Patents

Literature

50results about How to "Easy to adjust up and down position" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

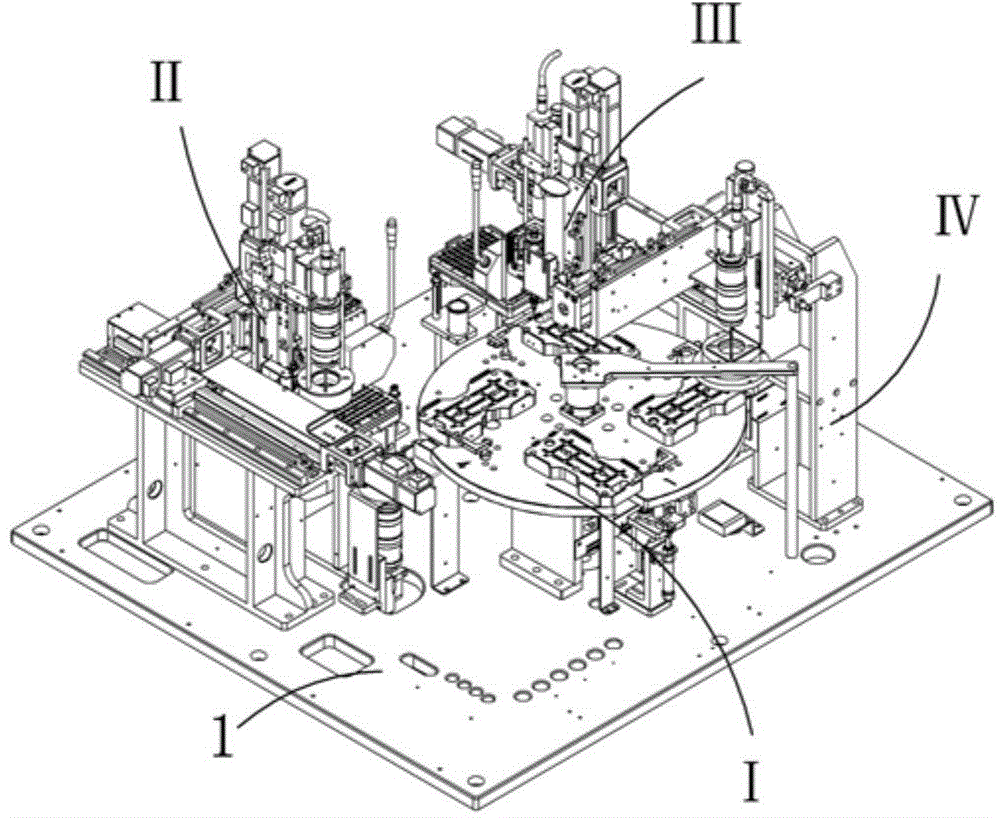

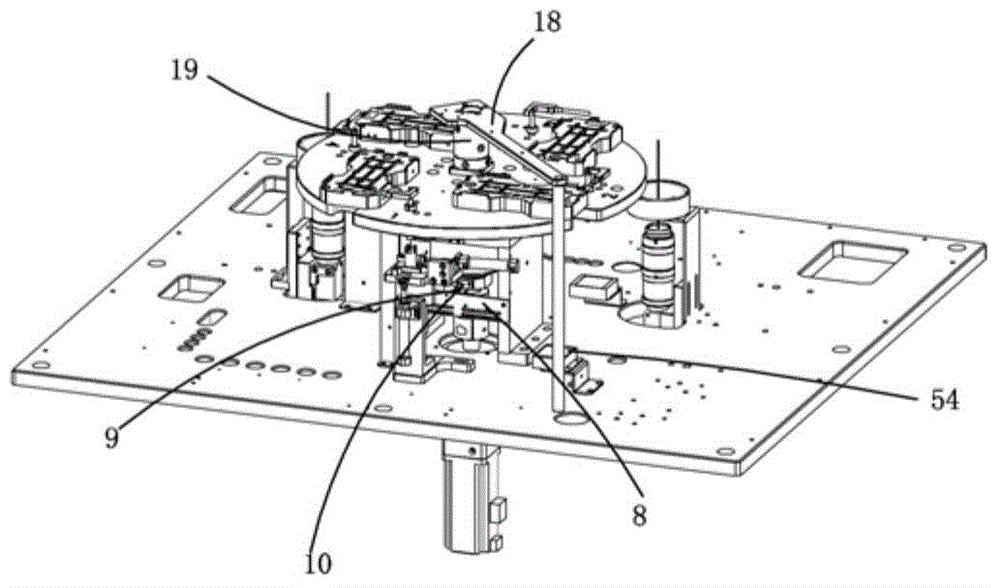

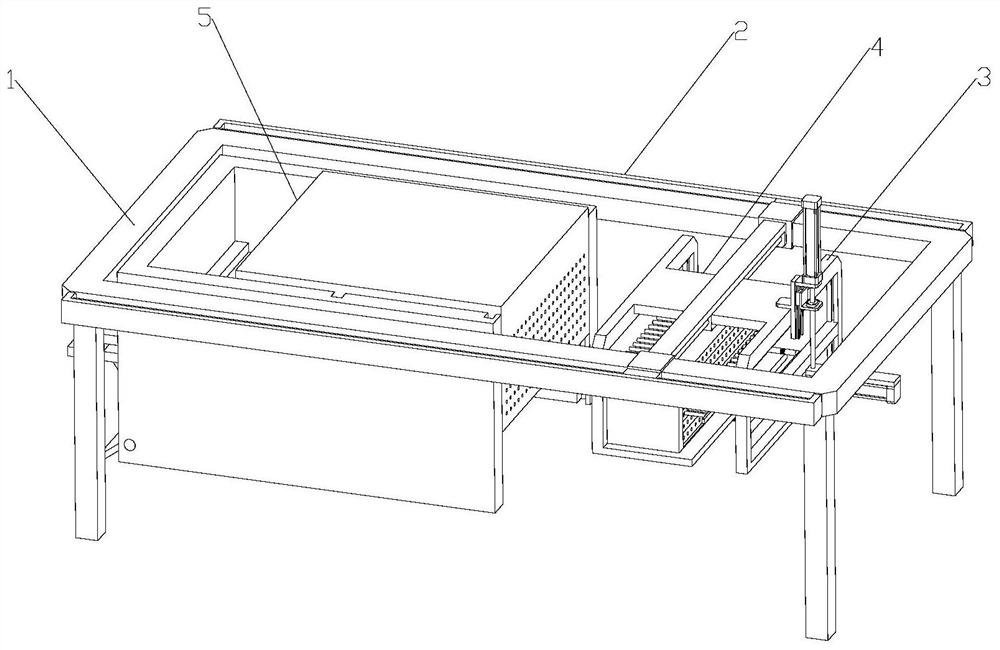

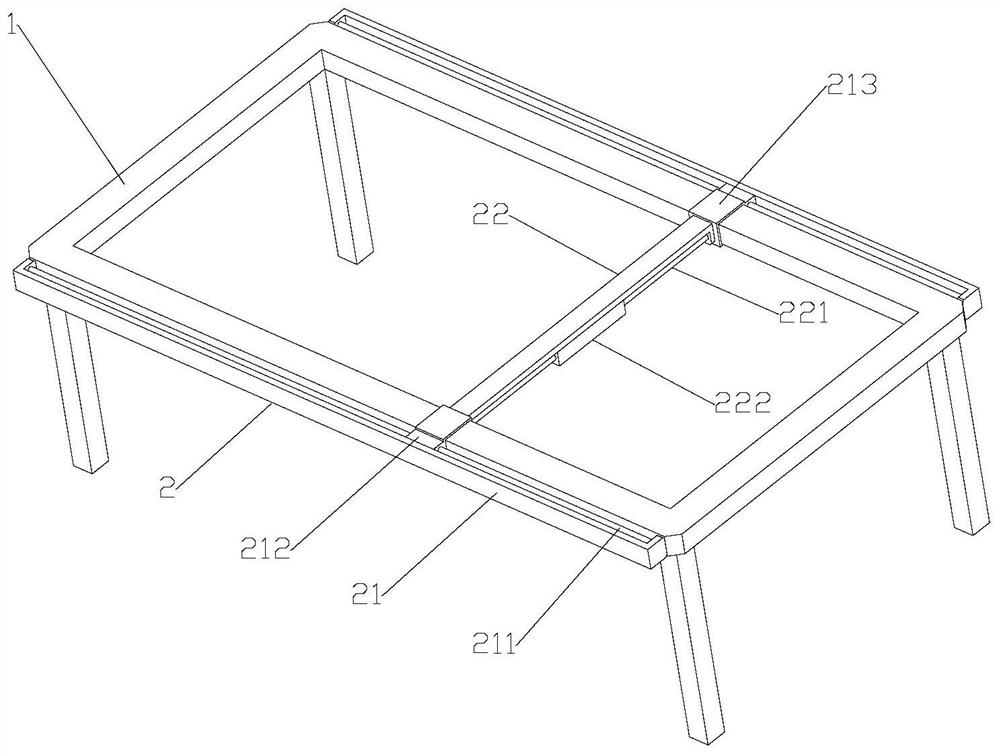

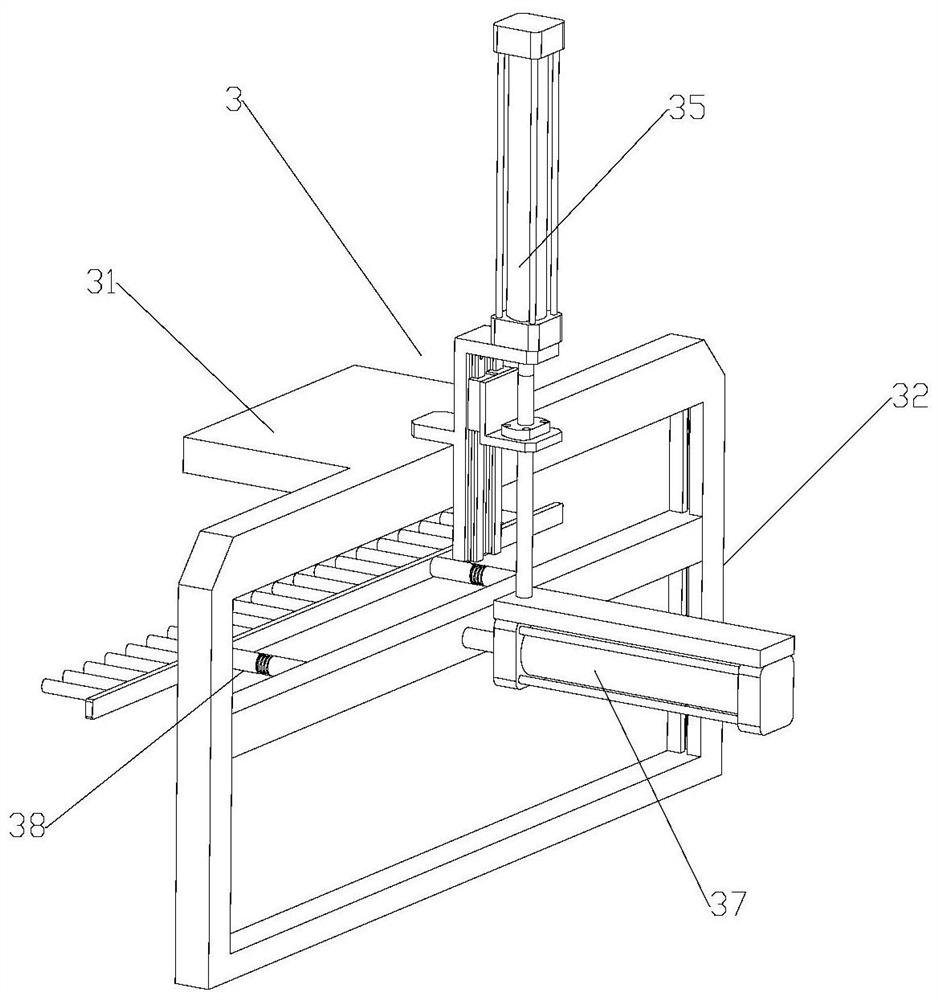

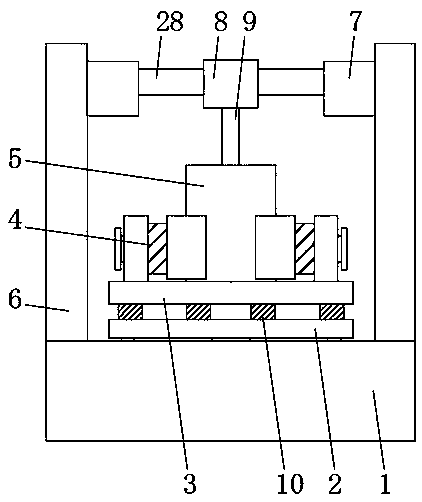

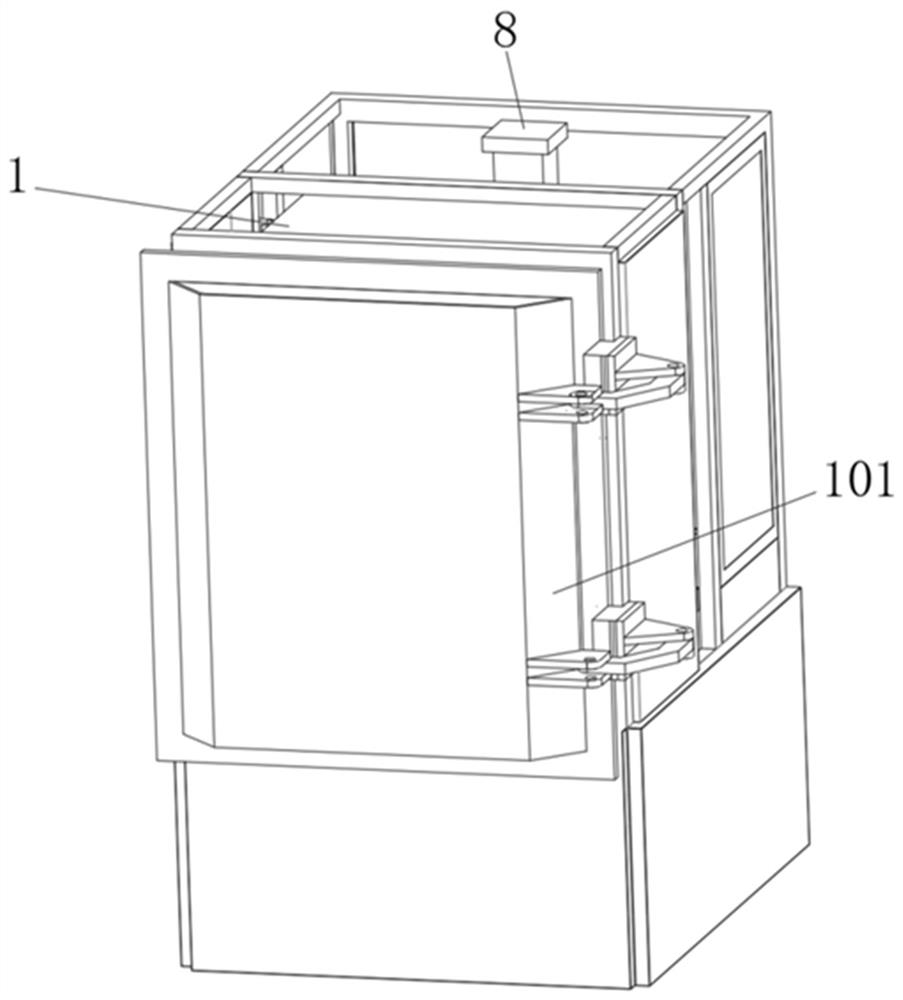

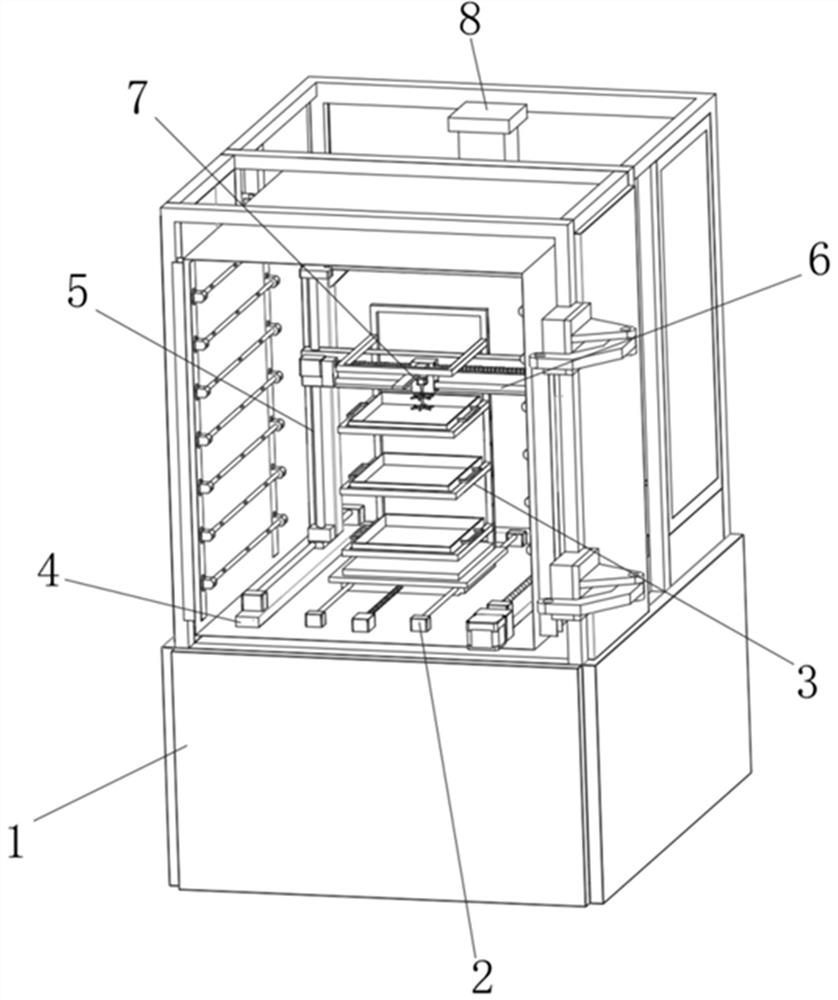

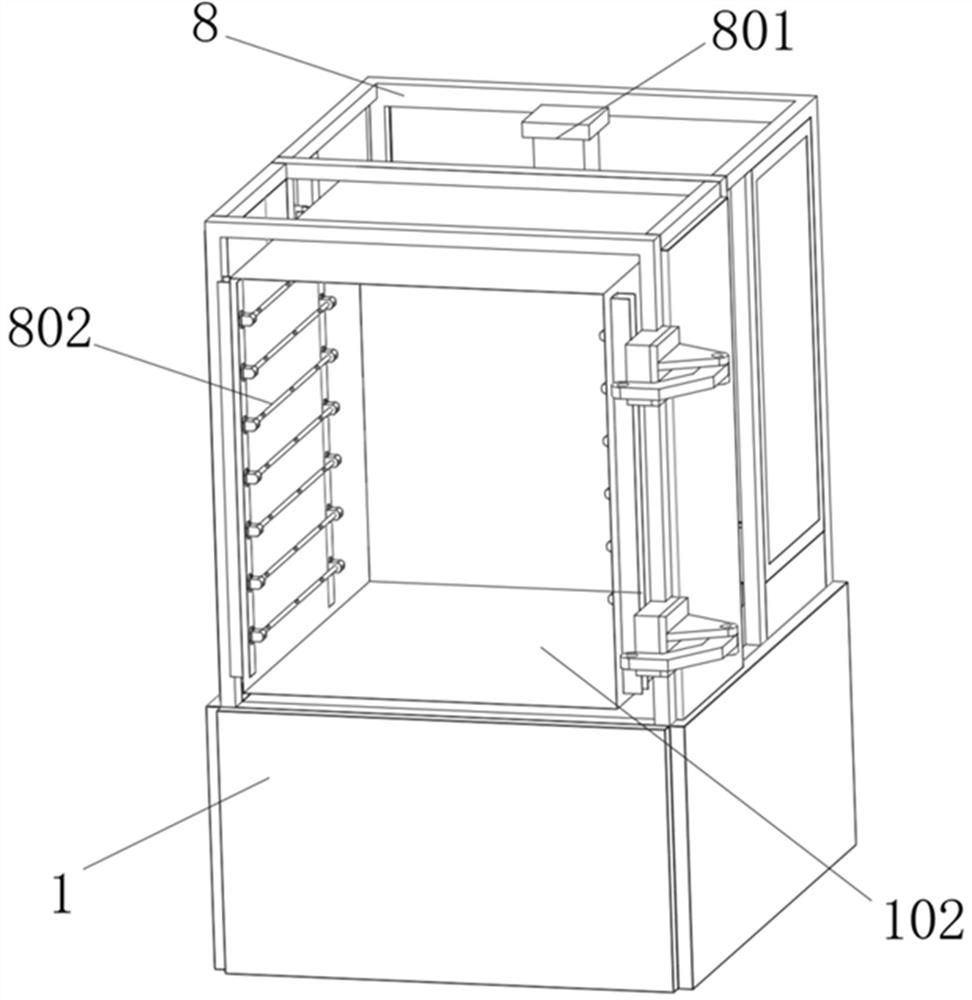

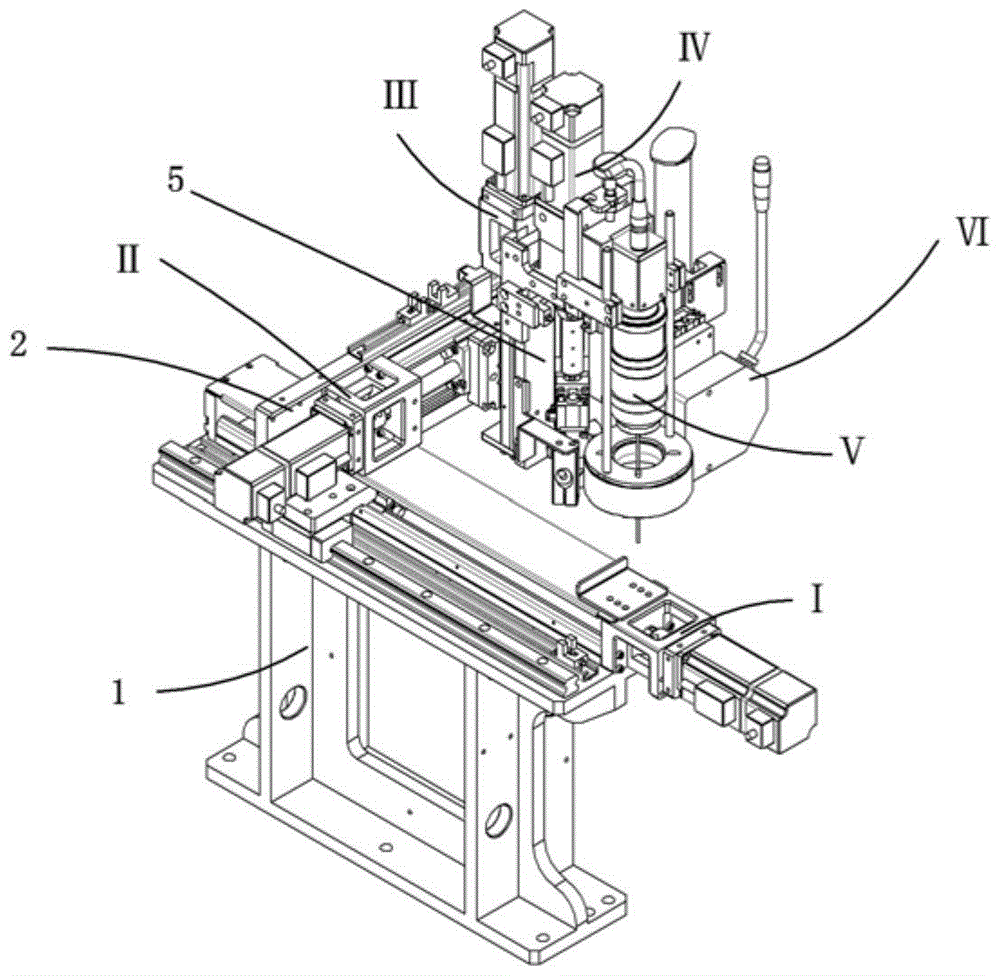

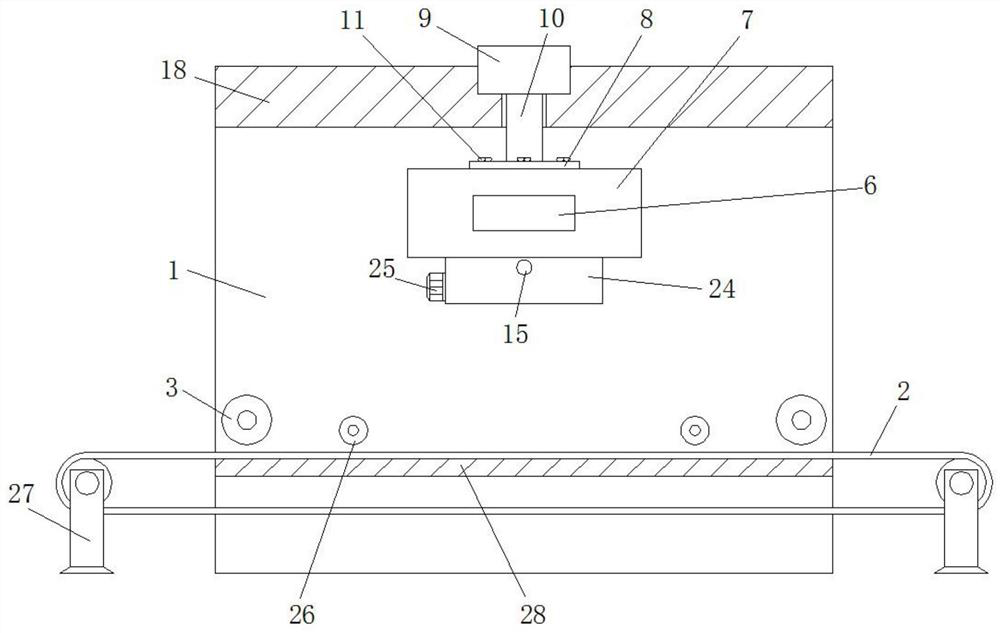

Full-automatic part assembly machine

ActiveCN104551660APrevent camera alignment and other workQuick and accurate assemblyAssembly machinesEngineeringWorkstation

The invention relates to a full-automatic part assembly machine. A rotary plate mechanism is mounted at the center of the bottom plate, a first part assembly workstation and a second part assembly workstation are identical in structure and mounted on the left rear portion and the right rear portion of the bottom plate respectively, and a detecting workstation is mounted on the front portion of the right side of the bottom plate. An operator places a workpiece on a carrier, a rotary motor rotates the carrier on a rotary plate to the first part assembly workstation, and a small part a is assembled onto the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the second part assembly workstation, and a small part b is assembled on the workpiece; after assembly, the rotary motor rotates the carrier on the rotary plate to the detecting workstation, a CCD on the detecting workstation takes pictures and detects whether the assembled workpiece is qualified or not; after detection, the rotary motor rotates the rotary plate to the initial position. The full-automatic part assembly machine is simple to operate, the small parts can be quickly and accurately assembled to the workpiece, labor is saved, production efficiency is improved, and production cost of enterprises is reduced.

