Portable working machine

A kind of operation machinery and portable technology, applied in agricultural machinery and tools, machinery equipment, agriculture, etc., can solve the problems of easy shaking of poles, troublesome loading and unloading of connecting structural parts, and fixing of poles that cannot be separated, so as to achieve the goal of not being easy to loosen open effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

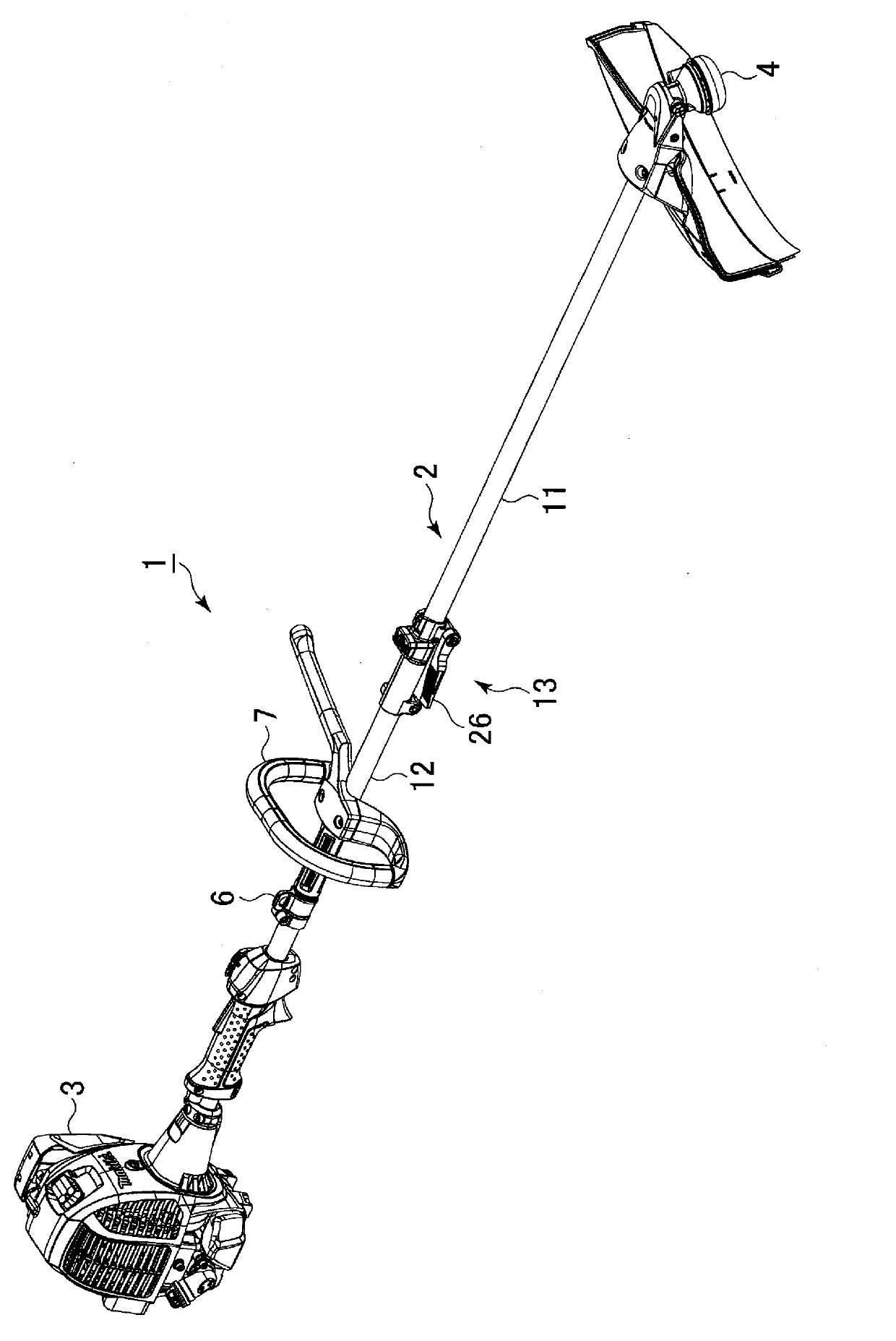

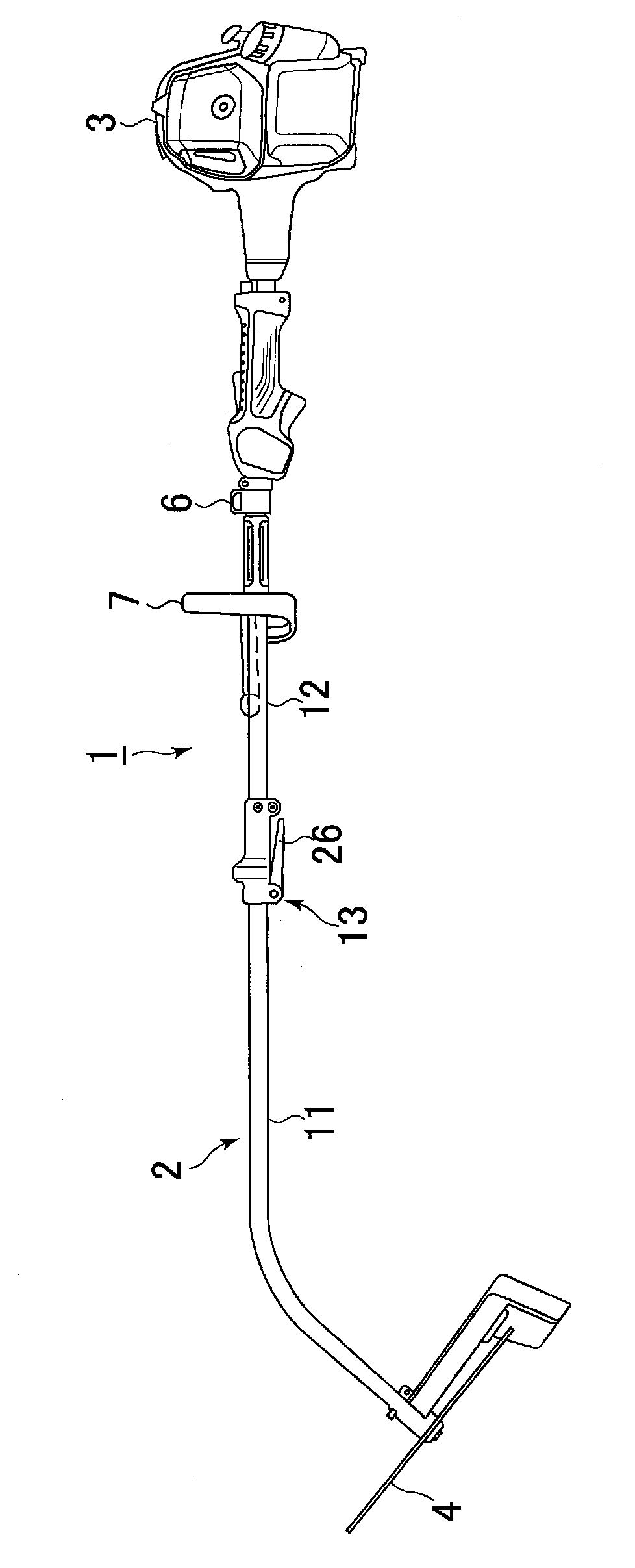

[0030] figure 1 It is a perspective view of the brush cutter 1 which concerns on embodiment of this invention.

