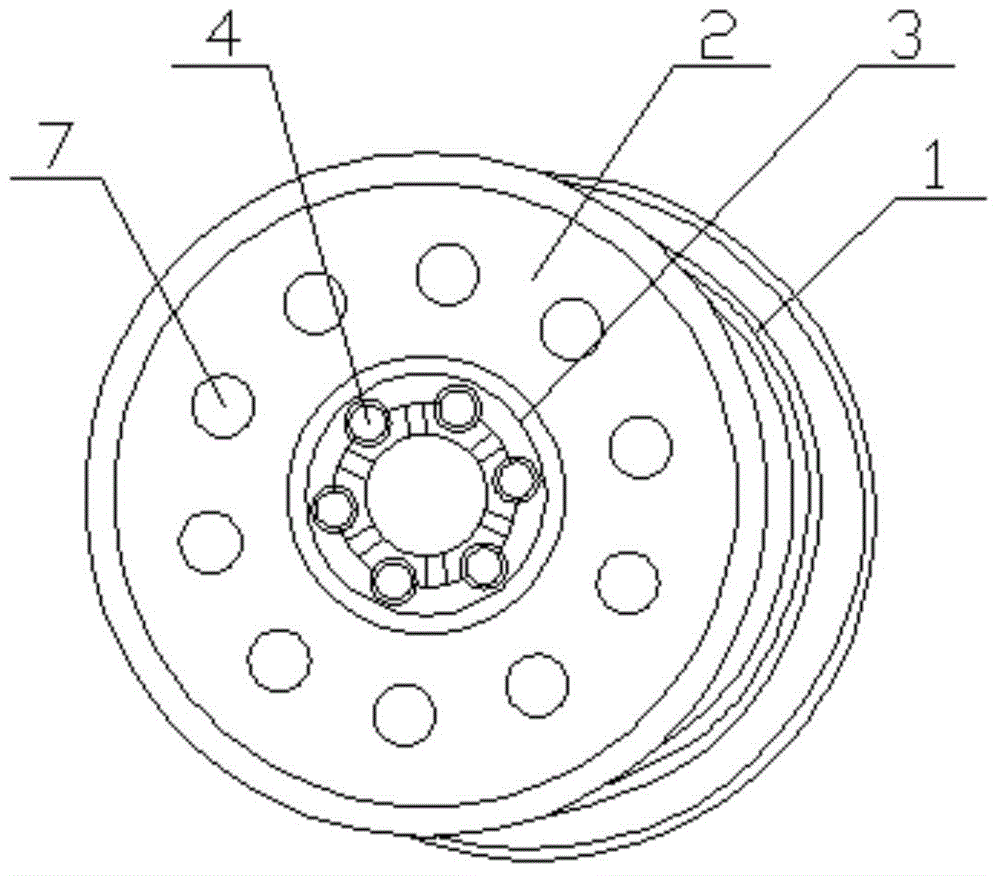

Automobile hub

InactiveCN104786730AReduce security risksImprove stress resistanceDisc wheelsWheel and axleAutomotive engineering

Owner:黄利文

Assembly type plate-shaped wall surface mounting structure with sound insulation material

The invention discloses an assembly type plate-shaped wall surface mounting structure with a sound insulation material, and belongs to the technical field of building engineering. The assembly type plate-shaped wall surface mounting structure comprises two supporting plates, wherein assembly wall plates are arranged on the left sides and the right sides of the opposite faces of the two supportingplates, and the right side faces of the assembly wall plates are fixedly connected with the left side faces of limiting assemblies. According to the assembly type plate-shaped wall surface mounting structure with the sound insulation material, the supporting plates, the assembly wall plates, threaded cylinders, threaded rods, movable connecting rods, clamping grooves, sliding plates, limiting blocks and limiting grooves are arranged, a plurality of clamping blocks arranged on the supporting plates can be effectively clamped into the clamping grooves, so that the sliding plates are effectivelylimited, the assembly wall plates can be mounted after a door cover is closed, and a plurality of assembly wall plates do not need to be mounted and fixed through a plurality of fasteners; and the twoassembly wall plates are mounted through the supporting plates, so that the mounting stability of the assembly wall plates is effectively improved, the assembly wall plates are not prone to loosening, and normal operation of workers is facilitated.