Owner:BOZHON PRECISION IND TECH CO LTD

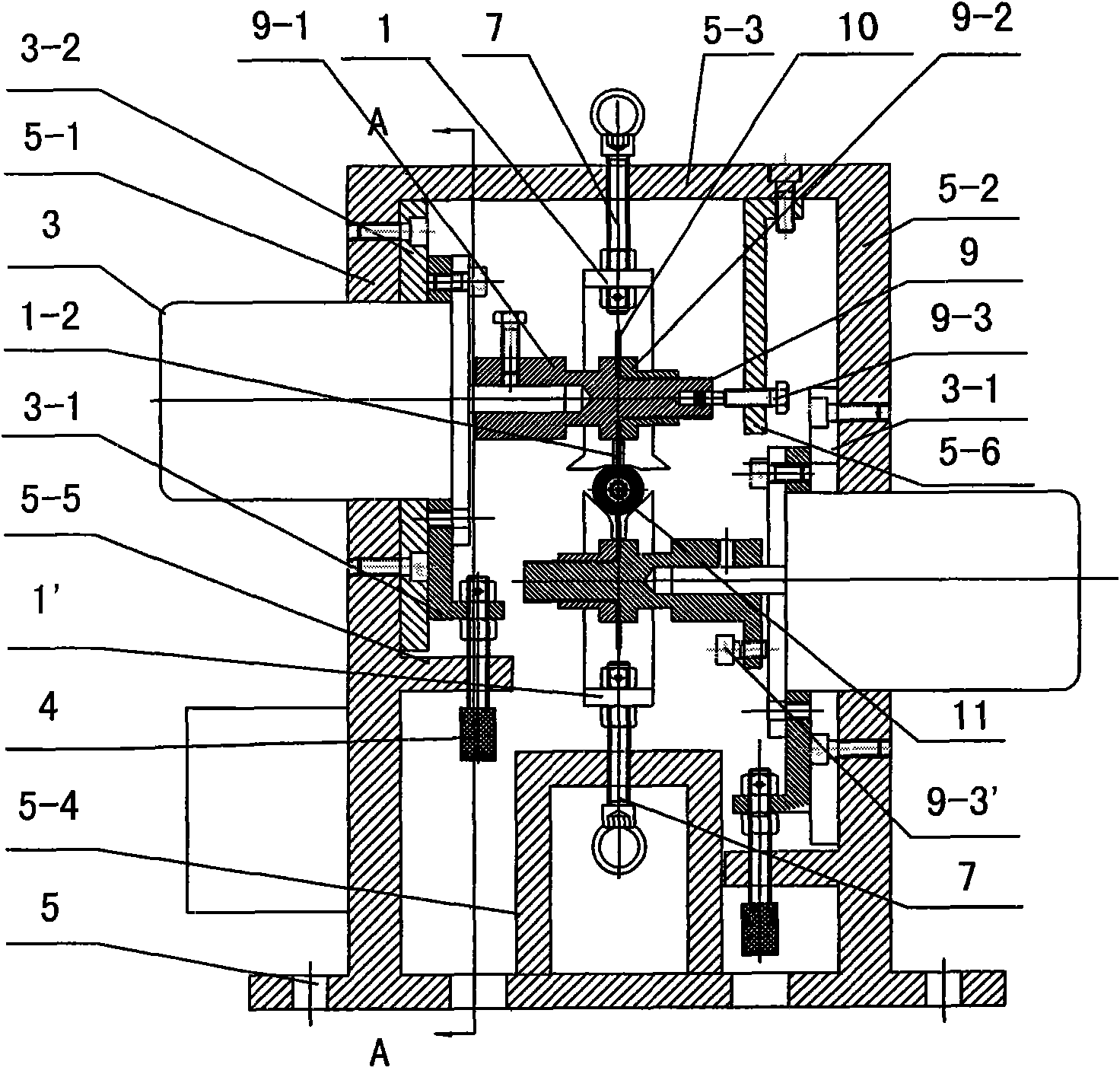

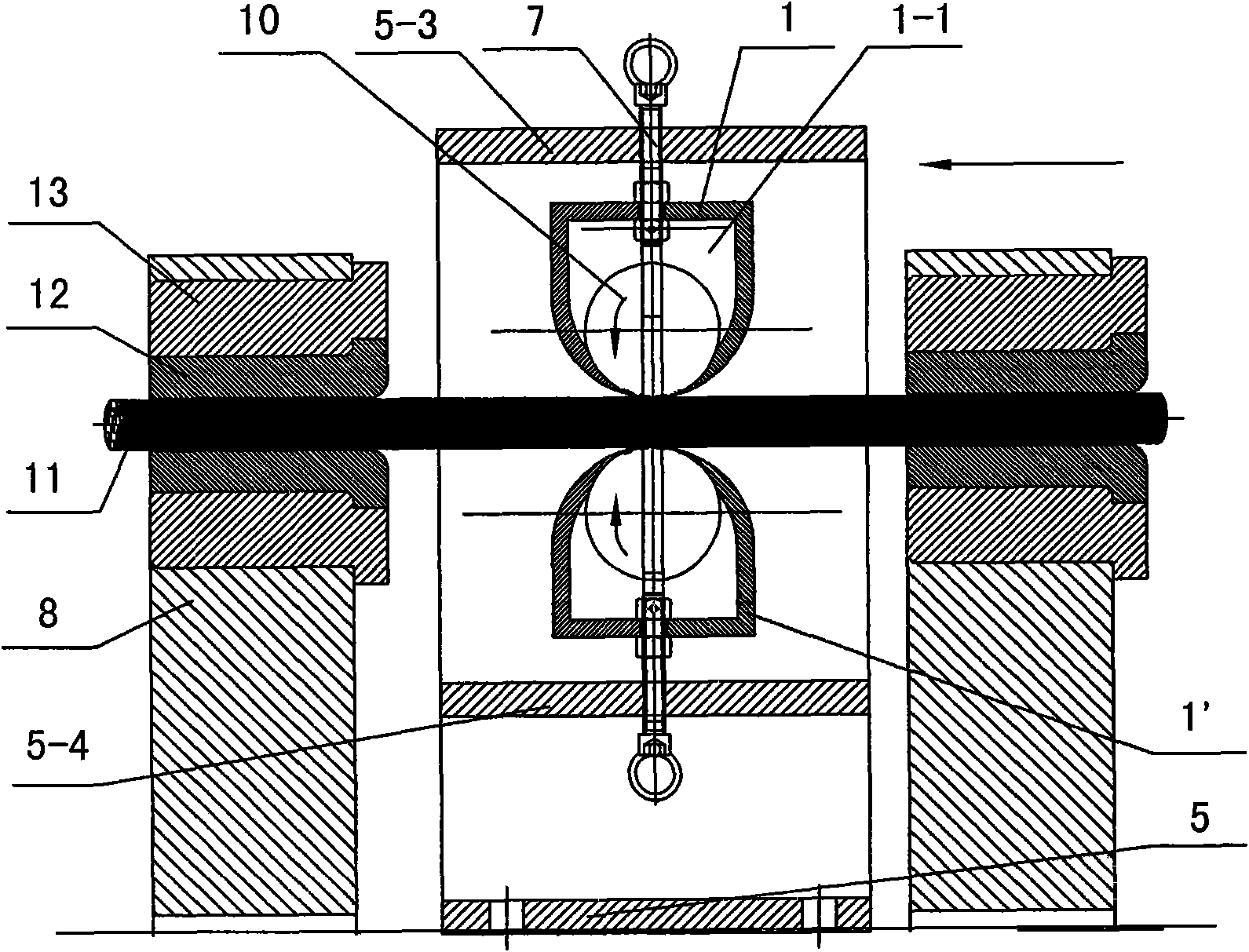

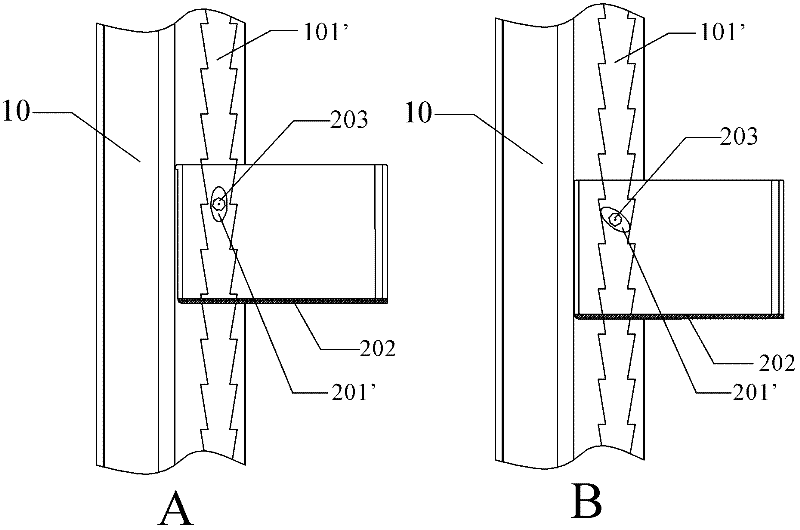

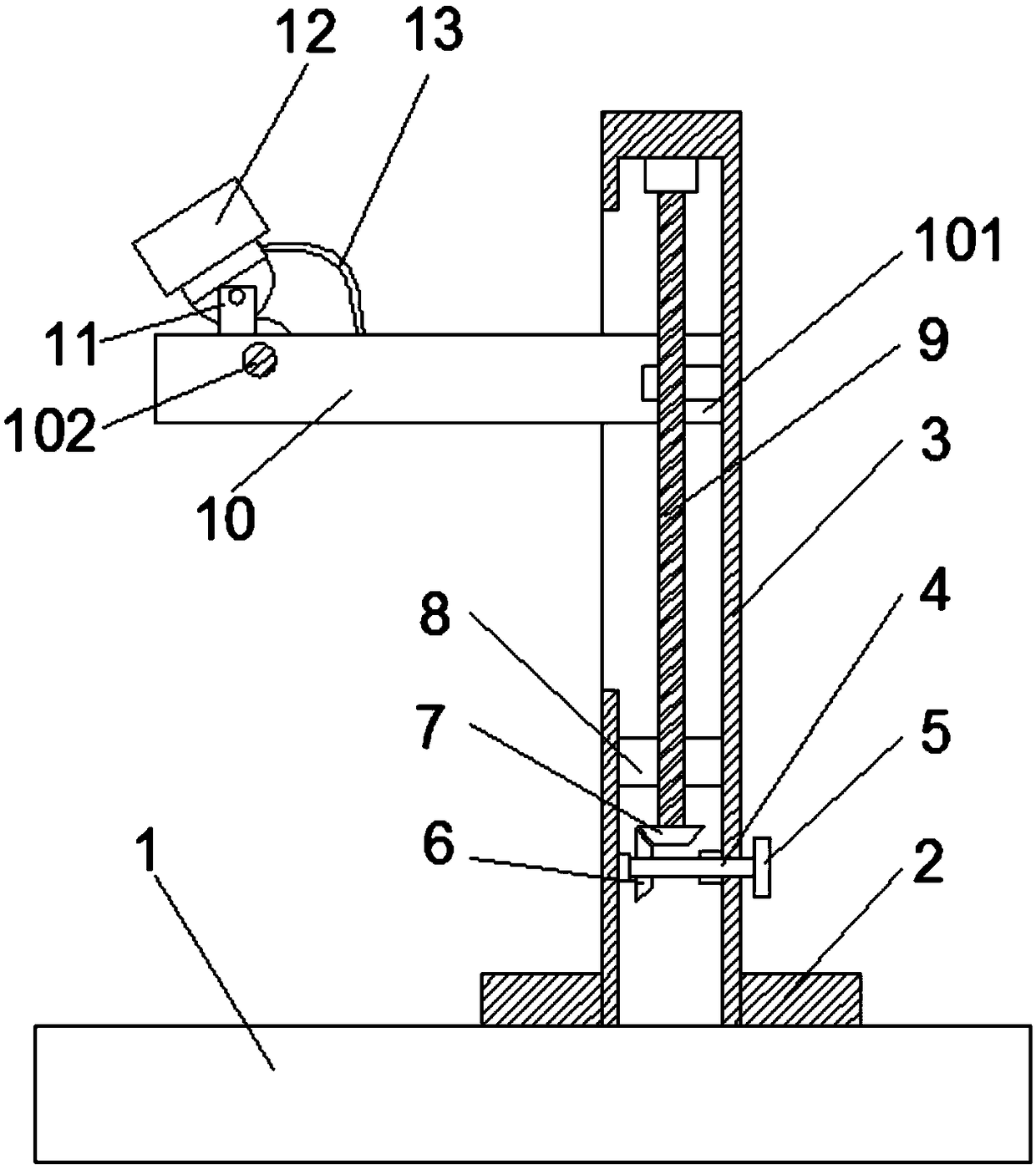

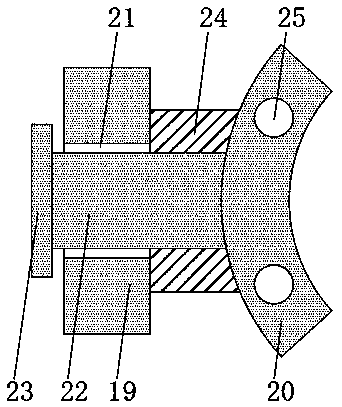

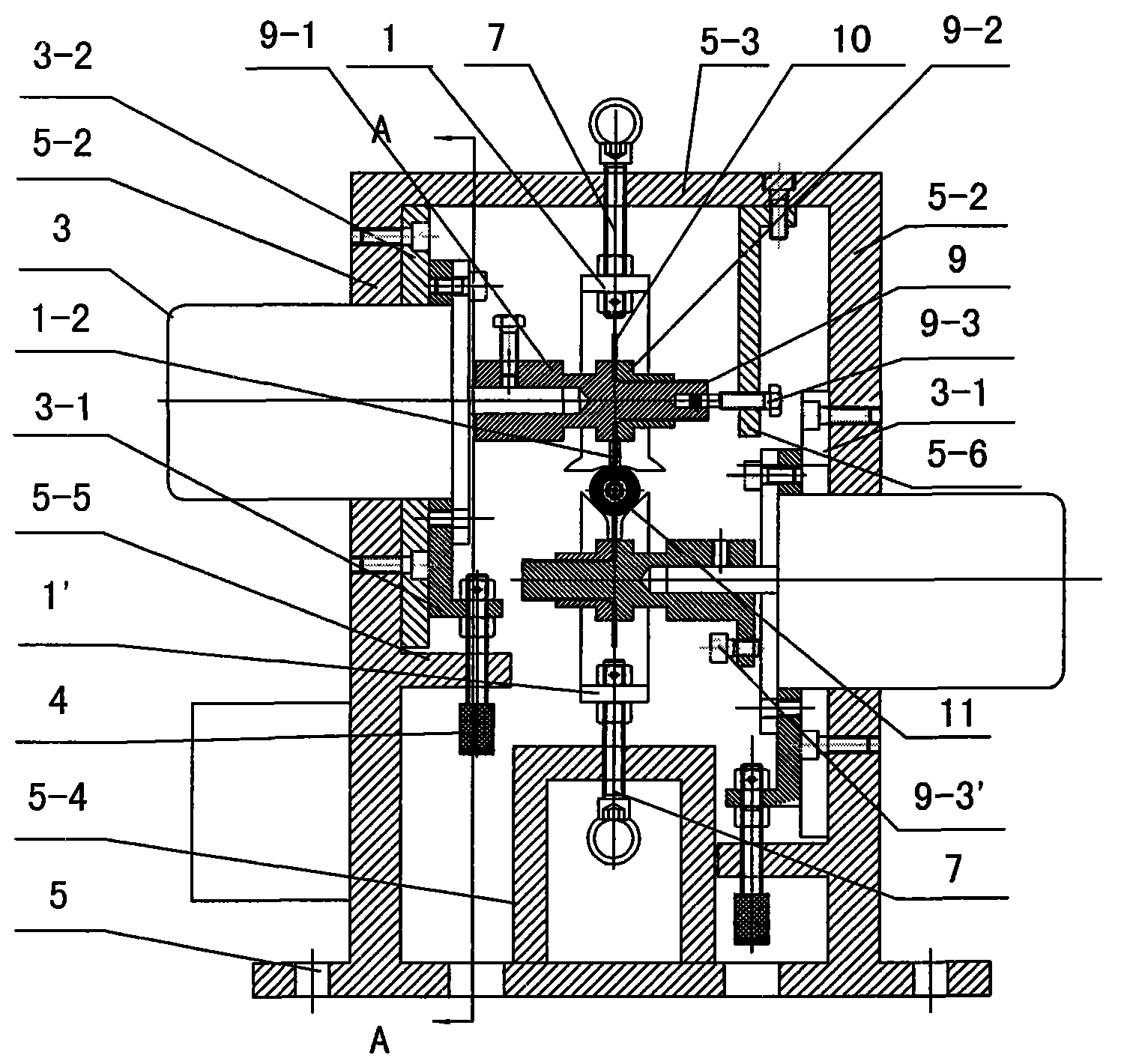

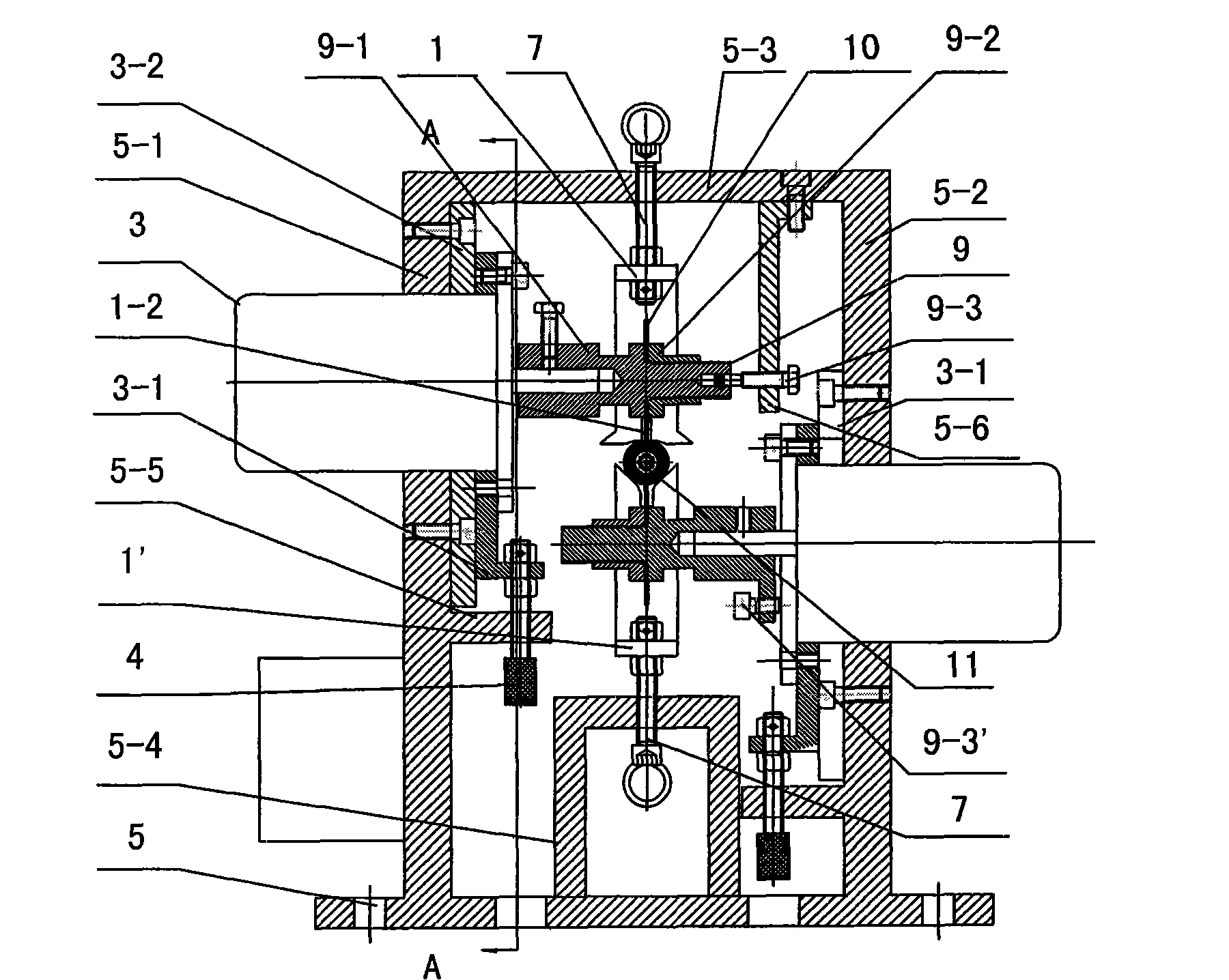

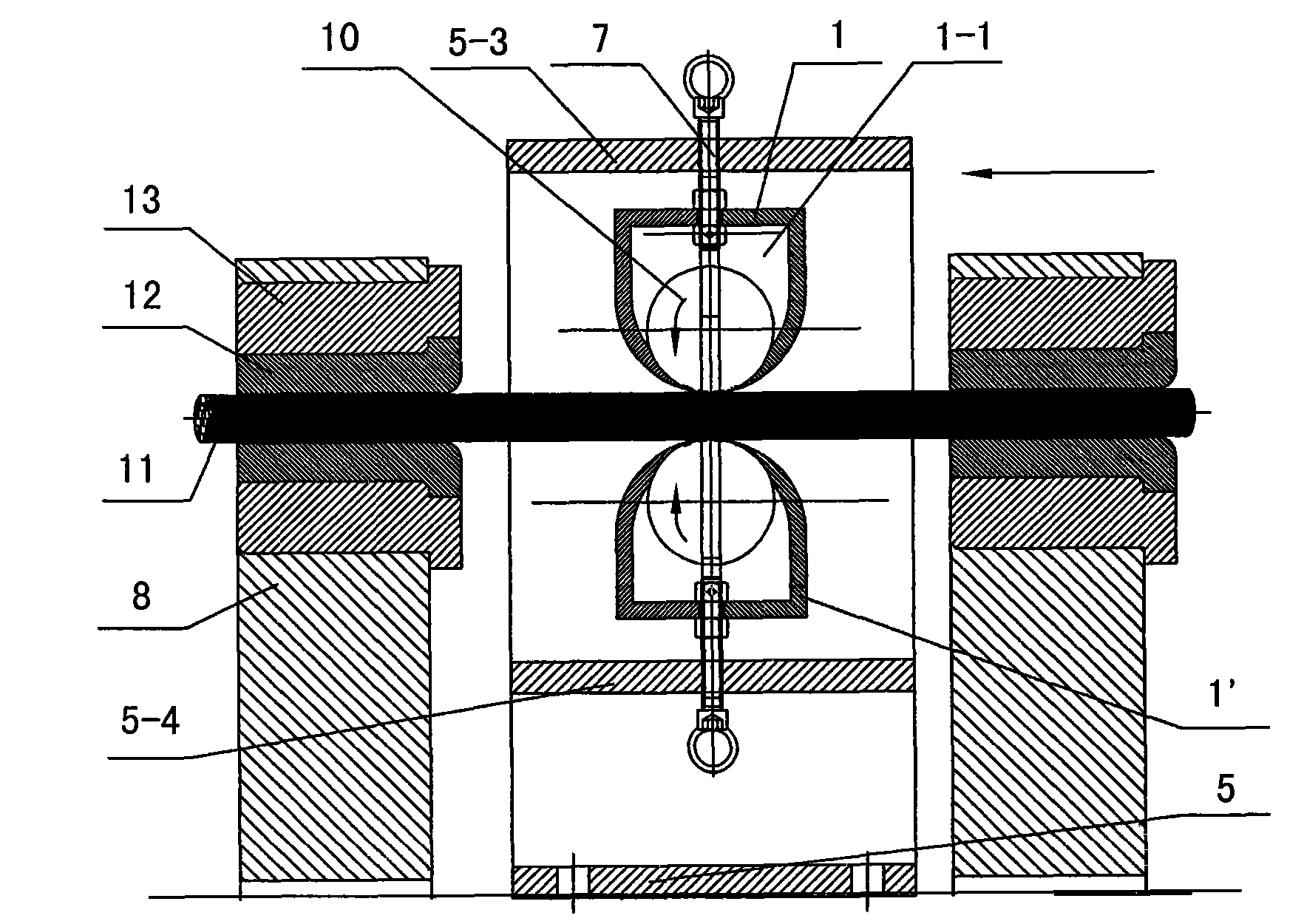

Optical cable and cable sheath peeling device

ActiveCN101587217AImprove peeling qualityImprove efficiencyFibre mechanical structuresApparatus for removing/armouring cablesMilling cutterEngineering

The invention relates to an optical cable and a cable sheath peeling device, belonging to the cable tool technology field. The support frame of the device comprises a door-shaped outer frame and an inner frame. An upper cable clamper and a lower cable clamper are respectively installed in a perpendicular screwed hole in the center of the transverse brace and the inner frame. The middle part of the clamper of the upper cable and the lower cable is provided with a relieving hole and a centering relieving hole along the axial direction of the milling cutter and the opposite ends forming a cross section are respectively provided with a clamping groove and a V-shaped groove with the arc shape. A perpendicular guide rail forming a moving pair with a motor installation seat is respectively at the upper part and the lower part in the inner side of the left vertical support and the right vertical support. A helical pair regulating the lifting of the motor installation seat is arranged at the lower end of the motor installation seat. A lockable milling fixture is sleeved in the main axle of the horizontal motor on the motor installation seat. One end of the milling fixture forms a left-and-right position screw thread fine tuning mechanism by a horizontal regulating screw. The device can effectively peel the optical cable or the cable sheath with easy operation.

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD +1

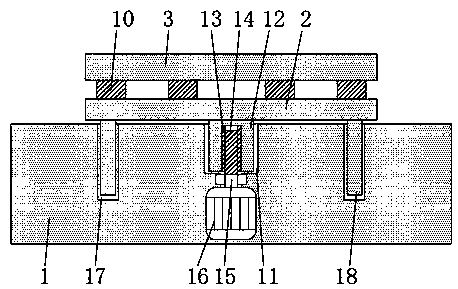

Mounting mechanism for bottle seat of refrigerator

ActiveCN102313433AEasy to adjust up and down positionMeet sealing requirementsLighting and heating apparatusSupportEngineeringBottle

The invention discloses a mounting mechanism for a bottle seat of a refrigerator, which comprises a groove sliding rail for supporting and a boss, wherein the groove sliding rail is arranged on the side wall of a lining of a door body of the refrigerator; the boss is arranged on the side surface of the bottle seat; the boss is embedded in the groove sliding rail; and the boss can move vertically along the groove sliding rail. Therefore, the convenient regulation of the upper position and the lower position of the bottle seat can be achieved, and the sealing requirements between bottle seats also can be met.

