Starter generator

A technology for starting generators and power generation components, which is applied to electrical components, electromechanical devices, electric components, etc., can solve the problems of large starting energy consumption, small central shaft mass, and low rotational inertia of generators, and achieves reduction of starting energy consumption, The effect of stable rotation and increased power generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

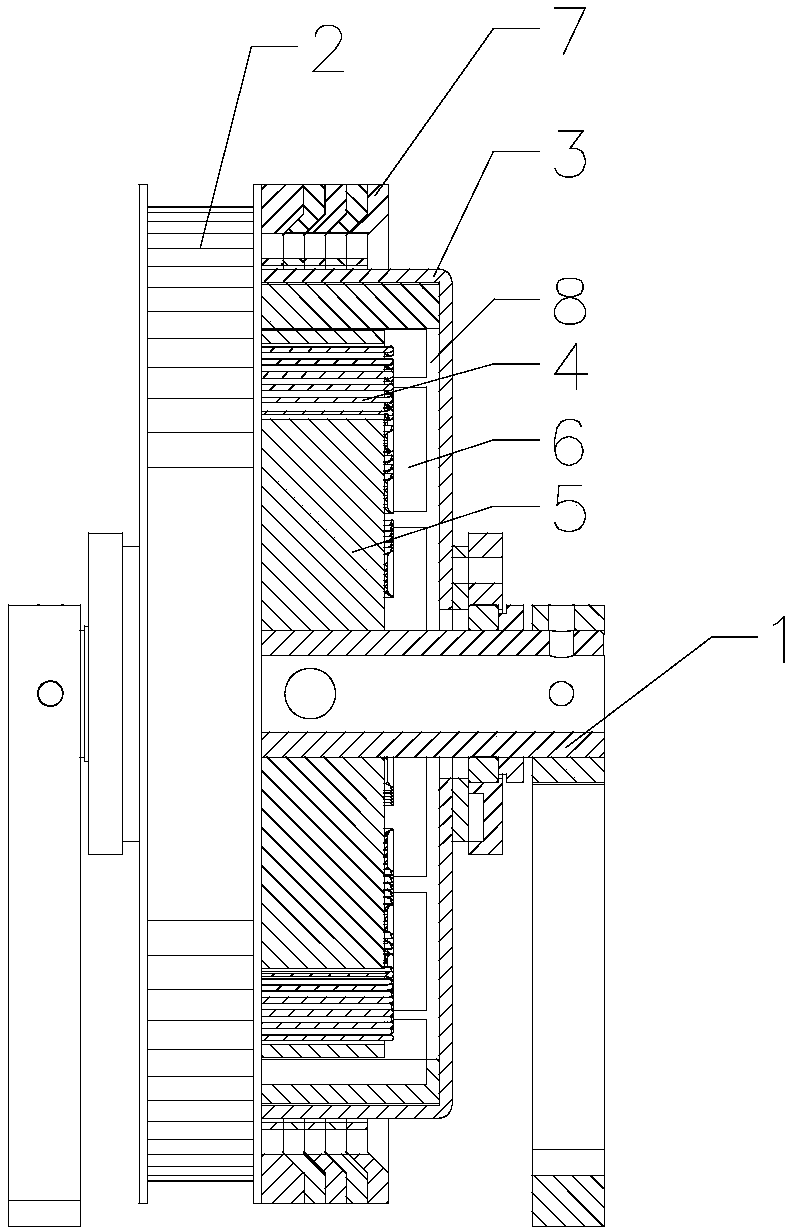

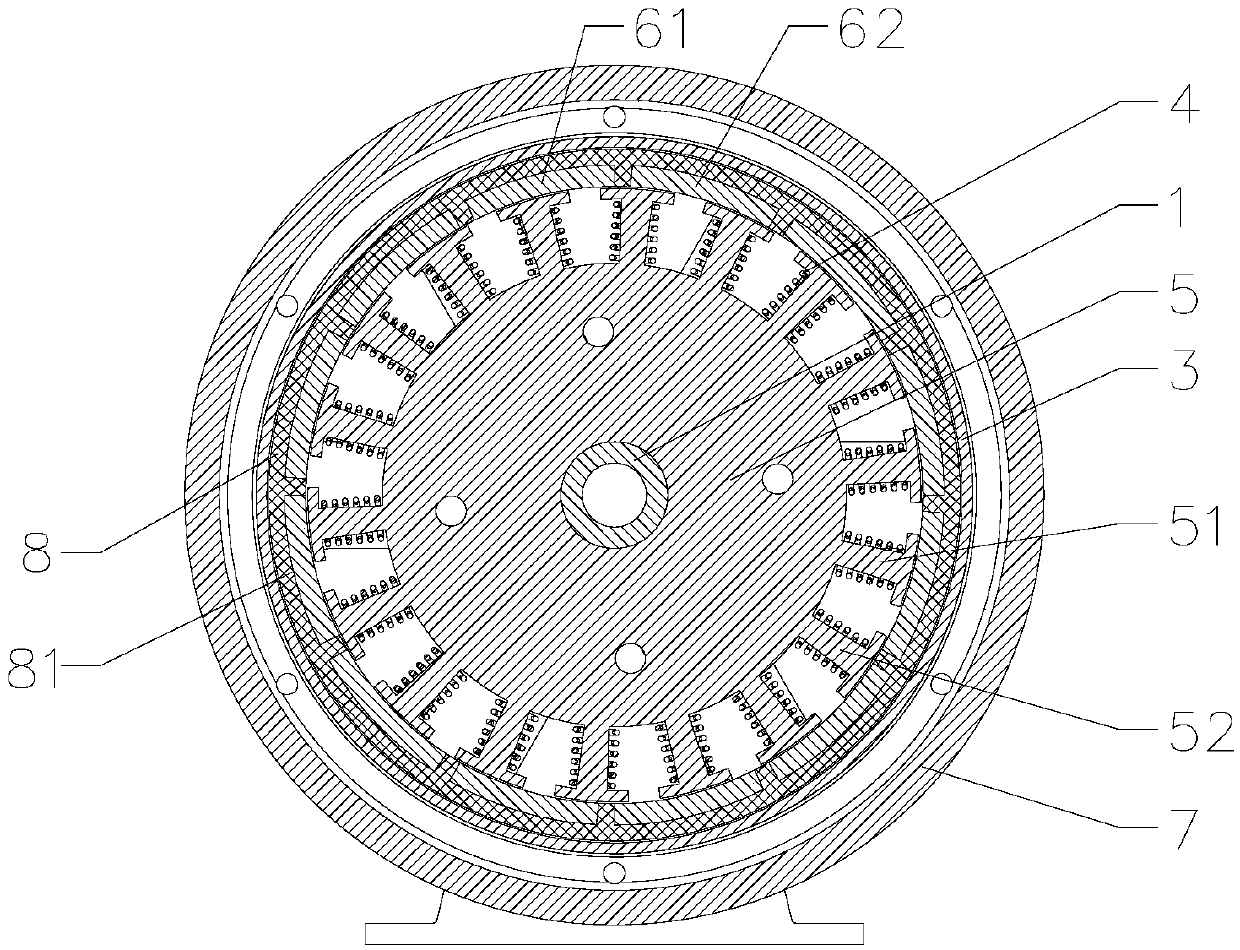

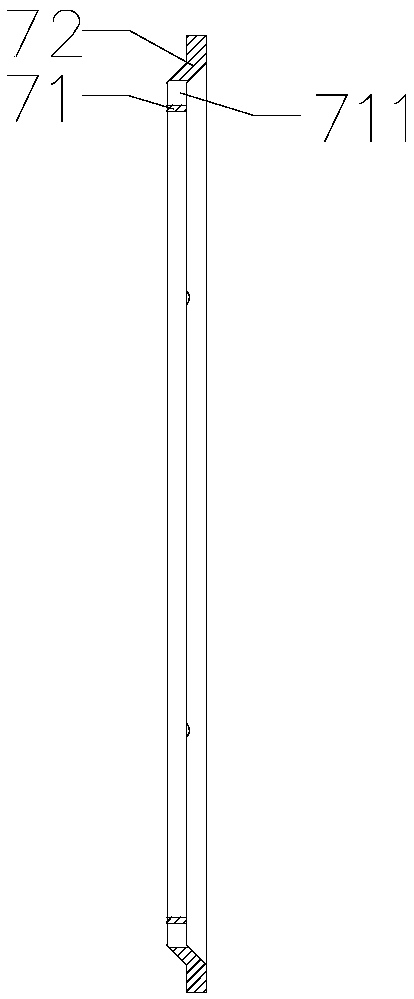

[0035] Such as Figures 1 to 3 As shown, the present invention provides a starter generator, including a fixed shaft 1, a transmission wheel 2 sleeved on the fixed shaft 1 and rotatably connected to the fixed shaft 1, and a housing 3 arranged on the transmission wheel 2. The transmission wheel 2 It is connected to the external power source by transmission, and the housing 3 is equipped with a power generation assembly. The power generation assembly includes an excitation coil 4 arranged on the fixed shaft 1 and a permanent magnet 6 arranged on the inner wall of the housing 3. The excitation coil is arranged on the fixed shaft 1 4. A permanent magnet 6 is set on the inner wall of the casing 3. Since the casing 3 is set on the transmission wheel 2, the permanent magnet 6 rotates together with the transmission wheel 2, thereby cutting the magnetic force line to generate power. Through the setting of the outer rotor inner stator, The rotor is fixed on the housing 3. The housing 3 ...

Embodiment 2

[0054] Such as Figure 4 As shown, the main difference between this embodiment and the first embodiment is that the casing 3 includes a first casing 31 and a second casing 32 .

[0055] The casing 3 includes a first casing 31 and a second casing 32, and the transmission wheel 2 is arranged between the first casing 31 and the second casing 32. The benefit of such an arrangement is that both ends of the transmission wheel 2 can be The power generation component is arranged so that the weights at both ends of the drive wheel 2 are more balanced, the use of the generator is more stable, and the power generation of the generator is increased, so that the power generation of the generator is more efficient.

Embodiment 3

[0057] Such as Figure 5 As shown, the main difference between the present embodiment and the first embodiment is that there are multiple power generating components arranged parallel and parallel inside the casing 3 along the axial direction of the casing 3 .

[0058] There are a plurality of power generating components arranged parallel to the inside of the housing 3 along the axial direction of the housing 3 . The advantage of such arrangement is that the power generation of the generator is increased and the power generation of the generator is more efficient. In this embodiment, there are two groups of power generation components, and the specific number can be selected according to the power generation capacity.

[0059] It can be understood that the power generation components can also be provided with 3 groups, 4 groups, 5 groups, 6 groups and so on.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com