Shaft type workpiece holder

A workpiece fixture and shaft workpiece technology, applied in the field of shaft workpiece fixtures, can solve the problems affecting workpiece machining accuracy, stable clamping of shaft workpieces, workpiece rotation, etc., and achieve the effect of high machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

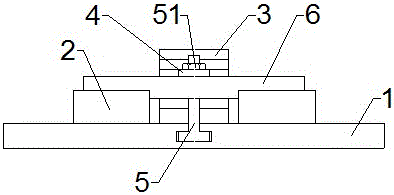

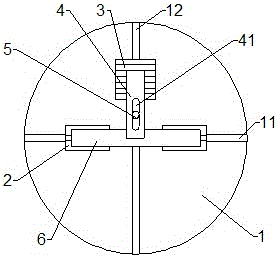

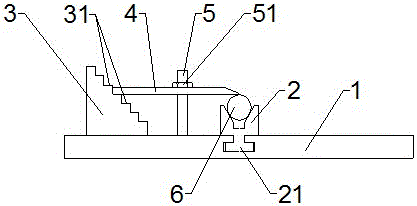

[0015] like figure 1 , figure 2 and image 3 As shown in the figure, the present invention discloses a shaft workpiece fixture, which includes an installation disc 1, a positioning V-shaped block 2 and a clamping device arranged on the installation disc 1. The installation disc 1 is provided with two mutual The vertical guide groove A11 and the guide groove B12, the cross-section of the guide groove A11 and the guide groove B12 are inverted T-shaped.

[0016] The positioning V-shaped blocks 2 are a pair, which are symmetrically arranged on the installation disk 1 along the extending direction of the guide groove A11, and the center lines of the two positioning V-shaped blocks 2 coincide with the center line of the guide groove A11; the lower end of the positioning V-shaped block 2 There is a slider A21 matched with the guide groove A11 and slidably matched with the mounting disc 1 .

[0017] The clamping device is arranged on the installation disk 1, and its center line co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com