Owner:HAIER GRP CORP +1

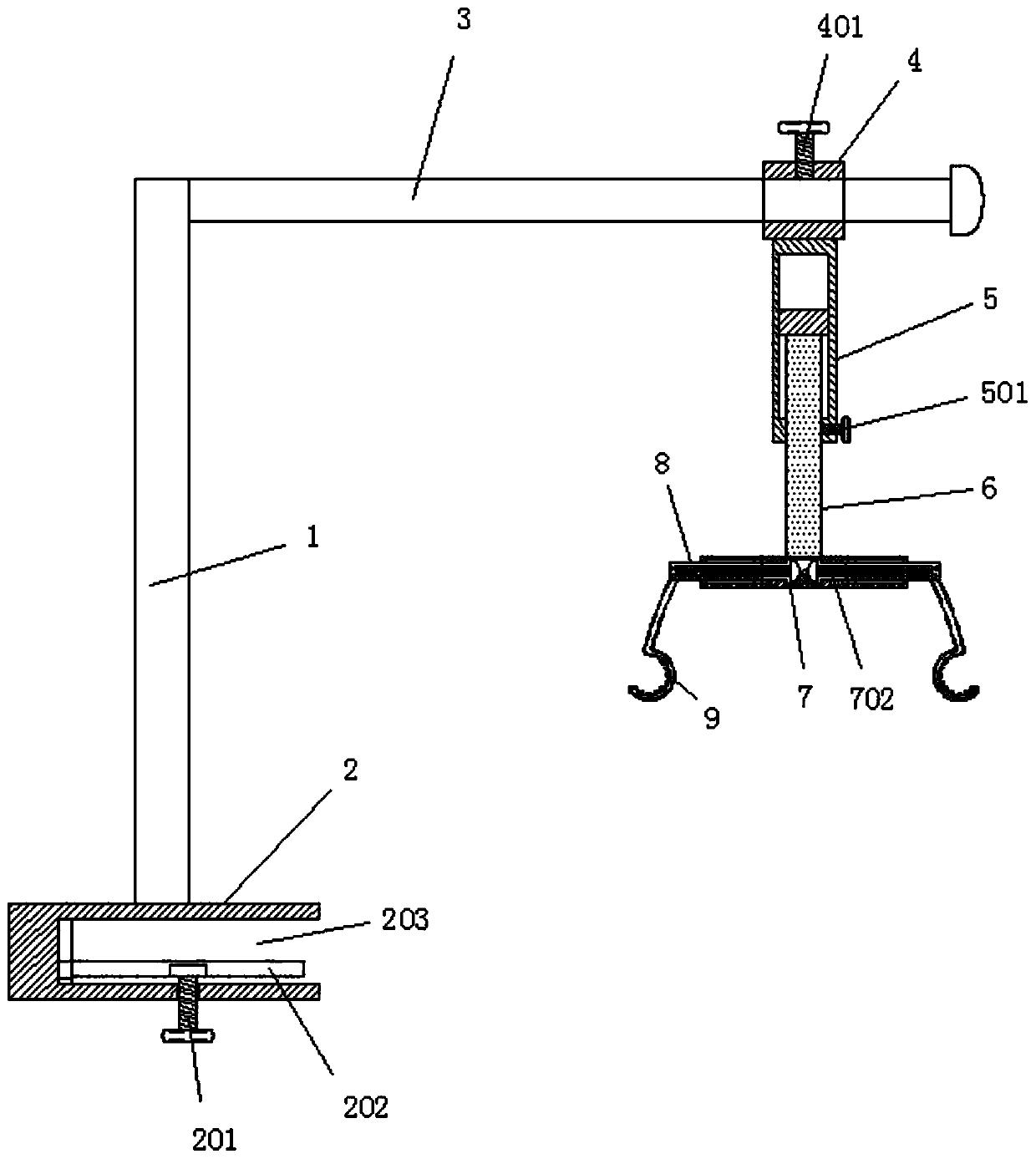

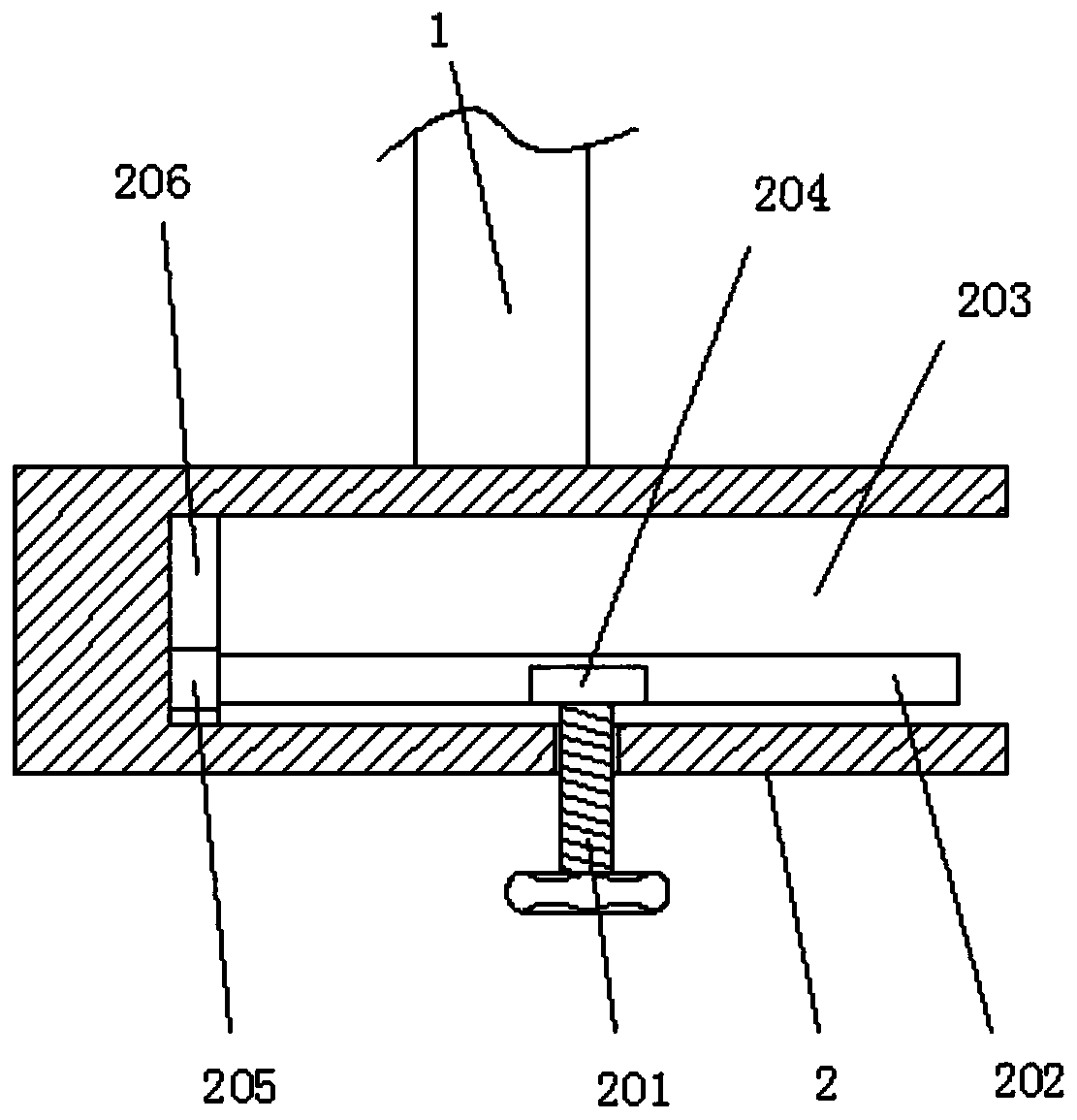

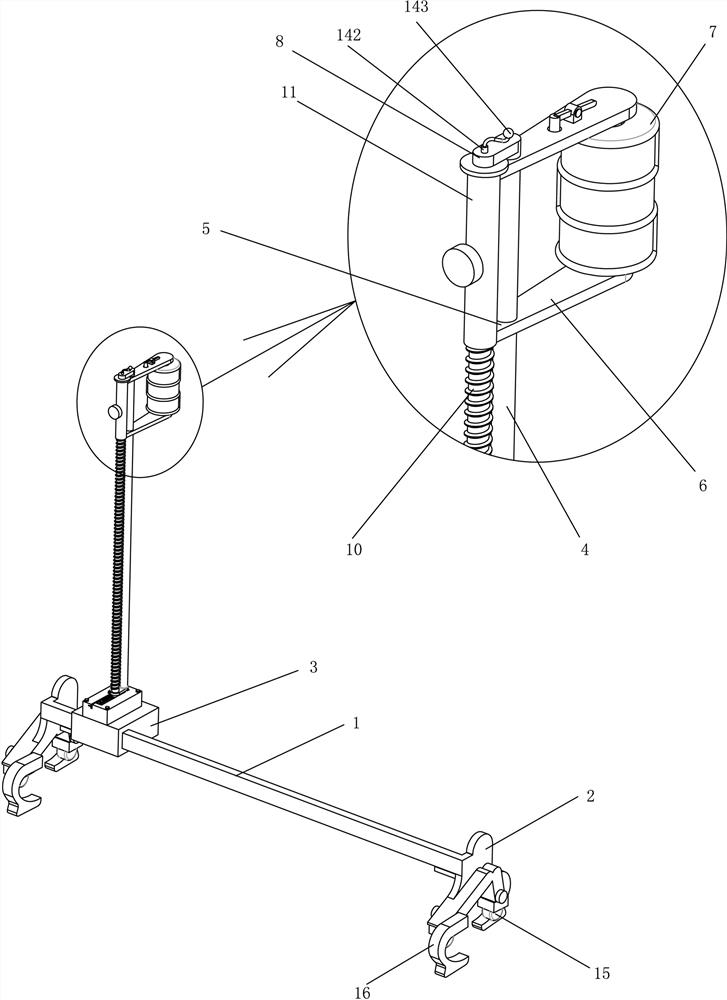

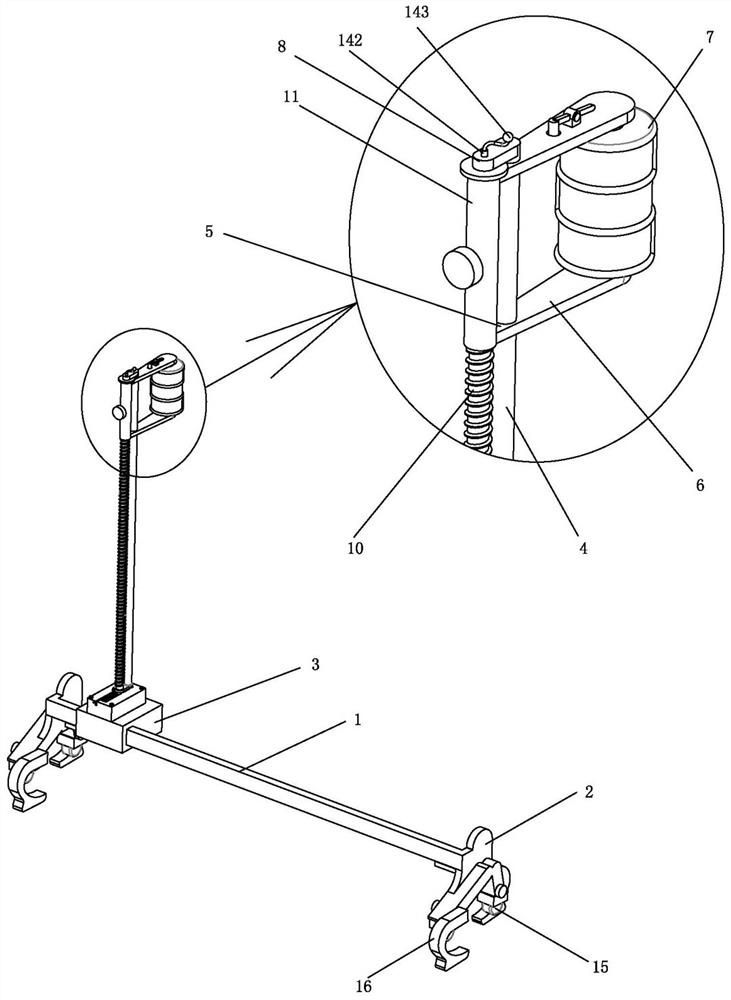

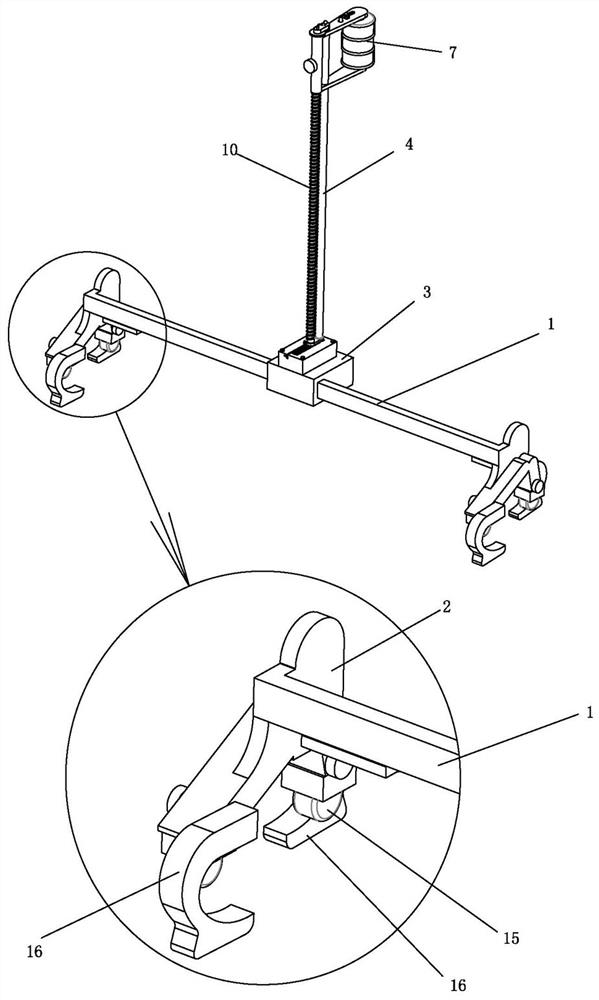

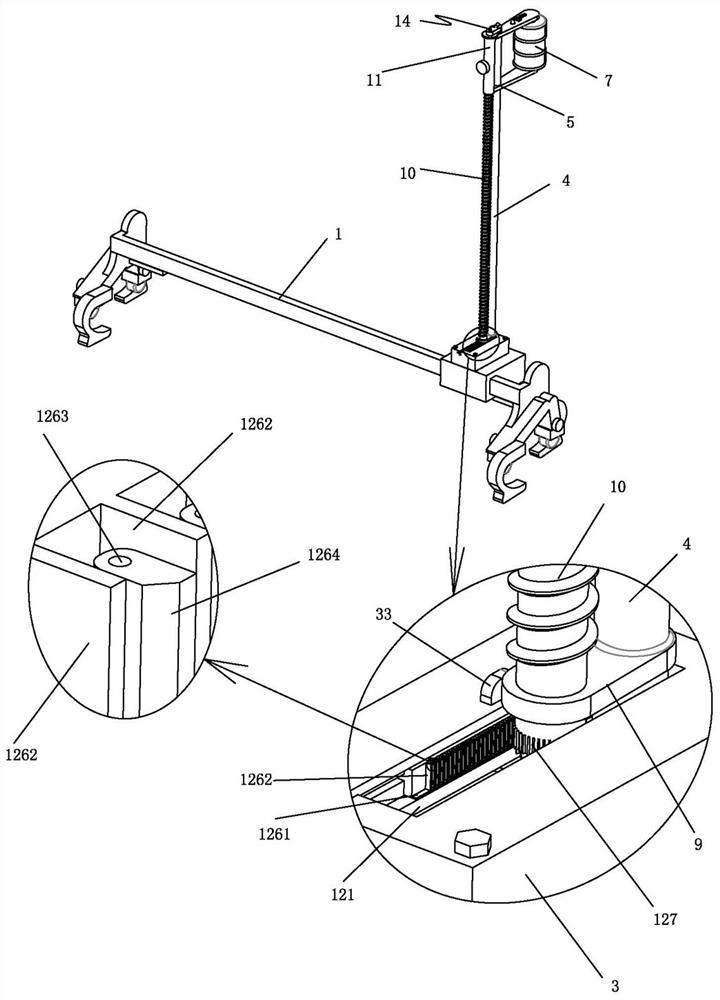

Sliding located draw hook for surgical operations of livers and gallbladders

InactiveCN110893110AEasy to adjustEasy to adjust up and down positionOperating tablesMedical practitionerStructural engineering

Owner:李捷

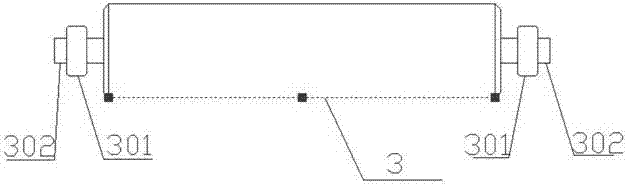

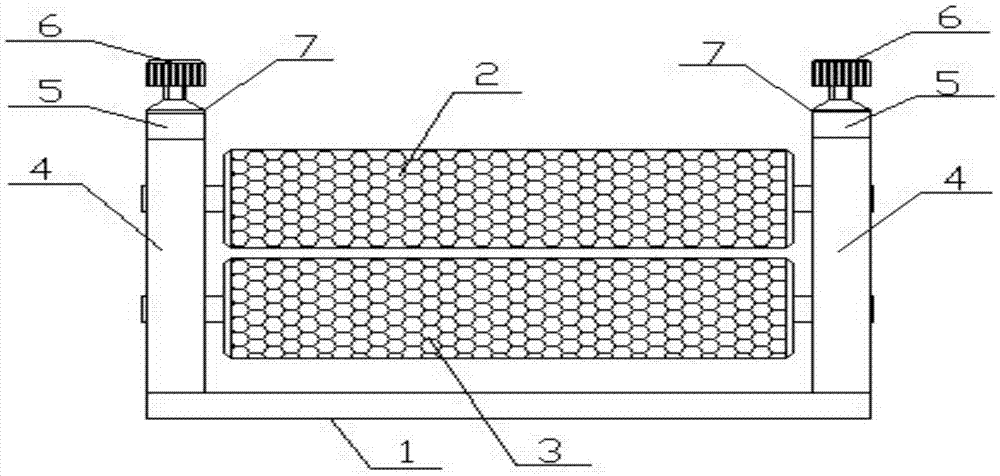

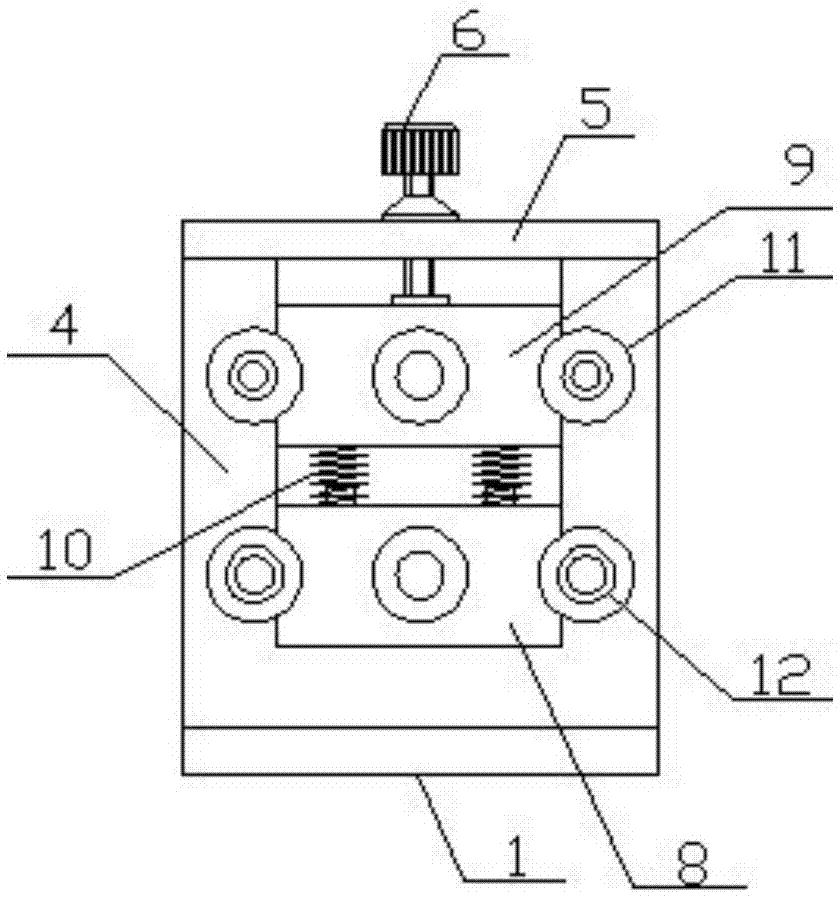

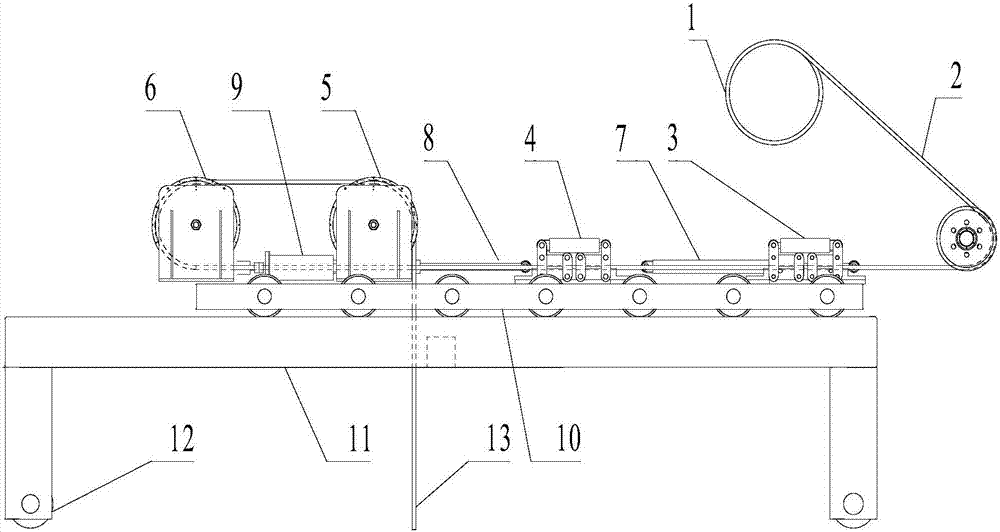

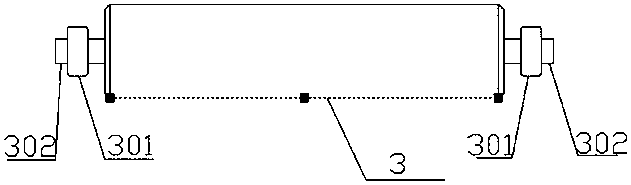

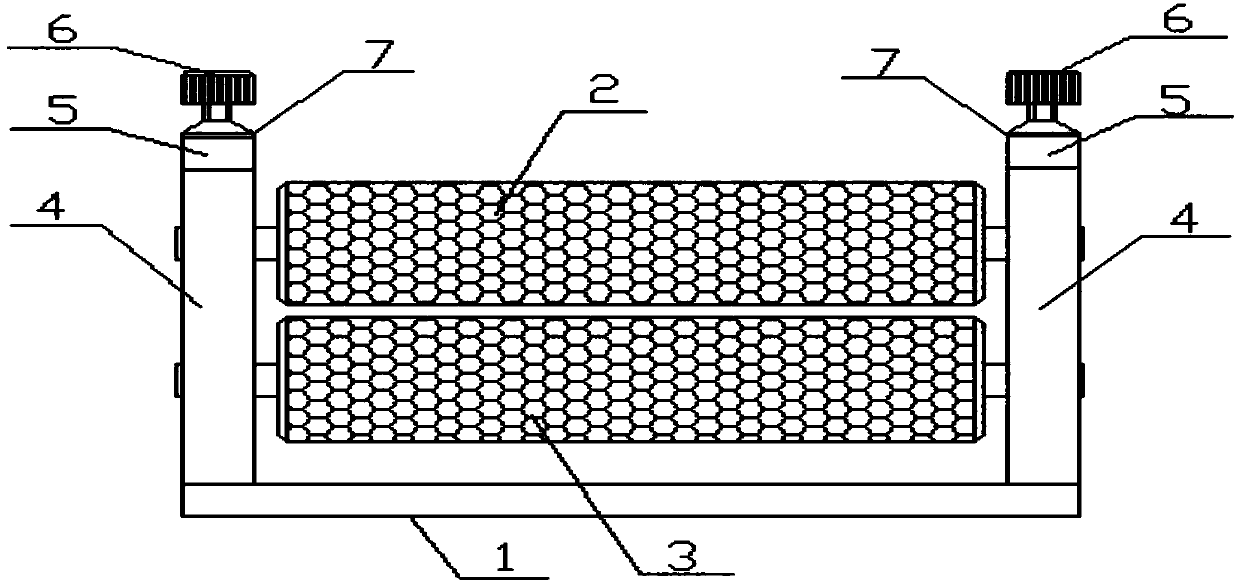

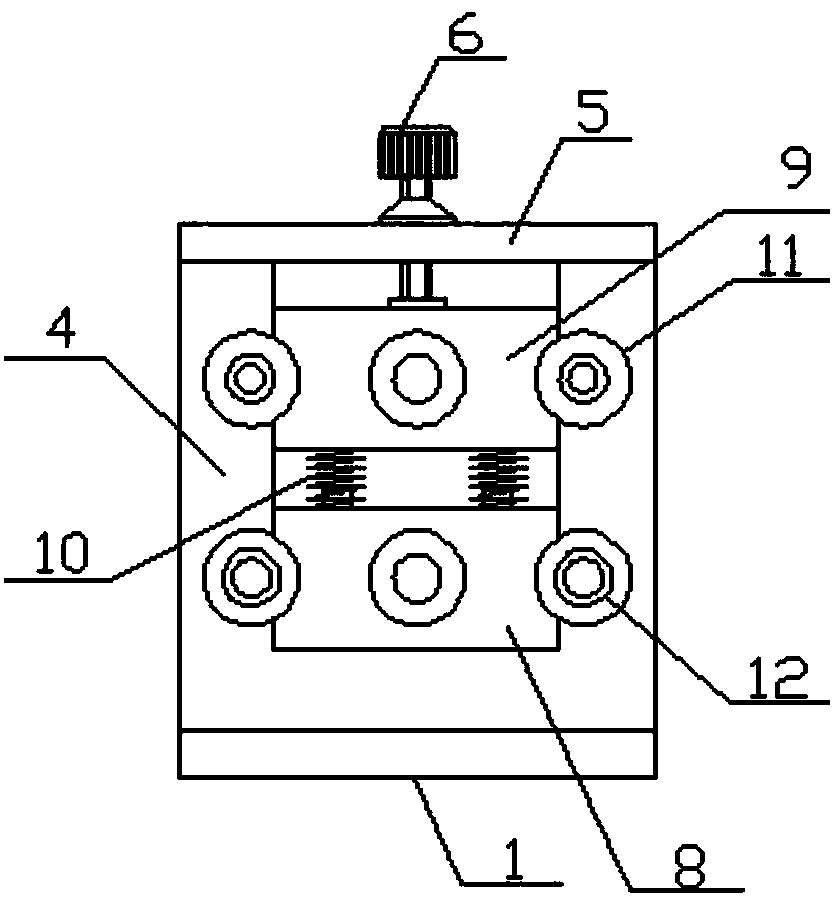

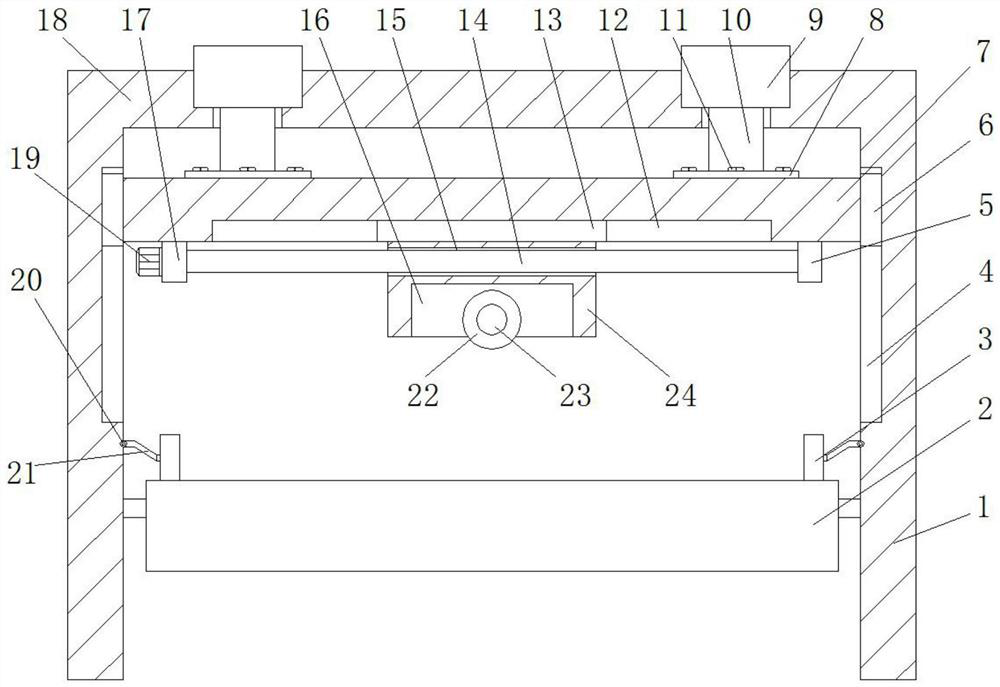

Conveying roller gap adjusting device

The invention discloses a transmission roller gap adjustment device, which comprises a bottom bracket, an upper pressure wheel, a lower roller, a U-shaped frame, a pressure plate, an adjusting screw, a fixed bearing seat, a movable bearing seat, and a spring. U-shaped frames are arranged on both sides of the bottom bracket, There is a U-shaped groove in the U-shaped frame, a pressure plate on the top, a fixed bearing seat on the bottom of the U-shaped groove, two positioning terminals on the upper end of the fixed bearing seat, a spring on the positioning terminal, a movable bearing seat on the spring, and a screw on the pressure plate. Hole 1 and screw hole 1 are provided with an adjusting screw rod, and the fixed bearing seat is provided with bearing hole 2, which is connected with the rolling bearing 2 on the shaft end 2 at both ends of the lower roller. The ball bearings on the shaft ends at both ends of the upper pressure wheel are connected, and four flat pads are arranged on the outside of the U-shaped groove, and the flat pads are connected to the U-shaped groove with fastening screws. The gap between the lower roller and the adjustment distance is controlled by a scale, which is suitable for conveying fabrics of different thicknesses.

