Conveying belt capable of reducing lateral side fuzz amount generation and preparing method of conveying belt

A conveyor belt and skeleton layer technology, which is applied in the field of conveyor belt and its preparation to reduce the amount of side hairiness, can solve the problems of reputation loss, poor quality of finished tires, and easy side hairiness of the conveyor belt, so as to avoid bulging or wavy pattern, reduce the effect of snake adjustment work, and eliminate the phenomenon of big knife bend

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

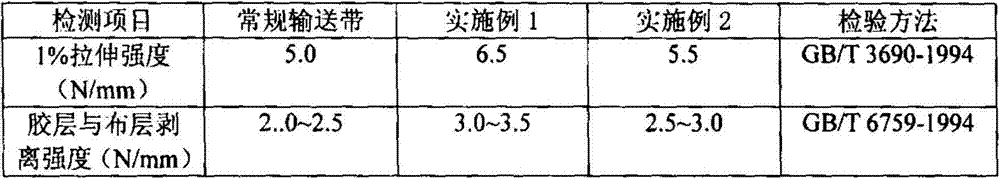

Examples

Embodiment 1

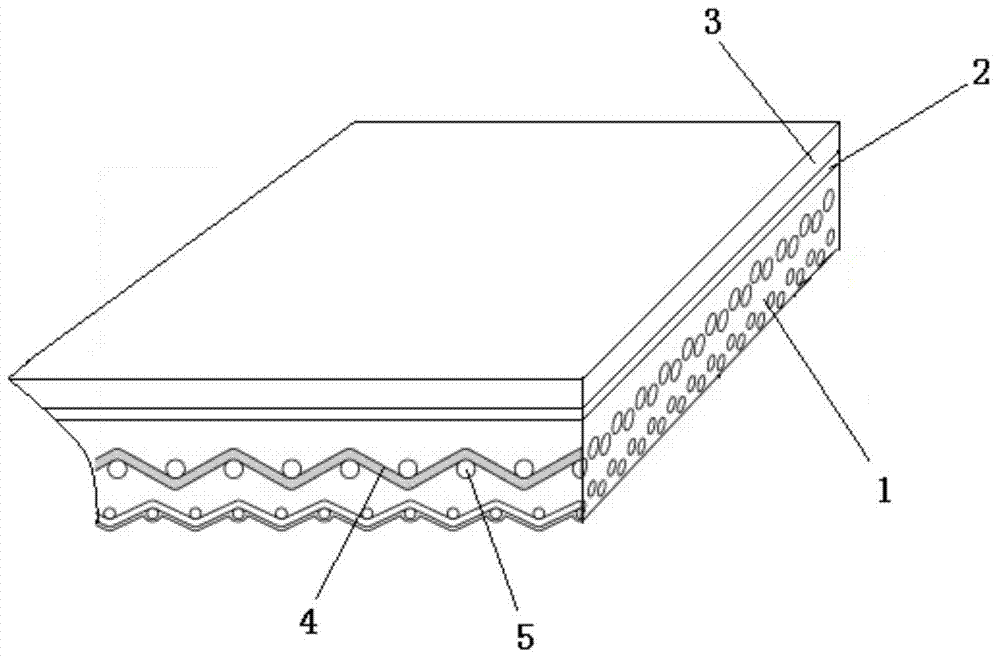

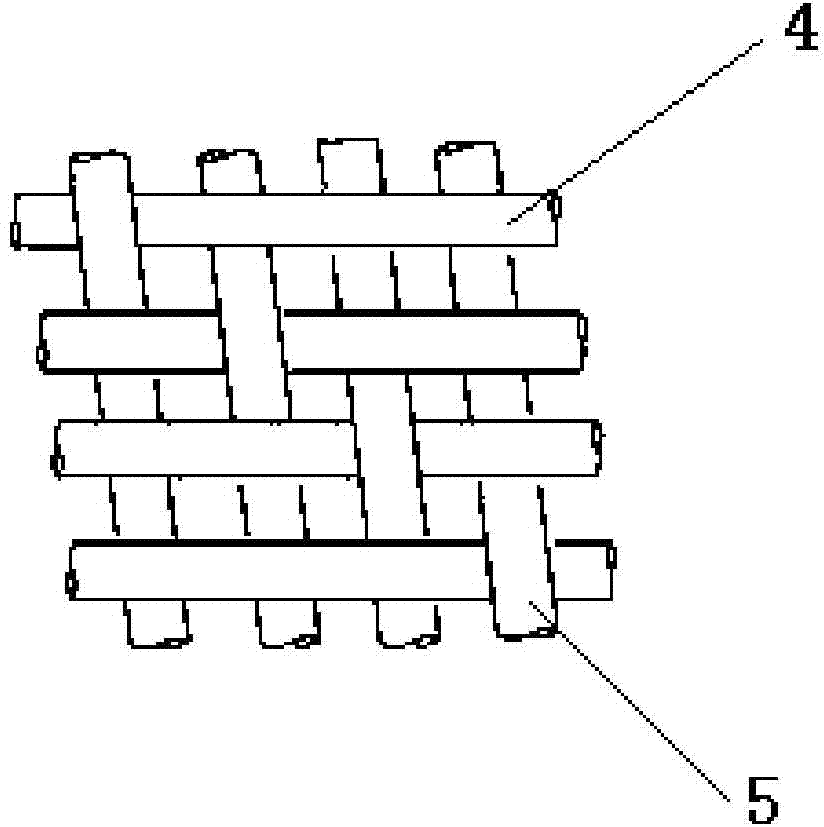

[0040] Such as Figure 1~2 As shown, in this embodiment, the skeleton layer 1 is composed of double-layer fabrics, including the surface fabric and the bottom fabric. 2 strands of polyester are spun into fiber yarns, and the weft yarn 4 adopts a PET polyester monofilament with a diameter of 0.25mm and a shrinkage rate of 0.2%.

[0041] In this embodiment, the bonding layer 2 is made of Spanish Macinsa Plastics Co., Ltd. Made of 125K thermoplastic polyurethane rubber, cover layer 3 is made of BASF polyester type TPU 670A thermoplastic polyurethane rubber.

[0042] The specific preparation method is as follows:

[0043] (1) The surface fabric and the bottom fabric are subjected to far-infrared heat treatment and finalized, the surface temperature of the fabric is controlled at 160°C, the machine speed is 10m / min, and the tension is set at 150kN;

[0044] (2) Completely immerse the skeleton layer 1 fabric after the far-infrared heat treatment in step (1) in the polyurethane g...

Embodiment 2