Owner:GOLD MANTIS FINE DECORATION TECH SUZHOU CO LTD

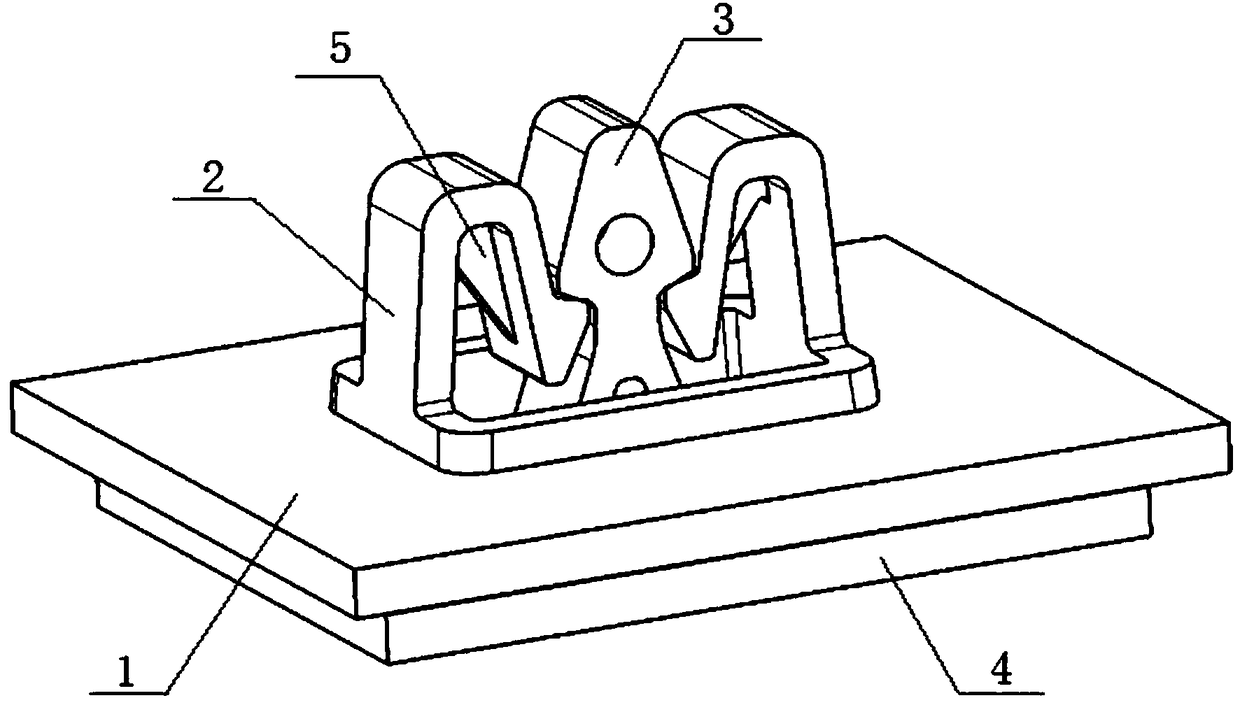

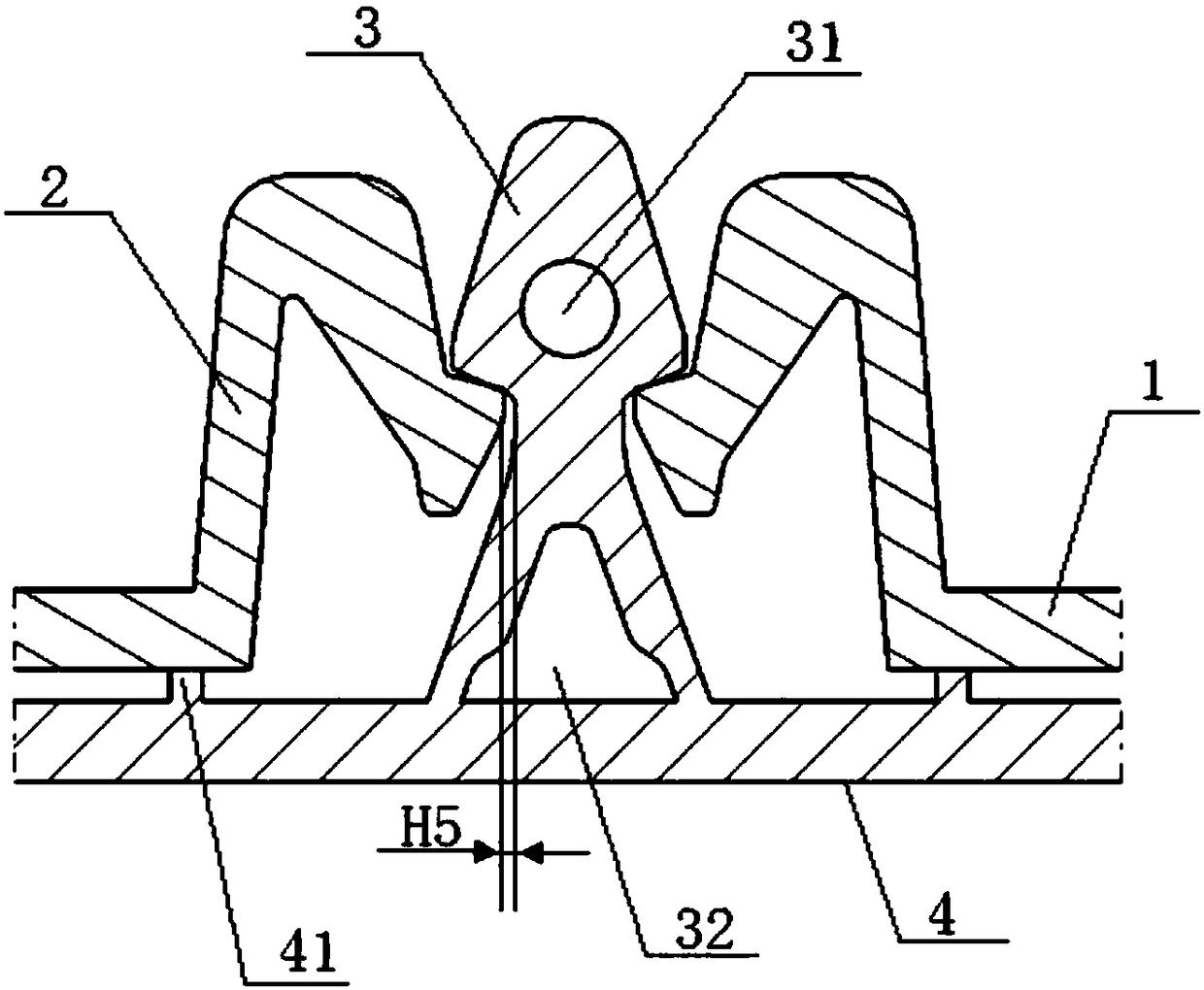

Installation structure capable of being repeatedly demounted

PendingCN108278259AHigh strengthReduced insertion forceDowelsUltimate tensile strengthAssembly structure

The invention relates to the field of assembly structures, in particular to an installation structure capable of being repeatedly demounted. The installation structure capable of being repeatedly demounted comprises a base and a snap joint. The top of the base is provided with two clamping corners which protrude upwards. The outer side faces of the upper ends of the clamping corners are provided with limiting parts in a protruding manner. The upper ends of the two clamping corners are bent towards the inner sides so that the two limiting parts can be oppositely arranged, a gap for the snap joint to enter or retreat is reserved between the two limiting parts, and the upper end of the snap joint penetrates the base, extends into the gap and is clamped to the two limiting parts. The installation structure capable of being repeatedly demounted has the beneficial effects that by means of the arrangement of the two clamping corners, the snap joint can flexibly and smoothly advance or retreatto coordinate with the limiting parts, meanwhile, the strength of the clamping corners is improved, the situation that the pulling and inserting force is reduced due to the repeated demounting of thesnap joint and the clamping corners is avoided, the strength of the installation structure is improved, and the assembling precision is guaranteed.