Owner:NINGBO ZHENHAI XIANGAO ELECTROMECHANICAL

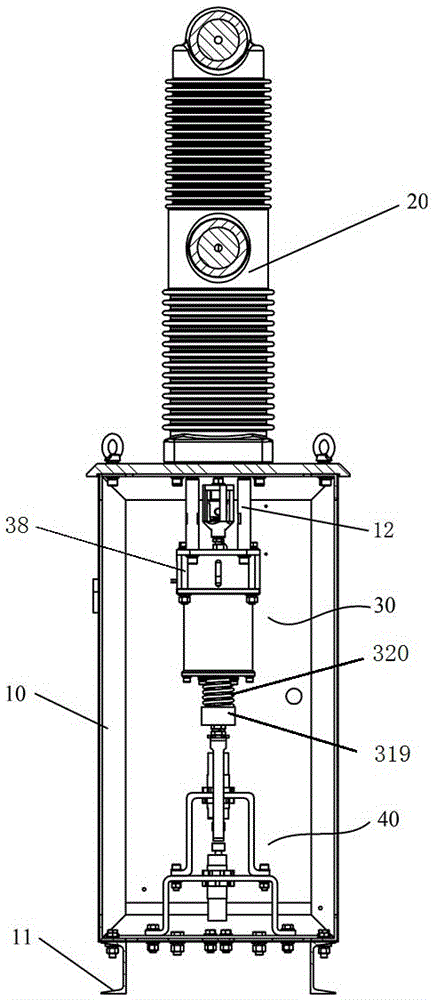

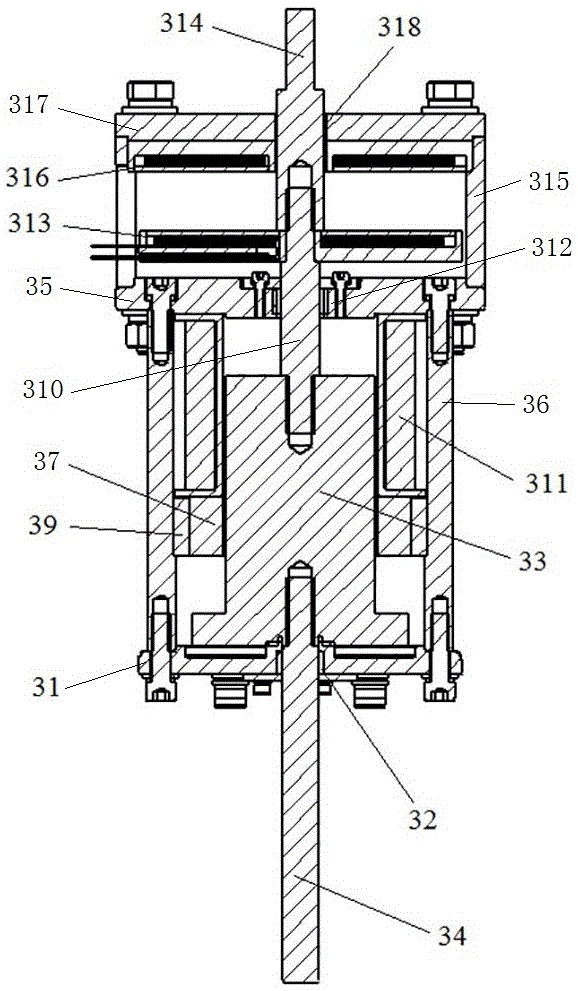

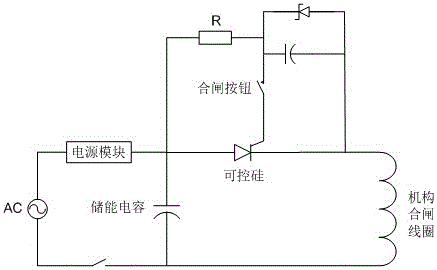

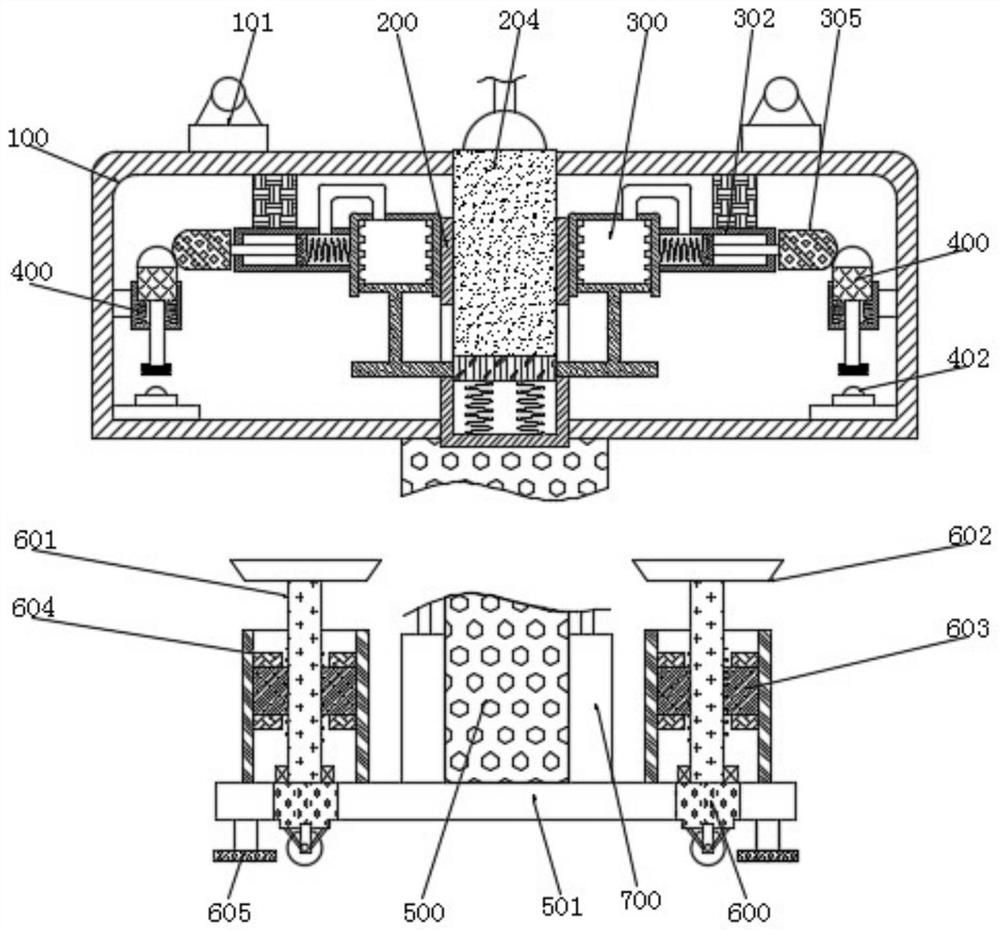

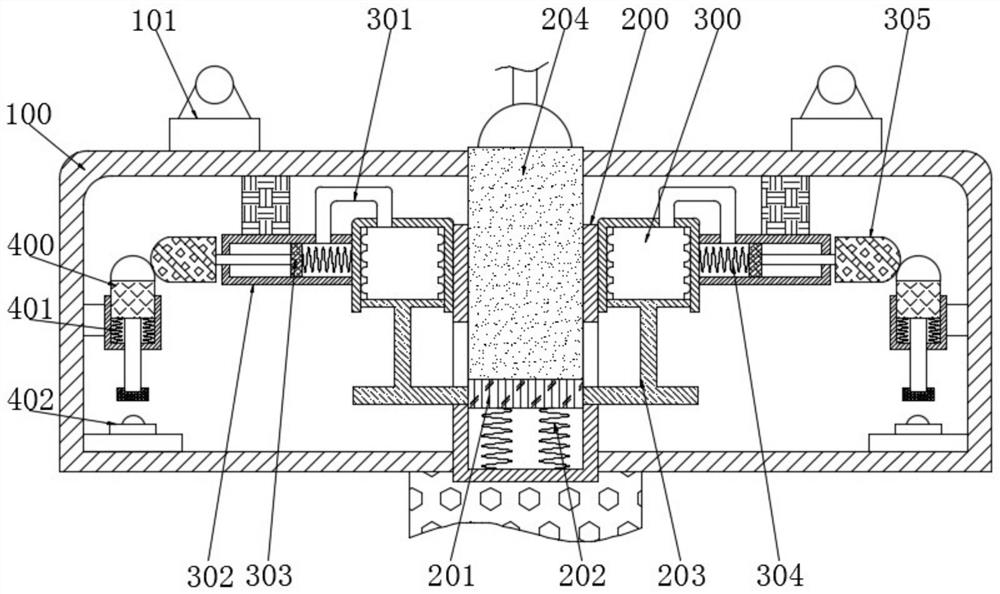

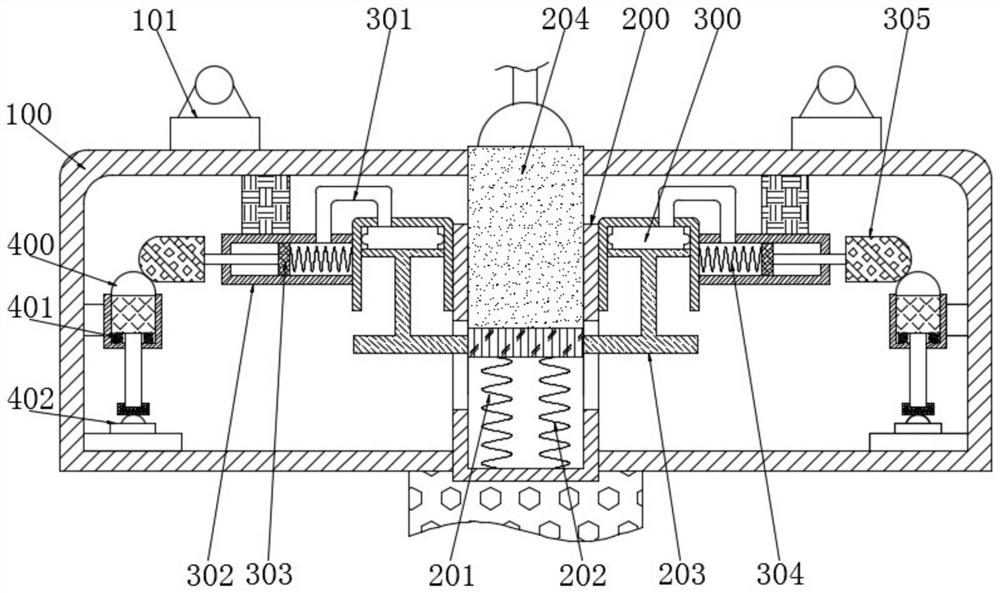

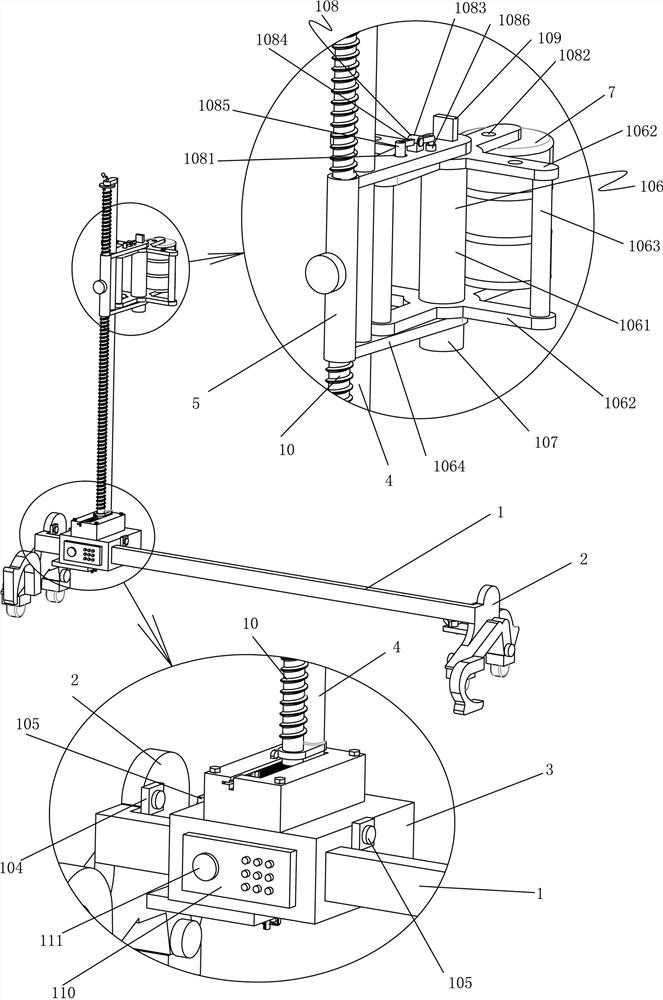

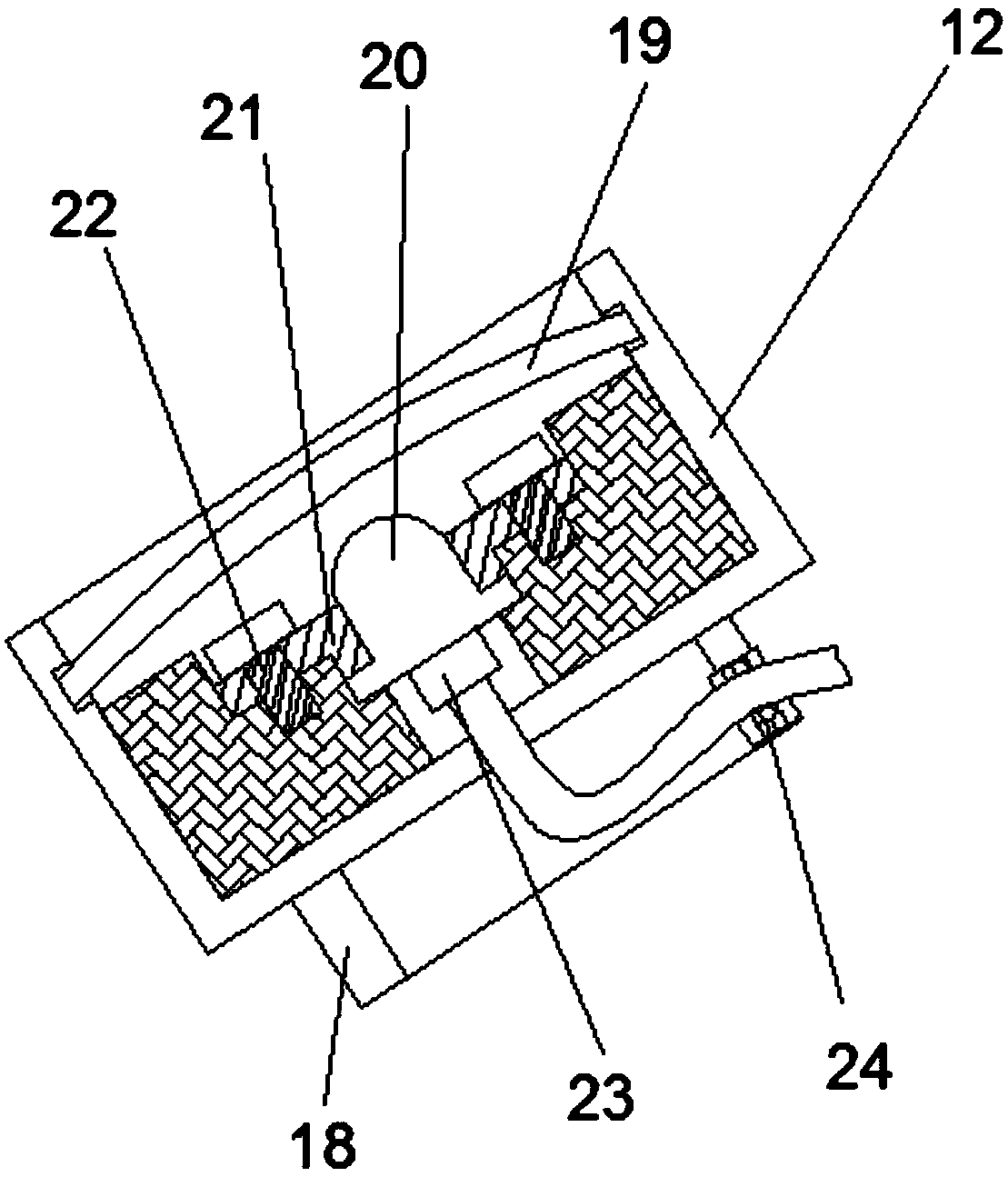

Breaking-closing buffer device and quick mechanical switch of using same

ActiveCN106783263ASimple structureEasy to process and assembleContact vibration/shock dampingElectrical and Electronics engineeringEngineering

The invention relates to a breaking-closing buffer device and a quick mechanical switch of using the same. The breaking-closing buffer device comprises a device rack, a buffer part and a buffer limiting seat, wherein the buffer limiting seat is used for being fixedly connected with a connecting rod of the quick mechanical switch; the buffer limiting seat comprises a push part matched with an impact end of the buffer part and a transmission connection part; the transmission connection part is used for being fixedly connected with the connecting rod of the mechanical switch; the transmission connection part is arranged at the outer side of the device rack and the transmission connection part and the push part are arranged at an interval along a buffer deformation direction of the buffer part; a transmission arm is connected between the transmission connection part and the push part; and the transmission arm is located at the outer side of the buffer part. The buffer device is simple in structure and convenient to process and assemble separately, a complicated guide cooperation relationship is not needed, abrasion and a guide accuracy problem are avoided and reduction of the maintenance frequency is facilitated.