[0059] In this embodiment, the skeleton layer 1 is composed of double-layer fabrics, including the surface fabric and the bottom fabric. Each layer of fabric is prepared by a 1 / 3 twill weave method, wherein the warp yarn 5 of the skeleton layer 1 fabric adopts 21 counts and 2 strands Polyester is spun into fiber yarn, and the weft yarn 4 adopts a PET polyester monofilament with a diameter of 0.3 mm and a shrinkage rate below 0.2%.

[0060] In this embodiment, the bonding layer 2 is made of Lubrizol TPU58277 thermoplastic polyurethane rubber, and the covering layer 3 is made of American DuPont G4778 thermoplastic polyester elastomer.

[0061] The specific preparation method is as follows:

[0062] (1) The surface fabric and the bottom fabric are subjected to far-infrared heat treatment and finalized, the surface temperature of the fabric is controlled at 160°C, the machine speed is 10m / min, and the tension is set at 150kN;

[0063] (2) Completely immerse the skeleton layer 1 f...

Embodiment 3

[0080] In this embodiment, the skeleton layer 1 is composed of double-layer fabrics, including the surface fabric and the bottom fabric. Each layer of fabric is prepared by a 1 / 3 twill weave method, wherein the warp yarn 5 of the skeleton layer 1 fabric adopts 21 counts and 2 strands Polyester is spun into fiber yarn, and the weft yarn 4 adopts a PET polyester monofilament with a diameter of 0.2 mm and a shrinkage rate of 0.2%.

[0081] Both the bonding layer 2 and the covering layer 3 are made of Bayer TPU-DP2786 thermoplastic polyurethane rubber.

[0082] The specific preparation method is as follows:

[0083] (1) The surface fabric and the bottom fabric are subjected to far-infrared heat treatment and finalized, the surface temperature of the fabric is controlled at 150°C, the machine speed is 10m / min, and the tension is set at 200kN;

[0084] (2) Completely immerse the skeleton layer 1 fabric after the far-infrared heat treatment in step (1) in the polyurethane glue. Afte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com