Owner:CHONGQING PINGWEI AUTO PARTS CO LTD

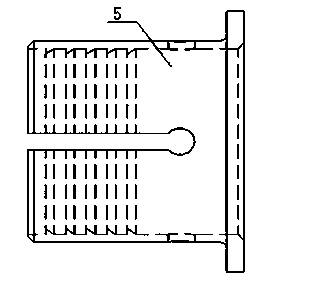

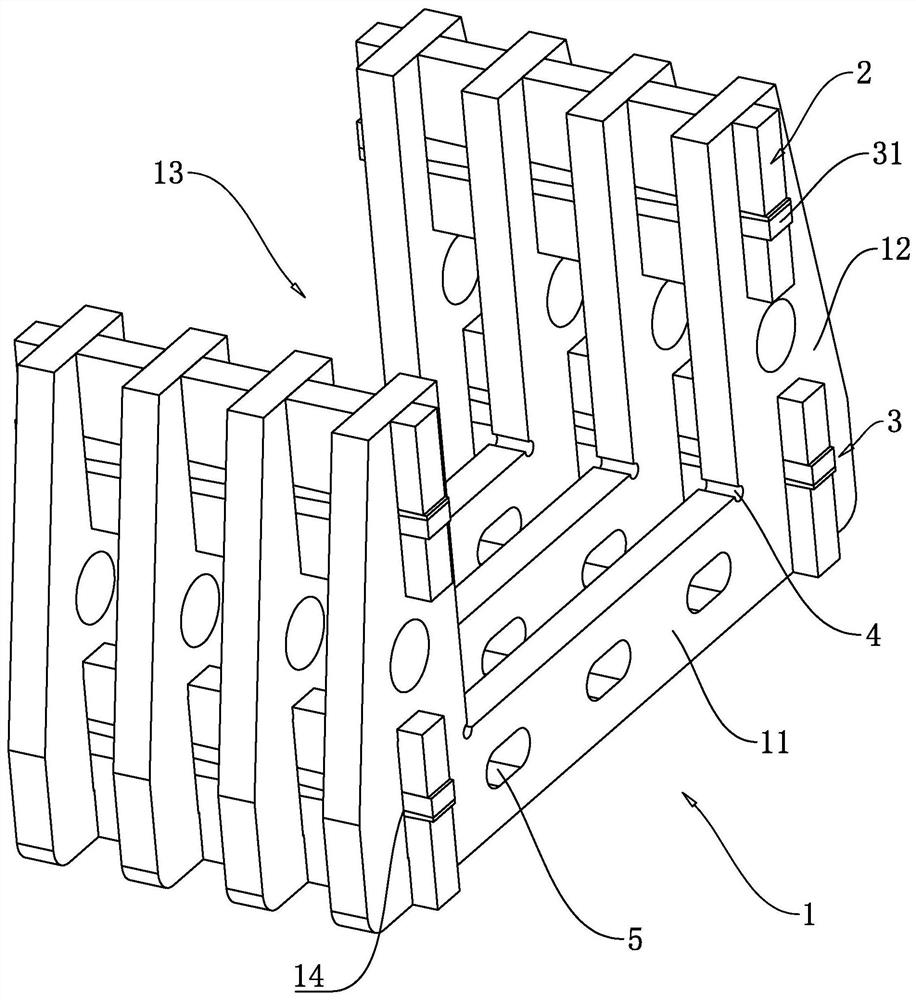

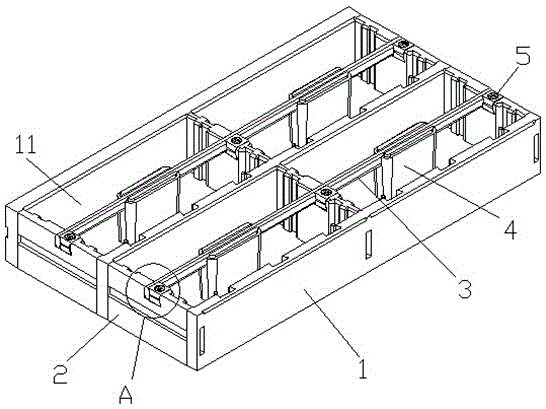

Brick making die containing with splicing hanging rods

ActiveCN105058563AImprove structural strengthNot easy to loosenCeramic shaping mandrelsCeramic shaping coresBrickEngineering

The invention discloses a brick making die containing with splicing hanging rods. The brick making die containing with the splicing hanging rods comprises multiple transverse long plates which are arranged in a parallel manner. The portion between every two adjacent transverse long plates is provided with multiple longitudinal short plates at intervals to form multiple brick making die cavities which are separated from each other. Each brick making die cavity is provided with a die core block. A long-strip hanging rod is arranged on the portion between every two adjacent transverse long plates in a parallel manner. The tops of the longitudinal short plates are provided with positioning through grooves corresponding to the long-strip hanging rods. The positioning through grooves are internally provided with upper fixing blocks and lower fixing blocks which are used for fixing the long-strip hanging rods. The cross section of each long-strip hanging rod is in a rectangular shape. The four corners of each rectangle are provided with chamfers respectively. In this way, according to the brick making die containing with the splicing hanging rods, installing and disassembling of the hanging rods can be completed through inside hexagonal bolts, the strength of the connected structure is high, the loosening problem is not prone to happening in the production process, replacing is more convenient, and the maintaining cost is lowered.

Owner:TAICANG FLEXSYS MOLD TECH CO LTD

Aerospace flexible nut closing-in device

ActiveCN107932049AAvoid poor fasteningMeet needsAircraft componentsMetal working apparatusAviationEngineering

The invention discloses an aerospace flexible nut closing-in device. The aerospace flexible nut closing-in device comprises a bottom plate and a first bolt; the first bolt is installed at the top of the bottom plate and penetrates through the bottom plate; a shell is installed outside a flexible nut; a plurality of first springs are installed in a right-side inner cavity of the shell; and an inserting block is installed at the bottoms of the first springs and penetrates through the shell and the bottom plate in sequence, and a pull rod is installed on the outer wall of the left side of the inserting block and penetrates through the shell. According to the aerospace flexible nut closing-in device, the purpose of arranging the flexible nut and other assemblies is achieved through the bottomplate, the situation that the fastening performance of the flexible nut is reduced due to the fact that the flexible nut is influenced by external factors is avoided as far as possible through the shell, the purpose that the shell is not prone to being loosened is achieved through the inserting block, thus, the flexible nut can be more stable and prevented from loosening, and the requirements of the modern aviation industry for the flexible nut closing-in device are met.

Owner:SHENZHEN QUANSHENG PRECISION TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com