Owner:PINGGAO GRP +1

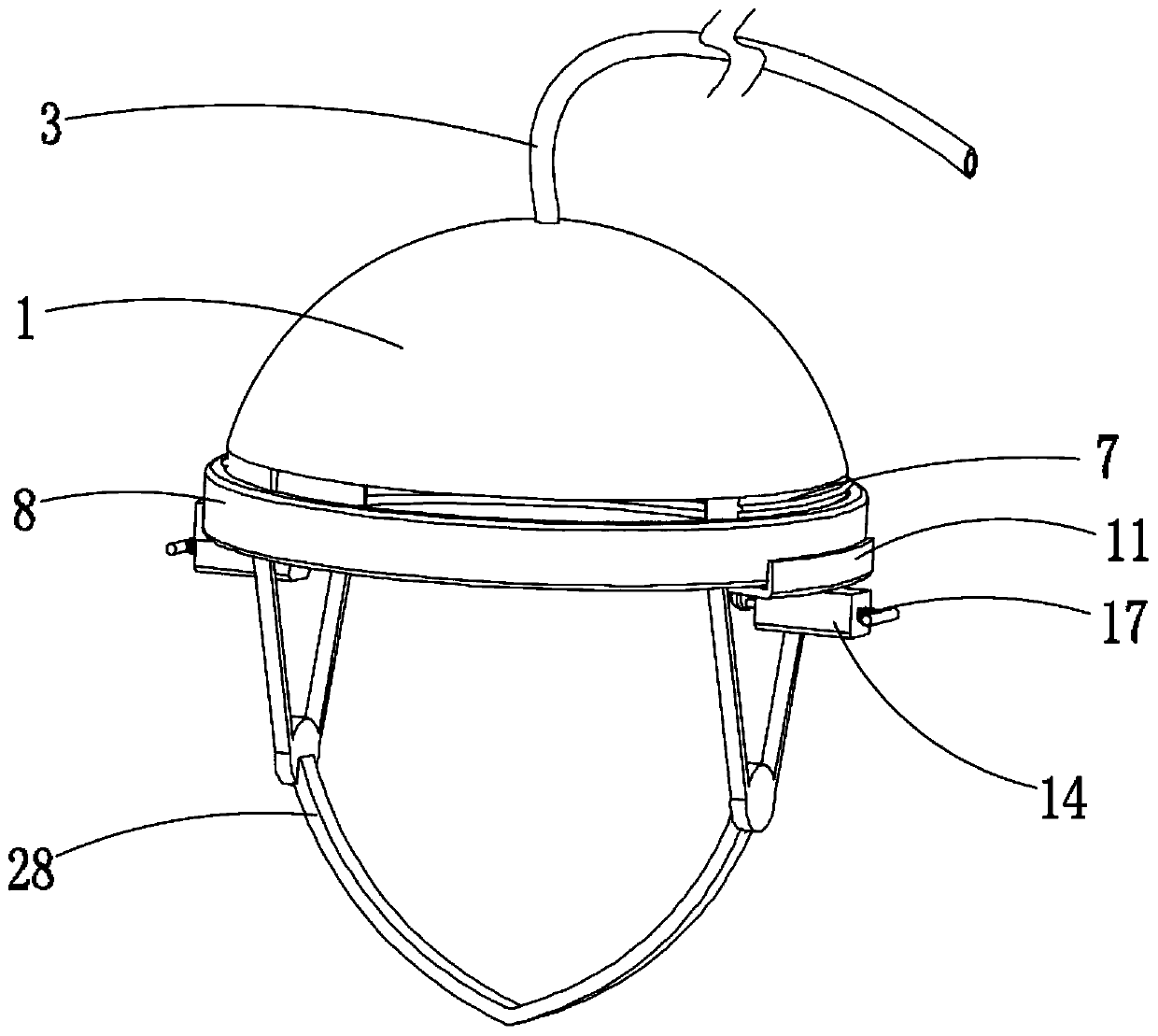

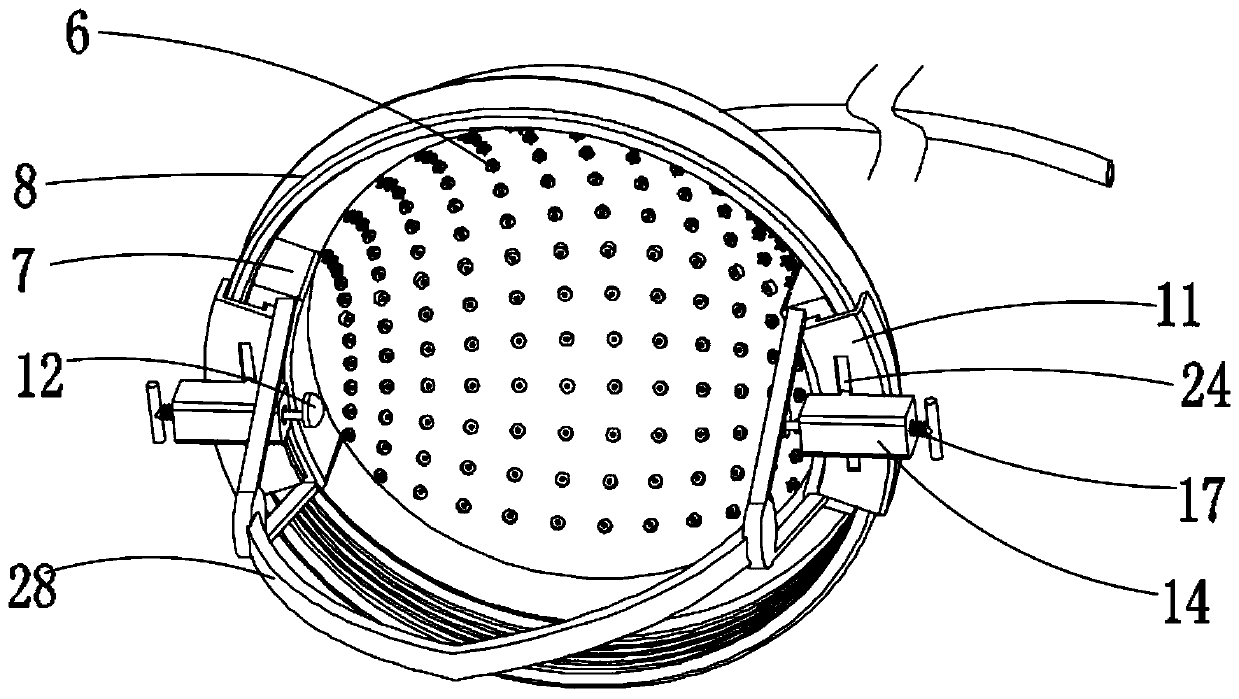

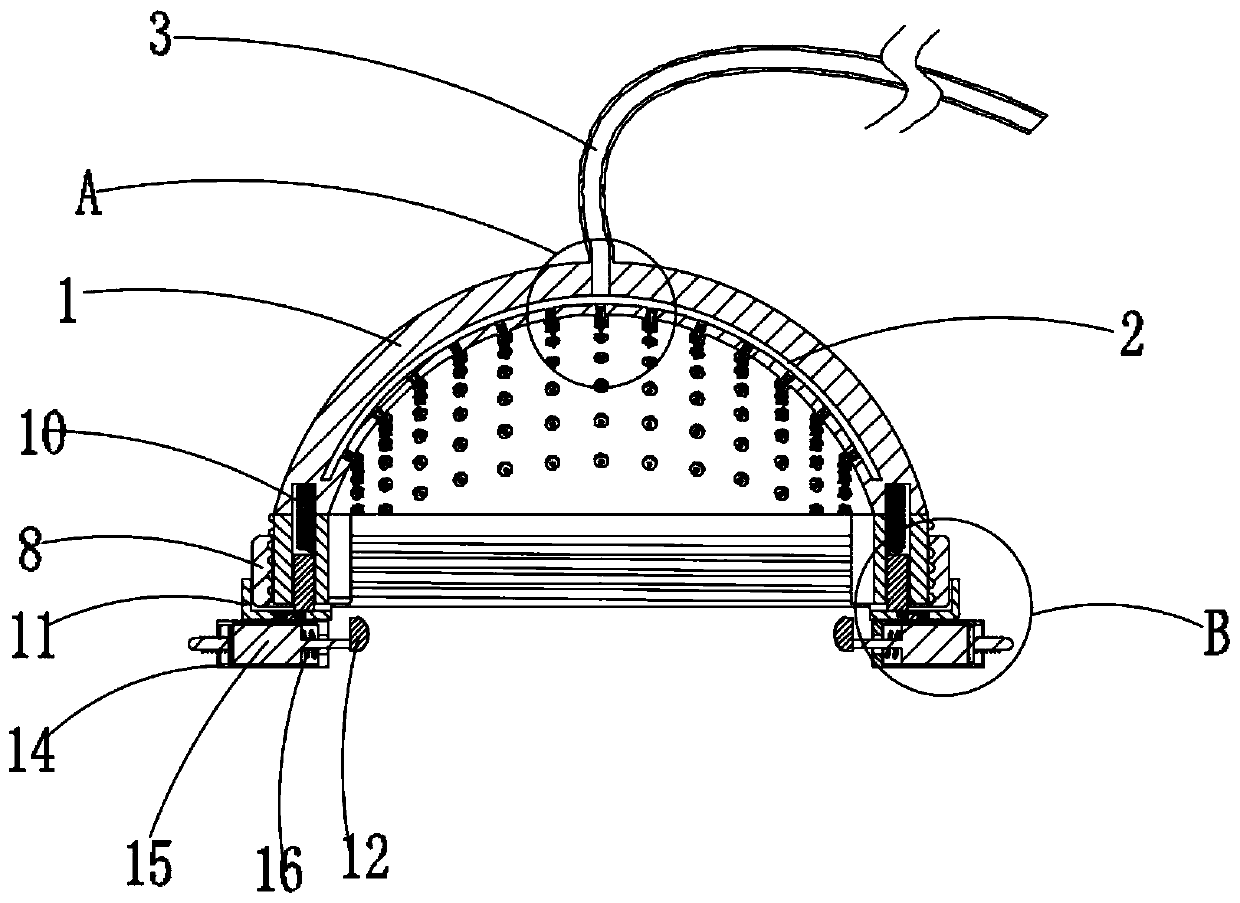

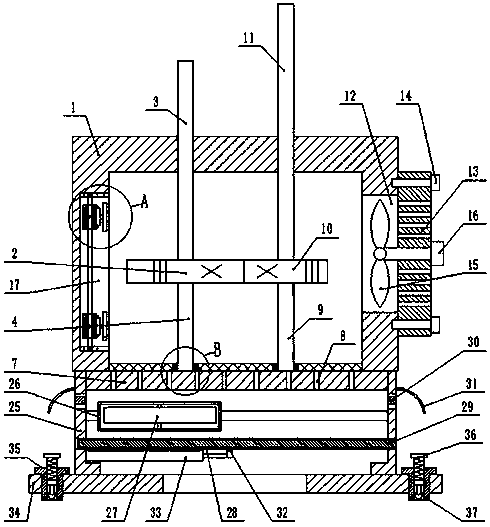

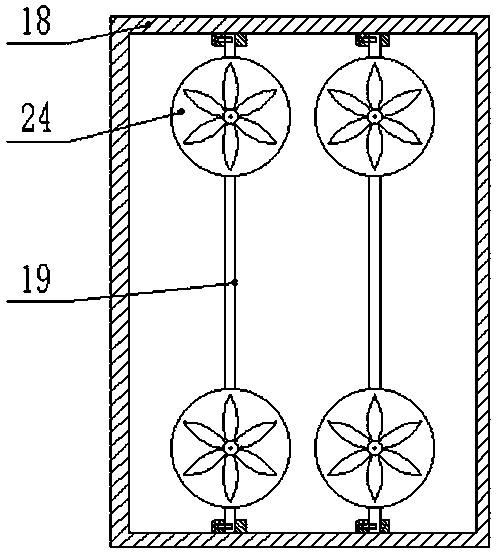

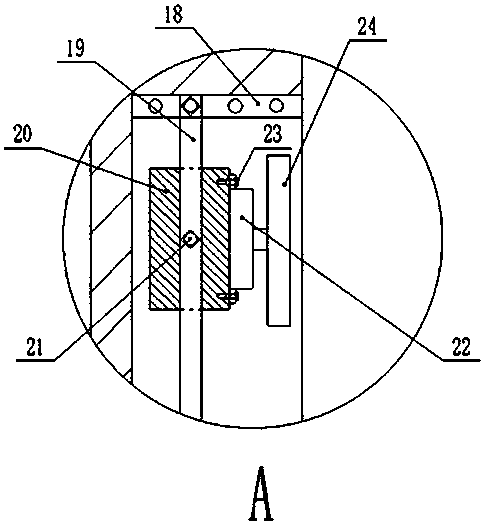

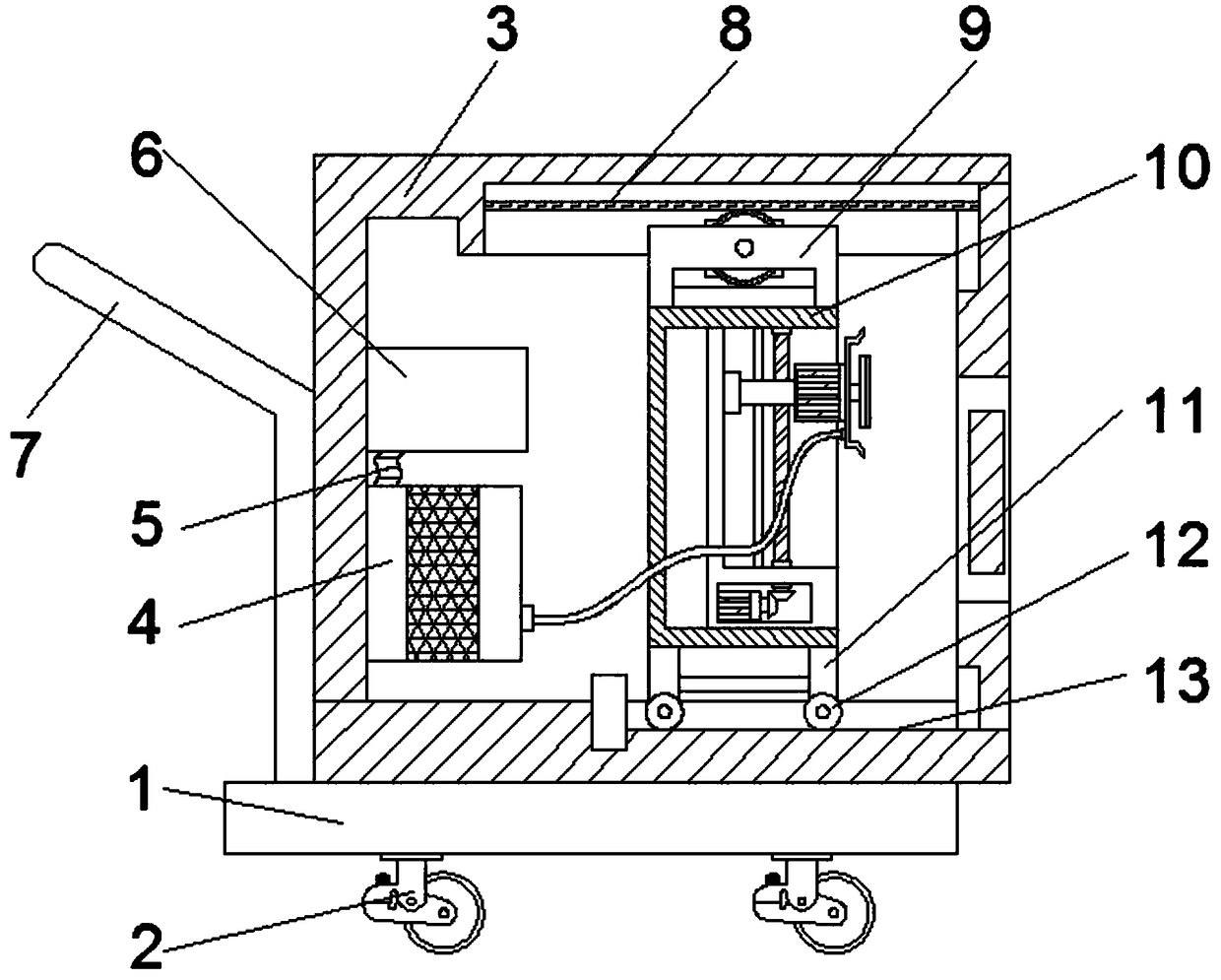

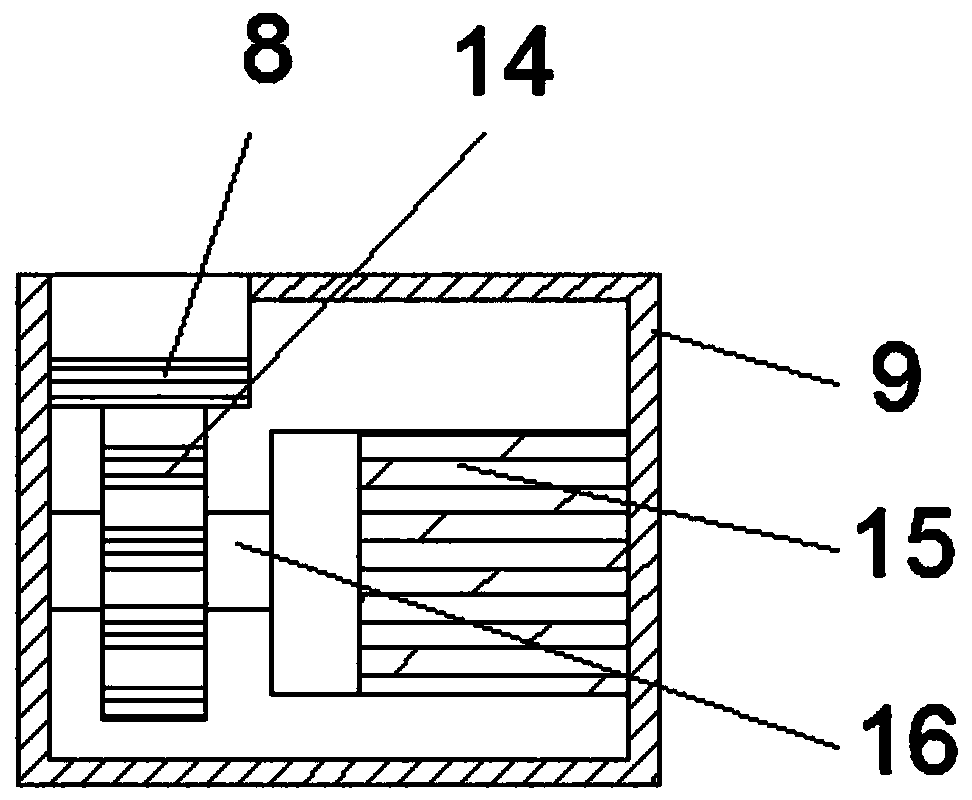

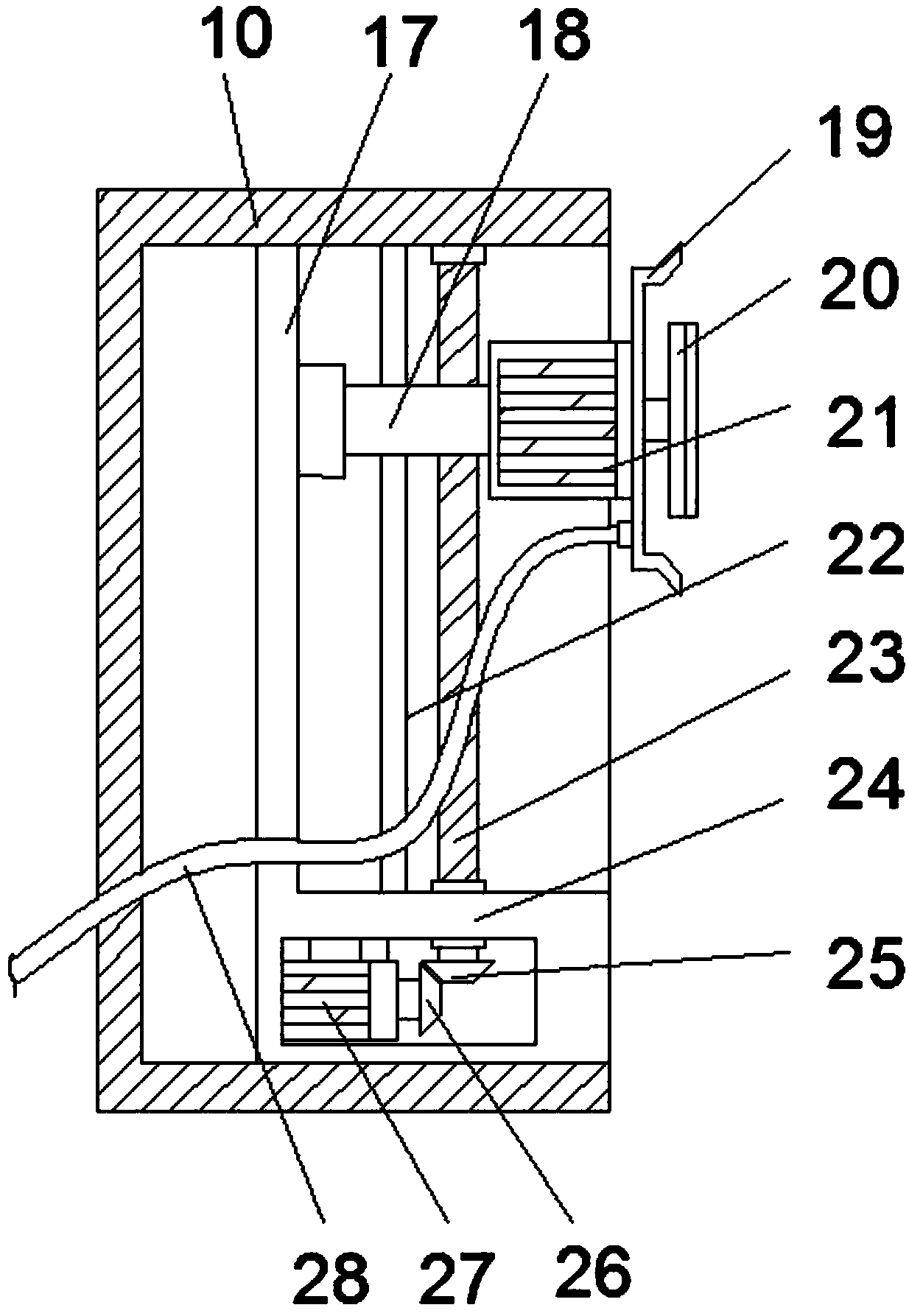

Migraine treatment device in neurology

ActiveCN110251390AEasy to wearAvoid artificial massageDevices for pressing relfex pointsSuction-kneading massageRight templeMicro motor

The invention relates to the field of medical instruments, in particular to a migraine treatment device in neurology. The migraine treatment device comprises a head cap, wherein an air cavity consistent with the appearance of the head cap is formed in the head cap shell; a reciprocating piston pump component is connected to the top of the head cap through a conduit; a plurality of groups of pricked massage components are uniformly arranged on the inner side of the head cap; arc-shaped screw plates are glued to the left and right sides of the lower side of the head cap; an annular adjusting piece is connected to the outer side of the arc-shaped screw plates in a threaded manner; arc-shaped grooves are formed in the middles of the arc-shaped screw plates; massage adjusting components are connected to the arc-shaped grooves through first springs; each the massage adjusting component comprises an L-shaped plate and an eccentric massage block; adjusting frames are arranged on the lower sides of the L-shaped plates; micro motors for driving the eccentric massage blocks are arranged in the adjusting frames; and second springs at the driving front ends of the micro motors are connected to the inner sides of the adjusting frames. Left and right temples of a patient are mechanically massaged and the head is pricked, so that manual massage is avoided, and the massage position and the massage force are adjusted according to the massage points and the massage comfort degree of different patients.

Owner:日照市岚山区人民医院

Efficient heat dissipation gear speed reducer

The invention discloses an efficient heat dissipation gear speed reducer. The efficient heat dissipation gear speed reducer comprises a gear speed reducer body; a large gear and a small gear are arranged in the gear speed reducer body, and are engaged with each other; one side of the large gear is fixedly connected with an output shaft; the output shaft penetrates through the gear speed reducer body; the other side of the large gear is fixedly connected with a connecting shaft A; and one side of the small gear is fixedly connected with an input shaft. As the gear speed reducer body is effectively cooled, efficient work of the gear speed reducer body is guaranteed; a heat dissipation device is arranged at the lower end of a gear speed reducer mounting box without exposing outside, so that the heat dissipation device is not easy to be corroded by natural environment, the service life of the heat dissipation device is prolonged, and the maintenance cost is reduced; a slide rod is provided, and the position of a heat dissipation fan can be adjusted on the slide rod, so that heat dissipation in one area can be guaranteed, and the heat dissipation efficiency is preferably guaranteed; andthe up-down position of the slide rod is conveniently adjusted, so that the heat dissipation area can be adjusted, and excellent heat dissipation effect is guaranteed.

Owner:HARBIN UNIV OF SCI & TECH

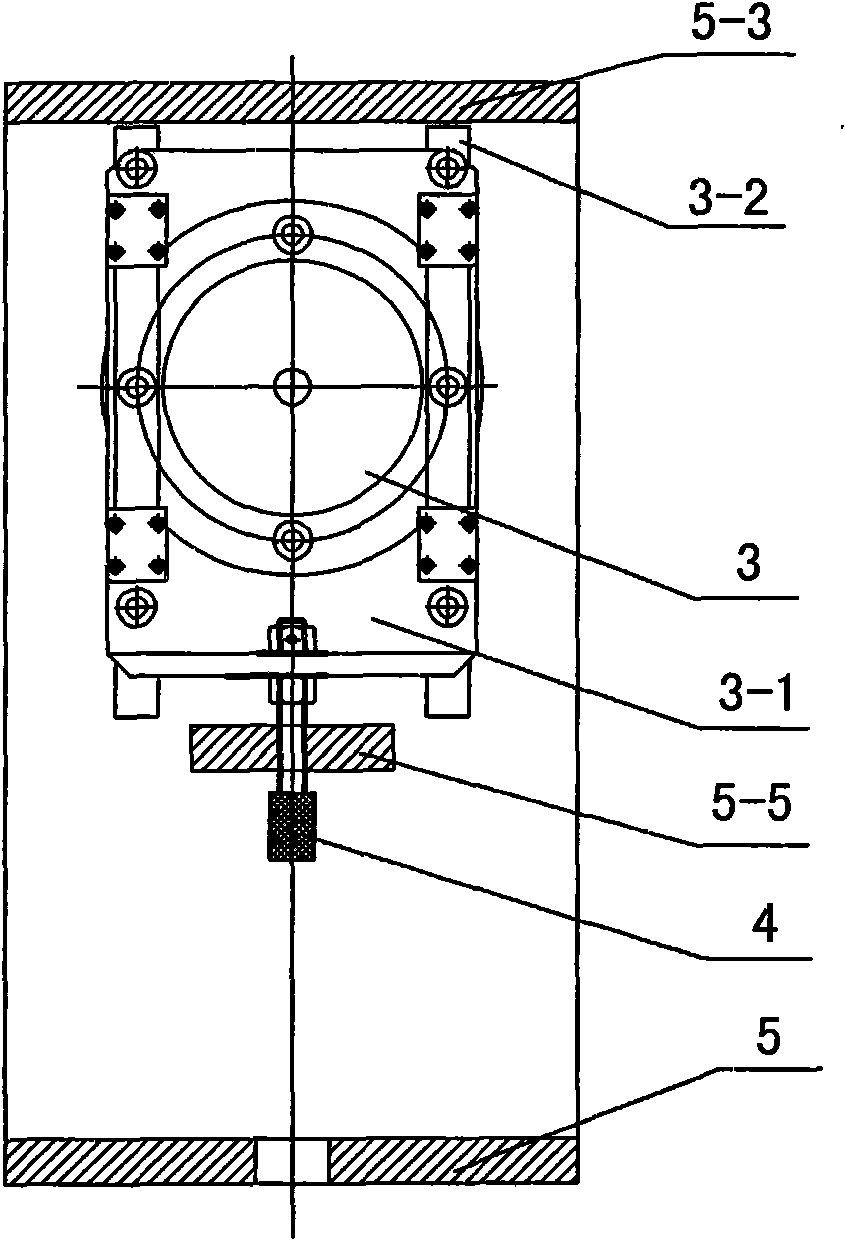

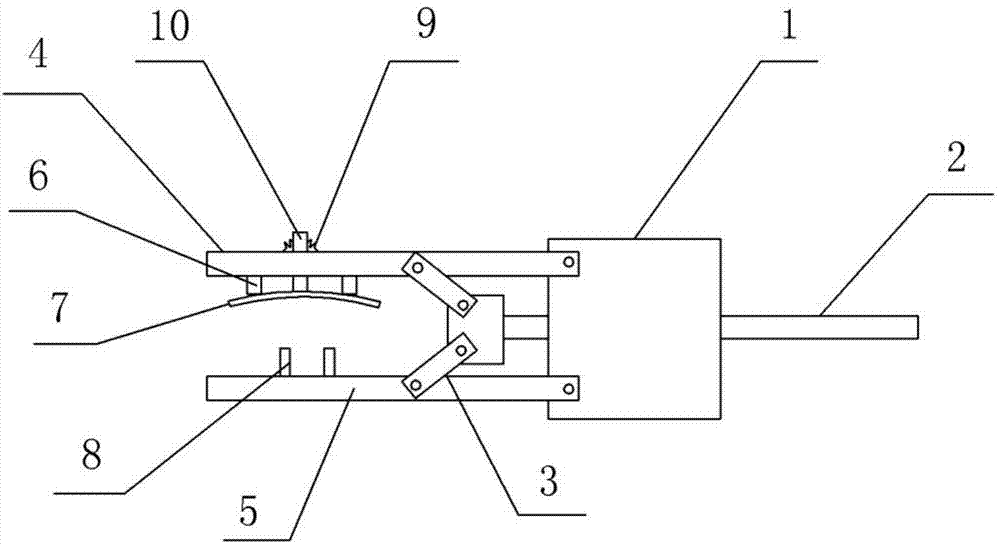

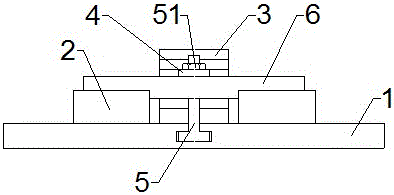

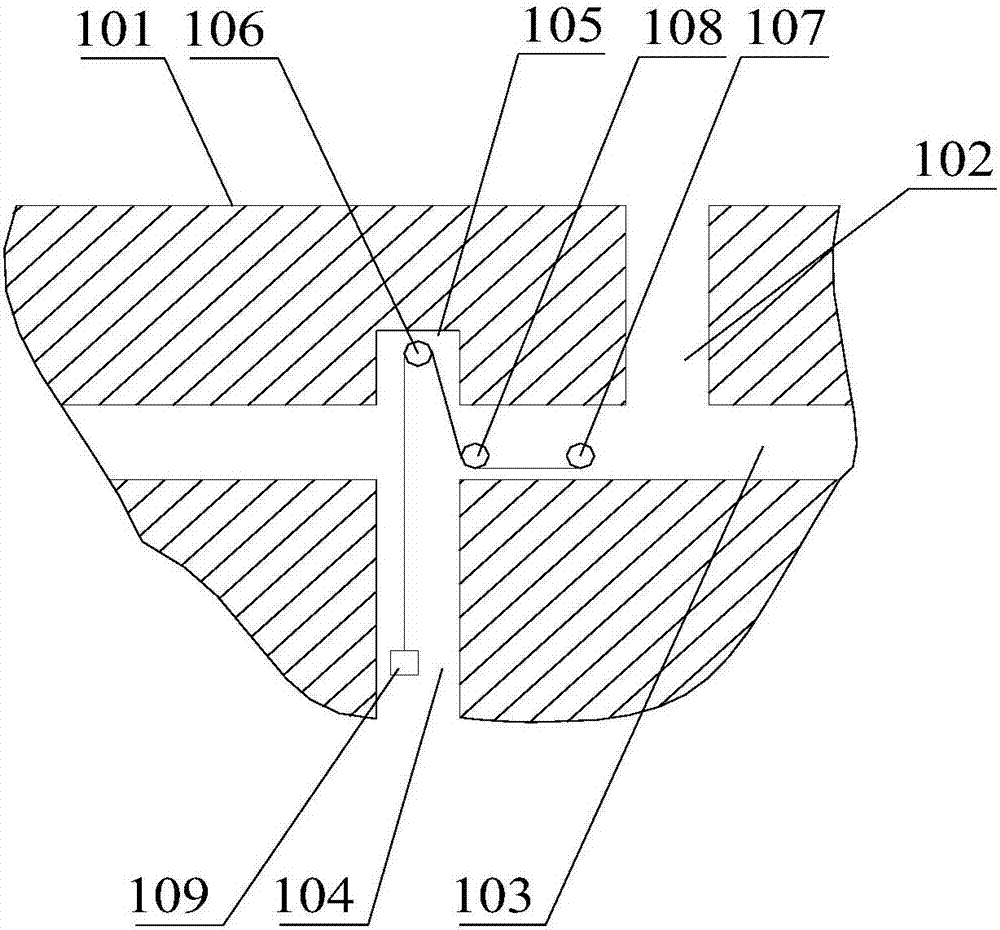

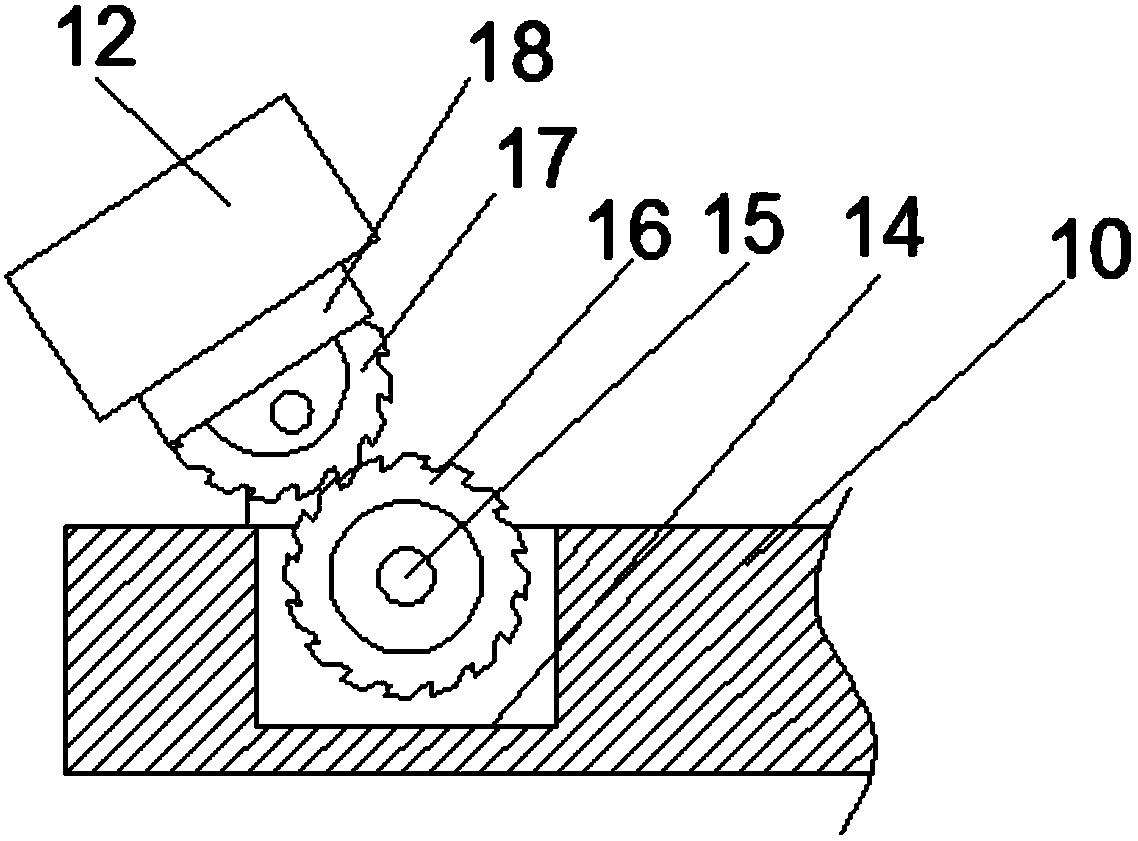

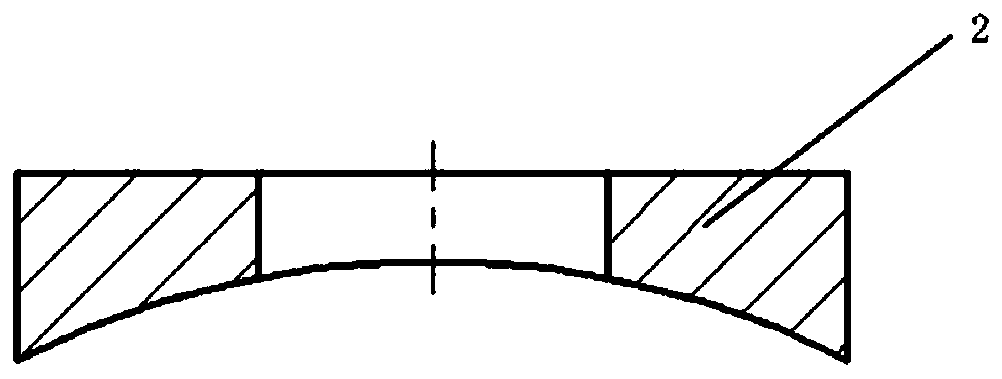

Clamping device used for clamping circular arc-shaped workpiece

InactiveCN104493629AEasy to holdEasy to adjust up and down positionMetal working apparatusEngineeringControl rod

The invention discloses a clamping device used for clamping a circular arc-shaped workpiece. The clamping device comprises a base, two clamping claws, a control rod and two driving rods, wherein the control rod is glidingly connected onto the base, one end of each of the two driving rods is respectively connected with the inner side of the two clamping claws, the other end of each of the two driving rods is respectively connected with the control rod, the two clamping claws are divided into the first clamping claw and a second clamping claw, two position limiting blocks, an elastic sheet and a slide rod are arranged on the first clamping claw, a through hole is formed in the first clamping claw, one end of the slide rod passes through the through hole, the other end of the slide rod is connected with the elastic sheet, the two position limiting blocks are respectively positioned at the inner side of the first clamping claw, the length of the elastic sheet is greater than the distance between the two position limiting blocks, the elastic sheet is glidingly connected onto the two position limiting blocks, and a clamping head positioned between the two position limiting blocks is arranged on the second clamping claw. The clamping device has the advantages that the elastic sheet arranged on the first clamping claw can be regulated according to the shape of the circular arc-shaped workpiece, the clamping head arranged on the second clamping claw can be used for conveniently regulating the vertical position of the slide rod, and the circular arc-shaped workpieces with different curvature can be conveniently clamped.

Owner:CHONGQING STRONG DUDLEY TECH DEV

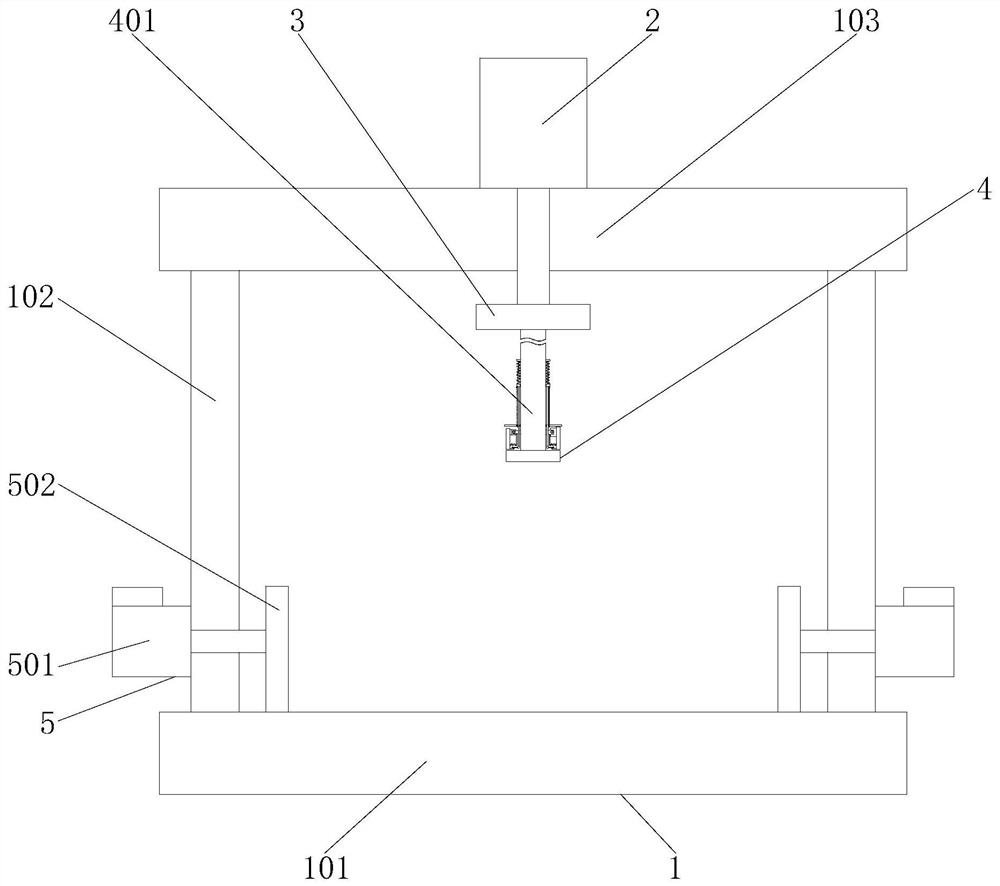

Automatic workpiece punching device

ActiveCN112658695AEasy to removeEasy to adjust up and down positionEdge grinding machinesPerforating toolsHydraulic cylinderPunching

The invention provides an automatic workpiece punching device to solve the technical problems that in the prior art, a punching device cannot carry out polishing treatment on burrs, flashes and the like at the penetrating position of a hole, and later workpiece utilization is inconvenient. The automatic workpiece punching device comprises a rack, wherein the rack comprises a bottom plate and a top plate which are arranged at an interval; a punching head is arranged on the top plate; a clamping mechanism for limiting a workpiece is arranged on the bottom plate; the punching head comprises a punching punch and a hydraulic cylinder; a connecting rod is arranged between the punching punch and the hydraulic cylinder; a plurality of auxiliary mechanisms are arranged in the circumferential direction of the connecting rod; and each auxiliary mechanism comprises a reset part, an adjusting part and a friction part, each adjusting part comprises a stabilizing block with one end connected with the connecting rod, each friction part comprises a friction plate with one end rotationally connected with the other end of the stabilizing block, one end of each reset part is connected with one friction plate, the other end of each reset part is connected with one adjusting part, the outer side surface of each friction plate is flush with the circumferential surface of the punching punch when the corresponding reset part is compressed, and each friction plate partially protrudes out of the circumferential surface of the punching punch when the corresponding reset part extends.