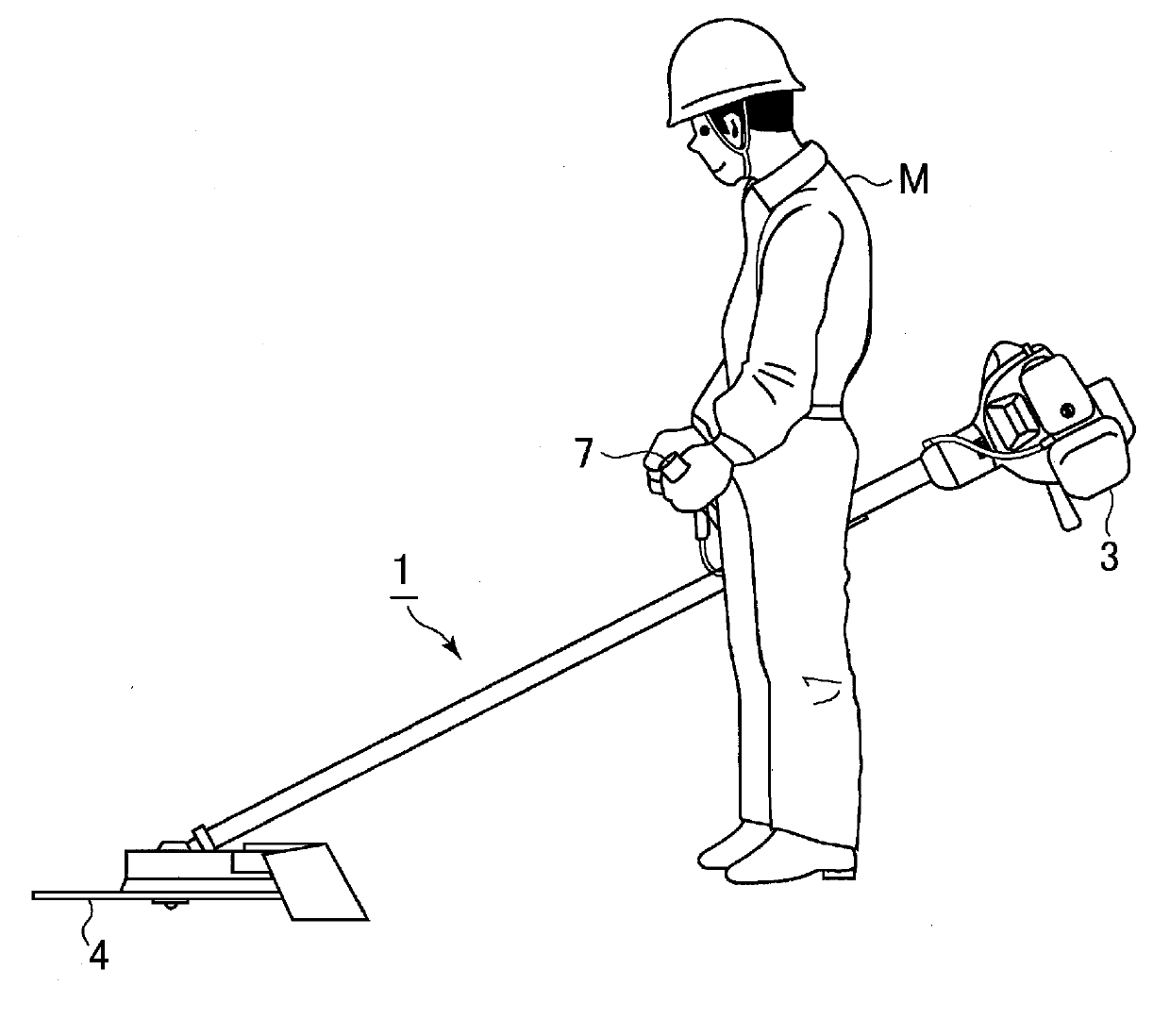

[0031] The brush cutter 1 is a type of portable work machine that is carried and used by an operator M. As shown in FIG.

[0032] The brush cutter 1 has an operating lever 2 formed from a long tube.

[0033] An engine 3 is provided at one end of the operating rod 2 . Instead of the engine 3, a drive motor operated by electric power from a storage battery may be used as a power source.

[0034] A tool 4 is mounted on the other end of the operating rod 2 . The work tool 4 is driven by a power source such as an engine 3 . In addition, the tool 4 is connected to the engine 3 by a transmission shaft built in the operating lever 2 , and the tool 4 is driven by the driving force of the engine 3 .

[0035] In addition, a hanger 6 , a handle 7 and the like are installed on the operating lever 2 .

[0036] figure 2 yes figure 1 An explanatory diagram of a usage state...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com