Owner:SHAOXING UNIV YUANPEI COLLEGE

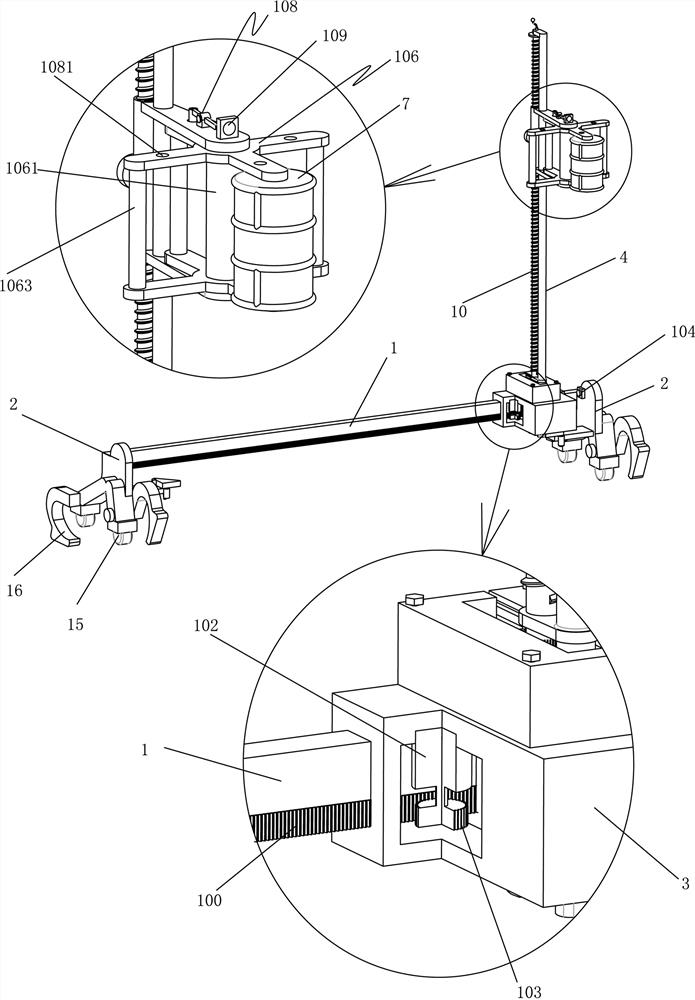

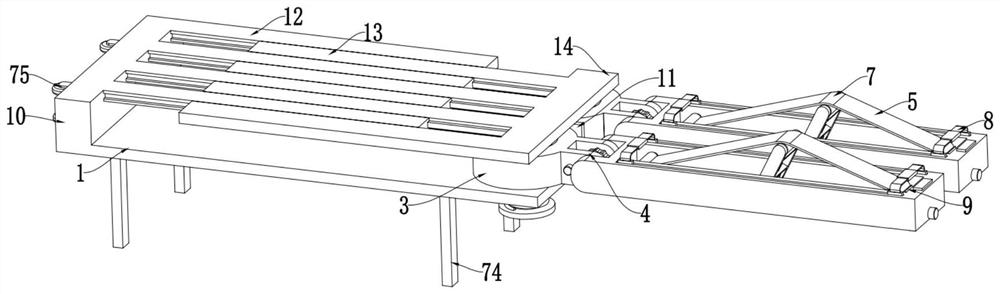

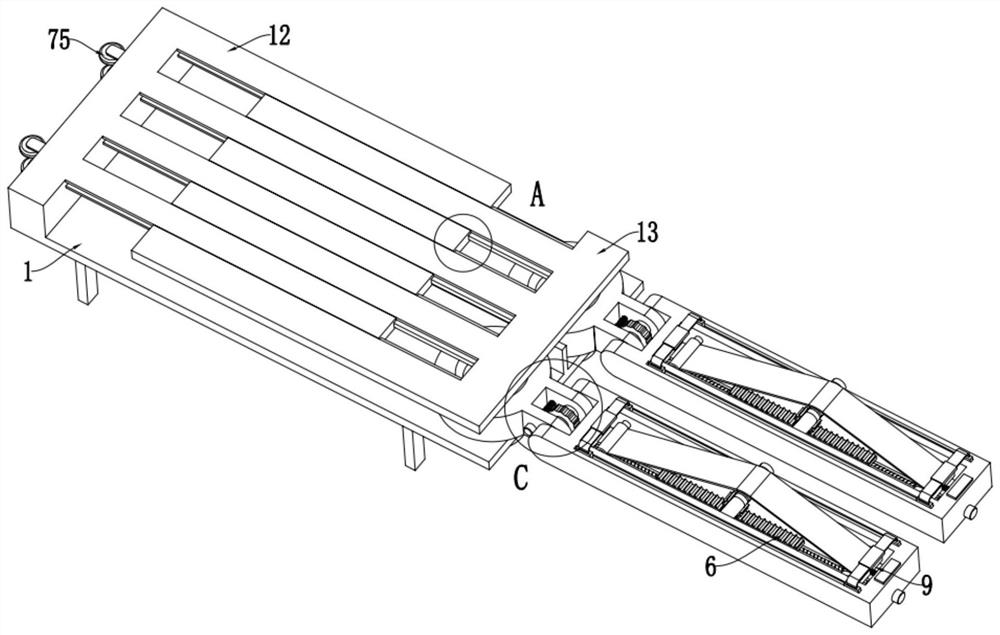

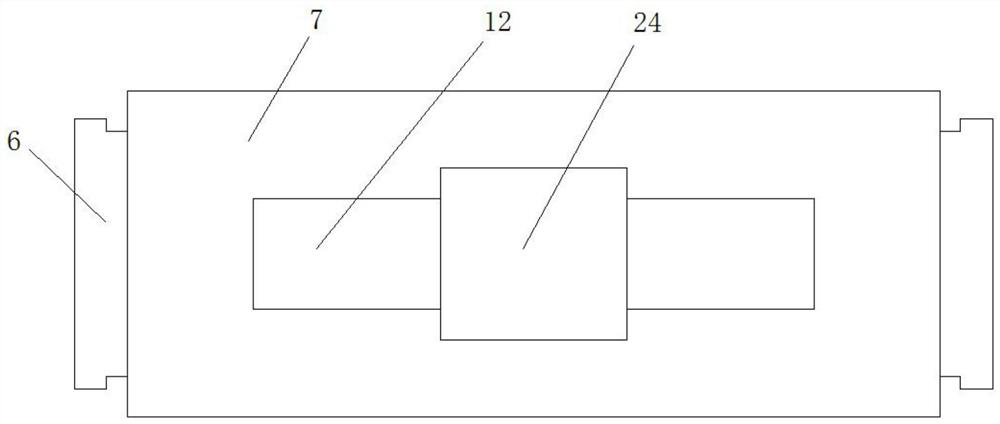

Diode packaging feeding device

ActiveCN112061759AEasy to adjust up and down positionEasy alignmentConveyor partsElectric machineryMaterials science

The invention discloses a diode packaging feeding device, and relates to the field of diode feeding. A feeding driving piece comprises a first pneumatic cylinder and a second pneumatic cylinder, the vertical and horizontal positions of a feeding driving rod can be adjusted conveniently, the feeding driving rod can be conveniently aligned with the ends of diodes, and the ends of the diodes can be effectively protected through the arrangement of a buffer component and are prevented from being damaged by pressure. A plurality of layers of diodes are arranged in a feeding fixing piece, when the height of the diodes is inconsistent with that of the feeding driving rod, the height of the diodes is adjusted through driving of a motor and meshing of a gear and a rack, the diodes and the feeding driving rod are made to be horizontal, and one layer of diodes can be pushed at a time. During use, a whole feeding die frame rotates around a first rotating rod, the bottom of one end of the feeding die frame presses a second rotating rod downwards, at the moment, a first rotating plate is lifted upwards, a movable plate penetrates through a penetrating groove, the movable plate is attached to thefeeding die frame, it can be guaranteed that the feeding die frame is in a horizontal state, and feeding precision is guaranteed.

Owner:广东铖电微电子有限公司

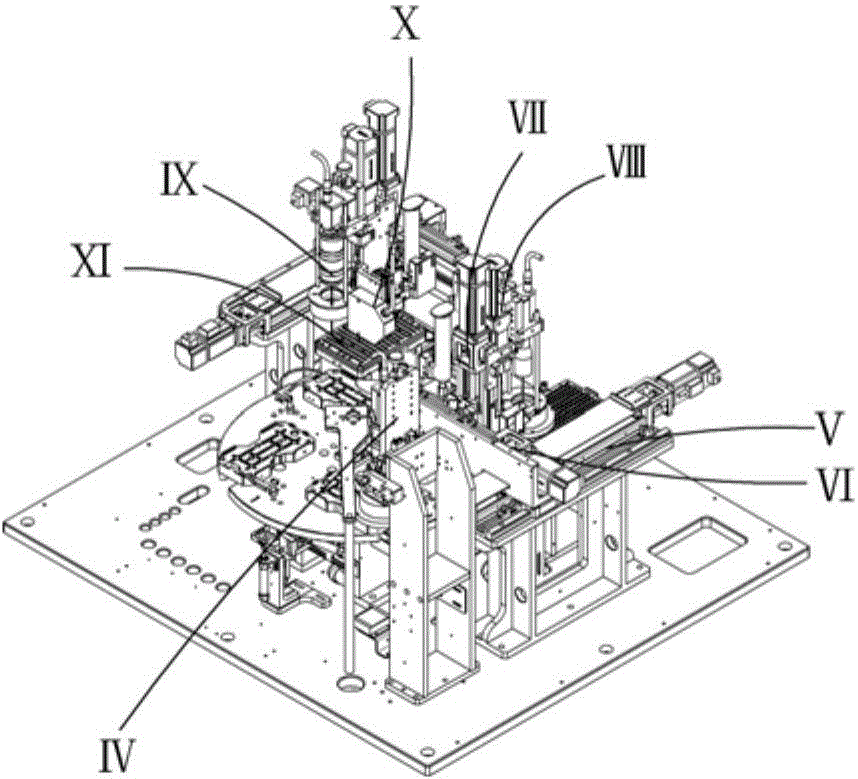

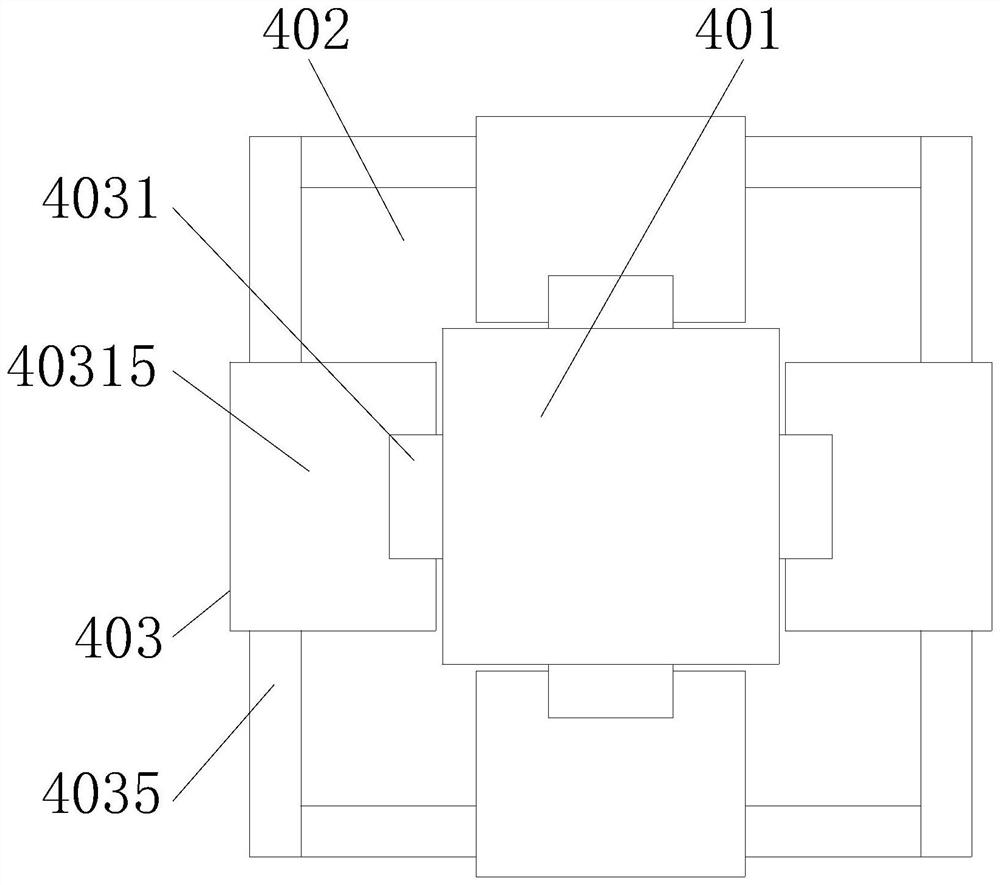

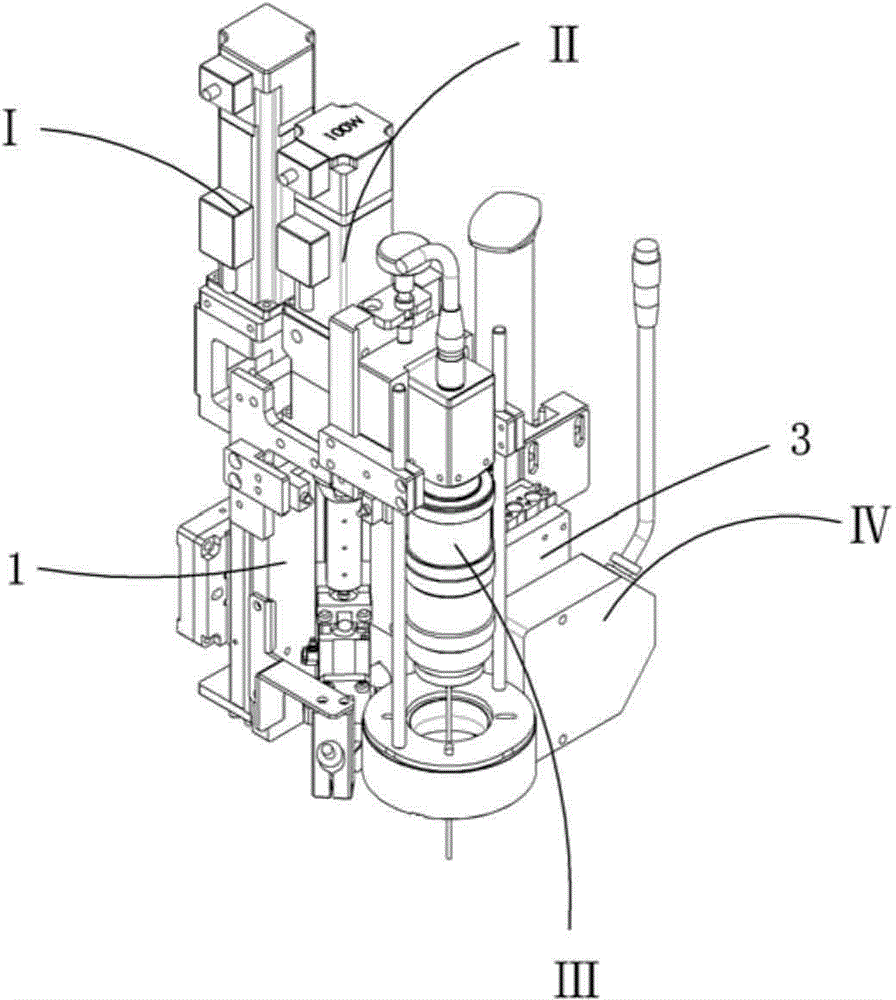

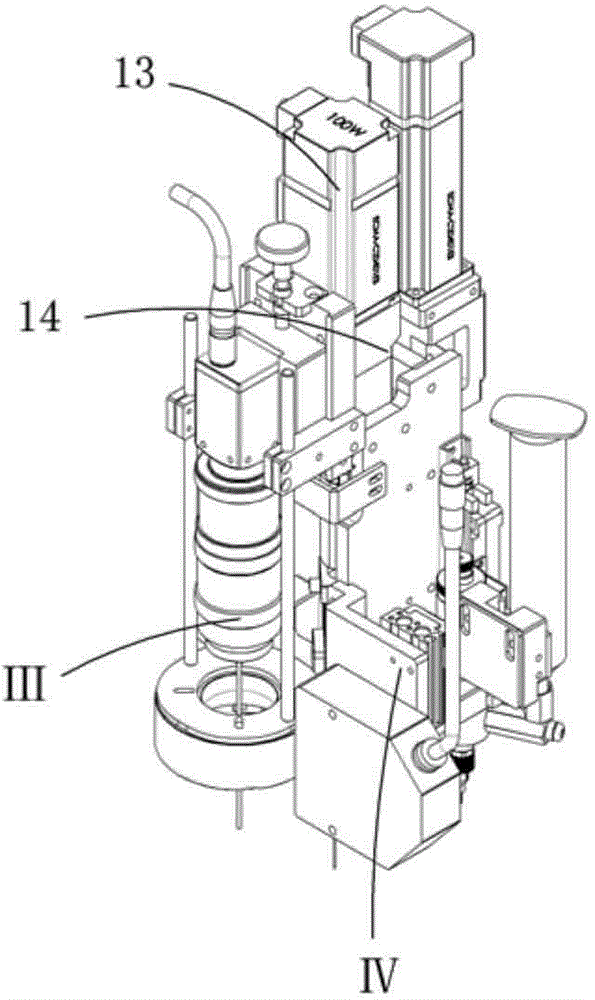

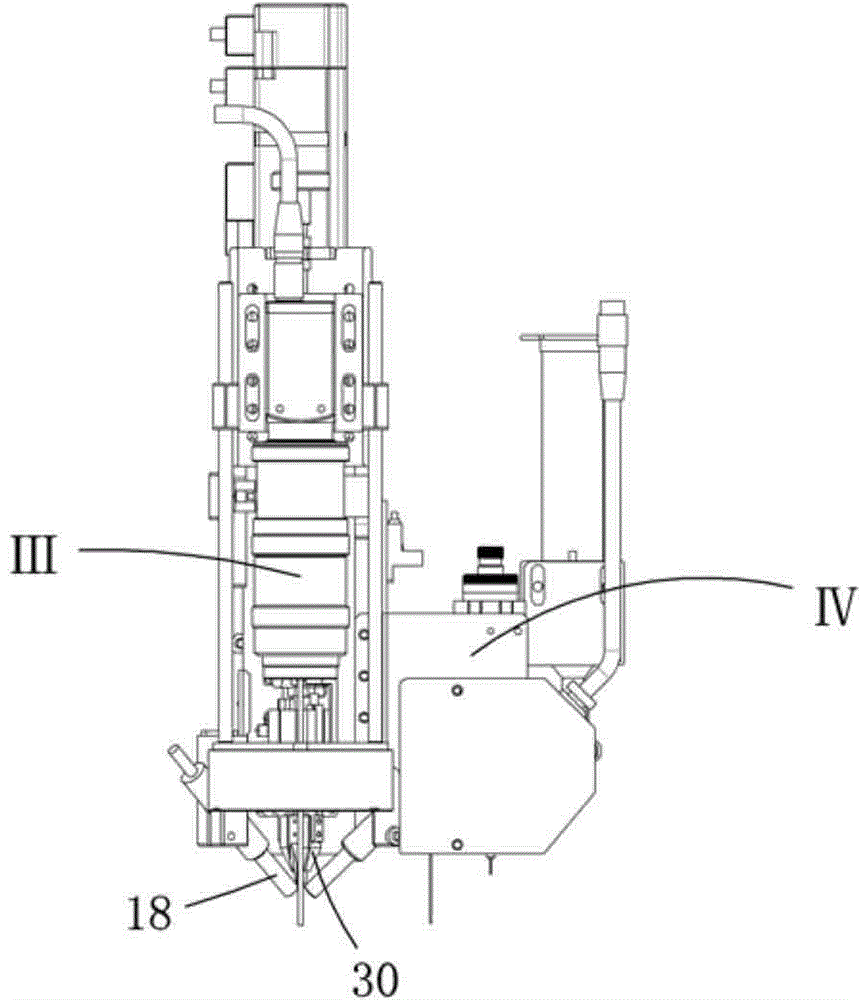

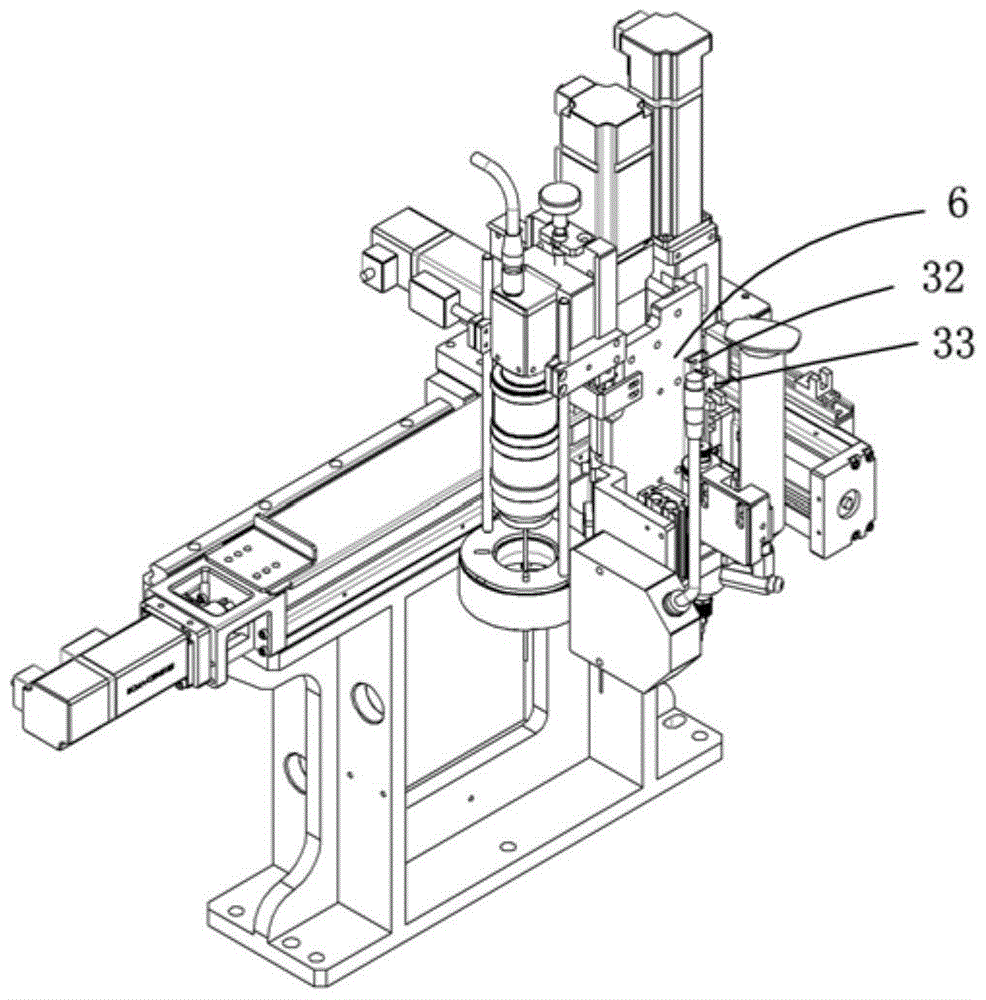

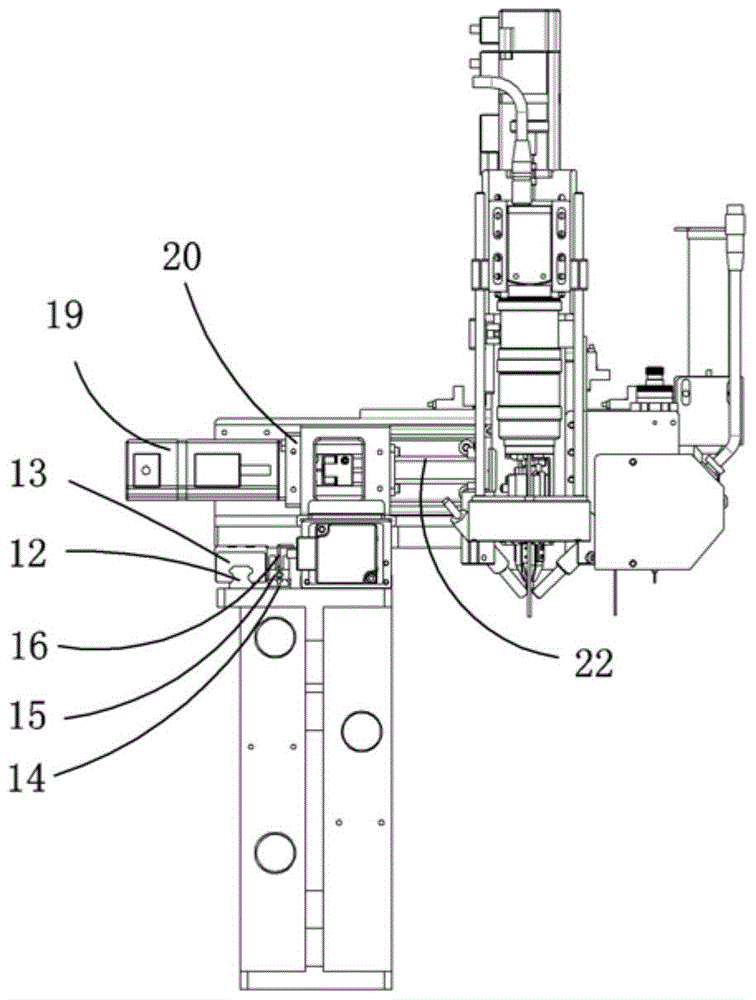

Adhesive dispensing and curing mechanism movable in Z-axis direction

InactiveCN104564948AEasy to adjust up and down positionEasy to replaceMaterial gluingAdhesiveMechanical engineering

The invention relates to an adhesive dispensing and curing mechanism movable in the Z-axis direction. The adhesive dispensing and curing mechanism is characterized in that the back of the Z-axis linear module of the Z-axis mechanism of the adhesive dispensing and curing mechanism is connected with a ZR connecting plate, and the lateral part of the Z-axis linear module is connected with a lateral fixing plate; an R-axis mechanism is mounted on the front portion of the Z-axis mechanism through the ZR connecting plate; a CCD mechanism is mounted on the front portion of the R-axis mechanism; an adhesive dispensing laser mechanism is mounted on the right side of the R-axis mechanism through a laser fixing plate; the Z-axis mechanism conveys the R-axis mechanism to an operation position; the clamping jaw of the R-axis mechanism moves to a small part fetching position to clamp a small part; the CCD mechanism moves above a product to take a picture so as to determine an adhesive dispensing position; the laser of the adhesive dispensing laser mechanism moves to the adhesive dispensing position of the product and measures adhesive dispensing height, and an adhesive dispensing valve moves to the adhesive dispensing position to perform adhesive dispensing; the clamping jaw moves to the adhesive dispensing position to adhere the small part and performs UV curing. By the adhesive dispensing and curing mechanism which is accurate in adhesive dispensing position, the small part can be accurately assembled to the electronic product, product quality is increased, work efficiency is increased, and cost is lowered.

Owner:BOZHON PRECISION IND TECH CO LTD

Infusion bottle auxiliary device for medical nurses

The invention relates to the technical field of medical instruments, and discloses an infusion bottle auxiliary device for medical nurses. The device comprises a device main body, the top of the device main body is fixedly connected with an alarm lamp, the interior of the device main body is fixedly connected with a sleeve, the interior of the sleeve is slidably connected with a movable block, and the bottom end of the movable block is fixedly connected with a first spring. The movable block is fixedly connected with a connecting frame, an air bag is fixedly connected with a catheter, and the lower end of the catheter is fixedly connected with a sealing cylinder. When the infusion bottle auxiliary device is used, along with reduction of liquid medicine in an infusion bottle, elastic force of the first spring can slowly jack up the movable block, the connecting frame moves upwards to extrude the air bag, air in the air bag exerts thrust on a piston piece, along with increase of the thrust of the air, the piston piece can drive a round block to move and extrude a sliding column to move downwards, and along with downward movement of a sliding column, the sliding column moves downwards to extrude the switch and turn on a switch, and when the switch is turned on, the alarm lamp is turned on to give out alarm sound indicating that the infusion bottle needs to be replaced so as to remind a nurse of replacing the infusion bottle.

Owner:曾爱月

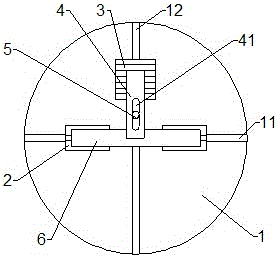

Shaft type workpiece holder

The invention relates to a shaft type workpiece holder used for clamping of a shaft type workpiece. The shaft type workpiece holder comprises a mounting disc, and positioning V-shaped blocks and a holding device that are arranged on the mounting disc, wherein the mounting disc is provided with a guide groove A and a guide groove B along the diameter direction of the mounting disc; the guide groove A and the guide groove B are mutually perpendicular; the cross sections of the guide groove A and the guide groove B are inverted-T-shaped; the number of the positioning V-shaped blocks is two; the positioning V-shaped blocks are symmetrically arranged on the mounting disc along the extension direction of the guide groove A; center lines of the two positioning V-shaped blocks are coincided with that of the guide groove A; the holding device is arranged on the mounting disc; the center line of the holding device is coincided with the center line of the guide groove B; and the holding device comprises a supporting block, a pressure plate and a locking bolt. The shaft type workpiece holder has the advantages that the shaft type workpiece is positioned by the two positioning V-shaped blocks, and is held by the holding device, thereby realizing the clamping of the shaft type workpiece; the clamping is more secure; the possibility of rotation is low; and the machining precision is higher.

Owner:NANTONG HENGDING HEAVY DUTY MACHINE TOOL

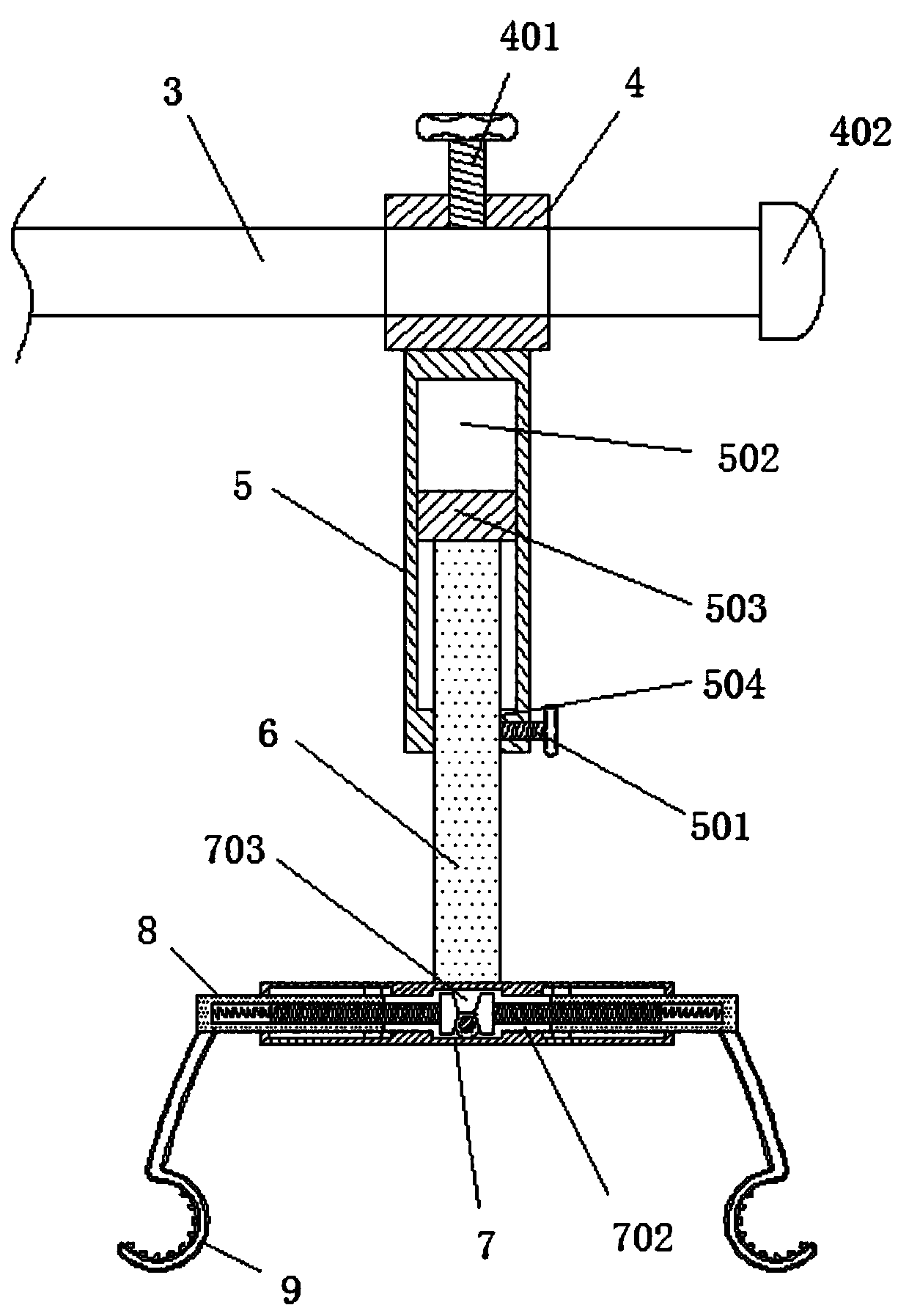

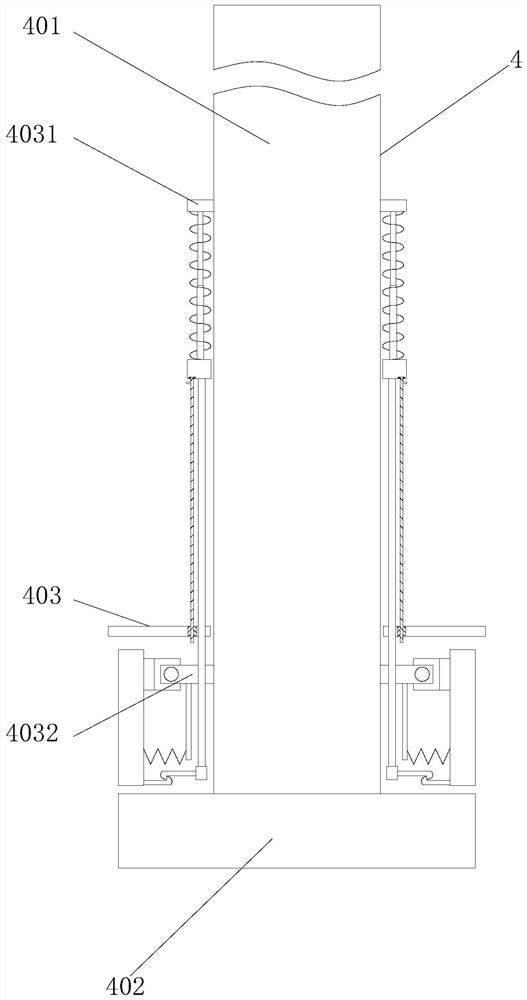

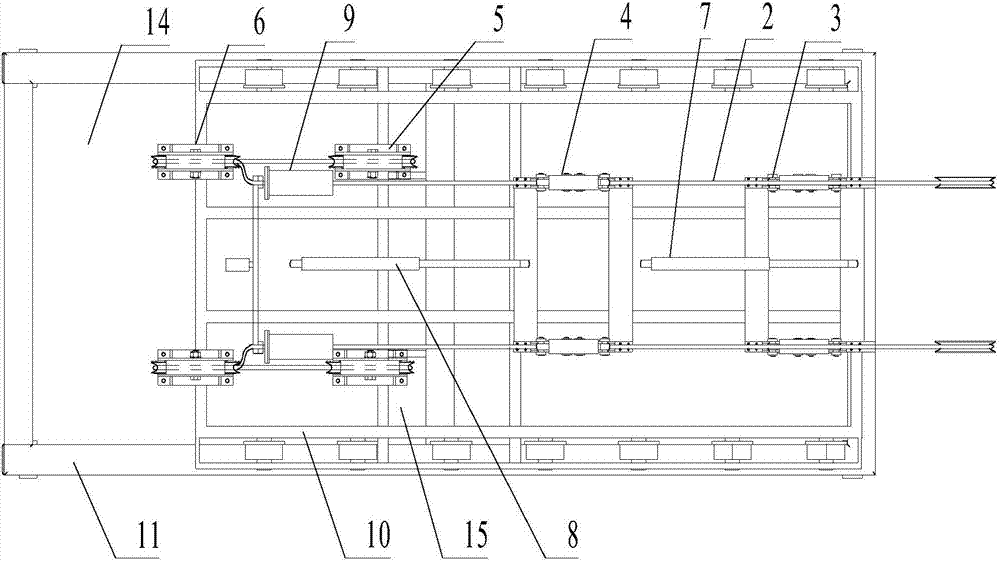

Vertical lifting device and method

ActiveCN106882708AEasy to adjust up and down positionDecentralization orderlyBase supporting structuresBraking devices for hoisting equipmentsEngineeringLifting weight

The invention discloses a vertical lifting device and method. The vertical lifting device comprises a fixed frame fixed to a foundation. A first cavity allowing for passing of lifting ropes is formed in the middle of the fixed frame. A sliding frame moving horizontally on the fixed frame is arranged above the fixed frame. A second cavity allowing for passing of the lifting ropes is formed in the middle of the sliding frame. Two or more stepping vehicles alternately placing or lifting weights are arranged on the sliding frame and slide on the sliding frame. The stepping vehicles are spaced in preset distances. The lifting ropes penetrate through the stepping vehicles in sequence. Each stepping vehicle is provided with a clamping part clamping the lifting ropes and a driving mechanism driving the stepping vehicle to move on the sliding frame.

Owner:TAIYUAN UNIV OF TECH

Intelligent building construction equipment and quality monitoring method and system based on Internet of Things

InactiveCN111612485ASimple structureEasy to useClosed circuit television systemsBuilding constructionsTextile printerTransceiver

The invention discloses intelligent building construction equipment and a quality monitoring method and system based on the Internet of Things. According to the intelligent building construction equipment, a sliding seat driven by a driving motor is sleeved on a sliding rail; a first touch switch is arranged on the inner side of a supporting seat; a second touch switch is arranged on the sliding seat; a sliding sleeve is sleeved on a guide vertical rod of the sliding seat on the sliding seat; a camera is arranged on a mounting frame on the front side of the sliding sleeve; a wall surface printing roller is arranged on the mounting frame; a signal transceiver is arranged on the controller on the sliding seat; lead screws in an upper connecting seat and a lower connecting seat are arranged in lead screw sleeves on the rear side of the sliding sleeve; a rotary driving mechanism is arranged between the sliding seat and the lower ends of the lead screws; moving driving mechanisms are arranged at the left end and the right end of the sliding rail respectively; and a reset driving mechanism is arranged on the upper connecting seat. The equipment is convenient to use, and the vertical position of the wall surface printing roller can be conveniently adjusted, so that the printing position accuracy is ensured, and the printing efficiency is effectively improved.

Owner:中山市道格装饰设计工程有限公司

High-tech energy light source fixing device

InactiveCN108982526AEasy to adjust up and down positionEasy to useOptically investigating flaws/contaminationGear driveDrive shaft

The invention discloses a high-tech energy light source fixing device. The device comprises an equipment base, a supporting frame fixing base and a supporting frame, wherein the supporting frame fixing base is arranged at the upper end of the equipment base, the supporting frame is arranged on the middle part of the upper end of the supporting frame fixing base, a lifting transverse board is arranged on the upper part of the left upper end of the supporting frame, a screw rod sleeve is arranged on the right end part of the lifting transverse board, a transmission shaft is arranged on the lowerpart of the right side of the interior of the supporting frame, and the left end of the transmission shaft is rotatably connected with the left side wall of the supporting frame through a bearing. When the high-tech energy light source fixing device is in use, a rotary knob is rotated to drive a fixing shaft to rotate, the fixing shaft drives a third gear to rotate, the third gear drives a half-gear to rotate, and then an angle of a light source installation chamber connected with the half-gear is controlled, so that the high-tech energy light source fixing device is beneficial for adjustingan angle of a light source, use and adjustment of the light source are facilitated, the bottom of the light source installation chamber and a light source fixing board are matched with each other, andthrough fixing bolts, the high-tech energy light source is fixed to the interior of the light source installation chamber, which is beneficial for fixing the light source.

Owner:繁昌县奉祥光电科技有限公司

Construction equipment and building construction method

ActiveCN111608366ASimple structureEasy to useBuilding constructionsTextile printerArchitectural engineering

The invention discloses construction equipment and a building construction method. The construction equipment comprises a slide rail, wherein supporting bases are respectively disposed on the left endand the right end of the slide rail. The equipment is characterized in that a slide base sleeves the slide rail; a guide vertical rod is disposed on the slide base; a slide sleeve sleeves the guide vertical rod; an installation frame is disposed on the front side of the slide sleeve; a wall face printing roller is disposed on the installation frame; an upper connection base is disposed on the rear side of the upper end of the guide vertical rod; a lower connection base is disposed on the rear side of the lower part of the guide vertical rod; screw rods are disposed in the upper connection base and the lower connection base; a screw rod sleeve is disposed on the rear side of the slide sleeve; the screw rod is disposed in the screw rod sleeve; a rotary driving mechanism is disposed betweenthe slide base and the lower end of the screw rod; movable driving mechanisms are disposed on the left end and the right end of the slide rail; and a reset driving mechanism is disposed on the upper connection base. The equipment is simple in structure and convenient to use, can easily adjust vertical positions of the wall face printing roller, is high in printing efficiency and can effectively guarantee printing quality.

Owner:湘西武陵建筑安装有限责任公司

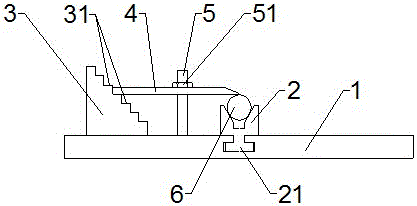

Clearance adjustment for conveying rollers of embroidery machine

The invention discloses a clearance adjustment for conveying rollers of an embroidery machine. The clearance adjustment comprises a base, an upper presser wheel, a lower roller, U-shaped frames, presser plates, adjusting screws, fixed bearing blocks, moving bearing blocks, and springs; the U-shaped frames are arranged on the two sides of the base respectively; the inside of each U-shaped frame isprovided with a U-shaped channel; one presser plate is arranged at the top of each U-shaped frame; one fixed bearing block is arranged at the inner bottom of each U-shaped channel; positioning terminals are arranged at the upper end of each fixed bearing block; each positioning terminal is provided with one spring; each spring is provided with one moving bearing block; each presser plate is provided with a screw hole I in which one adjusting screw is arranged; a bearing hole II is formed in each fixed bearing block; the bearing holes II are connected with rolling bearings II on the shaft endsII of the lower roller; one bearing hole I is formed in each moving bearing block; the bearing holes II are connected with ball bearings I at the shaft ends of the upper presser wheel; the outer sideof each U-shaped channel is provided with four flat washers; the flat washers are connected with the corresponding U-shaped channel via fastening screws. The upper presser wheel is adjustable; a clearance between the upper presser wheel and the lower roller is adjustable; a distance is controlled through graduation marks to adapt to conveying of fabrics different in thickness.

Owner:诸暨市伽马机电制造有限公司

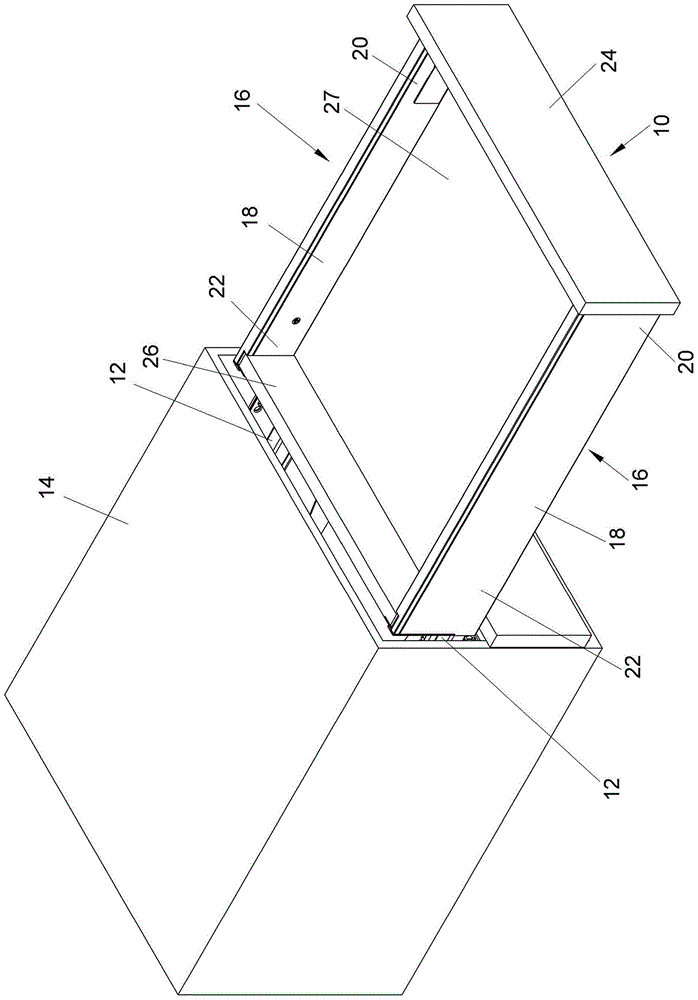

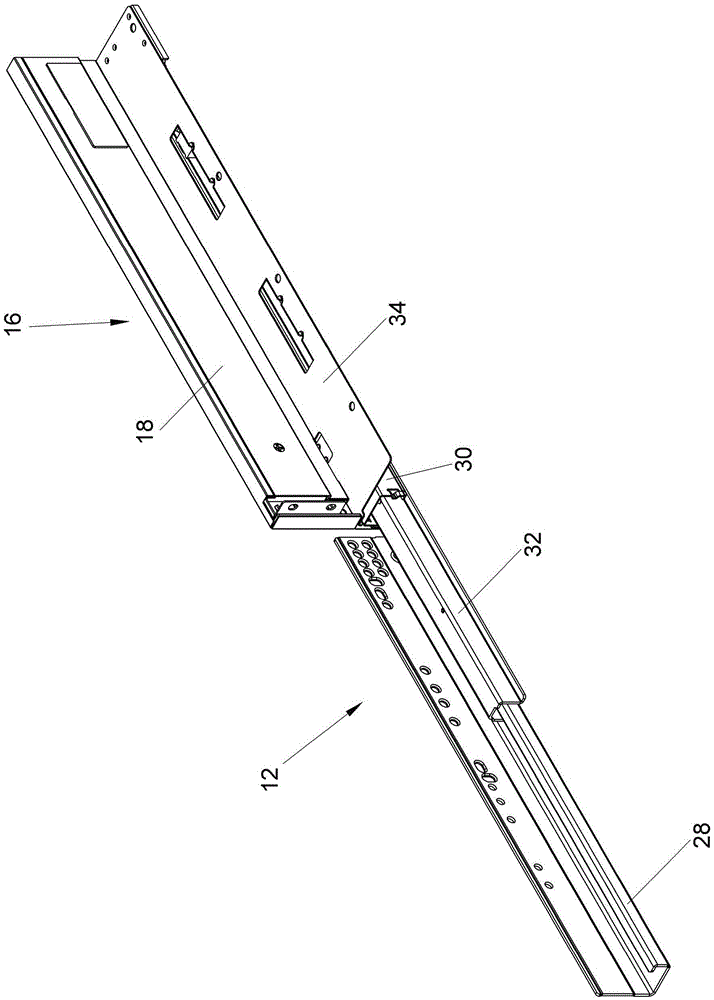

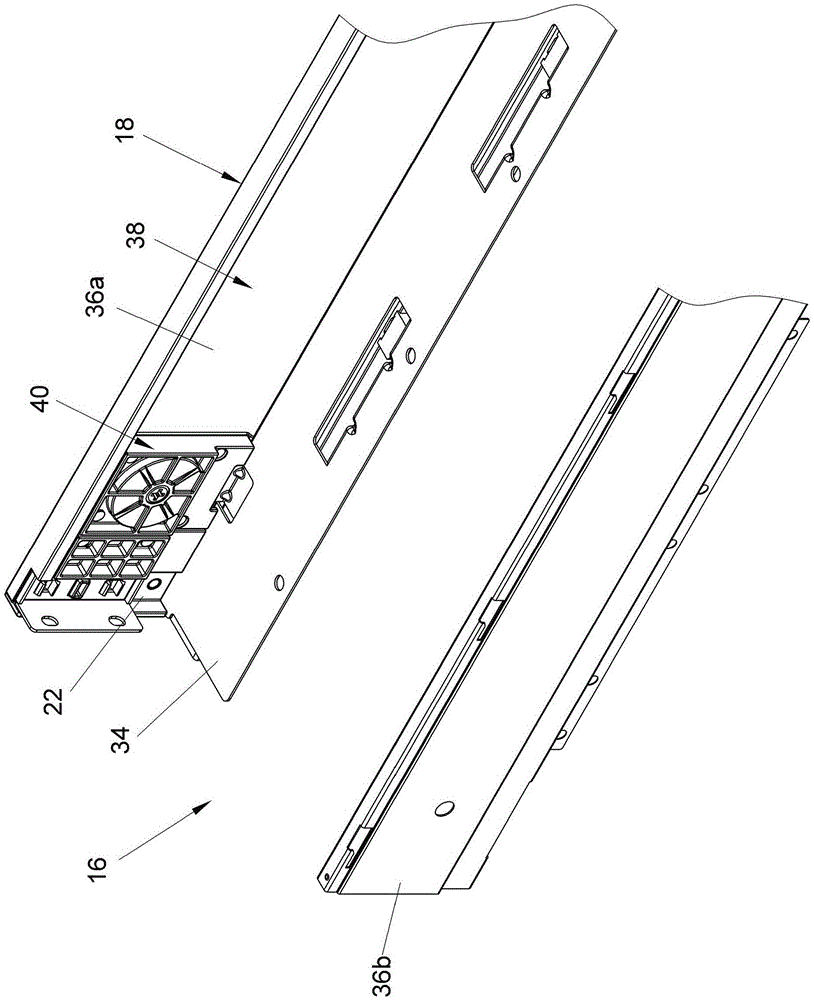

Drawer slide rail assembly

The invention relates to a drawer slide rail assembly. The drawer slide rail assembly comprises a first rail, a second rail, a drawer support and an adjusting device. The second rail can conduct longitudinally movable displacement relative to the first rail. The drawer support comprises a bearing piece and a drawer side wall connected to the bearing piece, and the bearing piece is installed on the second rail. The adjusting device is installed at the drawer side wall, and is used for adjusting the drawer support to lift and descend relative to the second rail. The drawer slide rail assembly comprises an adjusting device, and can conveniently adjust the drawer support relative to the upper and lower positions of the slide rail assembly.

Owner:KING SLIDE WORKS CO LTD +1

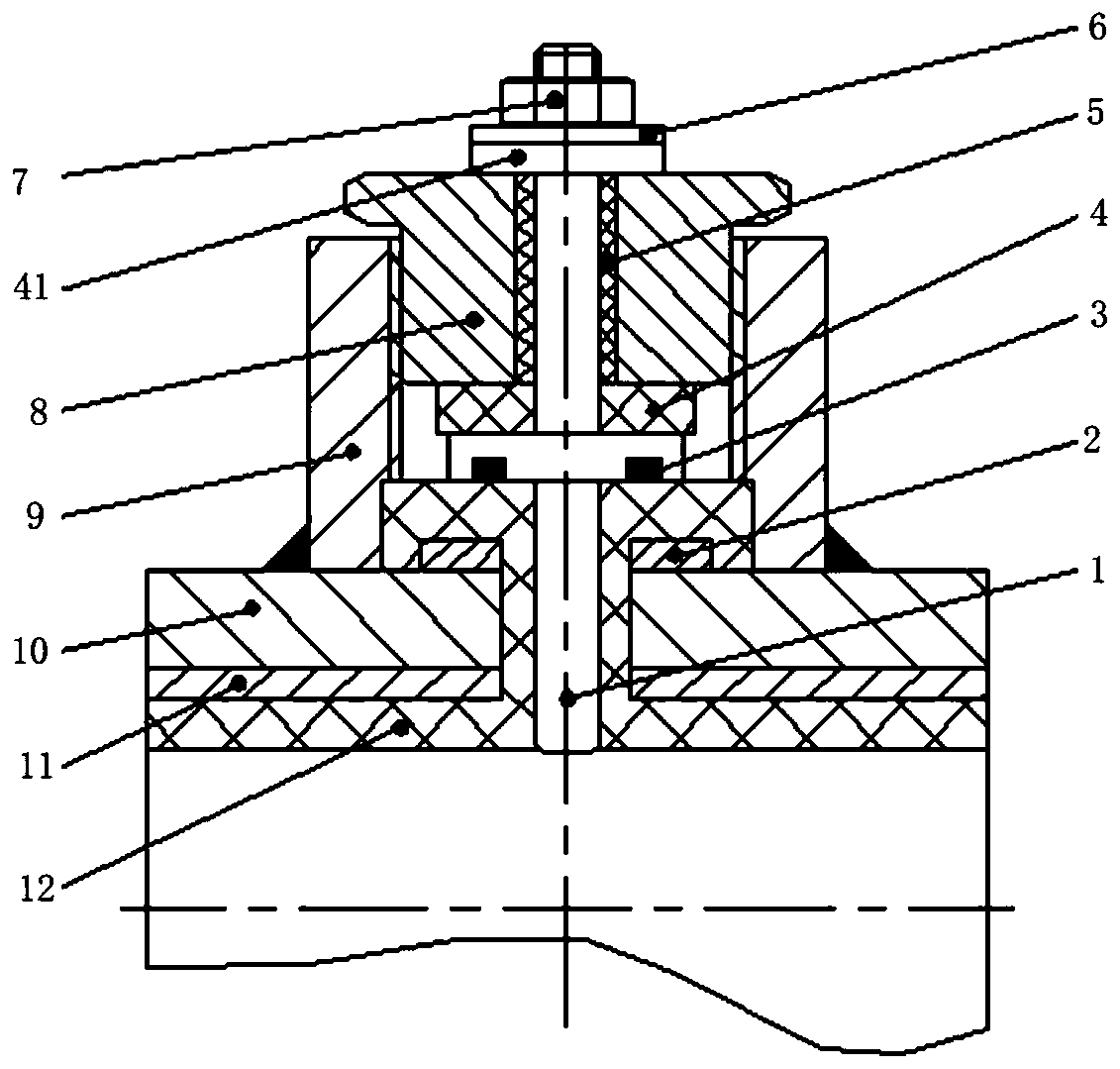

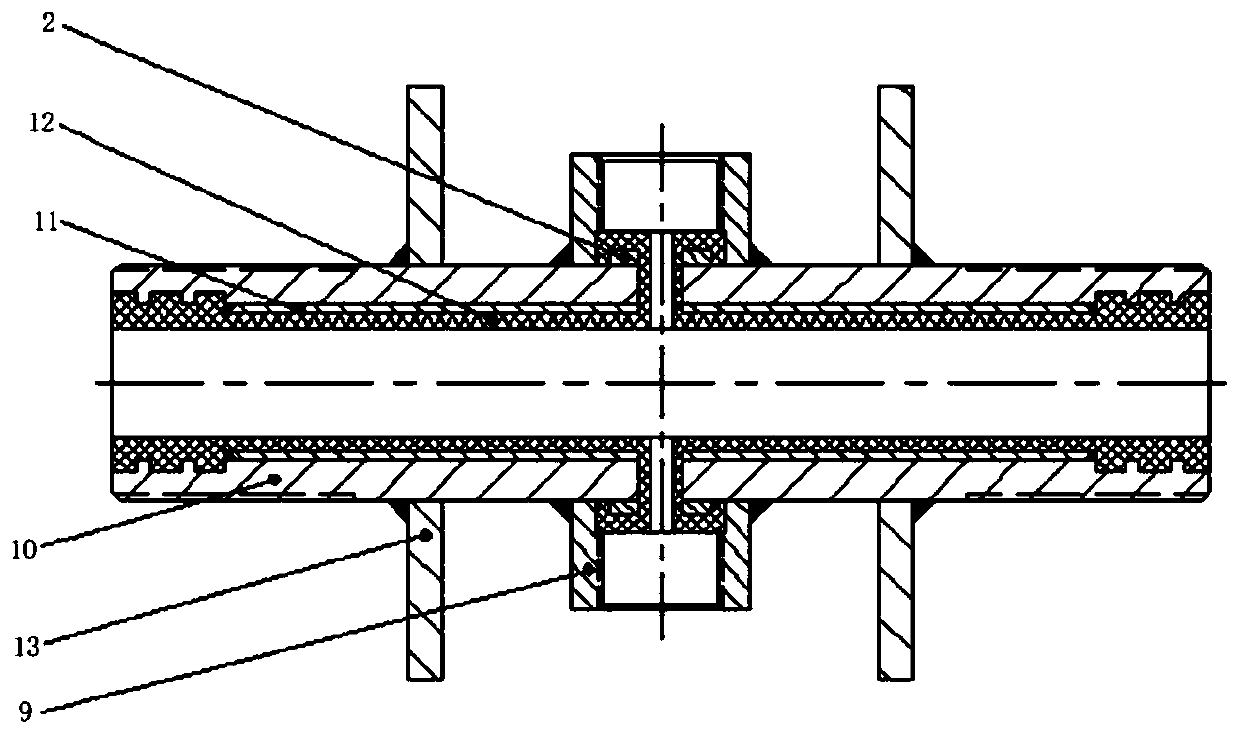

High-pressure electromagnetic flowmeter electrode packaging device

ActiveCN110411523AAchieve high pressure sealingGuaranteed stabilityVolume/mass flow by electromagnetic flowmetersEngineeringHigh pressure

The invention discloses a high-pressure electromagnetic flowmeter electrode packaging device. The device comprises an electrode pressing block, a guiding tube and an electrode holder; one end of the electrode pressing block is fixedly connected with an electrode holder hole formed in the electrode holder; the end, away from the electrode pressing block, of the electrode holder is connected with the outer wall of the guiding tube; one end of an electrode penetrates through an electrode pressing block hole formed in the electrode pressing block and a guiding tube hole formed in the guiding tubein sequence to stretch into the guiding tube; the area, located between the electrode pressing block and the outer wall of the guiding tube, of the electrode is provided with an electrode boss, and the electrode boss is located between the bottom end of the electrode pressing block and the outer wall of the guiding tube and is in sealed connection with the outer wall of the guiding tube. The electrode pressing block is fixedly connected with an electrode support, the electrode boss and the outer wall of the guiding tube are pressed by the electrode pressing block to ensure the stability of theconnection between the electrode boss and the outer wall of the guiding tube, by adopting a down-stroke compressed sealing mode, the pressure receiving range is enlarged, high-pressure sealing of theelectrode is achieved, and the application of an electromagnetic flowmeter is expanded.

Owner:MICRO SENSOR

Power distribution cabinet body grinding device

InactiveCN109079631AEasy to polishConvenient working environmentGrinding machinesGrinding/polishing safety devicesAfter treatmentEngineering

The invention discloses a power distribution cabinet body grinding device. The device comprises a flat plate, an equipment frame, a grinding device support and a gearbox; universal wheels are arrangedon the left side and the right side of the lower end of the flat plate, the equipment frame is arranged at the upper end of the flat plate, a rack is arranged on the top end inside the equipment frame, a dust suction device is arranged on the lower portion of the left side inside the equipment frame, and communicates with a dust collection chamber through a hose, and a sliding groove is formed inthe bottom end in the equipment frame. When the device is used, a second motor drives a grinding disc to rotate, the surface of a cabinet body is ground, a third motor works, a screw is driven to rotate, the screw and a sliding sleeve carry out mutual action, the second motor and a grinding disc connected with the second motor ascend or descend, the up and down grinding position can be adjusted,the multiple positions of the cabinet body can be conveniently ground, the dust suction device works, after treatment by the dust suction device, the dust is conveyed into the dust collection chamberthrough the hose, equipment cleaning is maintained, and work environment of the device can be conveniently maintained.

Owner:ANHUI JINMA ELECTRIC TECH CO LTD

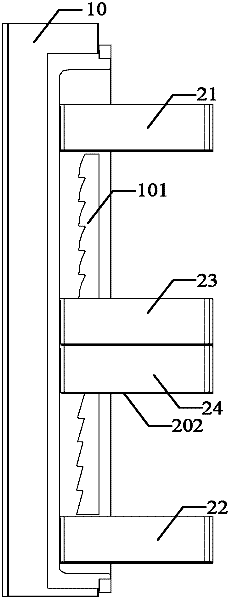

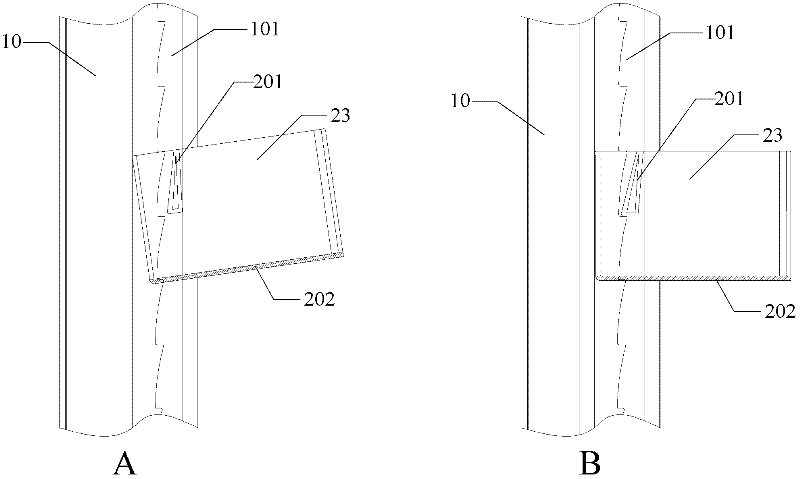

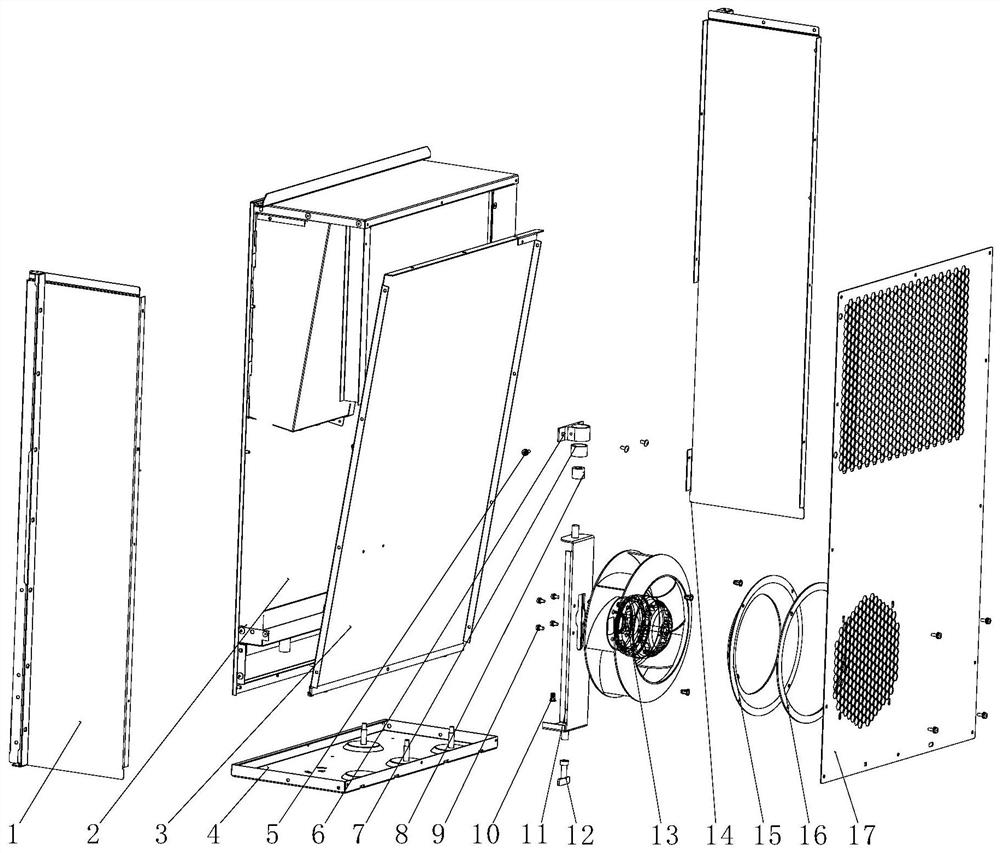

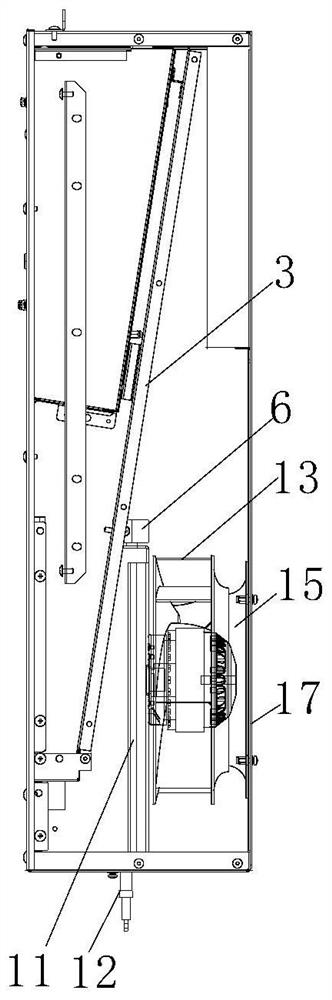

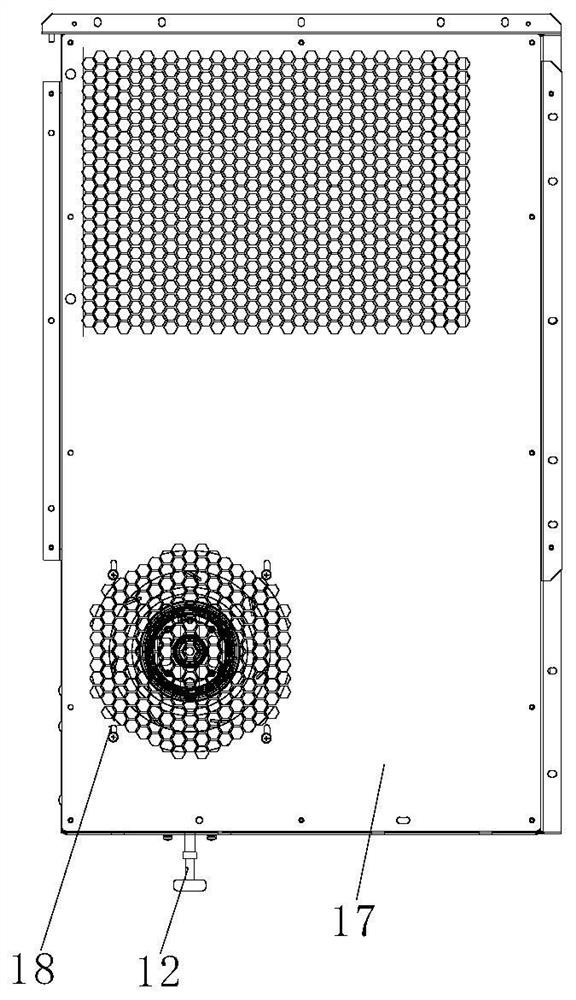

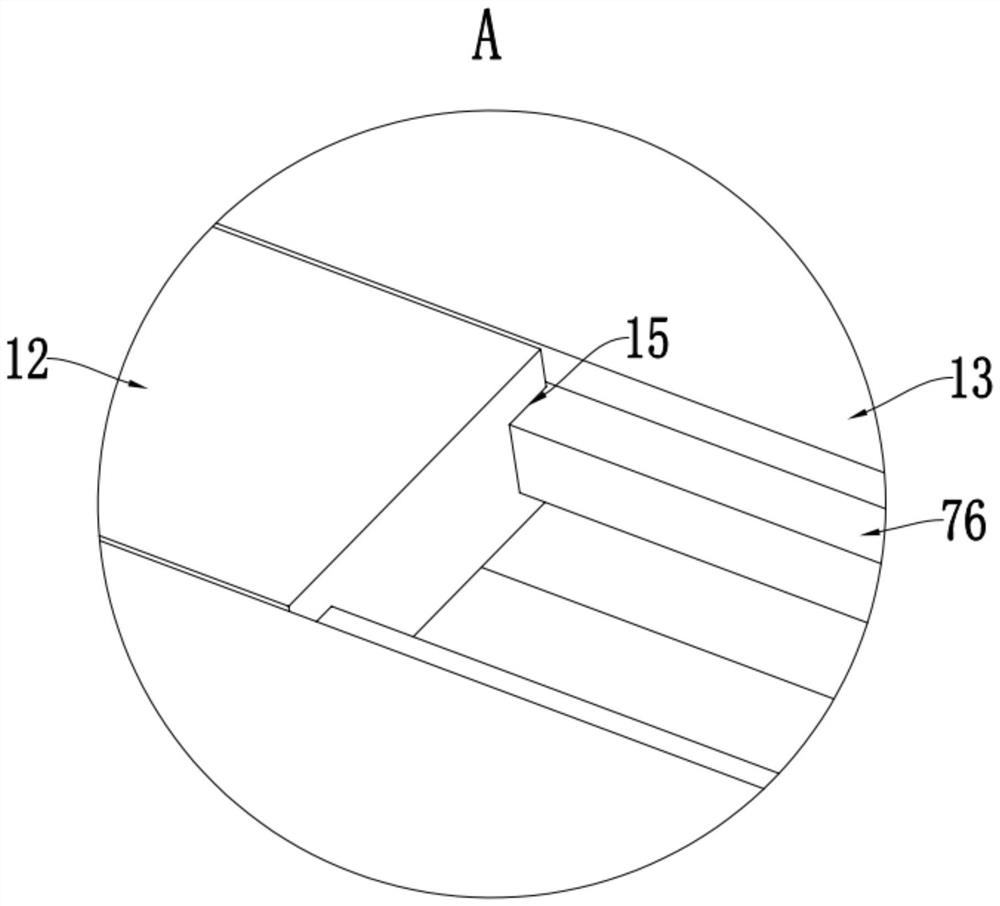

Fan mounting structure and cabinet air conditioner

PendingCN113654115AEasy to adjust up and down positionGuaranteed to workPump componentsLighting and heating apparatusImpellerEngineering

The invention provides a fan mounting structure and a cabinet air conditioner. The fan mounting structure comprises a centrifugal fan (13) and a rear panel (17) arranged on the air inlet side of the centrifugal fan (13), an air inlet is formed in the rear panel (17), a flow guide ring (15) is arranged on the side, facing the centrifugal fan (13), of the rear panel (17), the flow guide ring (15) corresponds to the air inlet, and the vertical position of the flow guide ring (15) relative to the rear panel (17) is adjustable. According to the fan mounting structure, the gap between an impeller and the flow guide ring can be conveniently adjusted, and the problem that the flow guide ring is abraded due to the fact that the gap between the impeller and the flow guide ring is too small in the working process of the impeller is effectively solved.

Owner:GREE ELECTRIC APPLIANCES INC

Method for rapidly producing transfer factors

PendingCN110339211AEfficient crushingKeep alivePeptide/protein ingredientsMammal material medical ingredientsFreeze thawingEnzymatic hydrolysis

The invention belongs to the field of veterinary biological products, and particularly relates to a method for rapidly producing transfer factors. The method includes the main steps of tissue homogenization, enzymatic hydrolysis, acid-base digestion, ultrasonic extraction, centrifugation, ultrafiltration, and the like. Compared with the traditional freeze-thaw process, the method has the advantages that the reagents adopted by the method are simple, the cost is low, cells are more fully broken, the production cycle is short, a lot of manpower and material resources are saved, the cost is significantly reduced, and the method is suitable for large-scale production of economic animal products.

Owner:商丘美兰生物工程有限公司

Supporting device with adjusting function for orthopedic trauma

PendingCN114432083APlay a supporting roleStable supportOperating tablesDiagnosticsOrthopedic departmentEngineering

The invention discloses an orthopedic trauma supporting device with an adjusting function, which comprises a supporting seat, a cross supporting assembly, electromagnetic friction horizontal adjusting mechanisms, a worm and gear vertical adjusting mechanism and a self-cleaning bending adjusting mechanism, the cross supporting assembly is arranged on the supporting seat, the electromagnetic friction horizontal adjusting mechanisms are symmetrically arranged on one side of the supporting seat, and the worm and gear vertical adjusting mechanism is arranged on the other side of the supporting seat. The worm and gear vertical adjusting mechanism is arranged on one side of the electromagnetic friction horizontal adjusting mechanism, the self-cleaning bending adjusting mechanism is arranged on the worm and gear vertical adjusting mechanism, and the self-cleaning bending adjusting mechanism comprises a bending adjusting moving assembly, a bending adjusting placing assembly, a movable binding assembly and a self-spraying cleaning wiping assembly. The invention belongs to the medical field of the orthopedics department, and particularly relates to an orthopedics department trauma supporting device with an adjusting function, which has the advantages that the stability of the device is improved, the operation space of medical staff in an operation is enlarged, the problem of automatic cleaning of the supporting device is solved, infection is avoided, and the supporting of four limbs is convenient to adjust.

Owner:毛及海

Optical cable and cable sheath peeling device

ActiveCN101587217BImprove peeling qualityImprove efficiencyFibre mechanical structuresApparatus for removing/armouring cablesMilling cutterScrew thread

Owner:NANJING WASIN FUJIKURA OPTICAL COMM LTD +1

Ultramicro low-temperature tremella powder sterilization device and working method thereof

InactiveCN114403336AStir wellEasy to adjust up and down positionFood preservationTremellaUltraviolet irradiation

The ultra-micro low-temperature tremella powder sterilization device comprises a baking oven, a pumping assembly, a sliding assembly, a lifting assembly, a moving assembly, a stirring assembly and an air blowing assembly, a cavity is formed in the baking oven, the sliding assembly is arranged in the cavity, and a supporting frame is welded to the top of the pumping assembly; the pumping assembly is arranged in the middle of the sliding assembly and is driven by a second motor, a fifth motor and a fourth motor, the front-back, left-right and up-down positions of an ultraviolet irradiation sterilizing lamp and the stirring assembly are adjusted, the device can stir and sterilize tremella powder more comprehensively, the area of the tremella powder irradiated by the ultraviolet irradiation sterilizing lamp is wider, and the sterilization effect is better. The use flexibility of the device is improved, and the tremella powder sterilization efficiency of the device is further improved.

Owner:王小平

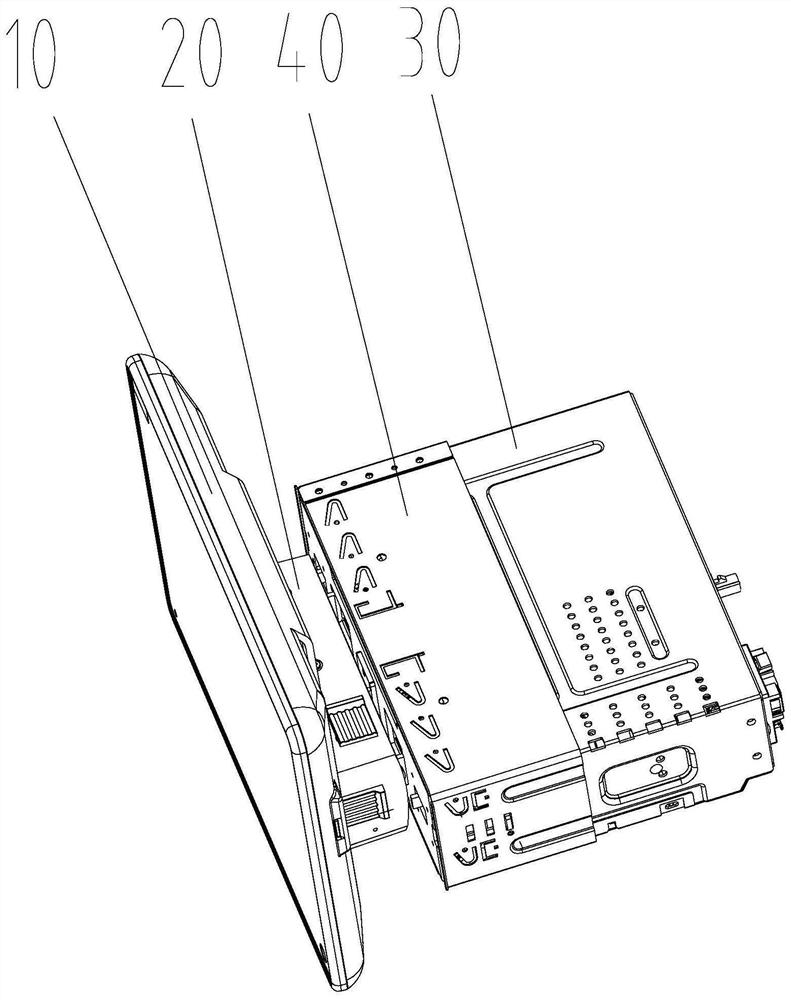

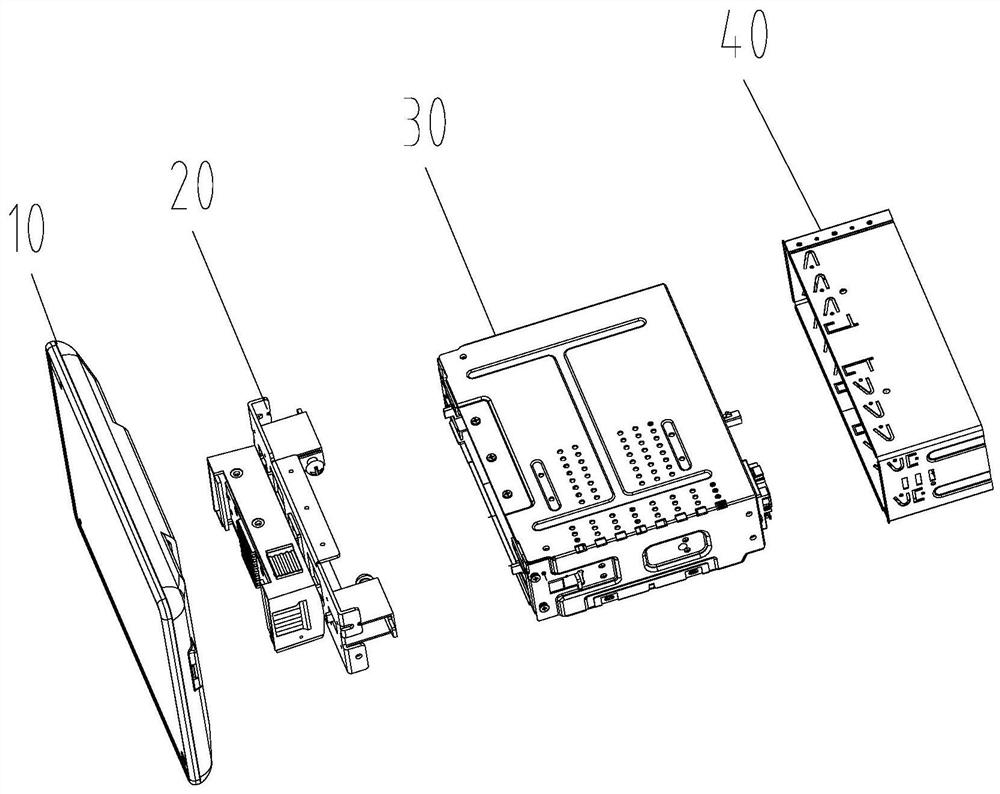

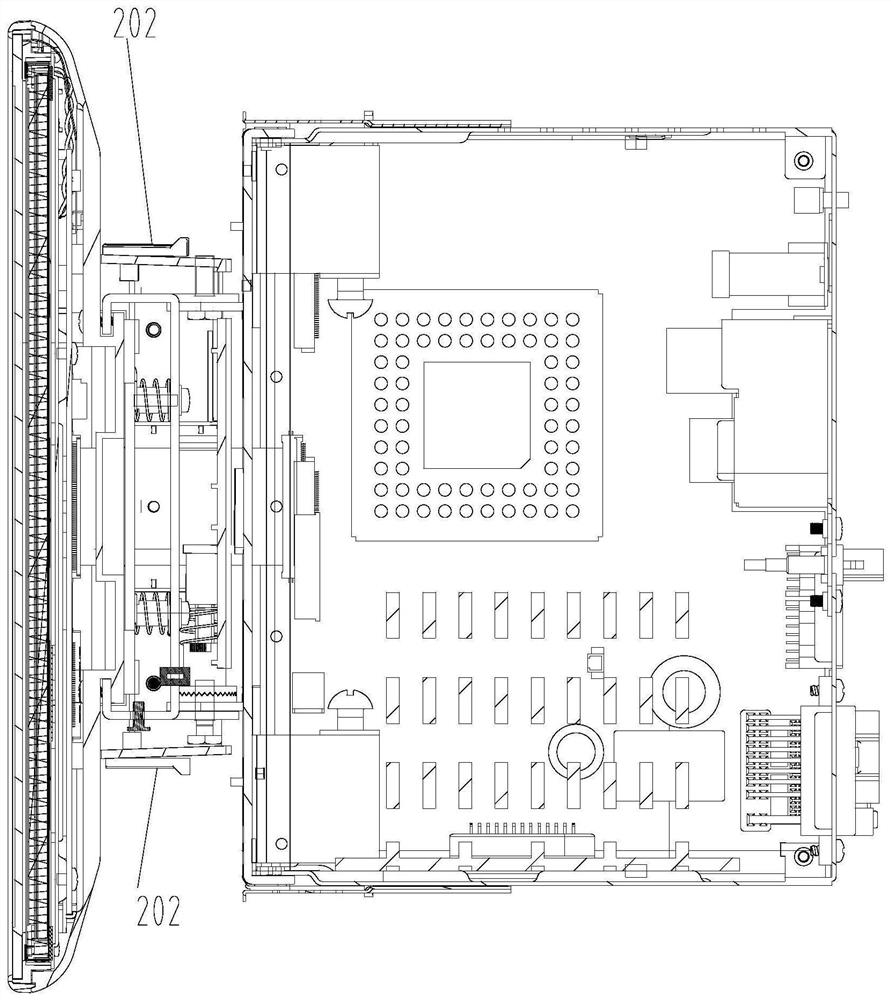

Three-way adjusting, mounting and fixing device for vehicle-mounted navigation equipment

PendingCN111660947AAchieve forward and backward movementRealize automatic resetVehicle componentsIn vehicleLiquid crystal

The invention relates to a three-way adjusting, mounting and fixing device of vehicle-mounted navigation equipment. The device comprises a panel assembly, a moving assembly, a host assembly and a cabinet barrel; the moving assembly is arranged on one side of the panel assembly; the host assembly is arranged on the moving assembly and located on the side, away from the panel assembly, of the movingassembly; the cabinet barrel is arranged on the periphery of the host assembly; and the side, facing the moving assembly, of the cabinet barrel is connected with the moving assembly; the panel assembly comprises a decorative ring, a touch screen, a panel, an LCD liquid crystal module, an LCD support, a TFT _ PCB and a shell; the moving assembly comprises an installation plate, a push rod, a pressing plate, a guide column, a first reset spring, a sliding support, a torsion rotating shaft bolt assembly, a host installation support, a decorative shield, a decorative cover, a cabinet barrel positioning assembly and an adjusting assembly; and the adjusting assembly comprises a rotating support, a third reset spring, a movable tooth-shaped stop buckle and a tooth-shaped stop buckle. The up-down, front-back and angle positions of the display screen can be manually adjusted, a host structure does not need to be replaced, and disassembly and assembly are simple.

Owner:SKYPINE ELECTRONICS SHENZHEN

A dispensing and curing mechanism for assembling small parts of electronic products

ActiveCN104549892BEasy to replaceEasy to adjust up and down positionPretreated surfacesCoatingsEngineeringMechanical engineering

Owner:BOZHON PRECISION IND TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com